I.C.T-S1200

I.C.T

spi machine

| Availability: | |

|---|---|

| Quantity: | |

| SMT SPI Solder Paste Inspection Machine

The SMT SPI Solder Paste Inspection Machine from I.C.T is designed to enhance the quality of printed circuit board assembly by detecting defects in solder paste application early in the process. This advanced equipment uses 3D imaging technology to measure volume, height, area, and shape of solder deposits with high precision, preventing issues like insufficient paste or bridging that could lead to costly rework or failures. Ideal for high-volume electronics manufacturing, it supports PCB sizes up to 450x500mm and integrates easily into SMT lines for seamless operation. With over 25 years of experience, I.C.T ensures this machine meets global standards, helping customers achieve efficient production, reduce waste, and maintain competitive edges in sectors like semiconductors and PCBA. By choosing our SMT SPI Solder Paste Inspection Machine, manufacturers can optimize their workflows from demand analysis to final adjustment.

| Feature

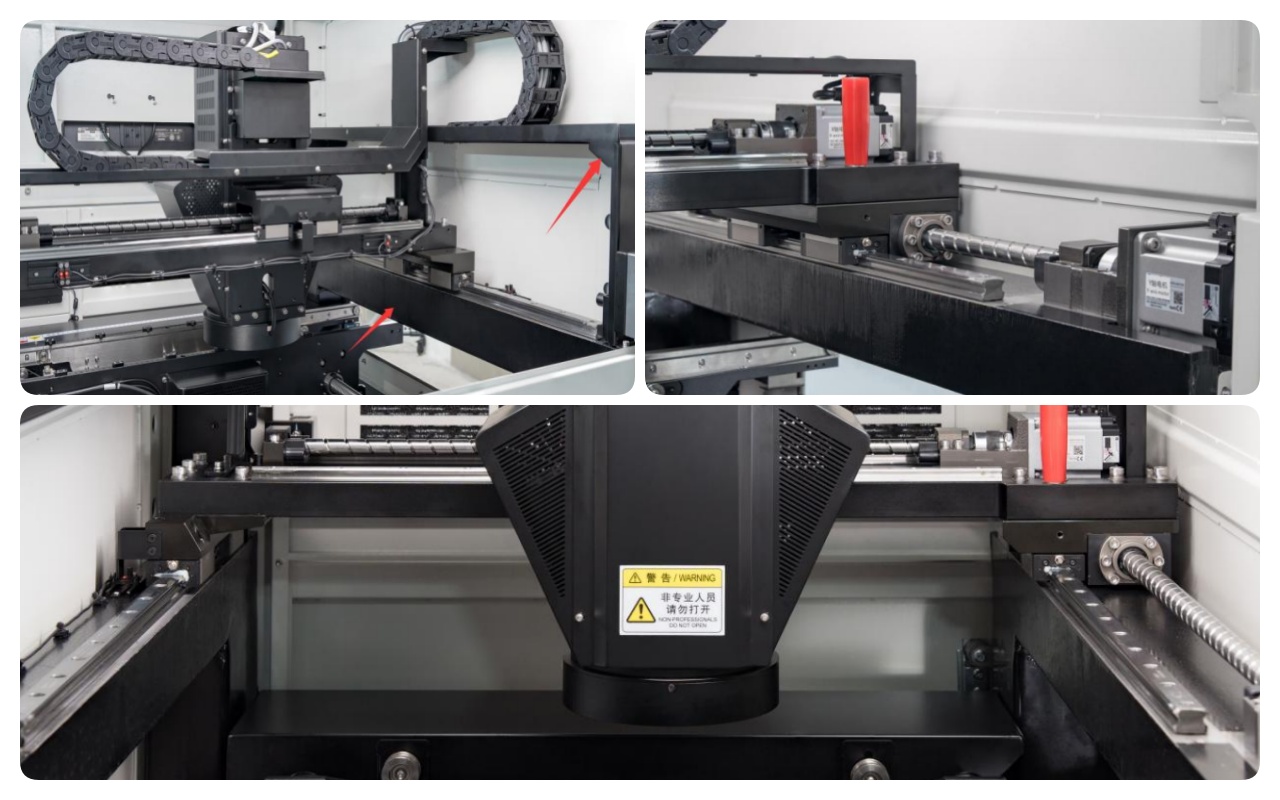

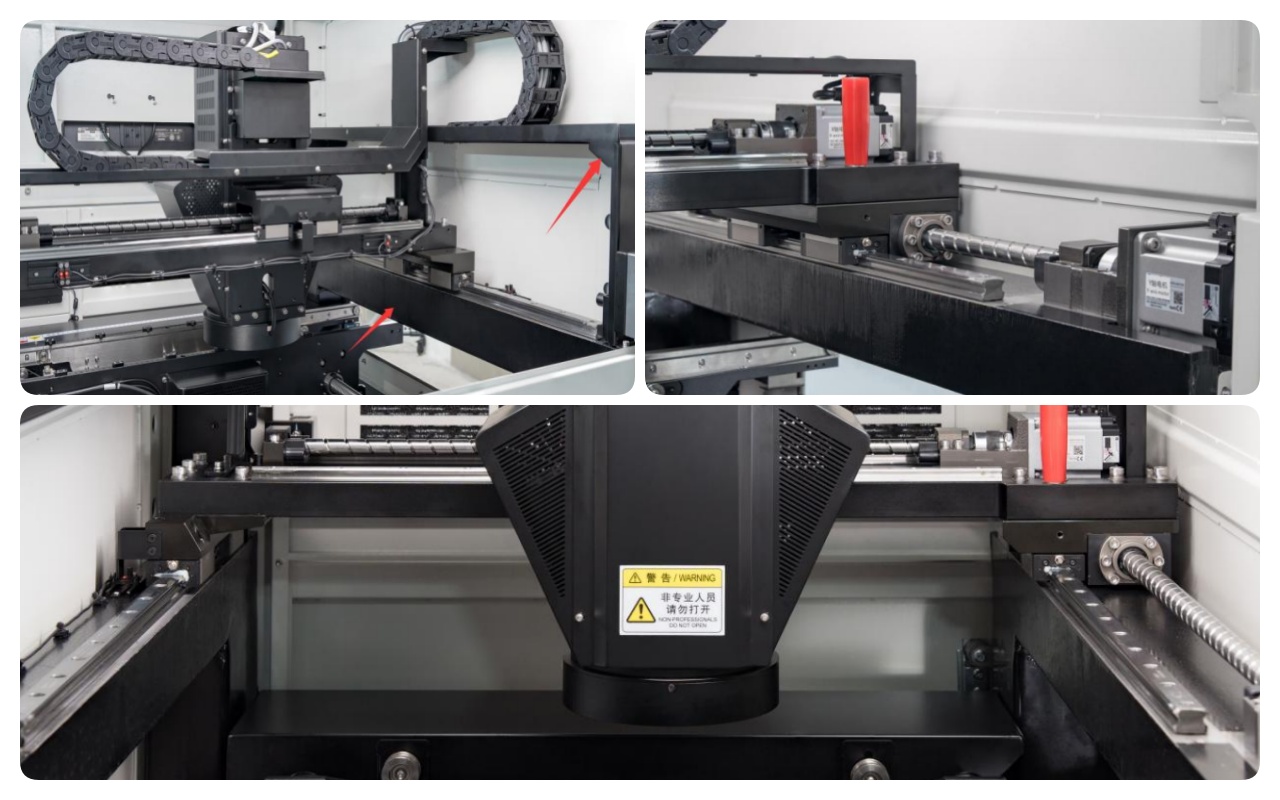

The platform system of the SMT SPI Solder Paste Inspection Machine features a sturdy frame built with high-quality materials to ensure stability during high-speed operations. This design minimizes vibrations and maintains alignment accuracy, which is crucial for consistent inspection results. It supports various PCB thicknesses and sizes, making it versatile for different manufacturing needs. I.C.T's engineering team has optimized this system to handle demanding environments, providing long-term reliability and low maintenance costs. Users benefit from quick setup and easy integration into existing lines, boosting overall productivity without compromising on safety or performance.

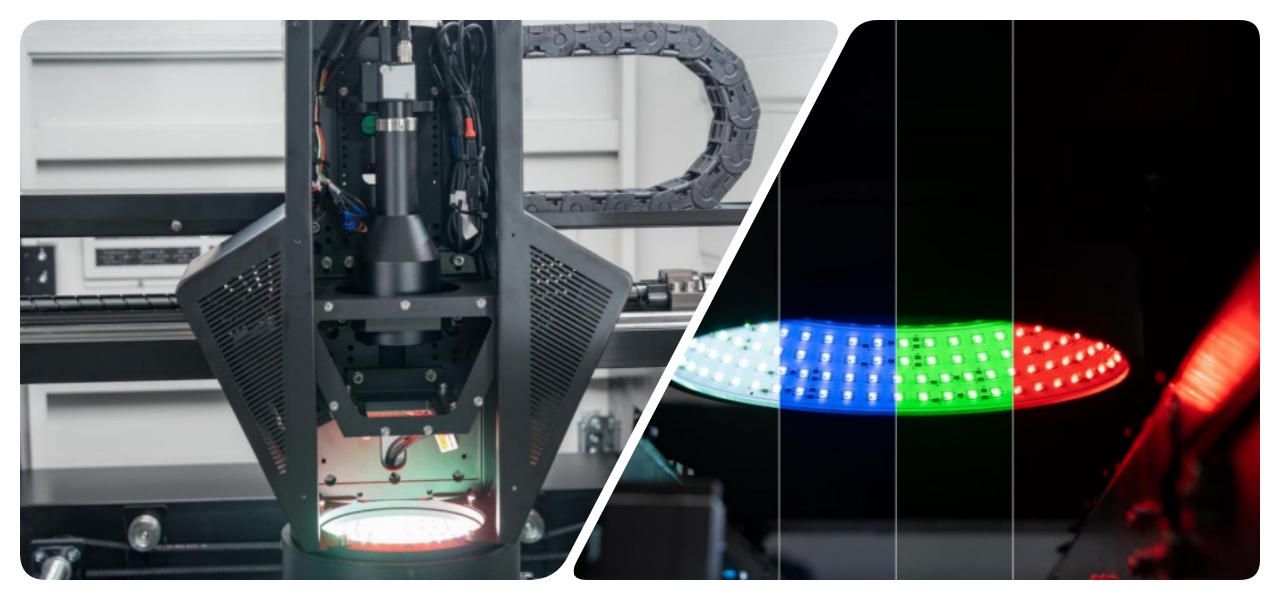

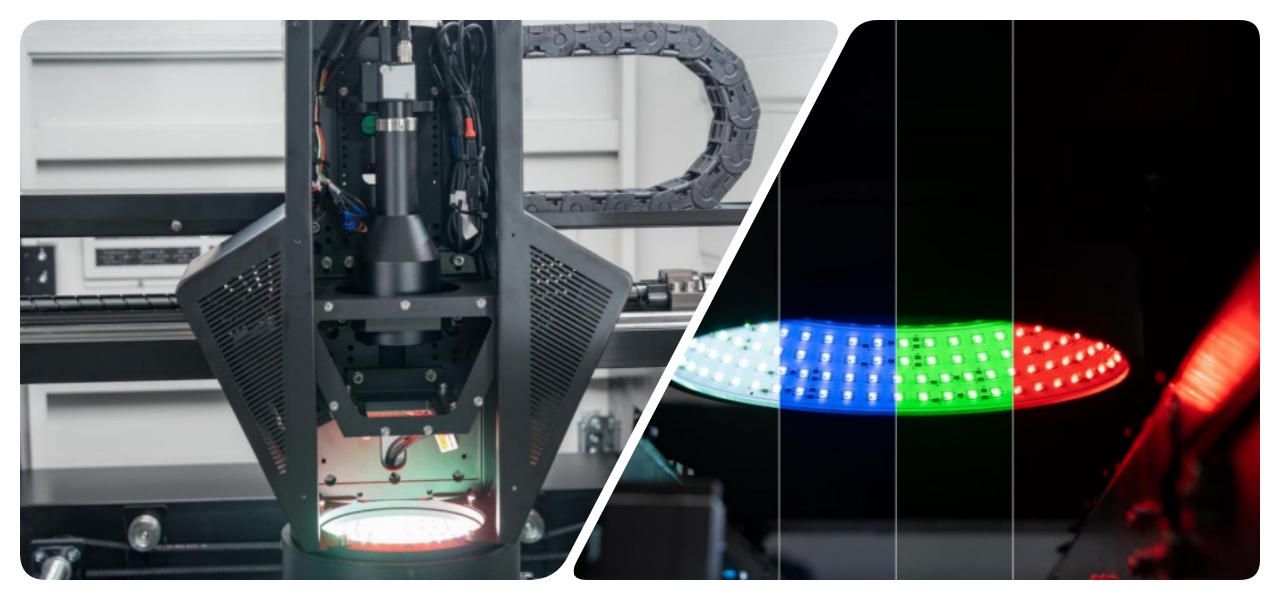

Equipped with a high-resolution camera and 3D projection technology, the vision system in the SMT SPI Solder Paste Inspection Machine captures detailed images of solder paste deposits. It analyzes parameters like volume and height in real-time, identifying defects with micron-level precision. This system adapts to varying lighting conditions and complex board layouts, ensuring thorough coverage. I.C.T incorporates smart algorithms that reduce false positives, allowing operators to focus on genuine issues. As a result, manufacturers experience improved yield rates and faster throughput, aligning with industry demands for defect-free products.

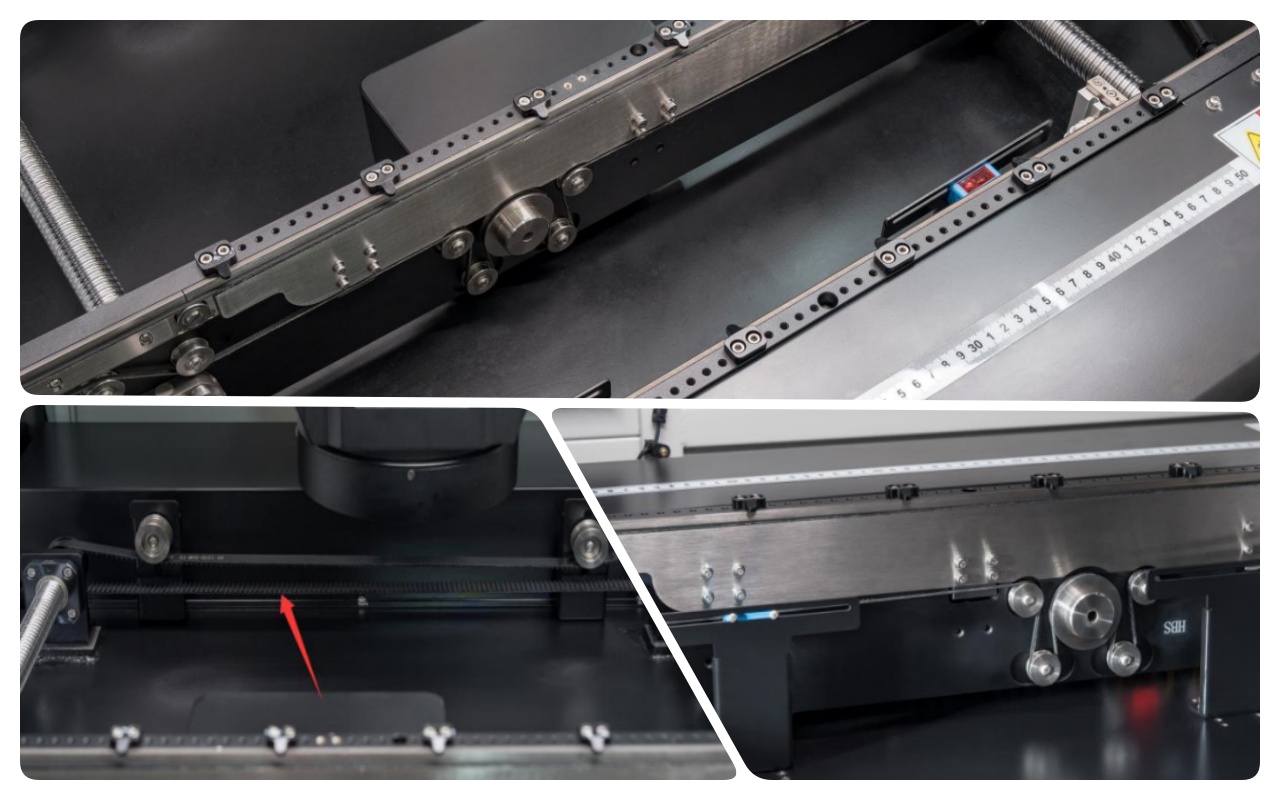

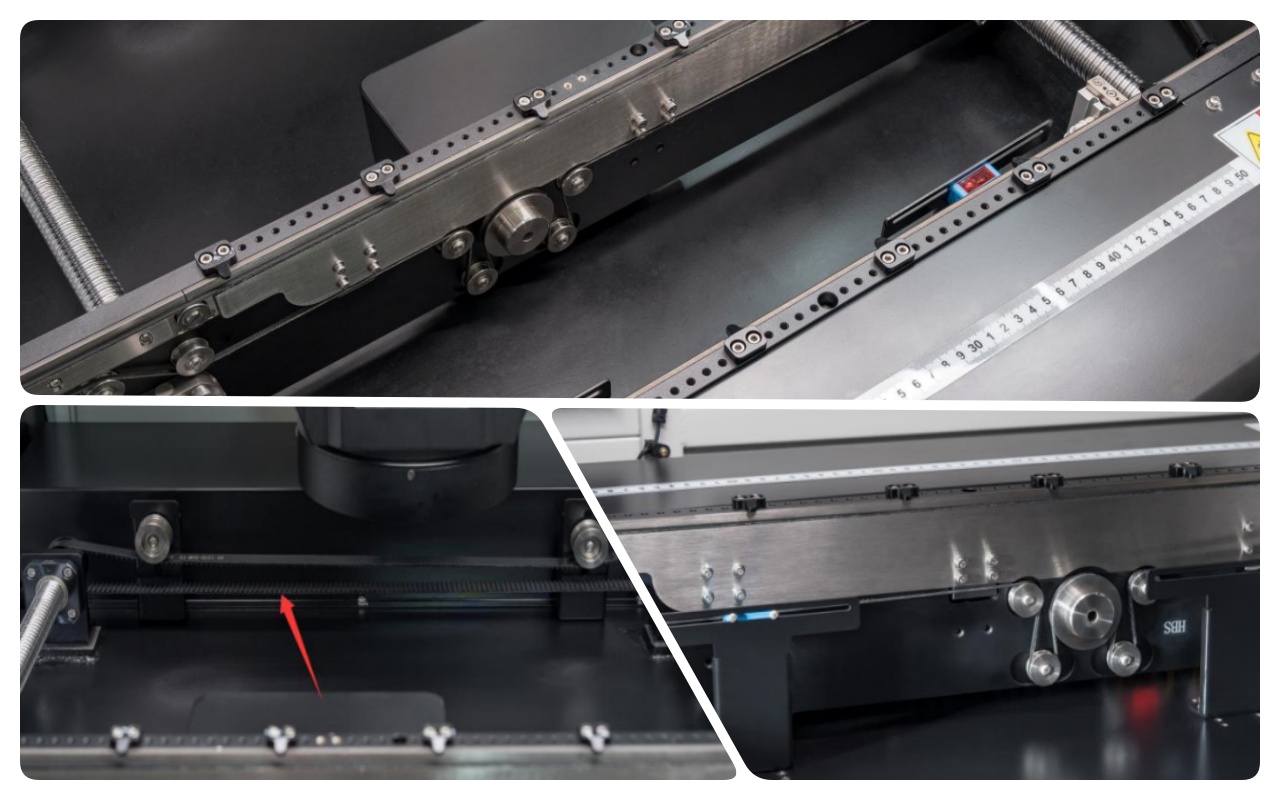

The transport system facilitates smooth PCB handling through automated conveyor belts that adjust to different board sizes automatically. It ensures precise positioning for inspections without manual intervention, reducing handling errors and cycle times. Built with durable components, this system supports dual-rail options for higher efficiency in busy production settings. I.C.T's focus on user-friendly design means minimal downtime during transitions, helping customers maintain continuous operations. This feature is key to scaling up manufacturing while keeping costs under control.

| Reflow Oven Specification

| Model | I.C.T-S510 | I.C.T-S510D | I.C.T-S1200 |

| PCB Size | 60*50~510*510mm | 50*60~510*310mm Dual rail 50*60~510*580 Single rai | 80*80~1200*500mm |

| PCB Tickness | 0.5 ~ 5.0mm | ||

| PCB Weight | ≤5.0kg | ||

| Conveyor Adjustment | Manual/automatic | ||

| Measure Type | Height,Area,Volume,Offset,Bridge,Shape(missing print,insufficient tin, excessive tin, bridging, offset, mal-shapes, surface contamination) | ||

| Paste Height | 0 ~ 550um | ||

| Min Pad Pitch | ≥100um | ||

| Measure Principle | 3D white light PSLM PMP(Programmable Spatial Light Modulation, Phase Measurement Profilometry) | ||

| Inspection Head Quantity | 1 | ||

| Camera Pixel | 5M, (10M/12M as option) | ||

| Detection Speed | 0.35 ~ 0.5s/FOV | ||

| Program Time | 5 ~ 10min | ||

| Data Type | Gerber Data 274D/274X, Scan PCB | ||

| Power | AC220,50/60Hz,1KVA | ||

| Machine Dimension | W1015*D1195*H1495mm | W1015*D1460*H1495mm | W1840*D1450*H1495mm |

| Weight | 850kg | 950kg | 1500kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data. |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Cutting Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Video

I.C.T recently completed the successful overseas installation and Factory Acceptance Test (FAT) support for two SMT production lines at a North American beauty device manufacturer. The project involved deploying advanced equipment, including laser marking machines for precise component identification, SMT printers paired with our SMT SPI Solder Paste Inspection Machine to ensure flawless paste application, Panasonic pick-and-place machines for high-speed component mounting, Heller reflow ovens for reliable soldering, AOI detection systems for post-assembly quality checks, PCB conveyors for seamless material flow, PCBA cleaning machines to remove residues, and automatic solder paste storage warmers to maintain material integrity. Our engineers provided on-site training and optimization, leading to smooth production acceptance. This case highlights I.C.T's commitment to delivering turnkey solutions that enhance efficiency and product quality in global markets.

| Professional Global Training & Support

I.C.T offers comprehensive service and training programs to support your SMT SPI Solder Paste Inspection Machine throughout its lifecycle. Our global network of service centers provides installation, maintenance, and troubleshooting with quick response times to minimize downtime. Experienced engineers conduct on-site or remote sessions, covering operation, calibration, and software updates. Training includes hands-on practice to build operator skills, ensuring safe and efficient use. We also provide ongoing technical support, spare parts supply, and process optimization consultations. This holistic approach helps customers maximize equipment performance, adapt to production changes, and achieve long-term success in electronics manufacturing.

| Customer Praise

Customers praise I.C.T engineers for their expertise and dedication during installations. They highlight the superior performance of our SMT SPI Solder Paste Inspection Machine in detecting defects accurately. Many appreciate our secure packaging and efficient transportation methods that ensure equipment arrives in perfect condition. Quick responses to queries and issues have built strong trust, with clients noting how our support resolves problems swiftly and effectively.

| Our Certification

I.C.T holds key certifications like CE for safety compliance, RoHS for environmental standards, and ISO9001 for quality management. We also possess multiple patents for innovative technologies in electronics manufacturing. These credentials demonstrate our commitment to high standards and continuous improvement. They assure customers that our SMT SPI Solder Paste Inspection Machine meets global regulations, promoting reliability and sustainability in production processes.

| About Us and Factory

I.C.T is a leading electronics manufacturing solutions provider with our own R&D and production facilities. Established in 2012, we employ over 89 staff, including 20 engineers, across 12,000 square meters. Our registered capital of $30 million supports rapid growth, serving more than 1,600 customers in 72 countries. With branch offices worldwide, we offer one-stop services from planning to optimization. Our factories feature strict testing workflows and robust quality management systems to ensure product excellence.

| SMT SPI Solder Paste Inspection Machine

The SMT SPI Solder Paste Inspection Machine from I.C.T is designed to enhance the quality of printed circuit board assembly by detecting defects in solder paste application early in the process. This advanced equipment uses 3D imaging technology to measure volume, height, area, and shape of solder deposits with high precision, preventing issues like insufficient paste or bridging that could lead to costly rework or failures. Ideal for high-volume electronics manufacturing, it supports PCB sizes up to 450x500mm and integrates easily into SMT lines for seamless operation. With over 25 years of experience, I.C.T ensures this machine meets global standards, helping customers achieve efficient production, reduce waste, and maintain competitive edges in sectors like semiconductors and PCBA. By choosing our SMT SPI Solder Paste Inspection Machine, manufacturers can optimize their workflows from demand analysis to final adjustment.

| Feature

The platform system of the SMT SPI Solder Paste Inspection Machine features a sturdy frame built with high-quality materials to ensure stability during high-speed operations. This design minimizes vibrations and maintains alignment accuracy, which is crucial for consistent inspection results. It supports various PCB thicknesses and sizes, making it versatile for different manufacturing needs. I.C.T's engineering team has optimized this system to handle demanding environments, providing long-term reliability and low maintenance costs. Users benefit from quick setup and easy integration into existing lines, boosting overall productivity without compromising on safety or performance.

Equipped with a high-resolution camera and 3D projection technology, the vision system in the SMT SPI Solder Paste Inspection Machine captures detailed images of solder paste deposits. It analyzes parameters like volume and height in real-time, identifying defects with micron-level precision. This system adapts to varying lighting conditions and complex board layouts, ensuring thorough coverage. I.C.T incorporates smart algorithms that reduce false positives, allowing operators to focus on genuine issues. As a result, manufacturers experience improved yield rates and faster throughput, aligning with industry demands for defect-free products.

The transport system facilitates smooth PCB handling through automated conveyor belts that adjust to different board sizes automatically. It ensures precise positioning for inspections without manual intervention, reducing handling errors and cycle times. Built with durable components, this system supports dual-rail options for higher efficiency in busy production settings. I.C.T's focus on user-friendly design means minimal downtime during transitions, helping customers maintain continuous operations. This feature is key to scaling up manufacturing while keeping costs under control.

| Reflow Oven Specification

| Model | I.C.T-S510 | I.C.T-S510D | I.C.T-S1200 |

| PCB Size | 60*50~510*510mm | 50*60~510*310mm Dual rail 50*60~510*580 Single rai | 80*80~1200*500mm |

| PCB Tickness | 0.5 ~ 5.0mm | ||

| PCB Weight | ≤5.0kg | ||

| Conveyor Adjustment | Manual/automatic | ||

| Measure Type | Height,Area,Volume,Offset,Bridge,Shape(missing print,insufficient tin, excessive tin, bridging, offset, mal-shapes, surface contamination) | ||

| Paste Height | 0 ~ 550um | ||

| Min Pad Pitch | ≥100um | ||

| Measure Principle | 3D white light PSLM PMP(Programmable Spatial Light Modulation, Phase Measurement Profilometry) | ||

| Inspection Head Quantity | 1 | ||

| Camera Pixel | 5M, (10M/12M as option) | ||

| Detection Speed | 0.35 ~ 0.5s/FOV | ||

| Program Time | 5 ~ 10min | ||

| Data Type | Gerber Data 274D/274X, Scan PCB | ||

| Power | AC220,50/60Hz,1KVA | ||

| Machine Dimension | W1015*D1195*H1495mm | W1015*D1460*H1495mm | W1840*D1450*H1495mm |

| Weight | 850kg | 950kg | 1500kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data. |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Cutting Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Video

I.C.T recently completed the successful overseas installation and Factory Acceptance Test (FAT) support for two SMT production lines at a North American beauty device manufacturer. The project involved deploying advanced equipment, including laser marking machines for precise component identification, SMT printers paired with our SMT SPI Solder Paste Inspection Machine to ensure flawless paste application, Panasonic pick-and-place machines for high-speed component mounting, Heller reflow ovens for reliable soldering, AOI detection systems for post-assembly quality checks, PCB conveyors for seamless material flow, PCBA cleaning machines to remove residues, and automatic solder paste storage warmers to maintain material integrity. Our engineers provided on-site training and optimization, leading to smooth production acceptance. This case highlights I.C.T's commitment to delivering turnkey solutions that enhance efficiency and product quality in global markets.

| Professional Global Training & Support

I.C.T offers comprehensive service and training programs to support your SMT SPI Solder Paste Inspection Machine throughout its lifecycle. Our global network of service centers provides installation, maintenance, and troubleshooting with quick response times to minimize downtime. Experienced engineers conduct on-site or remote sessions, covering operation, calibration, and software updates. Training includes hands-on practice to build operator skills, ensuring safe and efficient use. We also provide ongoing technical support, spare parts supply, and process optimization consultations. This holistic approach helps customers maximize equipment performance, adapt to production changes, and achieve long-term success in electronics manufacturing.

| Customer Praise

Customers praise I.C.T engineers for their expertise and dedication during installations. They highlight the superior performance of our SMT SPI Solder Paste Inspection Machine in detecting defects accurately. Many appreciate our secure packaging and efficient transportation methods that ensure equipment arrives in perfect condition. Quick responses to queries and issues have built strong trust, with clients noting how our support resolves problems swiftly and effectively.

| Our Certification

I.C.T holds key certifications like CE for safety compliance, RoHS for environmental standards, and ISO9001 for quality management. We also possess multiple patents for innovative technologies in electronics manufacturing. These credentials demonstrate our commitment to high standards and continuous improvement. They assure customers that our SMT SPI Solder Paste Inspection Machine meets global regulations, promoting reliability and sustainability in production processes.

| About Us and Factory

I.C.T is a leading electronics manufacturing solutions provider with our own R&D and production facilities. Established in 2012, we employ over 89 staff, including 20 engineers, across 12,000 square meters. Our registered capital of $30 million supports rapid growth, serving more than 1,600 customers in 72 countries. With branch offices worldwide, we offer one-stop services from planning to optimization. Our factories feature strict testing workflows and robust quality management systems to ensure product excellence.