SS-330

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Selective Soldering Wave Machine Overview

Proudly built in our own Dongguan factory, the I.C.T Selective Wave Soldering Machine is the ultimate off-line Selective Wave Soldering Machine for factories that need maximum flexibility and rock-solid quality. The PCB never moves – a feather-light cast-aluminum gantry riding Panasonic servos and precision rails brings flux and solder exactly where they’re needed. Inline nitrogen heating creates shiny, full fillets with almost no waste. Operators set every parameter – paths, temps, spray volume, wave height – on a big Windows touchscreen and save endless programs for lightning-fast job switches. Auto wave calibration, live CCD, German jet valve, and titanium pot make this Selective Wave Soldering Machine a true 24/7 profit machine.

| DIP Line Equipment List

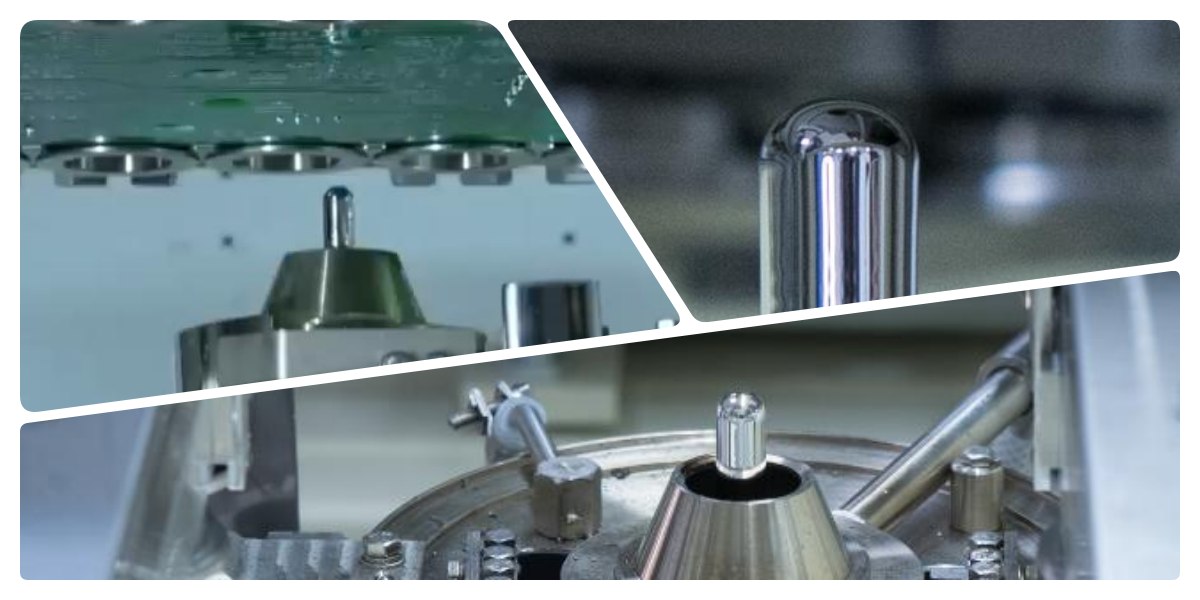

German high-frequency pulse valve shoots micro-dots of low-solids flux (<10%) repeatable to 0.02 mm. Pressurized tank plus digital flow meter lock pressure steady even when the tank is almost empty. Residue drops into a pull-out tray for two-second cleanup. Japanese SMC pneumatics and front gauges make daily checks effortless. An automatic pump guarantees constant supply. This smart flux module activates every pad perfectly on the Selective Wave Soldering Machine.

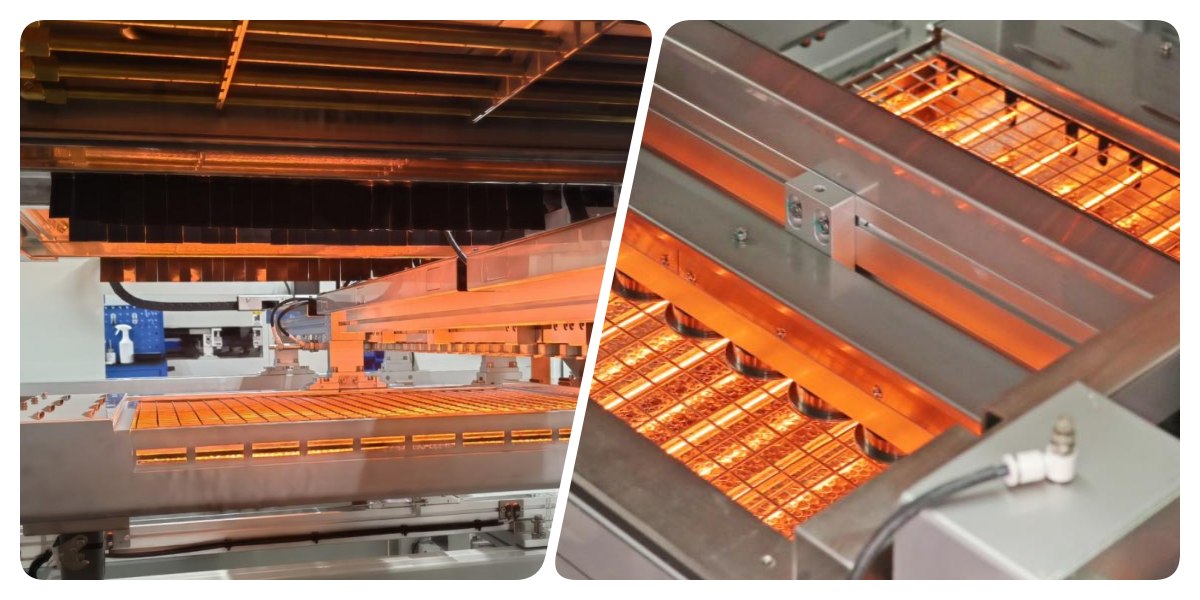

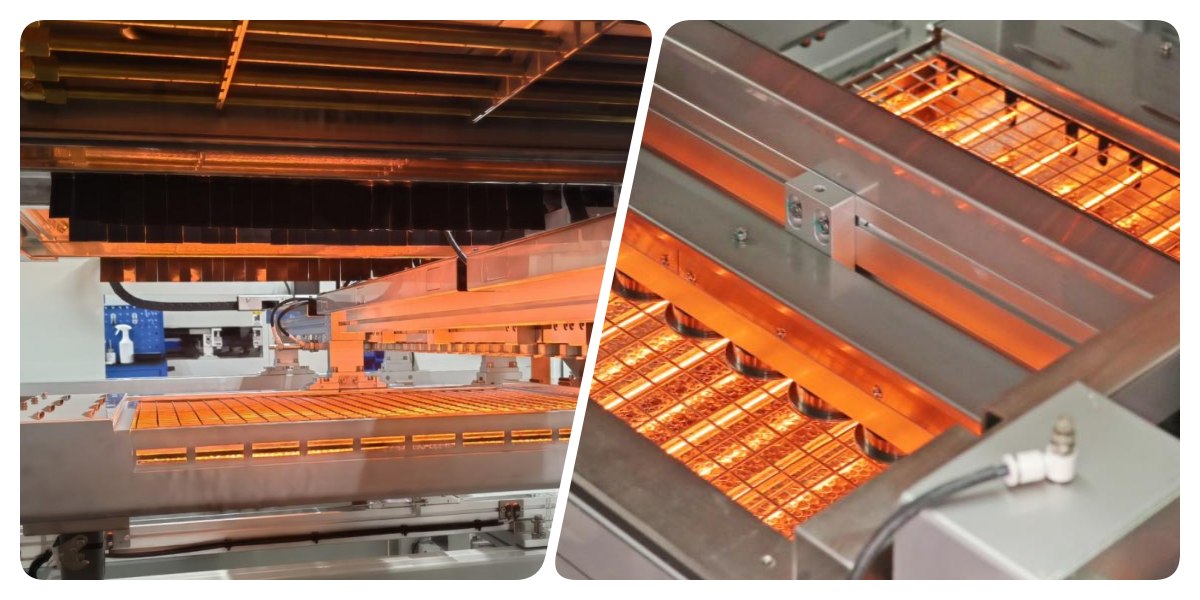

Standard bottom IR is fully adjustable; top hot-air convection or extra IR optional. Open-grid design plus thick high-temp insulation spreads heat evenly across the entire board. Top-brand heaters and plug-in motors run quiet and tool-free for years. Boards exit perfectly flux-activated and warp-free, ready for flawless joints on the off-line Selective Wave Soldering Machine.

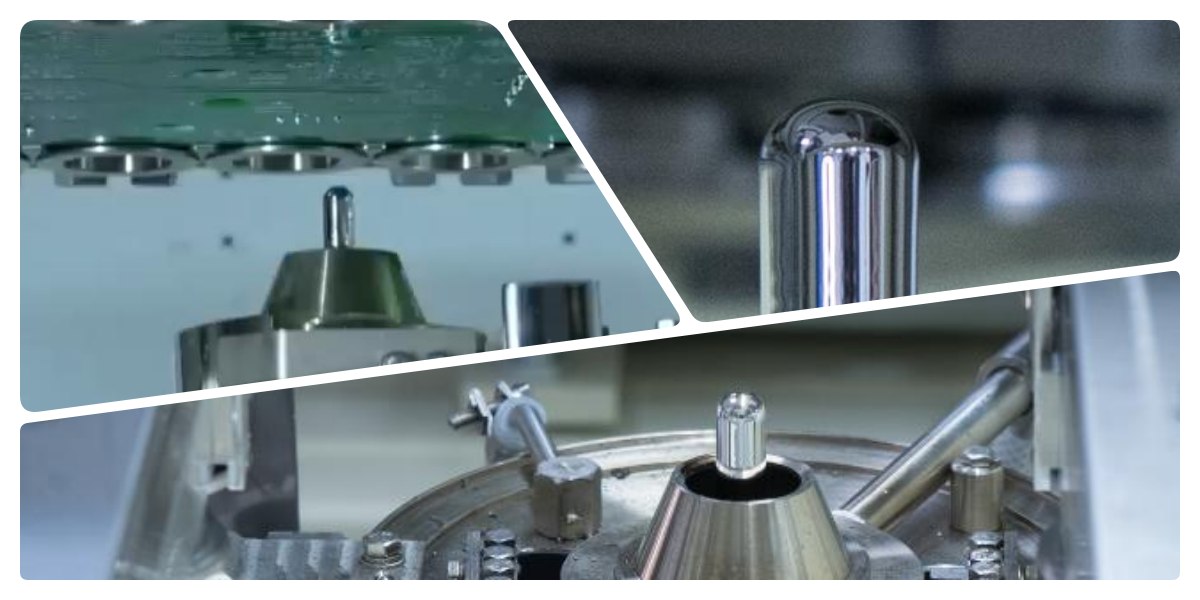

German electromagnetic pump and titanium pot generate a rock-steady mini wave that never drifts or leaks. Control N2 flow, solder temp, wave height, and auto-calibration straight from the touchscreen. Inline nitrogen delivers mirror-bright fillets and virtually zero dross. Laser monitors height, nozzles self-clean, and 900 hours of video are saved for traceability. This is the bulletproof heart of every Selective Wave Soldering Machine.

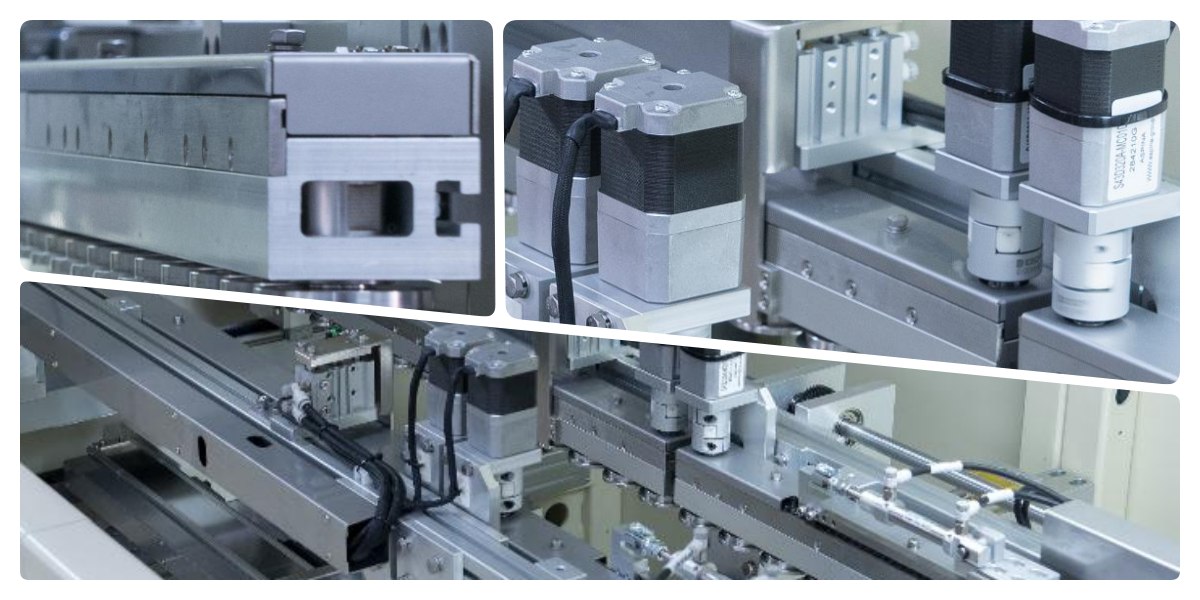

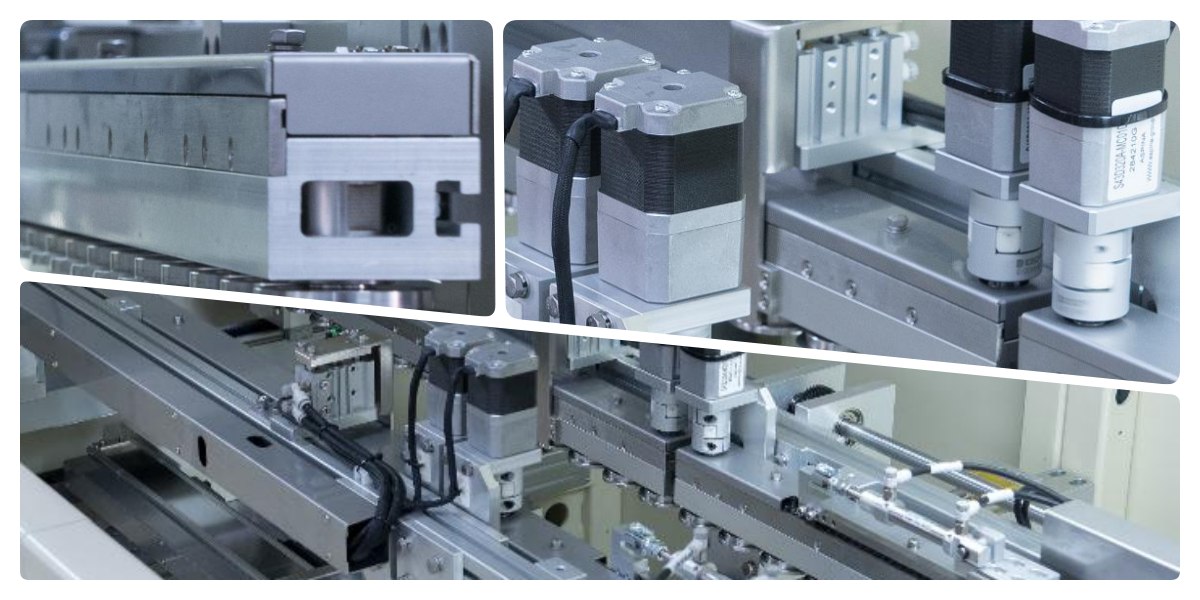

Three-section roller conveyor plus pneumatic side/top clamps hold boards up to 20 kg dead-still. Heavy-duty rails and high-precision servos move PCBs smoothly station to station. Thick or double-sided assemblies clear with ease. Built for nonstop duty on any off-line Selective Wave Soldering Machine line.

CE-certified PLC, Cat-6 wiring, and full MES connectivity deliver lightning response and bulletproof reliability. Guided wizards, picture-based edits, auto nozzle detection, and multi-language menus slash training time. Remote diagnostics keep the Selective Wave Soldering Machine earning around the clock.

Large color touchscreen, step-by-step guides, one-tap live CCD preview, and voice alerts make running the machine dead simple. Switch instantly between English, Chinese, Japanese, or Russian. Custom tower lights and Wi-Fi upgrades keep everyone informed without leaving the floor.

| Specification

| On-line Selective Wave Soldering Machine | ||||

| Model | I.C.T SS540 | I.C.T SS550 | I.C.T SS550P1 | I.C.T SS550P2 |

| On-line Modular | Spray + Preheating & Soldering | Spray + Preheating + Soldering | Spray + Preheating + Soldering +Soldering | Spray + Preheating + Soldering + Soldering+ Soldering |

| Soldering System | ||||

| Nozzle Quantity | 1 | 1 | 2 | 3 |

| Solder Pot Quantity | 1 set | 1 set | 2 set | 3 set |

| Double Pot (Option) | N/A | Option | Option | Option |

| Solder Pot Power | 2.35kw | 2.35kw | 4.70kw | 7.05kw |

| Flux System | ||||

| Flux Storage Tank | 1L | 1L | 2L | 2L |

| Flux Support | Flux Alarm, Automatic | |||

| Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1 set | |||

| Spray Nozzle Size | 130um (180um, 210um Option) | |||

| Spray Speed | 0~20mm/s | |||

| Spray Nozzle Move Speed | 0~400mm/s | |||

| Preheating System | ||||

| Preheating Mode | Hot air and IR | Hot air and IR | Hot air and IR | Hot air and IR |

| Preheating Area | L500*W500mm | L500*W500mm | L500*W500mm | L500*W500mm |

| Preheating Zone | Top hot air: 2, Bottom IR: 1 | |||

| Bottom Preheating Power | Max.12kw | |||

| Top Preheating Power | Max.6kw | |||

| Warm-up Time | Approx.15min (setting 150℃) | |||

| Control Mode | PC+PLC | |||

| Transport System | ||||

| PCB Size (with fixture) | 120*60~500*500mm | |||

| PCB Replacement | Online | |||

| PCB Top Clearance | 120mm | |||

| Transport Height | 900±20mm | |||

| Transport Width | 60~500mm | |||

| Dimension:mm | L1850*W1850*H1480 | L2560*W1750*H1480 | L2560*W1950*H1480 | L2600*W1950*H1480 |

| Weight | Approx: 800kg | Approx: 1200kg | Approx: 1300kg | Approx: 1500kg |

| DIP Line Equipment List

Our Through-Hole Technology Line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Product Name | Purpose in DIP Line |

|---|---|

Through hole pick and place machine | Automatically places components onto PCBs with precision for DIP production line. |

Automatic DIP soldering machine | Melts solder to form solid joints on PCBs during THT plug-in process. |

Automated selective soldering machine | Applies solder selectively to specific areas for accurate THT assembly |

| Post-wave Inline AOI | Inspects solder joints and placement defects on DIP assembled PCB. |

| Customer Success Video

In early 2025 a major Vietnamese camera-brand supplier flew to Dongguan for final acceptance of their new Selective Wave Soldering Machine. Our engineers loaded their actual production boards, ran complete cycles while the customer watched perfect THT joints form live on the CCD, then trained their team for two full days on programming, maintenance, and troubleshooting. They left 100% ready to hit volume the moment the crate arrived—another proof of I.C.T’s real global partnership.

| Professional Service and Training

From factory acceptance and crating to installation, startup, and lifetime support, we’ve got you covered worldwide. Twenty senior engineers plus local teams in 72 countries provide on-site or remote training whenever you need it. Spare-parts warehouses on three continents and true 24/7 hotlines keep your off-line Selective Wave Soldering Machine at peak uptime for decades.

| Customer Praise

Customers keep saying our engineers are patient, sharp, and truly care about their success. They love the pinpoint flux accuracy, rock-solid wave, and how fast the Selective Wave Soldering Machine pays for itself in higher yields and zero rework. Export crates arrive flawless, and same-day remote fixes have turned first-time buyers into lifelong partners around the world.

| Industry Certifications

Every Selective Wave Soldering Machine ships with CE safety certification, RoHS compliance, ISO9001 quality system, and multiple patents on jet valves, pumps, and laser calibration. These globally trusted marks prove you’re getting safe, green, battle-tested technology you can rely on anywhere on the planet.

| About I.C.T Company and Factory

Since 2012 we’ve grown into a 12,000 m² state-of-the-art campus with 89 team members, 20 dedicated engineers, and 8 global branches. Everything—R&D, fabrication, assembly, and burn-in testing—happens in-house. We serve over 1,600 factories in 72 countries with complete turnkey SMT and THT solutions, and every Selective Wave Soldering Machine leaves backed by rigorous inspection and proven quality systems.

| Selective Soldering Wave Machine Overview

Proudly built in our own Dongguan factory, the I.C.T Selective Wave Soldering Machine is the ultimate off-line Selective Wave Soldering Machine for factories that need maximum flexibility and rock-solid quality. The PCB never moves – a feather-light cast-aluminum gantry riding Panasonic servos and precision rails brings flux and solder exactly where they’re needed. Inline nitrogen heating creates shiny, full fillets with almost no waste. Operators set every parameter – paths, temps, spray volume, wave height – on a big Windows touchscreen and save endless programs for lightning-fast job switches. Auto wave calibration, live CCD, German jet valve, and titanium pot make this Selective Wave Soldering Machine a true 24/7 profit machine.

| DIP Line Equipment List

German high-frequency pulse valve shoots micro-dots of low-solids flux (<10%) repeatable to 0.02 mm. Pressurized tank plus digital flow meter lock pressure steady even when the tank is almost empty. Residue drops into a pull-out tray for two-second cleanup. Japanese SMC pneumatics and front gauges make daily checks effortless. An automatic pump guarantees constant supply. This smart flux module activates every pad perfectly on the Selective Wave Soldering Machine.

Standard bottom IR is fully adjustable; top hot-air convection or extra IR optional. Open-grid design plus thick high-temp insulation spreads heat evenly across the entire board. Top-brand heaters and plug-in motors run quiet and tool-free for years. Boards exit perfectly flux-activated and warp-free, ready for flawless joints on the off-line Selective Wave Soldering Machine.

German electromagnetic pump and titanium pot generate a rock-steady mini wave that never drifts or leaks. Control N2 flow, solder temp, wave height, and auto-calibration straight from the touchscreen. Inline nitrogen delivers mirror-bright fillets and virtually zero dross. Laser monitors height, nozzles self-clean, and 900 hours of video are saved for traceability. This is the bulletproof heart of every Selective Wave Soldering Machine.

Three-section roller conveyor plus pneumatic side/top clamps hold boards up to 20 kg dead-still. Heavy-duty rails and high-precision servos move PCBs smoothly station to station. Thick or double-sided assemblies clear with ease. Built for nonstop duty on any off-line Selective Wave Soldering Machine line.

CE-certified PLC, Cat-6 wiring, and full MES connectivity deliver lightning response and bulletproof reliability. Guided wizards, picture-based edits, auto nozzle detection, and multi-language menus slash training time. Remote diagnostics keep the Selective Wave Soldering Machine earning around the clock.

Large color touchscreen, step-by-step guides, one-tap live CCD preview, and voice alerts make running the machine dead simple. Switch instantly between English, Chinese, Japanese, or Russian. Custom tower lights and Wi-Fi upgrades keep everyone informed without leaving the floor.

| Specification

| On-line Selective Wave Soldering Machine | ||||

| Model | I.C.T SS540 | I.C.T SS550 | I.C.T SS550P1 | I.C.T SS550P2 |

| On-line Modular | Spray + Preheating & Soldering | Spray + Preheating + Soldering | Spray + Preheating + Soldering +Soldering | Spray + Preheating + Soldering + Soldering+ Soldering |

| Soldering System | ||||

| Nozzle Quantity | 1 | 1 | 2 | 3 |

| Solder Pot Quantity | 1 set | 1 set | 2 set | 3 set |

| Double Pot (Option) | N/A | Option | Option | Option |

| Solder Pot Power | 2.35kw | 2.35kw | 4.70kw | 7.05kw |

| Flux System | ||||

| Flux Storage Tank | 1L | 1L | 2L | 2L |

| Flux Support | Flux Alarm, Automatic | |||

| Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1 set | |||

| Spray Nozzle Size | 130um (180um, 210um Option) | |||

| Spray Speed | 0~20mm/s | |||

| Spray Nozzle Move Speed | 0~400mm/s | |||

| Preheating System | ||||

| Preheating Mode | Hot air and IR | Hot air and IR | Hot air and IR | Hot air and IR |

| Preheating Area | L500*W500mm | L500*W500mm | L500*W500mm | L500*W500mm |

| Preheating Zone | Top hot air: 2, Bottom IR: 1 | |||

| Bottom Preheating Power | Max.12kw | |||

| Top Preheating Power | Max.6kw | |||

| Warm-up Time | Approx.15min (setting 150℃) | |||

| Control Mode | PC+PLC | |||

| Transport System | ||||

| PCB Size (with fixture) | 120*60~500*500mm | |||

| PCB Replacement | Online | |||

| PCB Top Clearance | 120mm | |||

| Transport Height | 900±20mm | |||

| Transport Width | 60~500mm | |||

| Dimension:mm | L1850*W1850*H1480 | L2560*W1750*H1480 | L2560*W1950*H1480 | L2600*W1950*H1480 |

| Weight | Approx: 800kg | Approx: 1200kg | Approx: 1300kg | Approx: 1500kg |

| DIP Line Equipment List

Our Through-Hole Technology Line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Product Name | Purpose in DIP Line |

|---|---|

Through hole pick and place machine | Automatically places components onto PCBs with precision for DIP production line. |

Automatic DIP soldering machine | Melts solder to form solid joints on PCBs during THT plug-in process. |

Automated selective soldering machine | Applies solder selectively to specific areas for accurate THT assembly |

| Post-wave Inline AOI | Inspects solder joints and placement defects on DIP assembled PCB. |

| Customer Success Video

In early 2025 a major Vietnamese camera-brand supplier flew to Dongguan for final acceptance of their new Selective Wave Soldering Machine. Our engineers loaded their actual production boards, ran complete cycles while the customer watched perfect THT joints form live on the CCD, then trained their team for two full days on programming, maintenance, and troubleshooting. They left 100% ready to hit volume the moment the crate arrived—another proof of I.C.T’s real global partnership.

| Professional Service and Training

From factory acceptance and crating to installation, startup, and lifetime support, we’ve got you covered worldwide. Twenty senior engineers plus local teams in 72 countries provide on-site or remote training whenever you need it. Spare-parts warehouses on three continents and true 24/7 hotlines keep your off-line Selective Wave Soldering Machine at peak uptime for decades.

| Customer Praise

Customers keep saying our engineers are patient, sharp, and truly care about their success. They love the pinpoint flux accuracy, rock-solid wave, and how fast the Selective Wave Soldering Machine pays for itself in higher yields and zero rework. Export crates arrive flawless, and same-day remote fixes have turned first-time buyers into lifelong partners around the world.

| Industry Certifications

Every Selective Wave Soldering Machine ships with CE safety certification, RoHS compliance, ISO9001 quality system, and multiple patents on jet valves, pumps, and laser calibration. These globally trusted marks prove you’re getting safe, green, battle-tested technology you can rely on anywhere on the planet.

| About I.C.T Company and Factory

Since 2012 we’ve grown into a 12,000 m² state-of-the-art campus with 89 team members, 20 dedicated engineers, and 8 global branches. Everything—R&D, fabrication, assembly, and burn-in testing—happens in-house. We serve over 1,600 factories in 72 countries with complete turnkey SMT and THT solutions, and every Selective Wave Soldering Machine leaves backed by rigorous inspection and proven quality systems.