SMT Production Line for IFPD

I.C.T

SMT Production Line for IFPD

| Availability: | |

|---|---|

| Quantity: | |

| SMT Line Solutions for IFPD Details

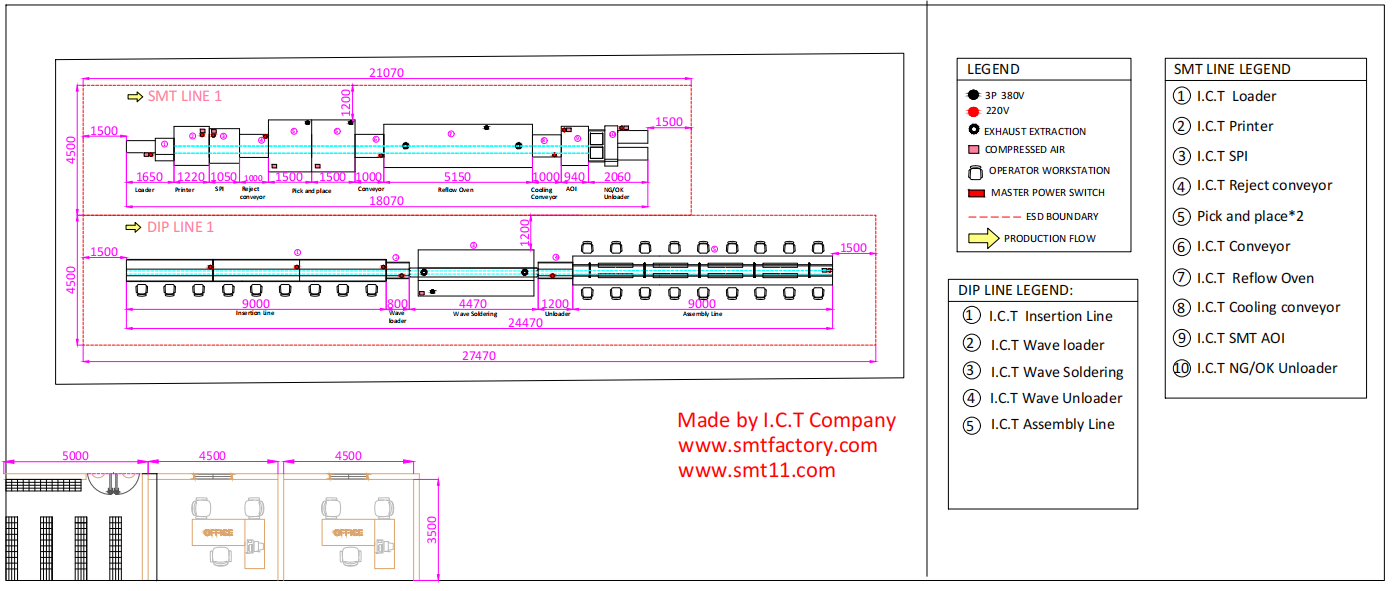

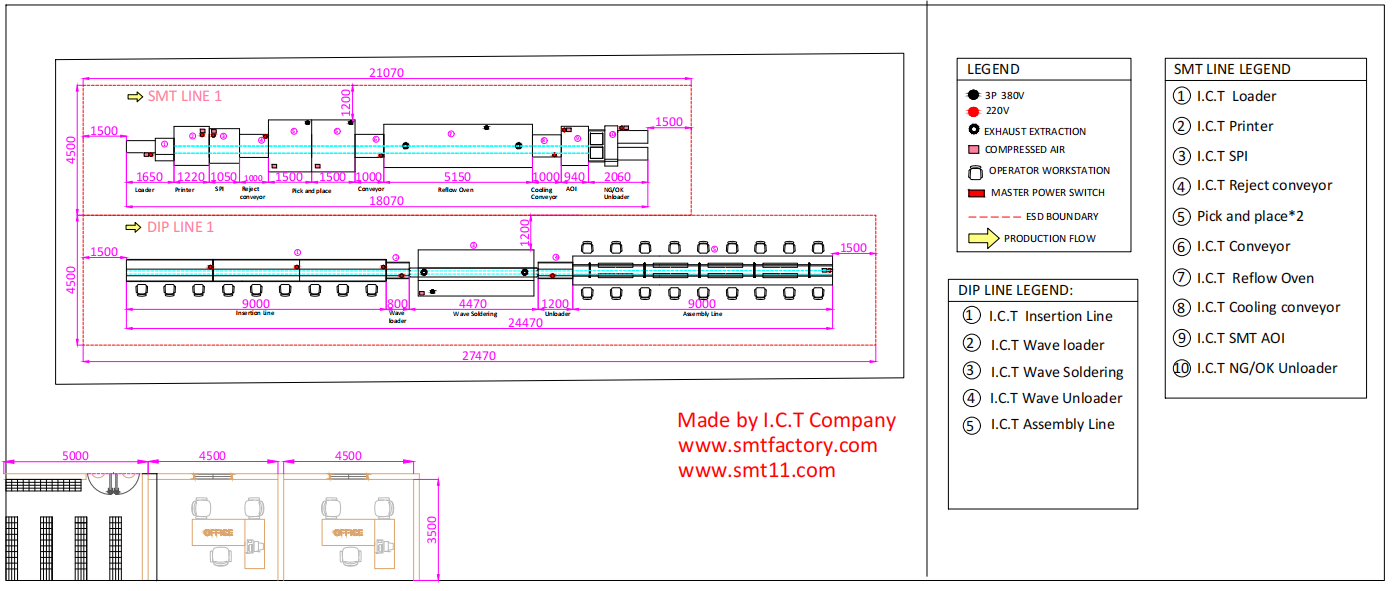

Dive into I.C.T's SMT Production Line Solutions for IFPD, powered by three fully-owned factories and a powerhouse of 22+ years in SMT/DIP innovation. We craft holistic factory blueprints, intricate layout diagrams, detailed manpower breakdowns, and crystal-clear ROI roadmaps tailored for interactive flat panel displays.

Choose from versatile semi-auto or powerhouse full-auto configurations, featuring smart auto loaders, state-of-the-art printers, lightning-fast placers, multi-zone reflow masters, cutting-edge AOI guardians, and intuitive unloaders. Just one sharp operator oversees the magic per shift. At a thrifty 18Kw/H, we champion green, wallet-friendly operations. Our global family spans education innovators, corporate collab hubs, digital signage pioneers, and beyond. Rollout wraps in 3 days flat, nailing air systems, power grids, exhaust flows, optimal lighting, and steady 23±1.5°C climates.

The 7-15 day bootcamp dives deep into intuitive software, hands-on upkeep, ironclad safety, and ninja-level fixes. Backed by 15+ years of worldwide wizardry, we crush downtime. End-to-End SMT Production Line Solutions for IFPD weave in big data insights, predictive smarts, and fluid links for a future-proof, glitch-free powerhouse. This plug-and-play ecosystem catapults newcomers and veterans alike into IFPD dominance with zero hassle and max velocity.

| Feature

Connected Factory Operations

SMT Production Line Solutions for IFPD orchestrate a symphony of machines via robust MES hubs, delivering live dashboards on yield, speed, and tweaks for peak performance. Loaders intuitively scale to mammoth 55-100+ inch boards, embracing every IFPD flavor from compact to colossal. Printers unleash 3D vision sorcery for flawless paste on dense LED webs and micro-pitches that demand perfection.

Placers blitz 01005 minis with unerring speed and grace. Reflow beasts lock temps at ±1.5°C across zones, forging bonds that laugh at stress. AOI wizards harness AI to snag tiniest gremlins on the fly. Unloaders whisk winners to glory or testing. This wizardry spikes yields 25%+ in End-to-End SMT Production Line Solutions for IFPD, scaling wildly for 4K dazzle, 8K brilliance, or tomorrow's wonders. Buffers juggle surges, remote portals empower global commanders, auto-swaps flip recipes in a blink, and traceability chains every atom for mix-it-up IFPD runs that slash swaps and supercharge audits.

Advanced Paste Application

Reflow titans pack 12+ zones with split convection reigns for pinpoint heat hugs. Nitrogen veils craft glossy, bubble-free miracles vital for screen stamina. Recipes morph on-the-fly by board bulk and crowd. Cool blasts shield giants from twists. Heat recyclers nail 18Kw/H thrift. Screens hoard endless profiles for grab-and-go. Backbone of End-to-End SMT Production Line Solutions for IFPD, promising endurance in brutal classroom or boardroom battles. Conveyors pulse in MES harmony.

Precise Thermal Management

AOI aces fire 8K ultra-scans at warp speed, hunting warps, LED drifts, solder slips, or intruders. AI evolves from battle data for sharper hunts. Feedback zaps placers for instant self-heals. Slashes runaways in SMT Production Line Solutions for IFPD. Rich analytics and visuals fuel quality quests. Rejects zip to fix bays sans line hiccups.

Intelligent Defect Detection

Kick off semi-auto, bolt on full-auto gems seamlessly. Blueprints stash spots for SPI extras, buffers, or IoT nodes. Crew math forecasts 70% leaner teams via auto-magic. Bespoke twists: cleanroom shields, static bans, ERP handshakes.

Expansion and Customization

Begin with a semi-automatic configuration and seamlessly upgrade to full automation by adding plug-in modules without major disruptions. Factory drawings incorporate reserved spaces for future additions like extra SPI units, buffers, or IoT hubs. We provide detailed labor models that predict up to 70% savings in manpower through automation. Customization options include cleanroom compatibility, ESD protection, and integration with existing ERP systems.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

An Algerian crew crafting functional phones jets in for a jaw-dropping acceptance spectacle. Armed with a dozen-plus PCBs and full component kits, they challenge us to prove the magic live. We fire up the beast: Full-auto printer lays paste like a pro artist. SPI sniffs every deposit for gold-standard volume and lock-on precision.

RX-8 zips through tiny bits—resistors, caps—with blistering agility. RS-1R muscles the big guns—ICs, connectors—flawlessly. Tray feeder drops shield covers sans a pause. Reflow welds it all in perfect harmony. AOI hunts heroes and villains post-bake. The 5700 separator slices multi-panels clean as a whistle. Zero drama, pure triumph—boards emerge flawless, speeds dazzle, integration shines.

This demo mirrors SMT Production Line Solutions for IFPD adaptability to mobile realms, showcasing universal prowess. Clients geek out on velocity, accuracy, and scalability. They sign off thrilled, envisioning their lines humming identical symphonies back home with End-to-End SMT Production Line Solutions for IFPD vibes.

| Service and Training Support

I.C.T crowns every SMT Production Line Solutions for IFPD quest with a dedicated captain, steering from spark to eternal shine. 3-day blitz: Gear syncs, trial blasts, fine-tune wizardry. 7-15 day immersion: MES conquests, giant-panel gymnastics, flaw forensics, upkeep rituals, safety shields. IoT sentinels forecast storms, enable wizard fixes afar. Parts rocket from 8 planet-spanning vaults. 15-year globe-trotting legacy, polyglot pros bridge worlds. Yearly tune-ups: Code evolutions, pulse checks, upgrade infusions for everlasting peak.

| Client Testimonials

Fans scream about sub-2-hour remote rescues keeping SMT Production Line Solutions for IFPD unstoppable. Mega-ovens defy gravity 24/7, temps rock-steady. Fort-knox crates conquer voyages. SLAs? Smashed with flair. End-to-End SMT Production Line Solutions for IFPD churn millions of panels, quality untouchable. Interfaces turn rookies to pros overnight.

| Certifications and Standards

CE stamps universal electric sanctity. RoHS bans toxins chain-wide. ISO9001 forges unbreakable quality loops and evolutions. Patents lock down conveyor geniuses and AI sleuths. Ironclad proof of SMT Production Line Solutions for IFPD global swagger. Pre-fly rigor in our labs seals the deal.

| About I.C.T Company and Factory

Three mega-factories blaze across 12000m², self-forged for total control. 89 warriors, 20 engineer alchemists fuel R&D fires. 25-year saga: 1600 loyalists in 72 lands. Bespoke End-to-End SMT Production Line Solutions for IFPD born in innovation crucibles. QC marathon: Intake scans, mid-flight probes, finale fireworks pre-exit. Web of hubs, depots, outposts for lightning strikes anywhere. Quest: Supreme cross-value electronics nexus, fusing brains and brawn.

| SMT Line Solutions for IFPD Details

Dive into I.C.T's SMT Production Line Solutions for IFPD, powered by three fully-owned factories and a powerhouse of 22+ years in SMT/DIP innovation. We craft holistic factory blueprints, intricate layout diagrams, detailed manpower breakdowns, and crystal-clear ROI roadmaps tailored for interactive flat panel displays.

Choose from versatile semi-auto or powerhouse full-auto configurations, featuring smart auto loaders, state-of-the-art printers, lightning-fast placers, multi-zone reflow masters, cutting-edge AOI guardians, and intuitive unloaders. Just one sharp operator oversees the magic per shift. At a thrifty 18Kw/H, we champion green, wallet-friendly operations. Our global family spans education innovators, corporate collab hubs, digital signage pioneers, and beyond. Rollout wraps in 3 days flat, nailing air systems, power grids, exhaust flows, optimal lighting, and steady 23±1.5°C climates.

The 7-15 day bootcamp dives deep into intuitive software, hands-on upkeep, ironclad safety, and ninja-level fixes. Backed by 15+ years of worldwide wizardry, we crush downtime. End-to-End SMT Production Line Solutions for IFPD weave in big data insights, predictive smarts, and fluid links for a future-proof, glitch-free powerhouse. This plug-and-play ecosystem catapults newcomers and veterans alike into IFPD dominance with zero hassle and max velocity.

| Feature

Connected Factory Operations

SMT Production Line Solutions for IFPD orchestrate a symphony of machines via robust MES hubs, delivering live dashboards on yield, speed, and tweaks for peak performance. Loaders intuitively scale to mammoth 55-100+ inch boards, embracing every IFPD flavor from compact to colossal. Printers unleash 3D vision sorcery for flawless paste on dense LED webs and micro-pitches that demand perfection.

Placers blitz 01005 minis with unerring speed and grace. Reflow beasts lock temps at ±1.5°C across zones, forging bonds that laugh at stress. AOI wizards harness AI to snag tiniest gremlins on the fly. Unloaders whisk winners to glory or testing. This wizardry spikes yields 25%+ in End-to-End SMT Production Line Solutions for IFPD, scaling wildly for 4K dazzle, 8K brilliance, or tomorrow's wonders. Buffers juggle surges, remote portals empower global commanders, auto-swaps flip recipes in a blink, and traceability chains every atom for mix-it-up IFPD runs that slash swaps and supercharge audits.

Advanced Paste Application

Reflow titans pack 12+ zones with split convection reigns for pinpoint heat hugs. Nitrogen veils craft glossy, bubble-free miracles vital for screen stamina. Recipes morph on-the-fly by board bulk and crowd. Cool blasts shield giants from twists. Heat recyclers nail 18Kw/H thrift. Screens hoard endless profiles for grab-and-go. Backbone of End-to-End SMT Production Line Solutions for IFPD, promising endurance in brutal classroom or boardroom battles. Conveyors pulse in MES harmony.

Precise Thermal Management

AOI aces fire 8K ultra-scans at warp speed, hunting warps, LED drifts, solder slips, or intruders. AI evolves from battle data for sharper hunts. Feedback zaps placers for instant self-heals. Slashes runaways in SMT Production Line Solutions for IFPD. Rich analytics and visuals fuel quality quests. Rejects zip to fix bays sans line hiccups.

Intelligent Defect Detection

Kick off semi-auto, bolt on full-auto gems seamlessly. Blueprints stash spots for SPI extras, buffers, or IoT nodes. Crew math forecasts 70% leaner teams via auto-magic. Bespoke twists: cleanroom shields, static bans, ERP handshakes.

Expansion and Customization

Begin with a semi-automatic configuration and seamlessly upgrade to full automation by adding plug-in modules without major disruptions. Factory drawings incorporate reserved spaces for future additions like extra SPI units, buffers, or IoT hubs. We provide detailed labor models that predict up to 70% savings in manpower through automation. Customization options include cleanroom compatibility, ESD protection, and integration with existing ERP systems.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

An Algerian crew crafting functional phones jets in for a jaw-dropping acceptance spectacle. Armed with a dozen-plus PCBs and full component kits, they challenge us to prove the magic live. We fire up the beast: Full-auto printer lays paste like a pro artist. SPI sniffs every deposit for gold-standard volume and lock-on precision.

RX-8 zips through tiny bits—resistors, caps—with blistering agility. RS-1R muscles the big guns—ICs, connectors—flawlessly. Tray feeder drops shield covers sans a pause. Reflow welds it all in perfect harmony. AOI hunts heroes and villains post-bake. The 5700 separator slices multi-panels clean as a whistle. Zero drama, pure triumph—boards emerge flawless, speeds dazzle, integration shines.

This demo mirrors SMT Production Line Solutions for IFPD adaptability to mobile realms, showcasing universal prowess. Clients geek out on velocity, accuracy, and scalability. They sign off thrilled, envisioning their lines humming identical symphonies back home with End-to-End SMT Production Line Solutions for IFPD vibes.

| Service and Training Support

I.C.T crowns every SMT Production Line Solutions for IFPD quest with a dedicated captain, steering from spark to eternal shine. 3-day blitz: Gear syncs, trial blasts, fine-tune wizardry. 7-15 day immersion: MES conquests, giant-panel gymnastics, flaw forensics, upkeep rituals, safety shields. IoT sentinels forecast storms, enable wizard fixes afar. Parts rocket from 8 planet-spanning vaults. 15-year globe-trotting legacy, polyglot pros bridge worlds. Yearly tune-ups: Code evolutions, pulse checks, upgrade infusions for everlasting peak.

| Client Testimonials

Fans scream about sub-2-hour remote rescues keeping SMT Production Line Solutions for IFPD unstoppable. Mega-ovens defy gravity 24/7, temps rock-steady. Fort-knox crates conquer voyages. SLAs? Smashed with flair. End-to-End SMT Production Line Solutions for IFPD churn millions of panels, quality untouchable. Interfaces turn rookies to pros overnight.

| Certifications and Standards

CE stamps universal electric sanctity. RoHS bans toxins chain-wide. ISO9001 forges unbreakable quality loops and evolutions. Patents lock down conveyor geniuses and AI sleuths. Ironclad proof of SMT Production Line Solutions for IFPD global swagger. Pre-fly rigor in our labs seals the deal.

| About I.C.T Company and Factory

Three mega-factories blaze across 12000m², self-forged for total control. 89 warriors, 20 engineer alchemists fuel R&D fires. 25-year saga: 1600 loyalists in 72 lands. Bespoke End-to-End SMT Production Line Solutions for IFPD born in innovation crucibles. QC marathon: Intake scans, mid-flight probes, finale fireworks pre-exit. Web of hubs, depots, outposts for lightning strikes anywhere. Quest: Supreme cross-value electronics nexus, fusing brains and brawn.