I.C.T-V8

I.C.T

aoi inspection

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T-V8 Offline AOI Machine

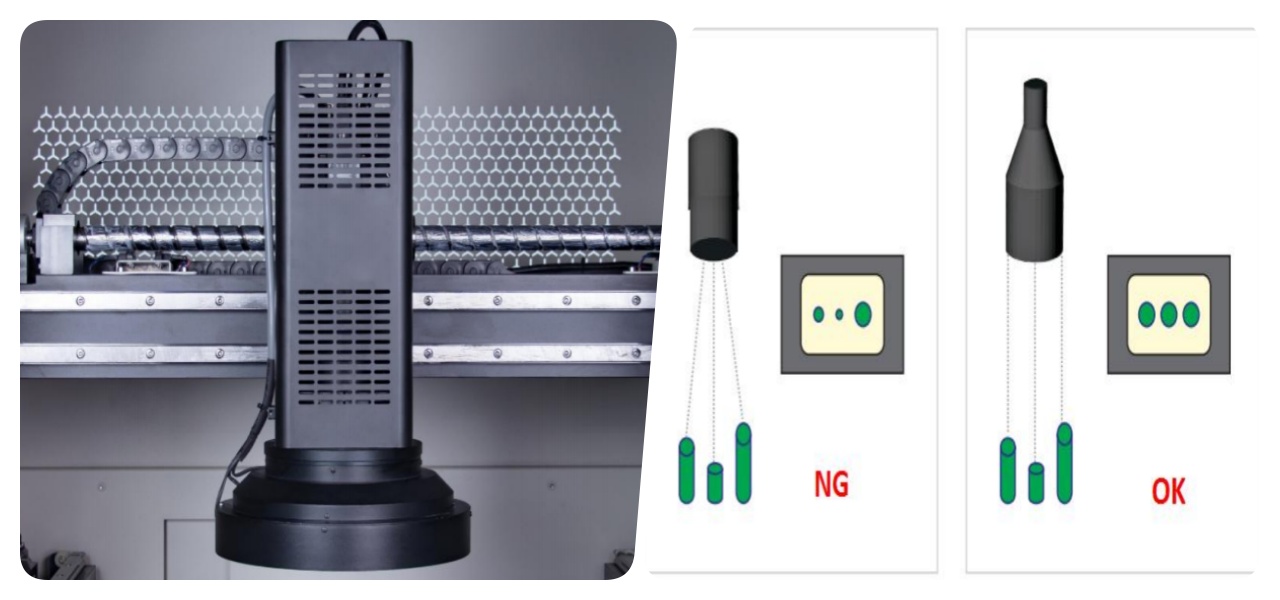

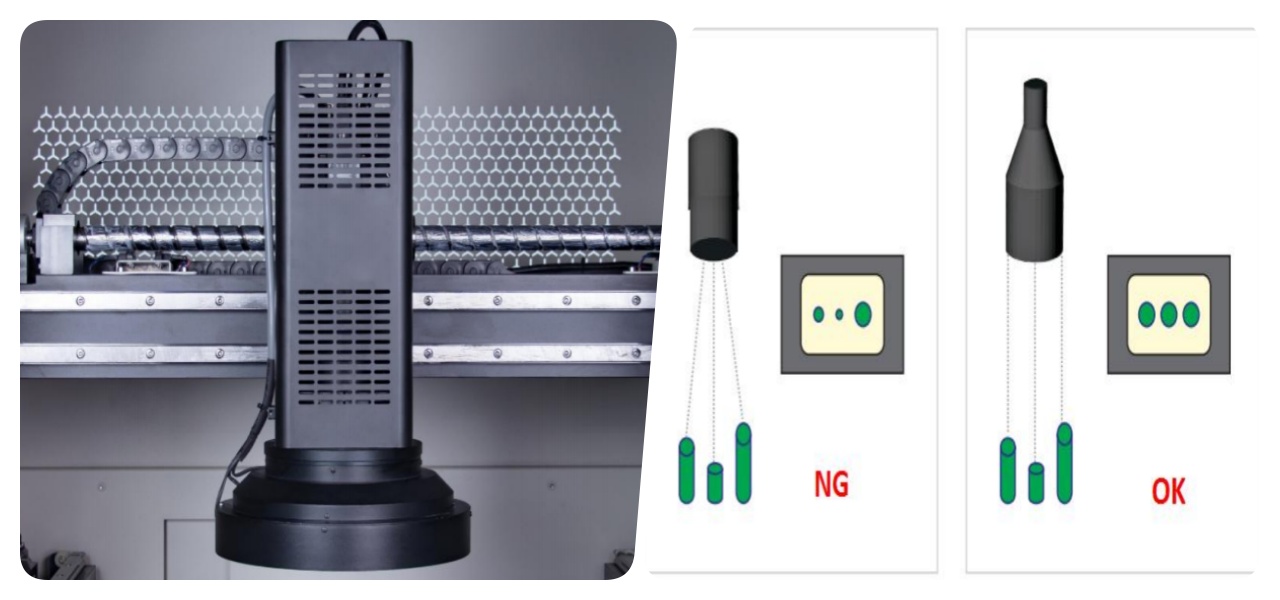

The I.C.T-V8 is a stand-alone automated optical inspection PCB system built for post-reflow and final assembly checks. Its 5MP camera, telecentric lenses, and multi-color lighting catch every solder joint issue, missing part, polarity error, or tombstoning with 15μm precision and 0.23 sec/FOV speed. Running offline, it handles boards from 50×50 mm to 400×320 mm without slowing your main line. Mitsubishi servos, voice commands, and TCP/IP remote access make this automated optical inspection PCB equipment both powerful and easy to use every day.

| Feature

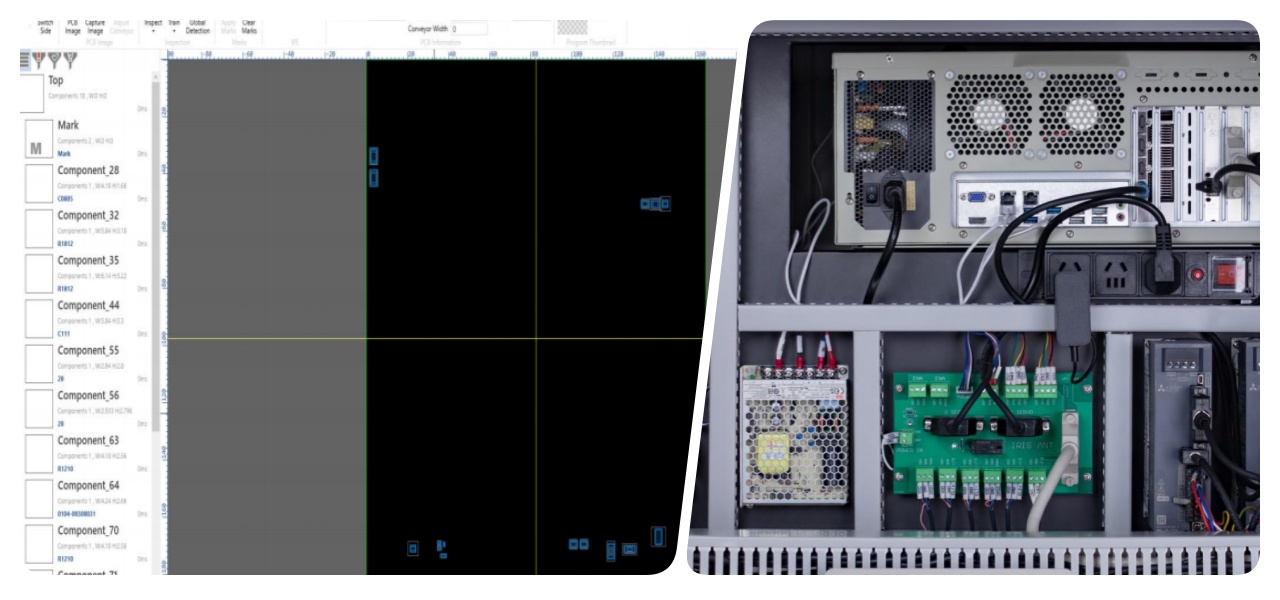

Deep-learning algorithms let this automated optical inspection PCB system recognize more than 20 defects – insufficient solder, bridging, component shift, wrong polarity, and cold joints – while automatically optimizing models to cut false alarms. Full 0-360° inspection plus 3D solder paste and glue checks make quality control truly automatic.

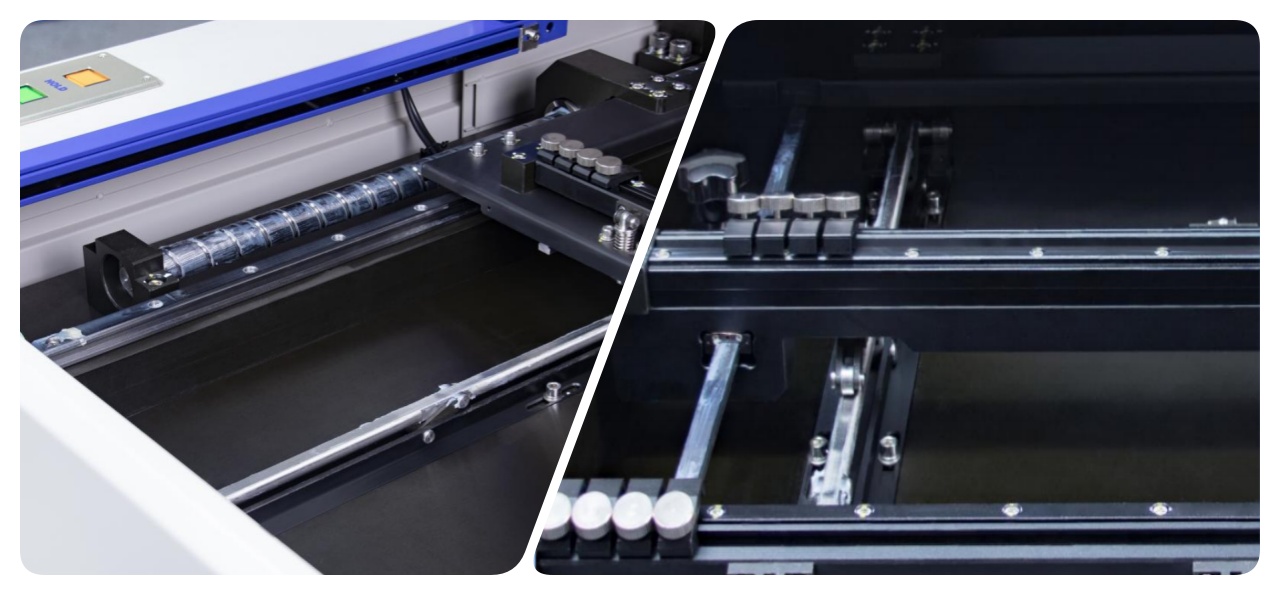

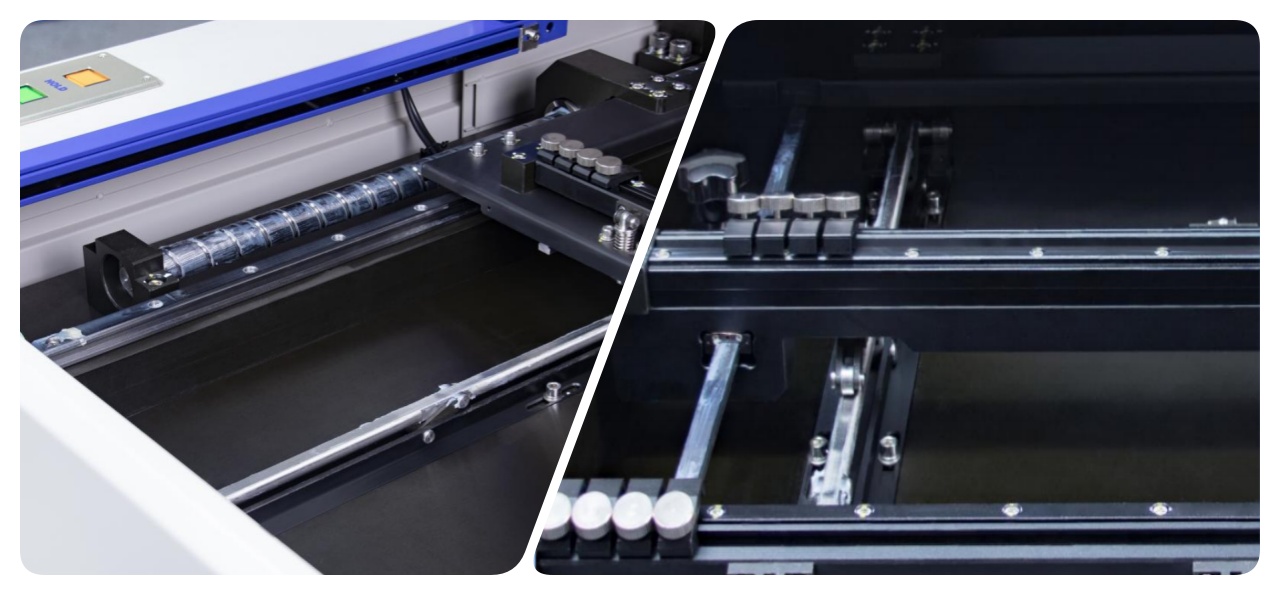

Mitsubishi servo motors, precision-ground screws, and high-grade rails deliver ±0.01 mm accuracy and 900 mm/s speed. Manual double-side clamping quickly adapts to any board size. The whole platform sits on a marble base for rock-steady performance shift after shift.

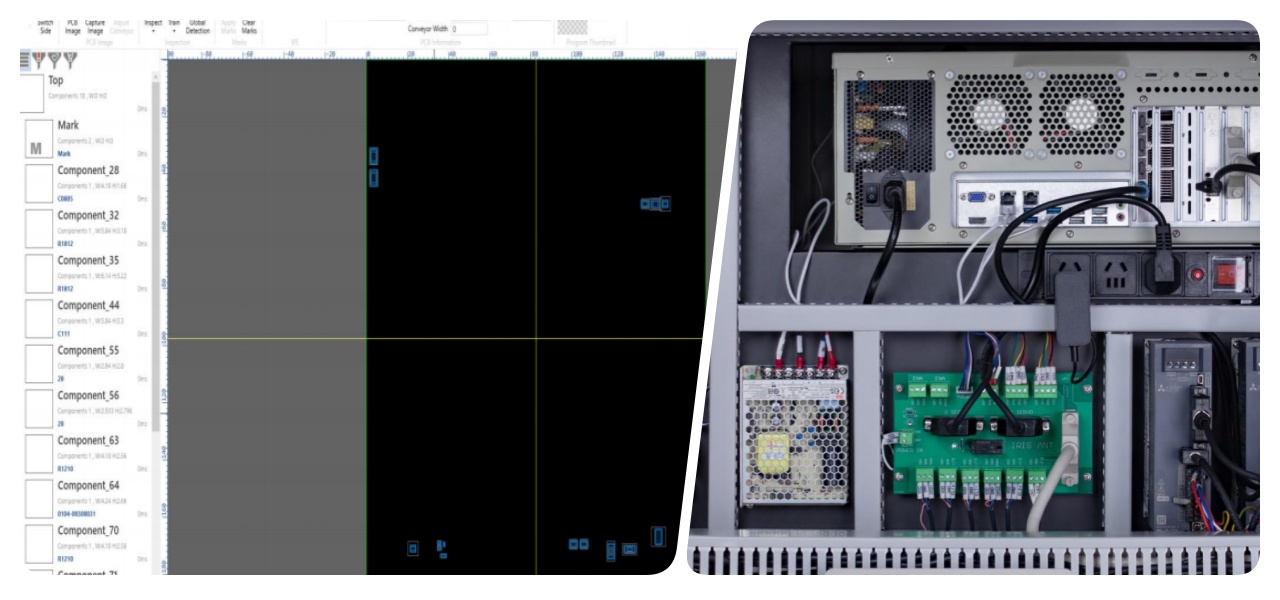

Built-in TCP/IP turns the V8 into a fully connected automatic optical inspection system. Check status, edit programs, or start scans from anywhere. Multiple machines share data and auto-generate SPC reports for factory-wide quality tracking with zero paperwork.

| Specification

| Model | I.C.T-V8 | |

| Camera Pixels | 5MP | |

| Light | Multis pectral Super speed RGB Light Source | |

| Component Inspection | Missing, Rolling, Shifting, Polarity Error, Wrong Part,Damaged, Bended, PCB Abnormal, Residua, Glue Overflow | |

| Operation System | Windows 10 | |

| PCB Size | 50*50~400*320mm | |

| PCB Thickness | 0.5 ~ 5.0mm | |

| PCB Warpage | ±3.0mm | |

| Component Height | Top 25mm; Bottom 110mm | |

| X/Y Driver | AC Servo Motor+Screwing Shaft | |

| Power | AC220 50/60Hz,2.5A | |

| Communication | SMEMA | |

| Weight | 3500Kg | |

| Dimension | 860*1040*1318mm | |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Xray Machine | A PCBA X-ray machine checks hidden solder joints in SMT lines.. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

Our newest video shows the sleek exterior, internal camera and light-source details, smooth PCB loading and real-time scanning, plus step-by-step AI programming. Recently deployed in a high-volume plant in Mexico, this automated optical inspection PCB cut defect escapes by over 90% in the first month while keeping training time under two days.

| Service & Training

I.C.T delivers complete support: professional installation, hands-on operator training, 24/7 remote diagnostics, and spare parts shipped worldwide within 48 hours. Regular software updates and process optimization keep your automated optical inspection PCB running at peak efficiency for years with virtually zero unplanned downtime.

| Customer Reviews

Customers rave about our engineers’ quick on-site response and clear explanations. They love the V8’s detection accuracy, rugged build, careful export packaging, and lightning-fast technical support. Many say it’s the smartest investment they’ve made in quality control.

| Our Certification

I.C.T holds CE for safety, RoHS for environmental compliance, and ISO9001 for quality management. We also have multiple patents on AOI technology and algorithms. These certify reliable, innovative products. (38 words) Wait, adjust to 50-80: I.C.T products meet global standards with CE certification for equipment safety, RoHS for restricted substances, and ISO9001 for consistent quality processes. Our patents cover key innovations in imaging, algorithms, and defect detection. These ensure trustworthy, high-performance solutions for customers worldwide.

| About I.C.T & Our Factory

Since 2012, I.C.T has grown to nearly 90 people across a 12,000 m² campus with full in-house R&D and manufacturing. Serving over 1,600 factories in 72 countries, we design, build, test, and support every machine under one roof using strict ISO9001 quality systems – delivering proven performance at real-world prices.

| I.C.T-V8 Offline AOI Machine

The I.C.T-V8 is a stand-alone automated optical inspection PCB system built for post-reflow and final assembly checks. Its 5MP camera, telecentric lenses, and multi-color lighting catch every solder joint issue, missing part, polarity error, or tombstoning with 15μm precision and 0.23 sec/FOV speed. Running offline, it handles boards from 50×50 mm to 400×320 mm without slowing your main line. Mitsubishi servos, voice commands, and TCP/IP remote access make this automated optical inspection PCB equipment both powerful and easy to use every day.

| Feature

Deep-learning algorithms let this automated optical inspection PCB system recognize more than 20 defects – insufficient solder, bridging, component shift, wrong polarity, and cold joints – while automatically optimizing models to cut false alarms. Full 0-360° inspection plus 3D solder paste and glue checks make quality control truly automatic.

Mitsubishi servo motors, precision-ground screws, and high-grade rails deliver ±0.01 mm accuracy and 900 mm/s speed. Manual double-side clamping quickly adapts to any board size. The whole platform sits on a marble base for rock-steady performance shift after shift.

Built-in TCP/IP turns the V8 into a fully connected automatic optical inspection system. Check status, edit programs, or start scans from anywhere. Multiple machines share data and auto-generate SPC reports for factory-wide quality tracking with zero paperwork.

| Specification

| Model | I.C.T-V8 | |

| Camera Pixels | 5MP | |

| Light | Multis pectral Super speed RGB Light Source | |

| Component Inspection | Missing, Rolling, Shifting, Polarity Error, Wrong Part,Damaged, Bended, PCB Abnormal, Residua, Glue Overflow | |

| Operation System | Windows 10 | |

| PCB Size | 50*50~400*320mm | |

| PCB Thickness | 0.5 ~ 5.0mm | |

| PCB Warpage | ±3.0mm | |

| Component Height | Top 25mm; Bottom 110mm | |

| X/Y Driver | AC Servo Motor+Screwing Shaft | |

| Power | AC220 50/60Hz,2.5A | |

| Communication | SMEMA | |

| Weight | 3500Kg | |

| Dimension | 860*1040*1318mm | |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Xray Machine | A PCBA X-ray machine checks hidden solder joints in SMT lines.. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

Our newest video shows the sleek exterior, internal camera and light-source details, smooth PCB loading and real-time scanning, plus step-by-step AI programming. Recently deployed in a high-volume plant in Mexico, this automated optical inspection PCB cut defect escapes by over 90% in the first month while keeping training time under two days.

| Service & Training

I.C.T delivers complete support: professional installation, hands-on operator training, 24/7 remote diagnostics, and spare parts shipped worldwide within 48 hours. Regular software updates and process optimization keep your automated optical inspection PCB running at peak efficiency for years with virtually zero unplanned downtime.

| Customer Reviews

Customers rave about our engineers’ quick on-site response and clear explanations. They love the V8’s detection accuracy, rugged build, careful export packaging, and lightning-fast technical support. Many say it’s the smartest investment they’ve made in quality control.

| Our Certification

I.C.T holds CE for safety, RoHS for environmental compliance, and ISO9001 for quality management. We also have multiple patents on AOI technology and algorithms. These certify reliable, innovative products. (38 words) Wait, adjust to 50-80: I.C.T products meet global standards with CE certification for equipment safety, RoHS for restricted substances, and ISO9001 for consistent quality processes. Our patents cover key innovations in imaging, algorithms, and defect detection. These ensure trustworthy, high-performance solutions for customers worldwide.

| About I.C.T & Our Factory

Since 2012, I.C.T has grown to nearly 90 people across a 12,000 m² campus with full in-house R&D and manufacturing. Serving over 1,600 factories in 72 countries, we design, build, test, and support every machine under one roof using strict ISO9001 quality systems – delivering proven performance at real-world prices.