I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Precise SMT PCBA Depaneling Routing Machine

This SMT PCBA Depaneling Routing Machine serves industries such as smartphones, smart wearables, tablets, automotive electronics, medical devices, and aerospace. It processes PCB sizes from 340×380mm to 450×600mm with thicknesses between 0.5 and 5.0mm. The new CCD vision system recognizes all types of marks and applies automatic correction for perfect positioning. A high-speed spindle operating at up to 80,000rpm performs cuts with minimal stress, high accuracy, low inertia, and rapid response. Dual platforms allow simultaneous processing of different products or combination into a single large platform. The ion air gun removes static electricity from PCB surfaces, preventing dust adhesion. Real-time sensors monitor the milling cutter to avoid damage. The separate vacuum dust collector operates with high suction and low noise. Humanized controls make operation simple and efficient.

| Feature

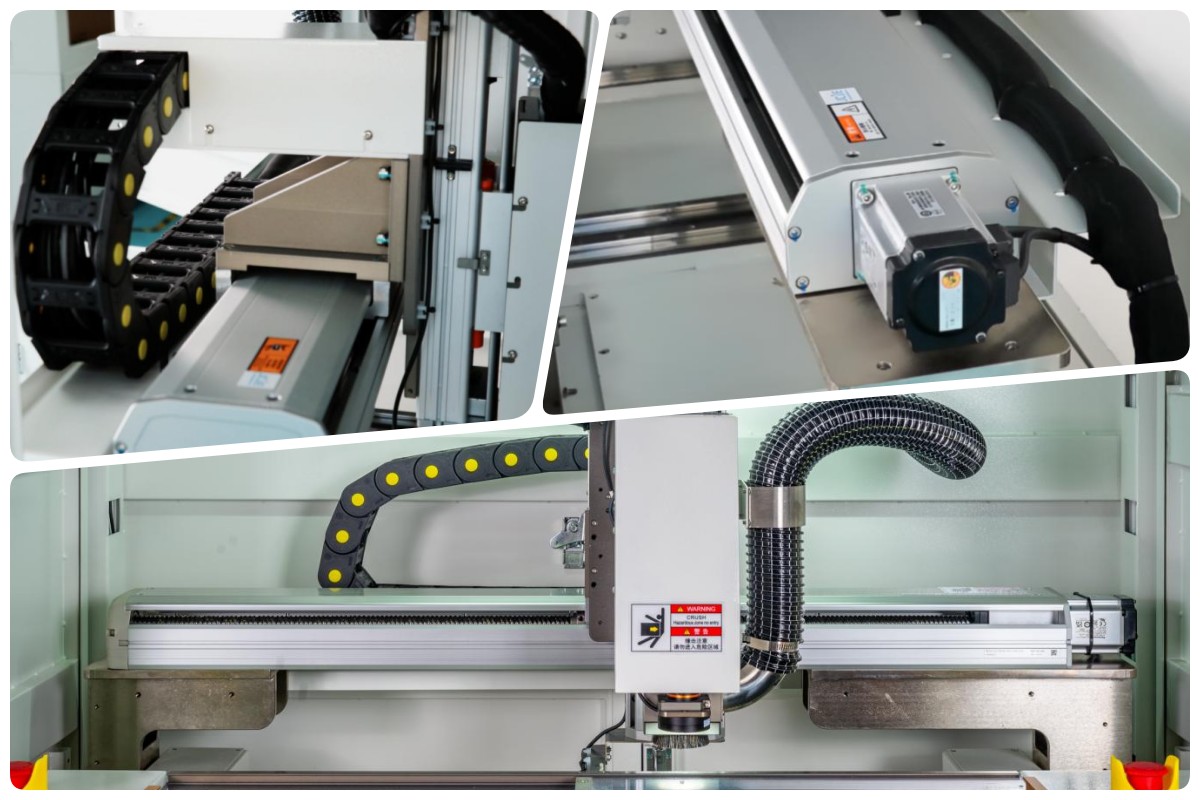

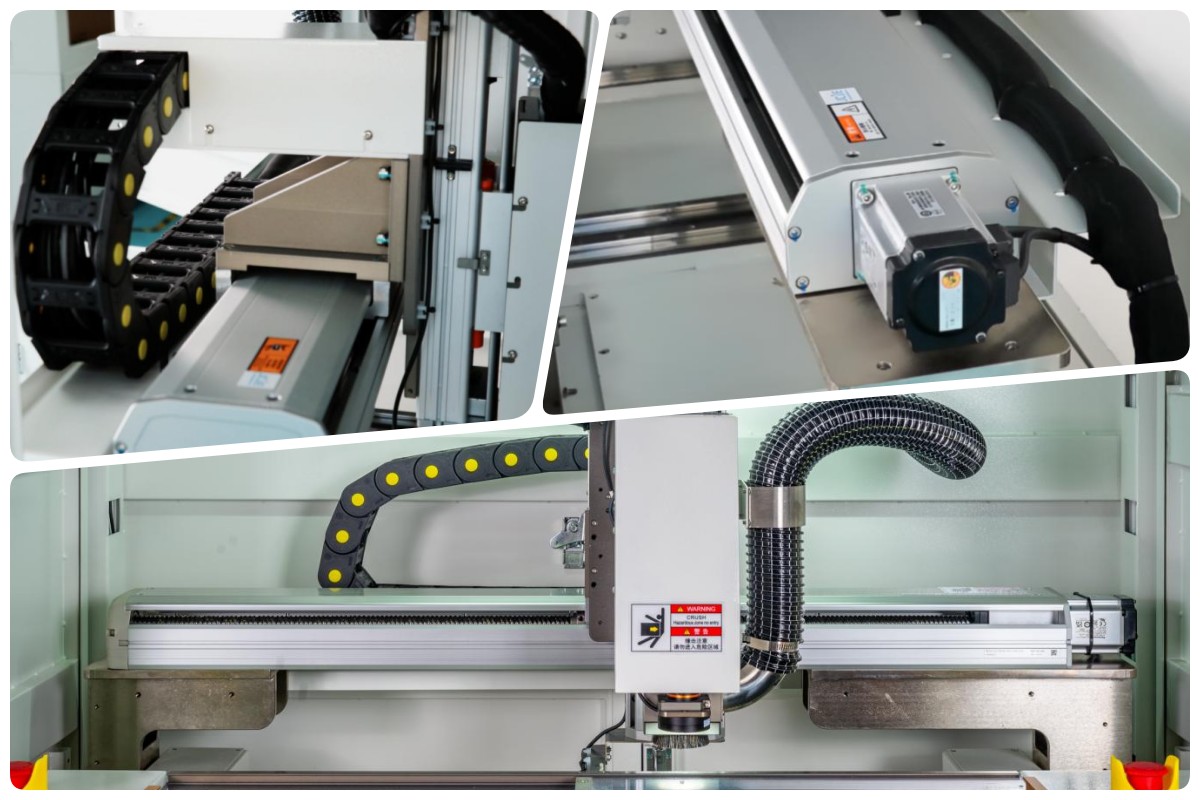

Transmission System

Imported Panasonic servo motors from Japan pair with high-precision screw rods to ensure exact motion control. Guide rails and ball screws from Taiwan maintain consistent accuracy. A stronger, thicker mechanical structure greatly improves overall stability during continuous operation. Flexible tank chains organize cables neatly and prevent interference with moving parts. The X-axis module features a unique dust-proof design that significantly reduces maintenance requirements. These components work together to deliver reliable performance, tight tolerances, and long service life in demanding production environments. The SMT PCBA Depaneling Routing Machine benefits from this robust system, keeping downtime low and precision high.

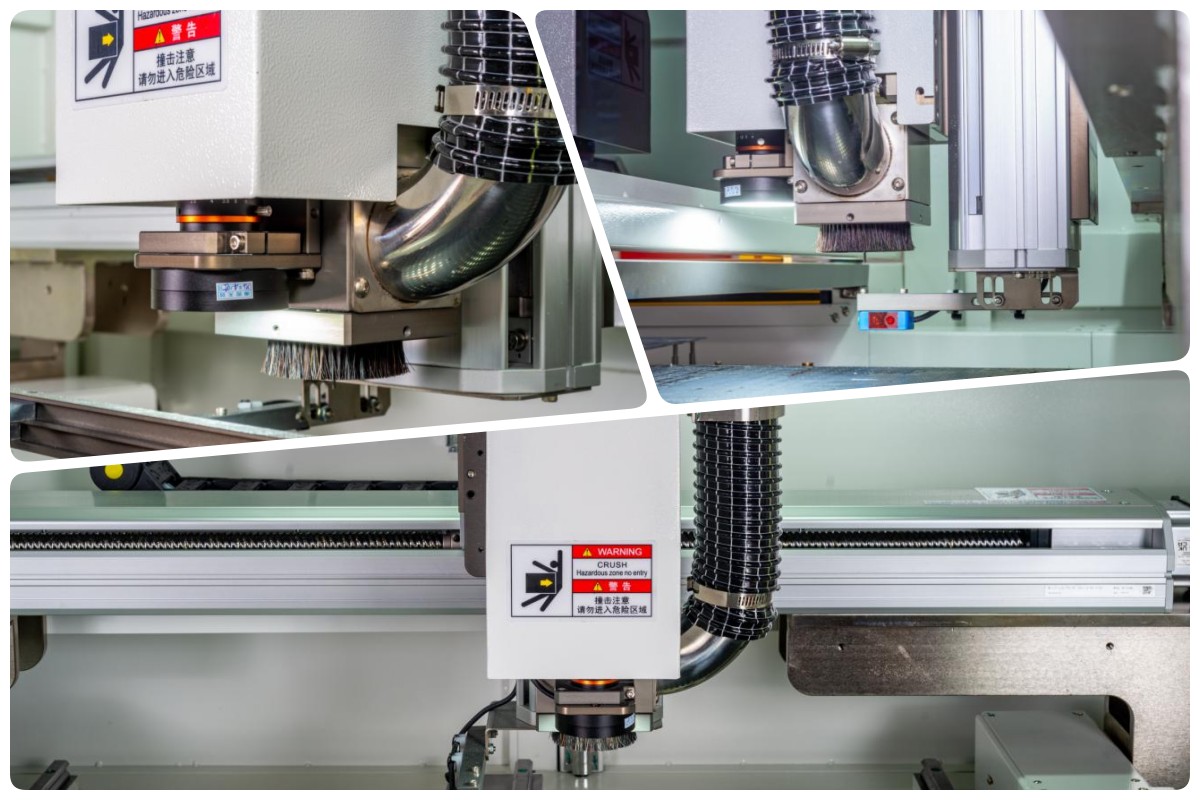

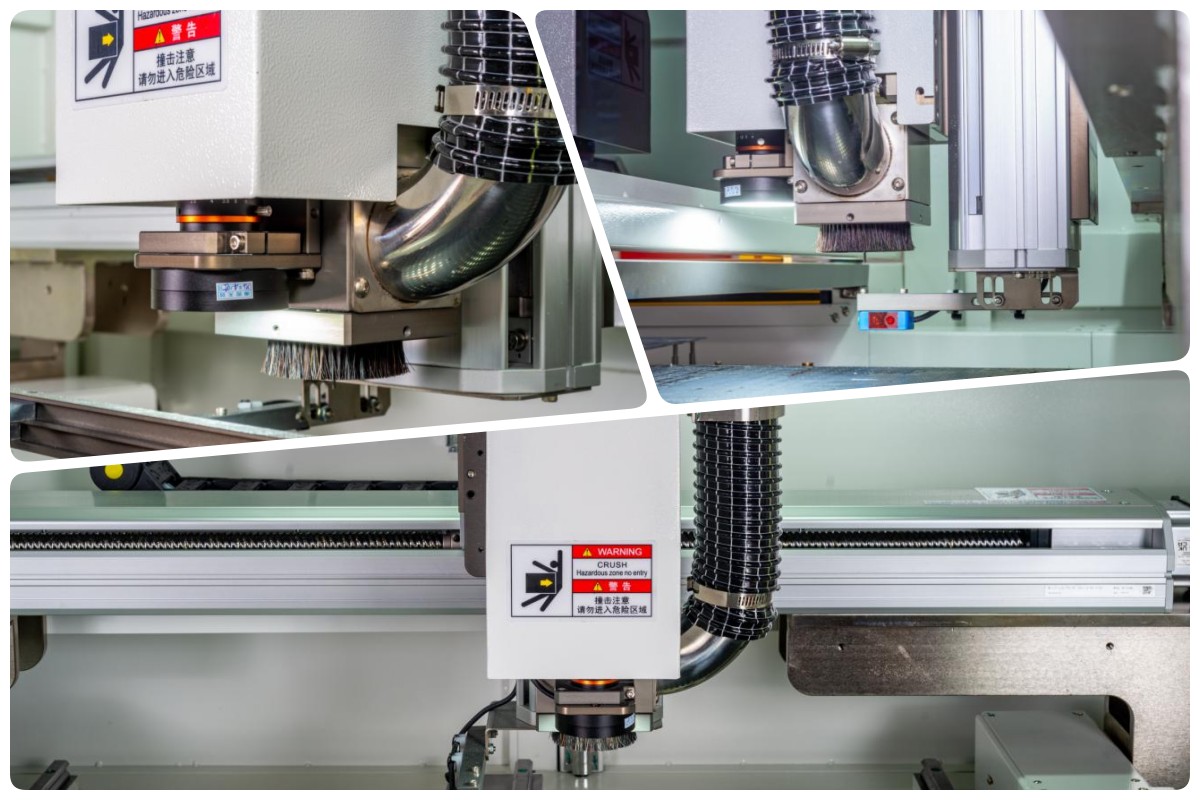

Router System

High-definition vision system aligns coaxially with the milling cutter for straightforward calibration. Standard tool breakage detection triggers an immediate alarm if the cutter breaks or wears out. Optional automatic tool changing function allows continuous operation without interruption, raising overall efficiency. The ion air gun effectively removes static electricity from the PCB surface and prevents dust from adhering. Imported high-speed spindle reduces cutting stress while providing excellent precision, small inertia, and fast response. Every feature combines to produce clean, burr-free edges on assembled boards. This PCBA Depaneling Routing Machine ensures consistent quality and protects delicate components throughout the process.

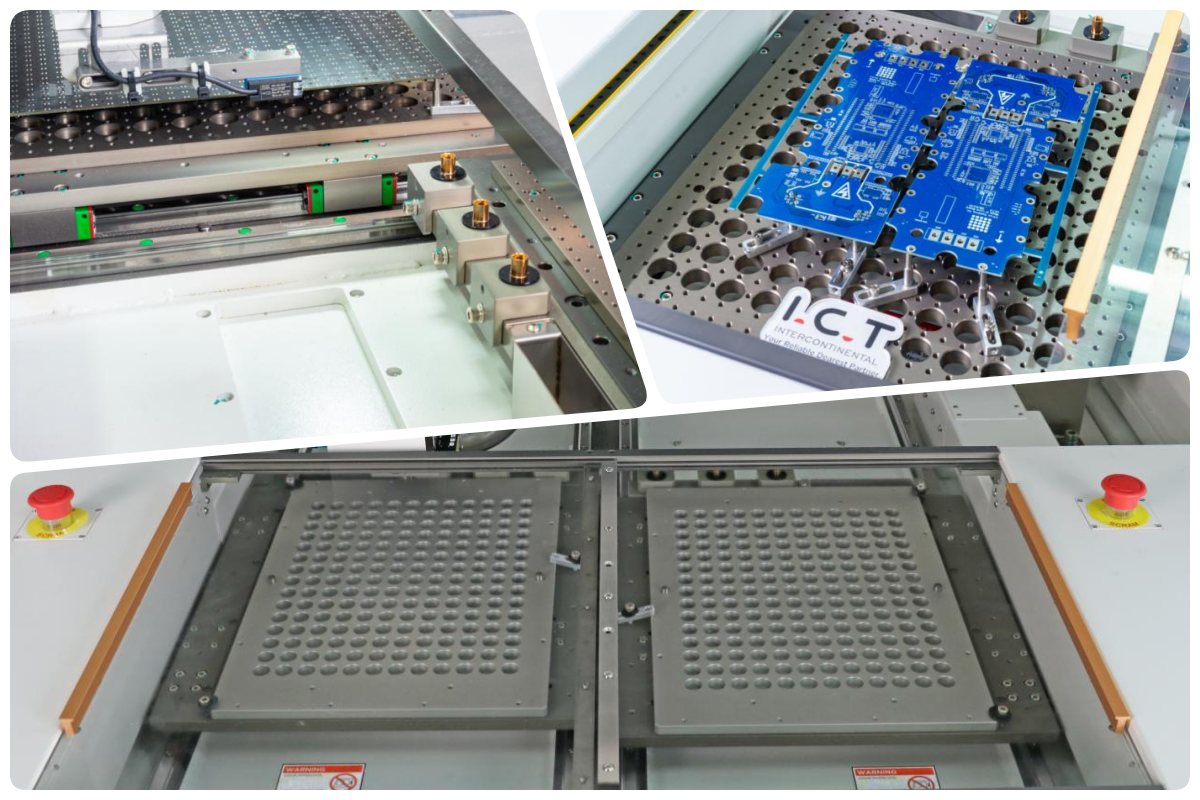

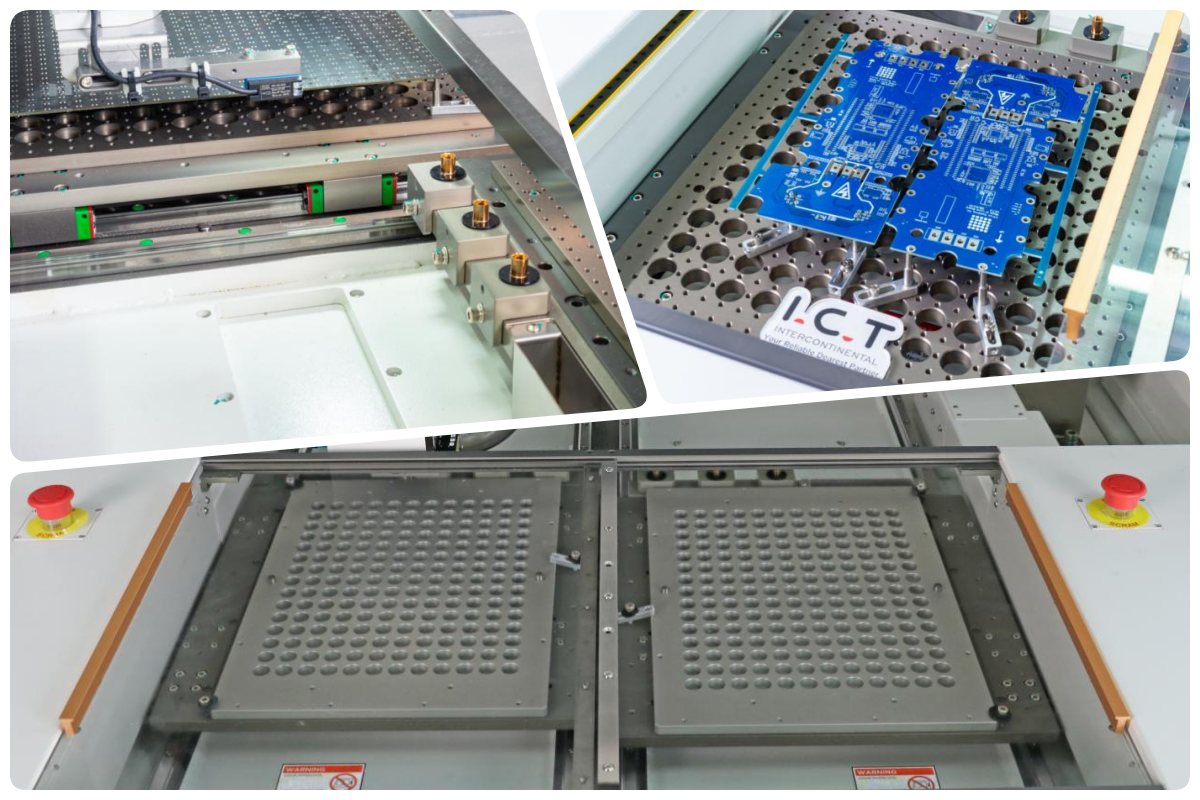

Platform System

The Y-axis is controlled by a slide rail and servo motor, ensuring excellent machine stability. Two-way emergency stop buttons, full safety covers, and light curtains provide multiple layers of protection. Start buttons located on both sides require simultaneous pressing to initiate operation safely. The standard honeycomb porous base offers strong suction and compatibility with various fixtures. Dual platforms support different products at the same time or merge into one larger working area. This design makes the SMT Routing Machine secure, adaptable, and suitable for high-volume production lines handling complex PCBA tasks.

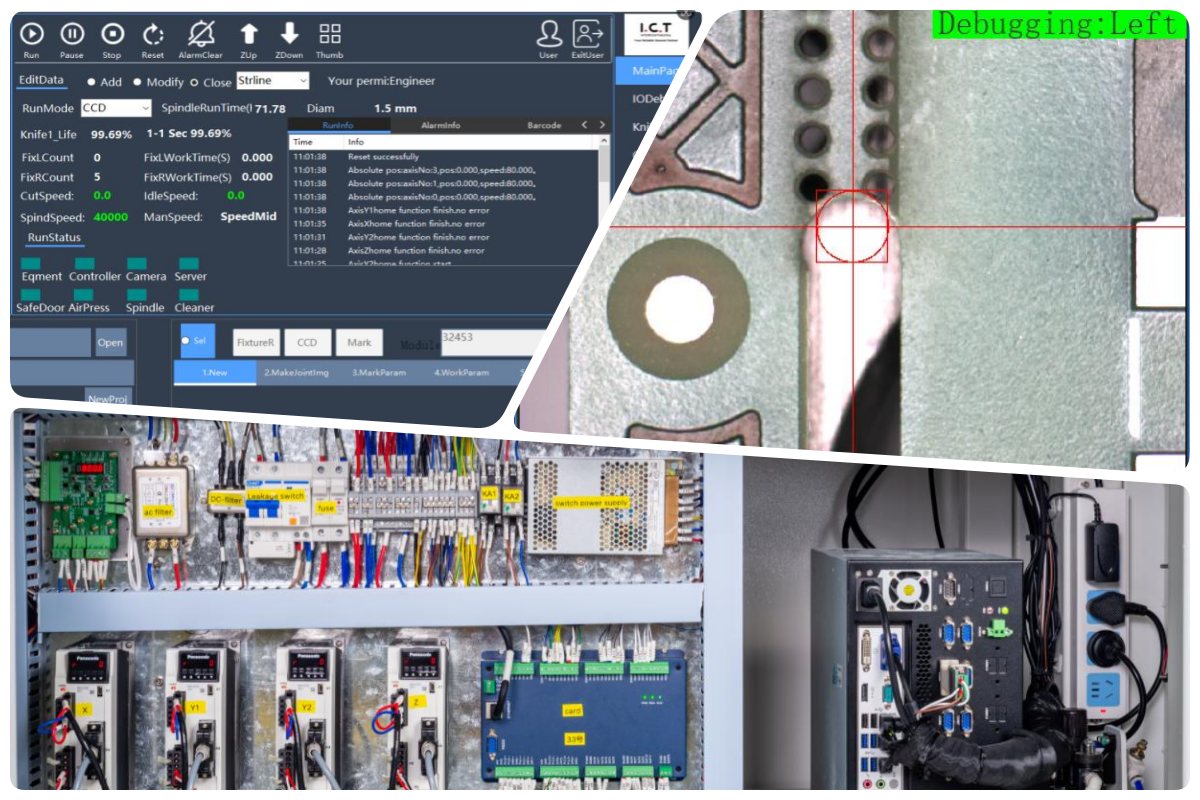

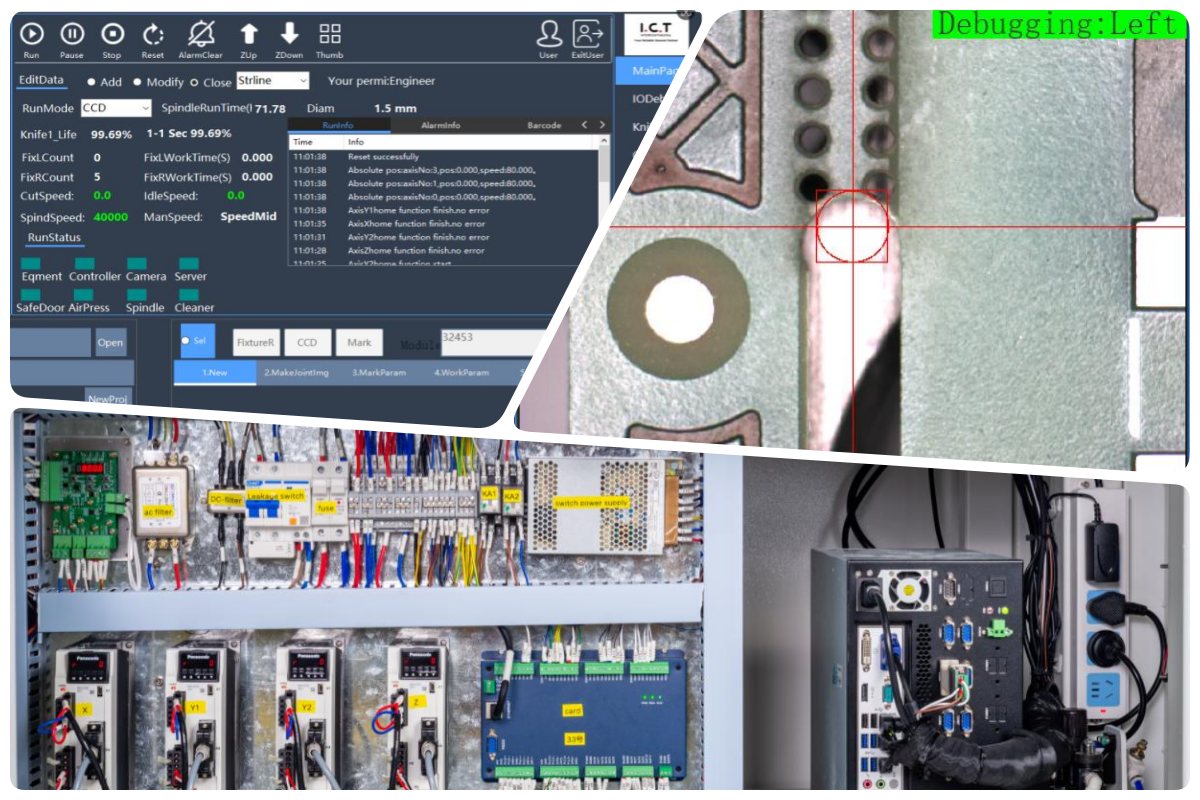

Control System

Industrial computer combined with a dedicated CNC controller delivers high control accuracy and strong resistance to interference. Production data is fully traceable with log report generation for quality management. The interface complies with CE standards and allows quick program changes between products. Coaxial CCD camera provides real-time visual monitoring of the cutting process. Operators find the system simple to learn and easy to operate consistently. These elements ensure the SMT PCBA Depaneling Routing Machine maintains stable performance and precise results during extended use in factory conditions.

Detail Display

Convection fan maintains even internal temperatures during operation. Side door safety sensors immediately stop the machine if doors open. ESD interface protects sensitive electronics from static discharge. Optional automatic tool changer enables seamless bit replacement without stopping. Broken knife detection sensor continuously monitors cutter condition. Self-locking pneumatic struts securely hold access doors in place. Each practical detail enhances safety, convenience, and reliability, making daily operation of the PCBA routing Machine smoother and more dependable for production teams.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

A customer from Algeria specializing in feature phones visited our factory for complete machine acceptance. They supplied more than ten PCB panels along with all required components. Our team demonstrated the entire SMT production line: automatic solder paste printing, SPI inspection, RX-8 placement for small components, RS-1R for larger parts, tray feeder for shield covers, reflow soldering, AOI quality check, and final separation using the I.C.T SMT PCBA Depaneling Routing Machine. The process ran without issues, delivering clean cuts, zero board stress, and high efficiency. The customer observed every step closely and expressed full satisfaction with the smooth performance and precise results before approving the equipment.

| Service and Training Support

I.C.T provides complete on-site installation and detailed operator training tailored to your production needs. Experienced engineers instruct safe machine handling, program setup, tool maintenance, and daily routines for the SMT PCBA Depaneling Routing Machine. Remote technical support responds quickly to questions, while spare parts ship promptly from global centers to minimize downtime. Service teams worldwide offer fast assistance and ongoing process advice as your requirements evolve. This comprehensive support ensures smooth startup, maximum uptime, and long-term value from your investment in our reliable equipment.

| Client Testimonials

Customers frequently commend our engineers for their fast, knowledgeable solutions and professional guidance during installation and support calls. They praise the SMT PCBA Depaneling Routing Machine for its consistent precision, clean cuts, and gentle handling of delicate boards. Many highlight the secure, professional packaging that protects machines perfectly during long-distance shipping. Quick responses to technical inquiries build strong trust and confidence. Overall, clients value I.C.T’s dependable equipment, excellent service, and commitment to quality that keeps their production running smoothly.

| Certifications and Standards

CE certification confirms full compliance with international safety standards. RoHS ensures materials meet strict environmental requirements. ISO9001 verifies a rigorous quality management system throughout design, manufacturing, and delivery. Multiple patents protect our innovative technologies and designs. These recognized certifications demonstrate I.C.T’s dedication to producing safe, reliable, and high-quality equipment that customers can trust worldwide.

| About I.C.T Company and Factory

I.C.T maintains its own research and development center along with full-scale production facilities. The company employs 89 staff members, including 20 dedicated engineers focused on continuous improvement. Established in 2012 with a registered capital of $30 million, I.C.T has experienced rapid growth, now serving more than 1600 customers across over 72 countries through 8 branch offices, sales centers, and warehouses. The modern factory follows strict testing procedures and a complete ISO9001 quality management system to guarantee every SMT PCBA Depaneling Routing Machine meets high standards before shipment. We provide comprehensive solutions and reliable global service to support long-term success for all partners.

| Precise SMT PCBA Depaneling Routing Machine

This SMT PCBA Depaneling Routing Machine serves industries such as smartphones, smart wearables, tablets, automotive electronics, medical devices, and aerospace. It processes PCB sizes from 340×380mm to 450×600mm with thicknesses between 0.5 and 5.0mm. The new CCD vision system recognizes all types of marks and applies automatic correction for perfect positioning. A high-speed spindle operating at up to 80,000rpm performs cuts with minimal stress, high accuracy, low inertia, and rapid response. Dual platforms allow simultaneous processing of different products or combination into a single large platform. The ion air gun removes static electricity from PCB surfaces, preventing dust adhesion. Real-time sensors monitor the milling cutter to avoid damage. The separate vacuum dust collector operates with high suction and low noise. Humanized controls make operation simple and efficient.

| Feature

Transmission System

Imported Panasonic servo motors from Japan pair with high-precision screw rods to ensure exact motion control. Guide rails and ball screws from Taiwan maintain consistent accuracy. A stronger, thicker mechanical structure greatly improves overall stability during continuous operation. Flexible tank chains organize cables neatly and prevent interference with moving parts. The X-axis module features a unique dust-proof design that significantly reduces maintenance requirements. These components work together to deliver reliable performance, tight tolerances, and long service life in demanding production environments. The SMT PCBA Depaneling Routing Machine benefits from this robust system, keeping downtime low and precision high.

Router System

High-definition vision system aligns coaxially with the milling cutter for straightforward calibration. Standard tool breakage detection triggers an immediate alarm if the cutter breaks or wears out. Optional automatic tool changing function allows continuous operation without interruption, raising overall efficiency. The ion air gun effectively removes static electricity from the PCB surface and prevents dust from adhering. Imported high-speed spindle reduces cutting stress while providing excellent precision, small inertia, and fast response. Every feature combines to produce clean, burr-free edges on assembled boards. This PCBA Depaneling Routing Machine ensures consistent quality and protects delicate components throughout the process.

Platform System

The Y-axis is controlled by a slide rail and servo motor, ensuring excellent machine stability. Two-way emergency stop buttons, full safety covers, and light curtains provide multiple layers of protection. Start buttons located on both sides require simultaneous pressing to initiate operation safely. The standard honeycomb porous base offers strong suction and compatibility with various fixtures. Dual platforms support different products at the same time or merge into one larger working area. This design makes the SMT Routing Machine secure, adaptable, and suitable for high-volume production lines handling complex PCBA tasks.

Control System

Industrial computer combined with a dedicated CNC controller delivers high control accuracy and strong resistance to interference. Production data is fully traceable with log report generation for quality management. The interface complies with CE standards and allows quick program changes between products. Coaxial CCD camera provides real-time visual monitoring of the cutting process. Operators find the system simple to learn and easy to operate consistently. These elements ensure the SMT PCBA Depaneling Routing Machine maintains stable performance and precise results during extended use in factory conditions.

Detail Display

Convection fan maintains even internal temperatures during operation. Side door safety sensors immediately stop the machine if doors open. ESD interface protects sensitive electronics from static discharge. Optional automatic tool changer enables seamless bit replacement without stopping. Broken knife detection sensor continuously monitors cutter condition. Self-locking pneumatic struts securely hold access doors in place. Each practical detail enhances safety, convenience, and reliability, making daily operation of the PCBA routing Machine smoother and more dependable for production teams.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

A customer from Algeria specializing in feature phones visited our factory for complete machine acceptance. They supplied more than ten PCB panels along with all required components. Our team demonstrated the entire SMT production line: automatic solder paste printing, SPI inspection, RX-8 placement for small components, RS-1R for larger parts, tray feeder for shield covers, reflow soldering, AOI quality check, and final separation using the I.C.T SMT PCBA Depaneling Routing Machine. The process ran without issues, delivering clean cuts, zero board stress, and high efficiency. The customer observed every step closely and expressed full satisfaction with the smooth performance and precise results before approving the equipment.

| Service and Training Support

I.C.T provides complete on-site installation and detailed operator training tailored to your production needs. Experienced engineers instruct safe machine handling, program setup, tool maintenance, and daily routines for the SMT PCBA Depaneling Routing Machine. Remote technical support responds quickly to questions, while spare parts ship promptly from global centers to minimize downtime. Service teams worldwide offer fast assistance and ongoing process advice as your requirements evolve. This comprehensive support ensures smooth startup, maximum uptime, and long-term value from your investment in our reliable equipment.

| Client Testimonials

Customers frequently commend our engineers for their fast, knowledgeable solutions and professional guidance during installation and support calls. They praise the SMT PCBA Depaneling Routing Machine for its consistent precision, clean cuts, and gentle handling of delicate boards. Many highlight the secure, professional packaging that protects machines perfectly during long-distance shipping. Quick responses to technical inquiries build strong trust and confidence. Overall, clients value I.C.T’s dependable equipment, excellent service, and commitment to quality that keeps their production running smoothly.

| Certifications and Standards

CE certification confirms full compliance with international safety standards. RoHS ensures materials meet strict environmental requirements. ISO9001 verifies a rigorous quality management system throughout design, manufacturing, and delivery. Multiple patents protect our innovative technologies and designs. These recognized certifications demonstrate I.C.T’s dedication to producing safe, reliable, and high-quality equipment that customers can trust worldwide.

| About I.C.T Company and Factory

I.C.T maintains its own research and development center along with full-scale production facilities. The company employs 89 staff members, including 20 dedicated engineers focused on continuous improvement. Established in 2012 with a registered capital of $30 million, I.C.T has experienced rapid growth, now serving more than 1600 customers across over 72 countries through 8 branch offices, sales centers, and warehouses. The modern factory follows strict testing procedures and a complete ISO9001 quality management system to guarantee every SMT PCBA Depaneling Routing Machine meets high standards before shipment. We provide comprehensive solutions and reliable global service to support long-term success for all partners.