I.C.T-5600

I.C.T

PCB Cleaning Machine

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T-5600 Offline PCBA Cleaning Machine

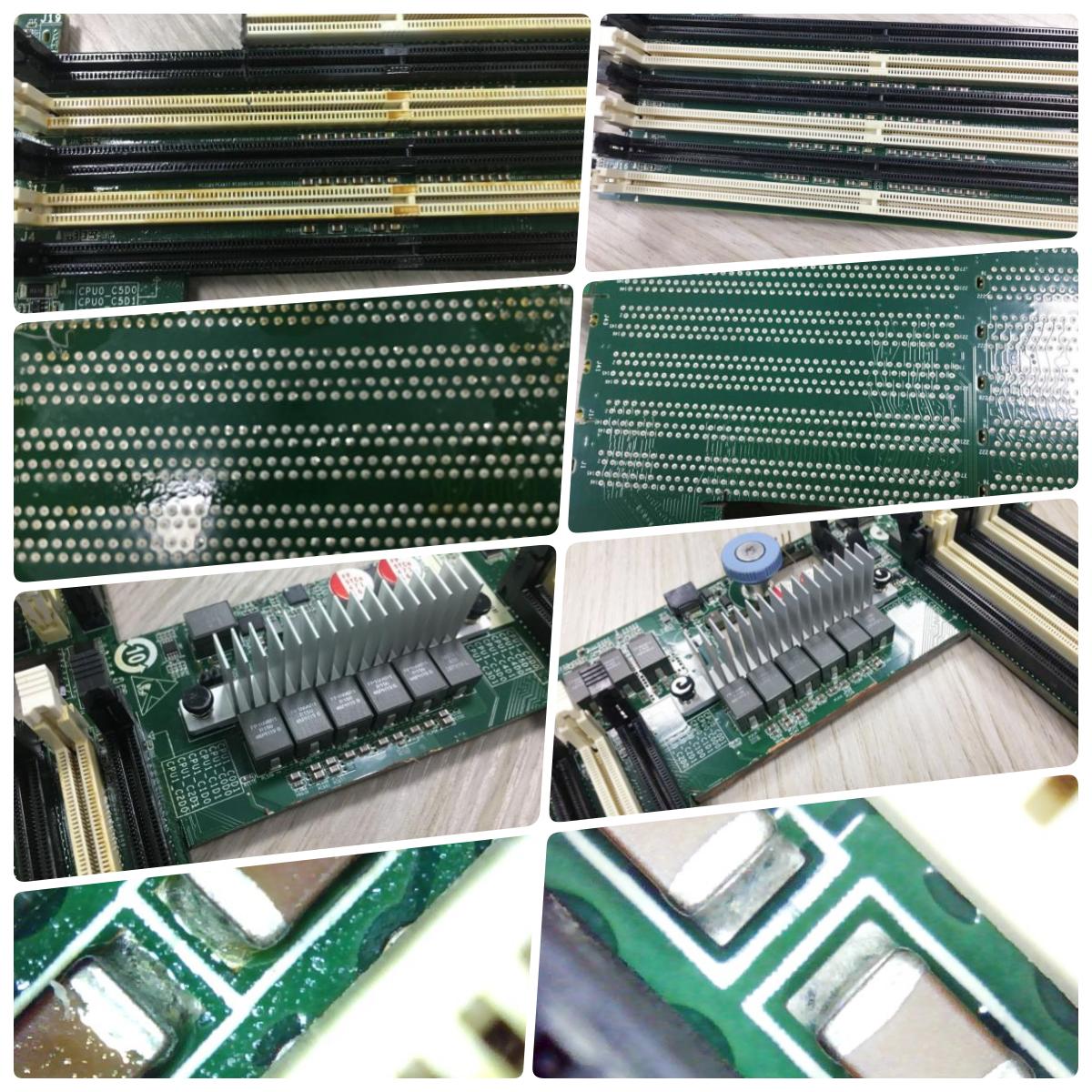

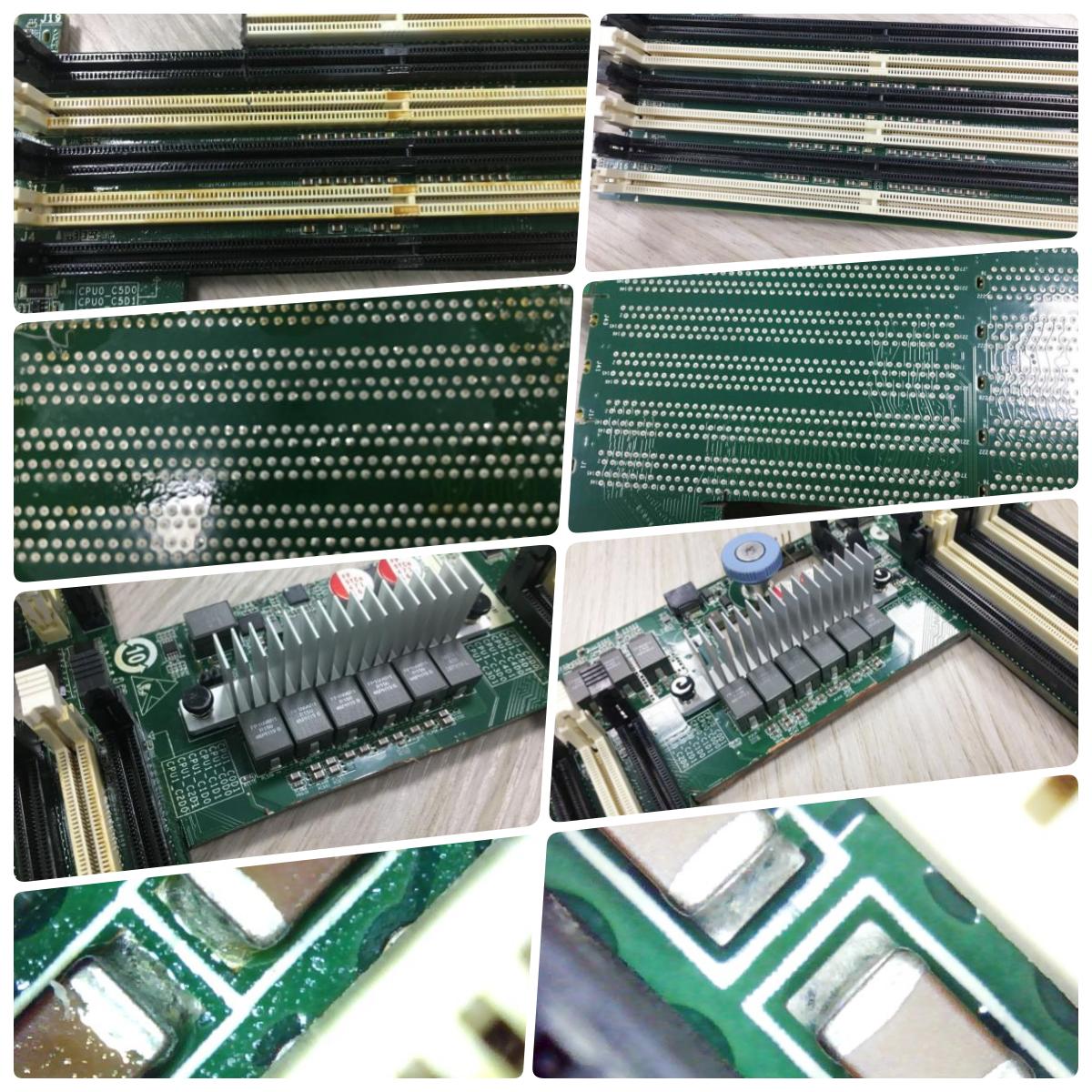

The I.C.T-5600 Offline PCBA Cleaning Machine delivers reliable batch cleaning for PCBA boards in a compact design. It handles various contaminants such as rosin flux, water-soluble flux, no-clean flux, and solder paste residues on SMT and THT assemblies. This machine suits industries like aviation, aerospace, medical devices, new energy, automotive electronics, and instrumentation. Its offline setup works well for small-scale or multi-variety production where flexibility matters. With a large observation window, operators see the full cleaning process clearly. The system uses heated detergent, multi-angle sprays, and efficient circulation to achieve excellent results. Easy controls and password protection make daily operation simple and secure. The I.C.T-5600 also saves resources through smart detergent recycling and air blow-off features. Overall, it provides high cleanliness while keeping operation cost-effective and environmentally friendly.

| Feature

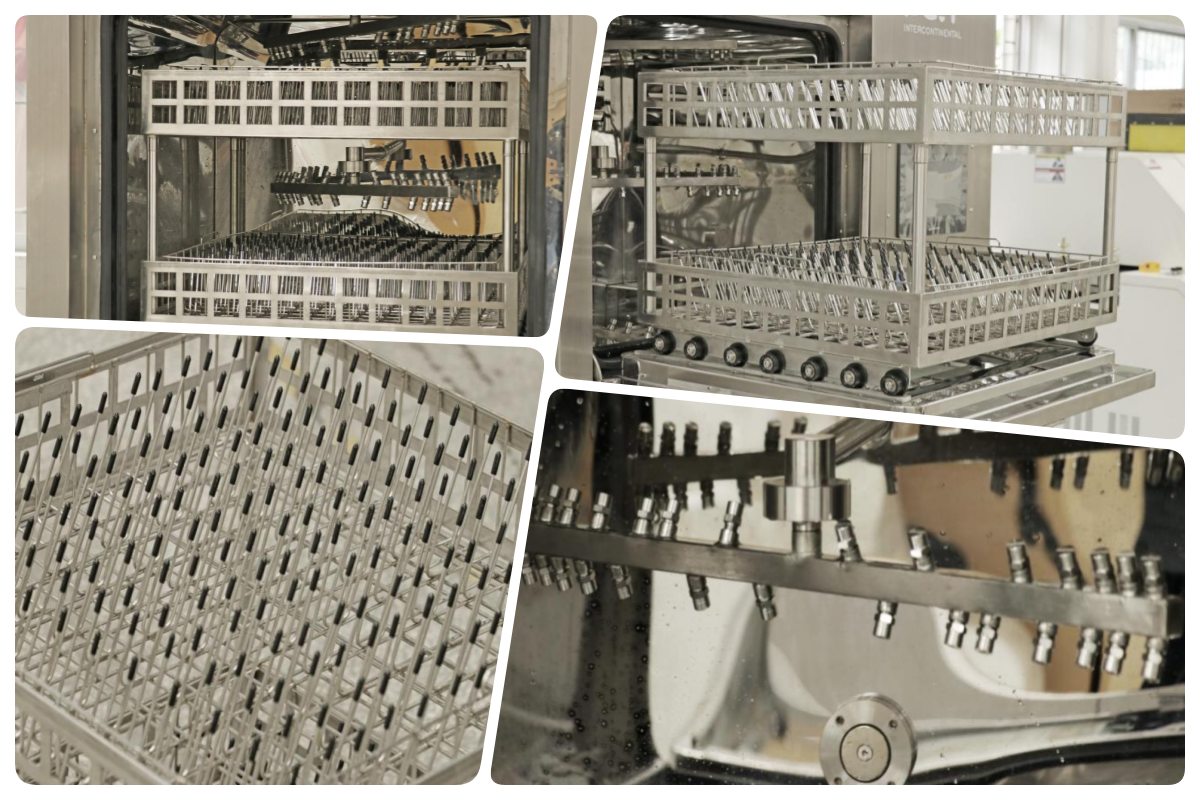

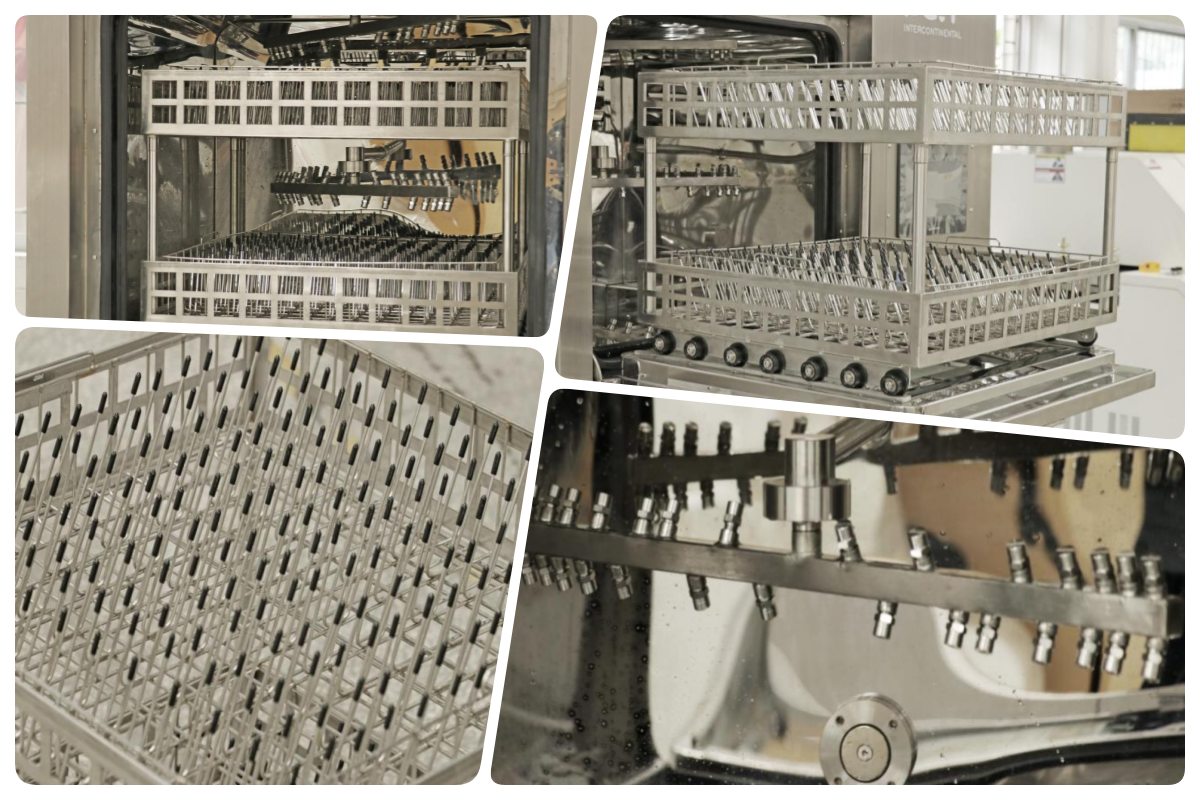

The cleaning room uses full SUS304 stainless steel for long life and strong sealing. Multiple spray channels deliver uniform cleaning liquid coverage. The standard double-layer basket holds more boards, and universal fixtures come with flexible plastic sleeves to prevent scratching PCBA surfaces. When the door opens, it forms a handy temporary platform with slides and small wheels for easy loading. The tilted bottom with dense filter nets prevents water buildup and keeps the tank clean. A retractable magnetic push rod moves the basket back and forth, ensuring thorough spray coverage. Unique nozzle spacing reaches every corner, leaving no dead zones. This design makes cleaning more complete and protects boards during the process.

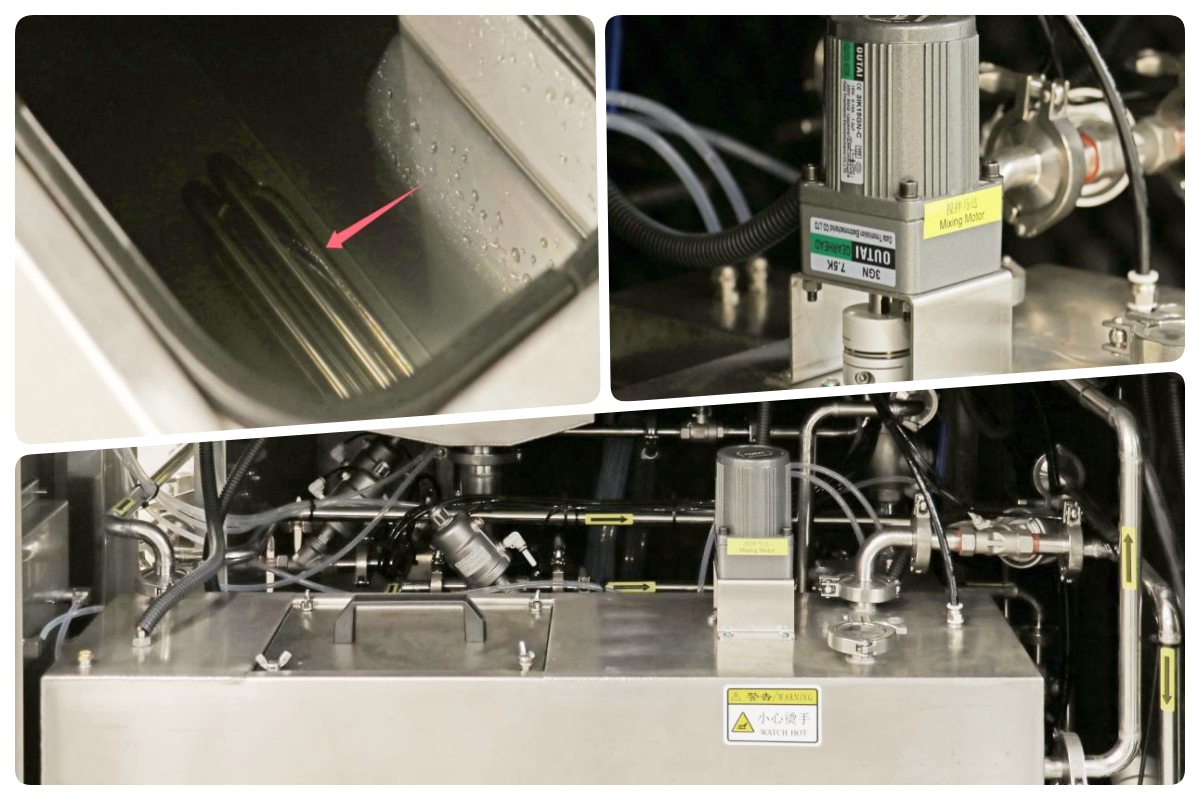

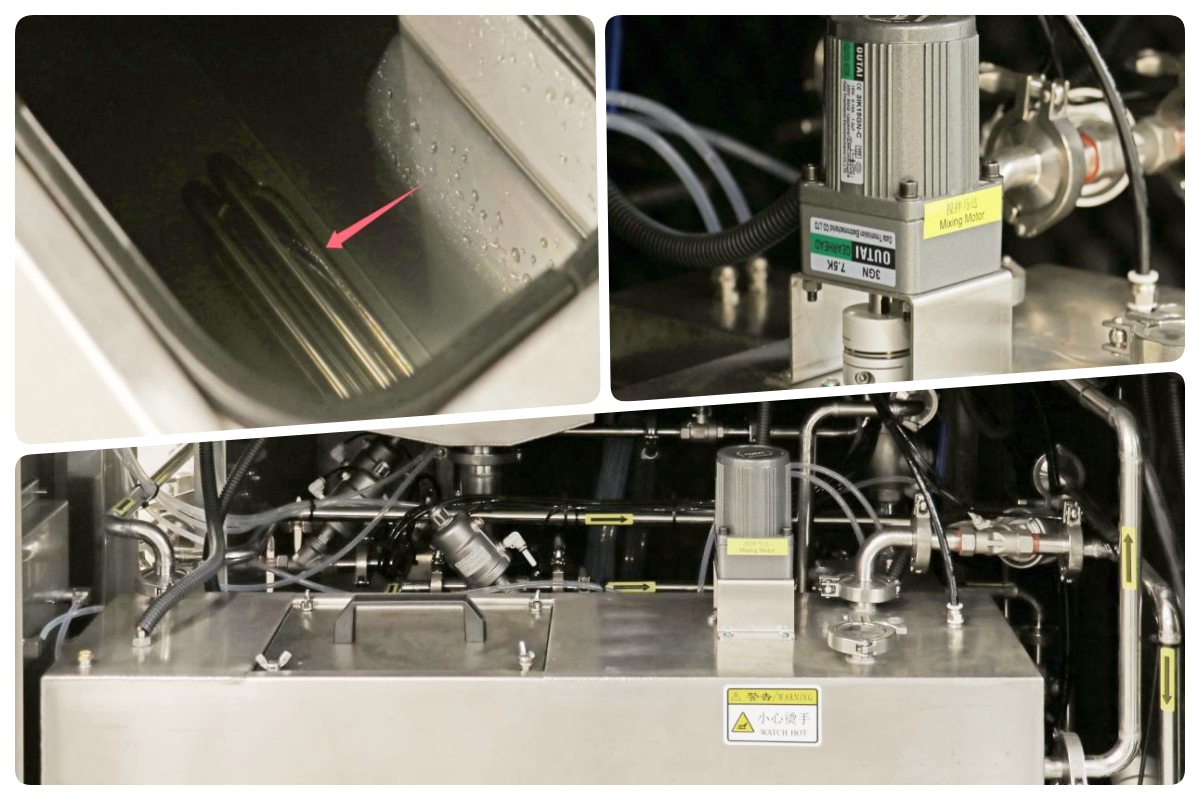

The circulation pipe system is independently developed for efficiency and space saving. A high-power diaphragm pump delivers strong flow and reliable performance. The smart pipeline route recycles cleaning liquid effectively while taking up minimal space inside the machine. This setup supports repeated use of detergent without quality loss. Filters inside keep the liquid clean during cycles. The design reduces waste and maintains consistent cleaning power throughout the batch. Operators benefit from lower running costs and less frequent fluid changes. The robust structure resists corrosion and ensures stable operation over time.

Washer fluid tanks include a 60L diluent tank and 30L concentrate tank for stable supply. The system heats detergent to the right temperature quickly, improving cleaning speed. An inner filter allows repeated use of liquid. Real-time DI water resistivity measurement tracks cleaning quality. After cleaning, compressed air blows remaining detergent from pipes and pumps back to the tank, saving up to 50% fluid. This feature lowers costs and reduces waste. Tanks use SUS304 material for durability and easy maintenance. The setup supports consistent results even in long production runs.

Although primary focus is on spray cleaning, the I.C.T-5600 ensures boards exit clean and ready for next steps. Residual moisture is minimized through efficient process design and air blow features. The system avoids water spots or leftover contaminants that could affect quality. In batch mode, boards dry naturally after thorough rinsing and air purge. This keeps ionic contamination low and meets strict IPC standards. The overall process prepares PCBA for conformal coating, testing, or assembly without extra drying time.

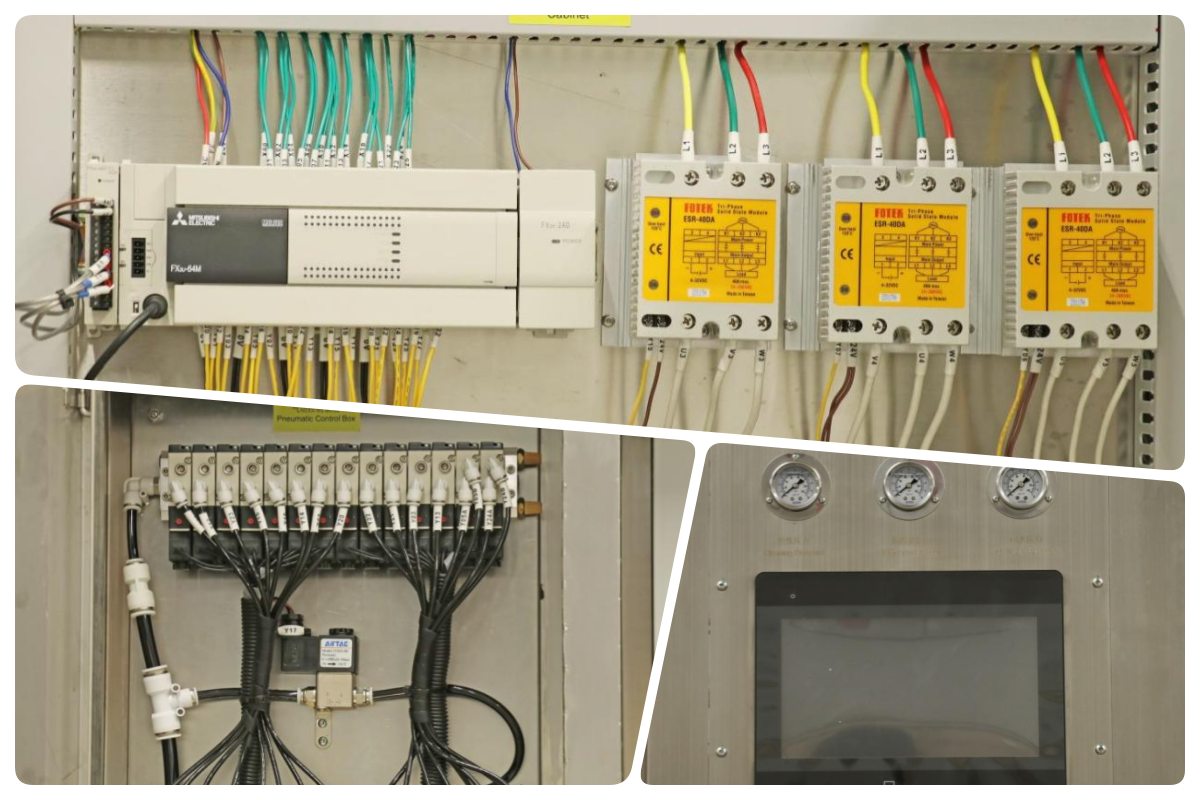

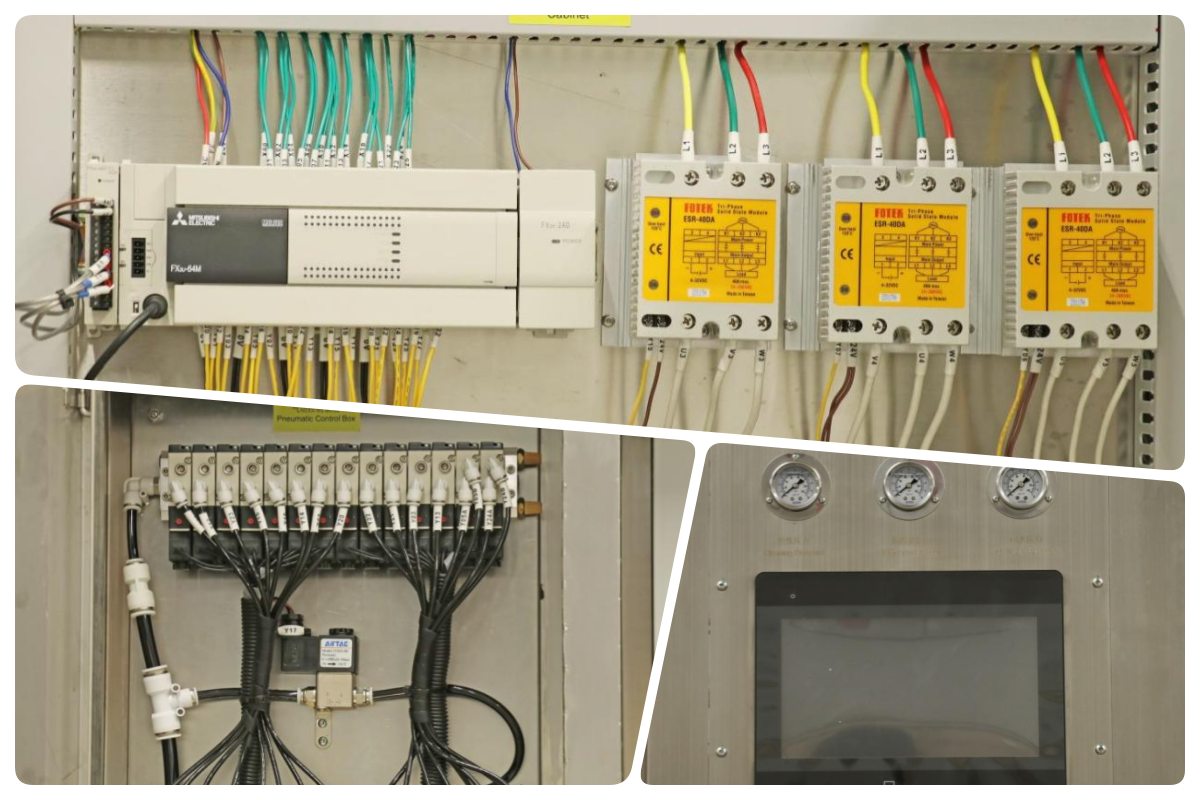

The control system offers an easy interface for quick parameter setup. Operators set cleaning time, temperature, and cycles simply. Different passwords protect settings for safety and traceability. The panel shows process status clearly, including real-time resistivity data. Alarms notify users of issues like low liquid levels. This user-friendly design reduces training time and mistakes. Reliable controls ensure consistent cleaning results batch after batch. The system supports high standards in demanding industries.

| Comparison Before and After

| Specification

| Parameter | I.C.T-5600 (Offline) | I.C.T-6300 (Online) |

|---|---|---|

| Cleaning Type | Offline batch, basket loading | Online continuous, belt conveyor |

| PCBA/Basket Size | 610 × 560 × 100 mm × 2 layers | Up to 600 × 400 × 100 mm (max conveyor width) |

| Cleaning Method | Multi-spray with heating, rinse, hot air dry | High-pressure spray, chemical + DI rinse + hot air dry |

| Tank Capacity (Diluent/Clean) | 60L (dilution) / 17L (spray tank) | 240L (clean liquid tank) |

| Concentrate Tank | 30-32L | Equipped with concentrated tank + auto add/discharge |

| Power Supply | Not specified (typically lower, ~30-50 kW est.) | 380V 3P 50/60Hz, 110-122 kW |

| Machine Dimensions | Compact (exact not listed, smaller footprint) | 5200 × 1750 × 1650-1700 mm |

| Drying | Hot air dry 10-30 min | Multi-stage hot air dry (dry 1 & dry 2) |

| Control System | Touch screen, easy parameters, password | PC + PLC, English software, adjustable pressures |

| DI Water Resistivity Monitoring | Yes, real-time | Yes, monitoring system |

| Typical Use | Small-multi variety, high-mix batches | High-volume batch, inline SMT lines |

| SMT Line Equipment List

I.C.T provides full SMT production line solutions to pair with the PCBA Cleaning Machine. Typical lines include laser marking machines for traceability, Solder paste printers with SPI for accurate solder paste deposition, high-speed chip mounters like JUKI models for component placement, reflow ovens such as I.C.T for solid soldering, AOI equipment for quality inspection, PCB conveyors for smooth transfer, and automatic solder paste storage thaw boxes for consistent paste quality. Optional additions like selective soldering and wave soldering support mixed technology boards. These machines work together to build efficient, reliable SMT lines from start to finish. I.C.T helps customers choose and integrate the right setup for their needs.

| Customer Success Video

I.C.T successfully installed and supported Factory Acceptance Testing (FAT) for two complete SMT production lines at a North American beauty instrument manufacturer. The project included laser marking machines, SMT printers with SPI, Panasonic mounters, Heller reflow ovens, AOI inspection systems, PCB conveyors, PCBA cleaning machines, and full-automatic solder paste storage thaw boxes. Our engineers traveled overseas to handle installation, debugging, and training on site. The customer passed production acceptance smoothly and started full operation without delays. This case shows I.C.T's strong ability to deliver turnkey solutions and reliable support for international clients in high-demand industries.

| Service and Training

I.C.T offers complete service and training to ensure smooth machine use. Our experienced engineers provide on-site installation, commissioning, and operation training. We teach cleaning parameter setup, daily maintenance, and troubleshooting steps. Remote support is available for quick problem solving. Training covers safety, fluid management, and quality checks. Customers receive clear manuals and videos for reference. Our team responds fast to questions and offers process optimization advice. This helps users achieve best performance and long equipment life. We stand by our machines with ongoing technical support worldwide.

| Customer Reviews

Customers praise our engineers for their professional skills, patience, and quick response to issues during installation and training. Many highlight the PCBA Cleaning Machine's excellent cleaning results and stable performance in daily use. They appreciate the solid SUS304 build quality and smart detergent-saving features. Packaging and transportation receive compliments for secure, damage-free delivery even over long distances. Fast email and remote support wins trust, as problems get solved promptly. Overall, clients value I.C.T as a reliable partner for high-quality equipment and service.

| Our Certification

I.C.T machines meet international standards with CE certification for safety, RoHS compliance for environmental protection, and ISO9001 for quality management systems. We also hold multiple patents on cleaning technology and design. These certificates confirm our commitment to high quality, safety, and eco-friendly production. Customers trust our PCBA Cleaning Machine because it passes strict tests and regulations. Our certifications support reliable use in medical, automotive, and aerospace fields where standards are critical.

| About Us and Factory

I.C.T owns its own R&D and production facilities in Dongguan, China. With 89 staff members, including 20 experienced engineers, we have grown quickly since 2012. We serve over 1600 customers across 72 countries with full SMT, DIP, and coating solutions. Our 12,000 m² factory follows strict testing processes at every step, from parts to final assembly. A strong quality management system ensures consistent product reliability. We focus on innovation, customer needs, and global support to help manufacturers build and optimize their lines effectively.

| I.C.T-5600 Offline PCBA Cleaning Machine

The I.C.T-5600 Offline PCBA Cleaning Machine delivers reliable batch cleaning for PCBA boards in a compact design. It handles various contaminants such as rosin flux, water-soluble flux, no-clean flux, and solder paste residues on SMT and THT assemblies. This machine suits industries like aviation, aerospace, medical devices, new energy, automotive electronics, and instrumentation. Its offline setup works well for small-scale or multi-variety production where flexibility matters. With a large observation window, operators see the full cleaning process clearly. The system uses heated detergent, multi-angle sprays, and efficient circulation to achieve excellent results. Easy controls and password protection make daily operation simple and secure. The I.C.T-5600 also saves resources through smart detergent recycling and air blow-off features. Overall, it provides high cleanliness while keeping operation cost-effective and environmentally friendly.

| Feature

The cleaning room uses full SUS304 stainless steel for long life and strong sealing. Multiple spray channels deliver uniform cleaning liquid coverage. The standard double-layer basket holds more boards, and universal fixtures come with flexible plastic sleeves to prevent scratching PCBA surfaces. When the door opens, it forms a handy temporary platform with slides and small wheels for easy loading. The tilted bottom with dense filter nets prevents water buildup and keeps the tank clean. A retractable magnetic push rod moves the basket back and forth, ensuring thorough spray coverage. Unique nozzle spacing reaches every corner, leaving no dead zones. This design makes cleaning more complete and protects boards during the process.

The circulation pipe system is independently developed for efficiency and space saving. A high-power diaphragm pump delivers strong flow and reliable performance. The smart pipeline route recycles cleaning liquid effectively while taking up minimal space inside the machine. This setup supports repeated use of detergent without quality loss. Filters inside keep the liquid clean during cycles. The design reduces waste and maintains consistent cleaning power throughout the batch. Operators benefit from lower running costs and less frequent fluid changes. The robust structure resists corrosion and ensures stable operation over time.

Washer fluid tanks include a 60L diluent tank and 30L concentrate tank for stable supply. The system heats detergent to the right temperature quickly, improving cleaning speed. An inner filter allows repeated use of liquid. Real-time DI water resistivity measurement tracks cleaning quality. After cleaning, compressed air blows remaining detergent from pipes and pumps back to the tank, saving up to 50% fluid. This feature lowers costs and reduces waste. Tanks use SUS304 material for durability and easy maintenance. The setup supports consistent results even in long production runs.

Although primary focus is on spray cleaning, the I.C.T-5600 ensures boards exit clean and ready for next steps. Residual moisture is minimized through efficient process design and air blow features. The system avoids water spots or leftover contaminants that could affect quality. In batch mode, boards dry naturally after thorough rinsing and air purge. This keeps ionic contamination low and meets strict IPC standards. The overall process prepares PCBA for conformal coating, testing, or assembly without extra drying time.

The control system offers an easy interface for quick parameter setup. Operators set cleaning time, temperature, and cycles simply. Different passwords protect settings for safety and traceability. The panel shows process status clearly, including real-time resistivity data. Alarms notify users of issues like low liquid levels. This user-friendly design reduces training time and mistakes. Reliable controls ensure consistent cleaning results batch after batch. The system supports high standards in demanding industries.

| Comparison Before and After

| Specification

| Parameter | I.C.T-5600 (Offline) | I.C.T-6300 (Online) |

|---|---|---|

| Cleaning Type | Offline batch, basket loading | Online continuous, belt conveyor |

| PCBA/Basket Size | 610 × 560 × 100 mm × 2 layers | Up to 600 × 400 × 100 mm (max conveyor width) |

| Cleaning Method | Multi-spray with heating, rinse, hot air dry | High-pressure spray, chemical + DI rinse + hot air dry |

| Tank Capacity (Diluent/Clean) | 60L (dilution) / 17L (spray tank) | 240L (clean liquid tank) |

| Concentrate Tank | 30-32L | Equipped with concentrated tank + auto add/discharge |

| Power Supply | Not specified (typically lower, ~30-50 kW est.) | 380V 3P 50/60Hz, 110-122 kW |

| Machine Dimensions | Compact (exact not listed, smaller footprint) | 5200 × 1750 × 1650-1700 mm |

| Drying | Hot air dry 10-30 min | Multi-stage hot air dry (dry 1 & dry 2) |

| Control System | Touch screen, easy parameters, password | PC + PLC, English software, adjustable pressures |

| DI Water Resistivity Monitoring | Yes, real-time | Yes, monitoring system |

| Typical Use | Small-multi variety, high-mix batches | High-volume batch, inline SMT lines |

| SMT Line Equipment List

I.C.T provides full SMT production line solutions to pair with the PCBA Cleaning Machine. Typical lines include laser marking machines for traceability, Solder paste printers with SPI for accurate solder paste deposition, high-speed chip mounters like JUKI models for component placement, reflow ovens such as I.C.T for solid soldering, AOI equipment for quality inspection, PCB conveyors for smooth transfer, and automatic solder paste storage thaw boxes for consistent paste quality. Optional additions like selective soldering and wave soldering support mixed technology boards. These machines work together to build efficient, reliable SMT lines from start to finish. I.C.T helps customers choose and integrate the right setup for their needs.

| Customer Success Video

I.C.T successfully installed and supported Factory Acceptance Testing (FAT) for two complete SMT production lines at a North American beauty instrument manufacturer. The project included laser marking machines, SMT printers with SPI, Panasonic mounters, Heller reflow ovens, AOI inspection systems, PCB conveyors, PCBA cleaning machines, and full-automatic solder paste storage thaw boxes. Our engineers traveled overseas to handle installation, debugging, and training on site. The customer passed production acceptance smoothly and started full operation without delays. This case shows I.C.T's strong ability to deliver turnkey solutions and reliable support for international clients in high-demand industries.

| Service and Training

I.C.T offers complete service and training to ensure smooth machine use. Our experienced engineers provide on-site installation, commissioning, and operation training. We teach cleaning parameter setup, daily maintenance, and troubleshooting steps. Remote support is available for quick problem solving. Training covers safety, fluid management, and quality checks. Customers receive clear manuals and videos for reference. Our team responds fast to questions and offers process optimization advice. This helps users achieve best performance and long equipment life. We stand by our machines with ongoing technical support worldwide.

| Customer Reviews

Customers praise our engineers for their professional skills, patience, and quick response to issues during installation and training. Many highlight the PCBA Cleaning Machine's excellent cleaning results and stable performance in daily use. They appreciate the solid SUS304 build quality and smart detergent-saving features. Packaging and transportation receive compliments for secure, damage-free delivery even over long distances. Fast email and remote support wins trust, as problems get solved promptly. Overall, clients value I.C.T as a reliable partner for high-quality equipment and service.

| Our Certification

I.C.T machines meet international standards with CE certification for safety, RoHS compliance for environmental protection, and ISO9001 for quality management systems. We also hold multiple patents on cleaning technology and design. These certificates confirm our commitment to high quality, safety, and eco-friendly production. Customers trust our PCBA Cleaning Machine because it passes strict tests and regulations. Our certifications support reliable use in medical, automotive, and aerospace fields where standards are critical.

| About Us and Factory

I.C.T owns its own R&D and production facilities in Dongguan, China. With 89 staff members, including 20 experienced engineers, we have grown quickly since 2012. We serve over 1600 customers across 72 countries with full SMT, DIP, and coating solutions. Our 12,000 m² factory follows strict testing processes at every step, from parts to final assembly. A strong quality management system ensures consistent product reliability. We focus on innovation, customer needs, and global support to help manufacturers build and optimize their lines effectively.