I.C.T

PCB Laser Marking

| Availability: | |

|---|---|

| Quantity: | |

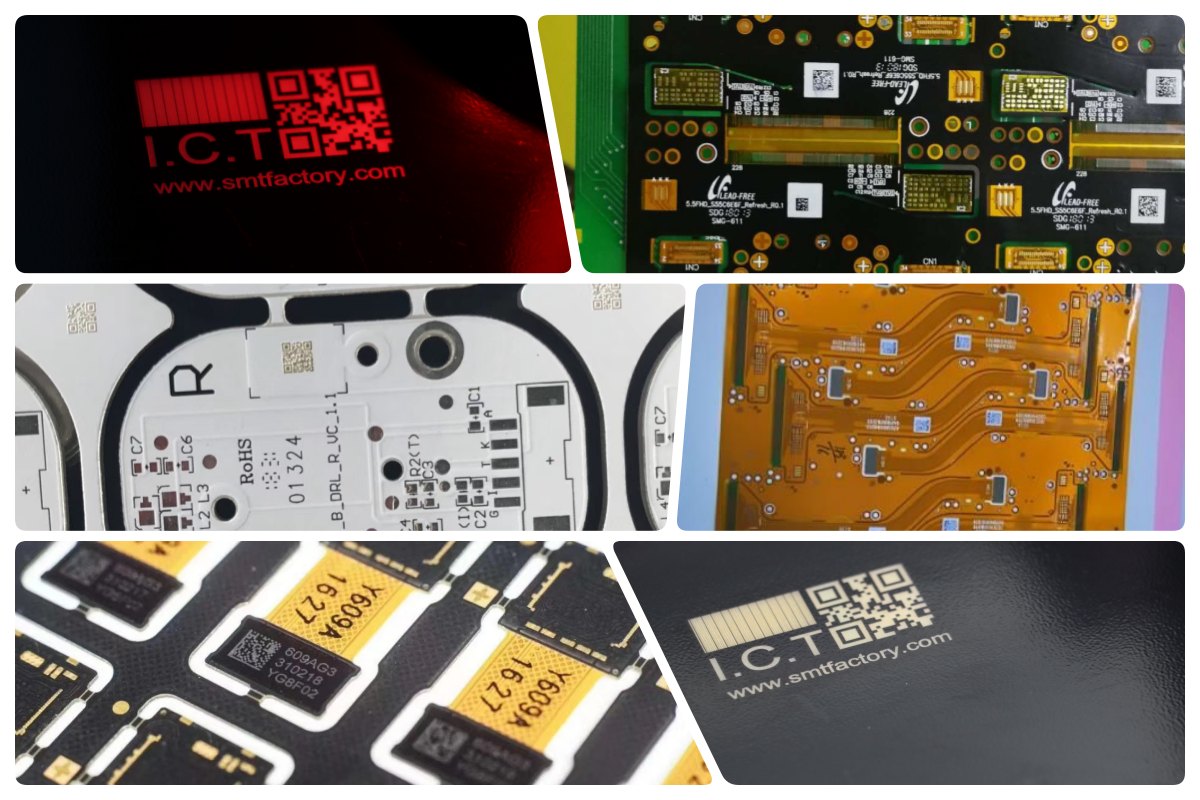

| Solid PCB Marking with Laser Technology

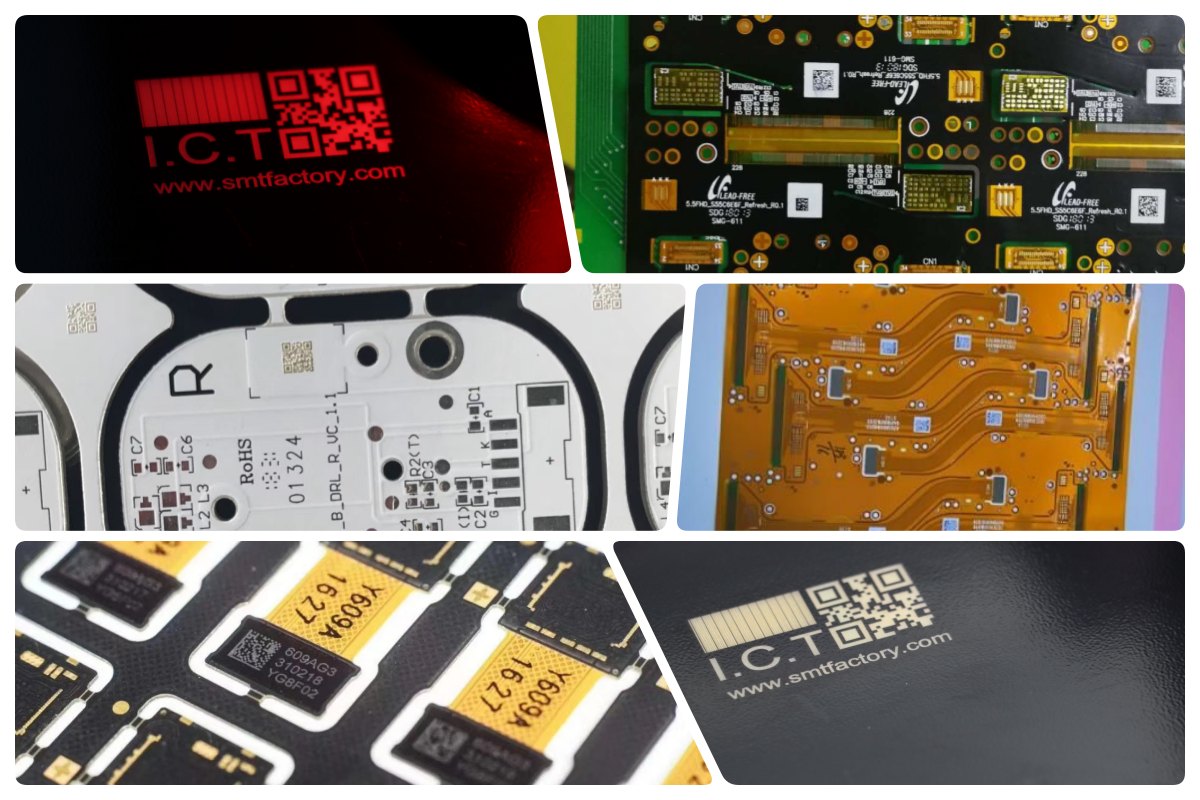

This laser mug printing machine marks PCBs permanently with barcodes, QR codes, text, or patterns in the electronics world. Built for SMT lines, it links up easily and sends data to MES systems in real time. Four models cover board sizes up to 510 by 460 mm, holding tight precision at ±0.05 mm. Pick UV, green, fiber, or CO₂ lasers depending on what material you run—FR4, metals, plastics, or sensitive coatings. The 30 watt fiber laser marking machine option gives strong, lasting results on metals and traces. No ink, no labels, no reprints by mistake. It cuts costs, keeps the shop cleaner, and meets tough rules for product tracking in busy manufacturing.

| Feature

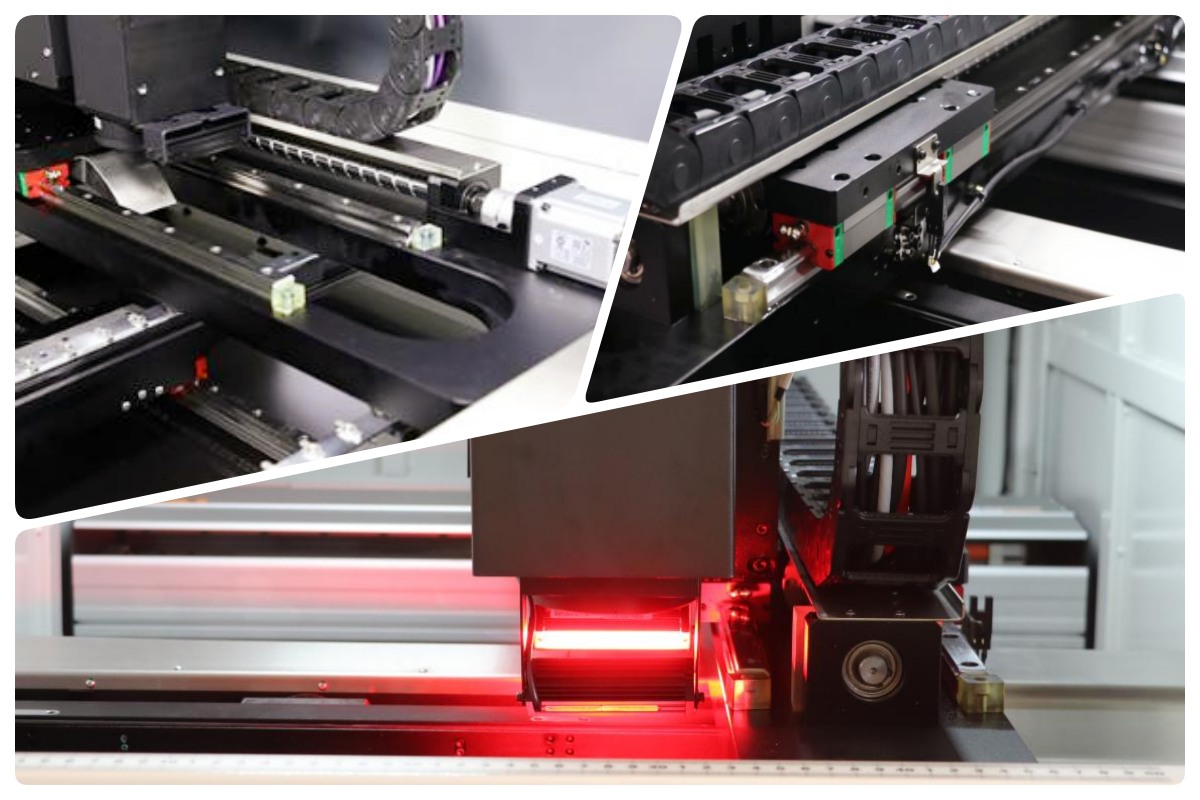

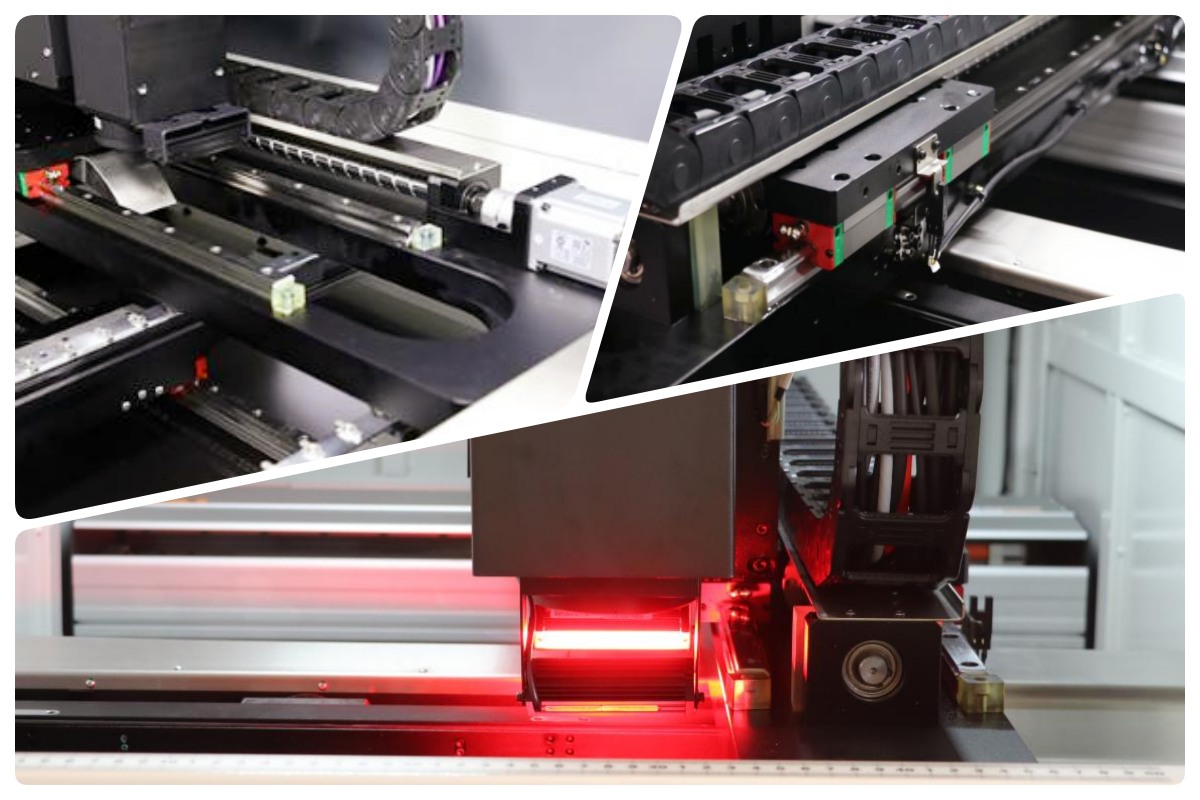

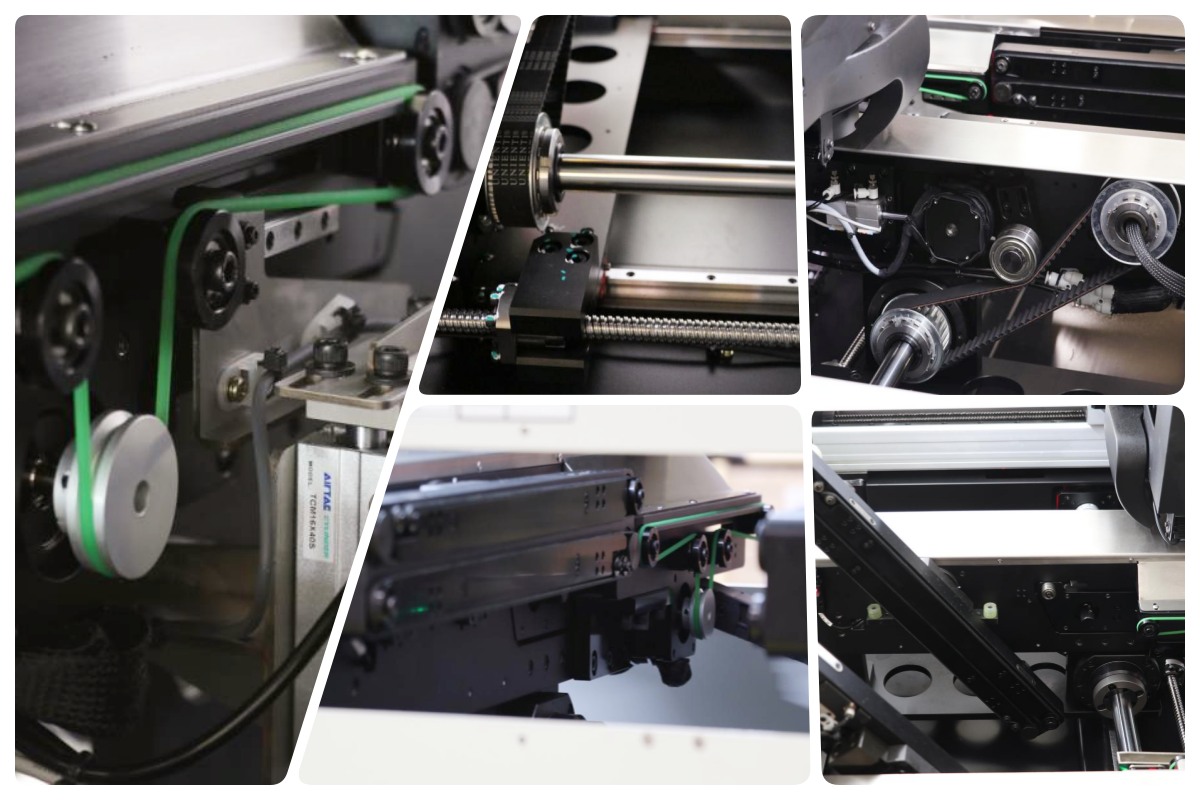

Built-to-Last Driving System

The machine stands on an arch bridge frame with ball screws and heavy guides from reliable makers like TBI and HIWIN. Two separate servo motors run the X and Y axes on their own, giving steady, exact moves across the work area. Closed tank chains bend without catching, and extra profiles keep motion even. A simple dust cover blocks grit and cuts how often you need to clean or fix things. Workers in hard-running SMT plants count on this setup day after day—it holds position true and asks little in return over long shifts.

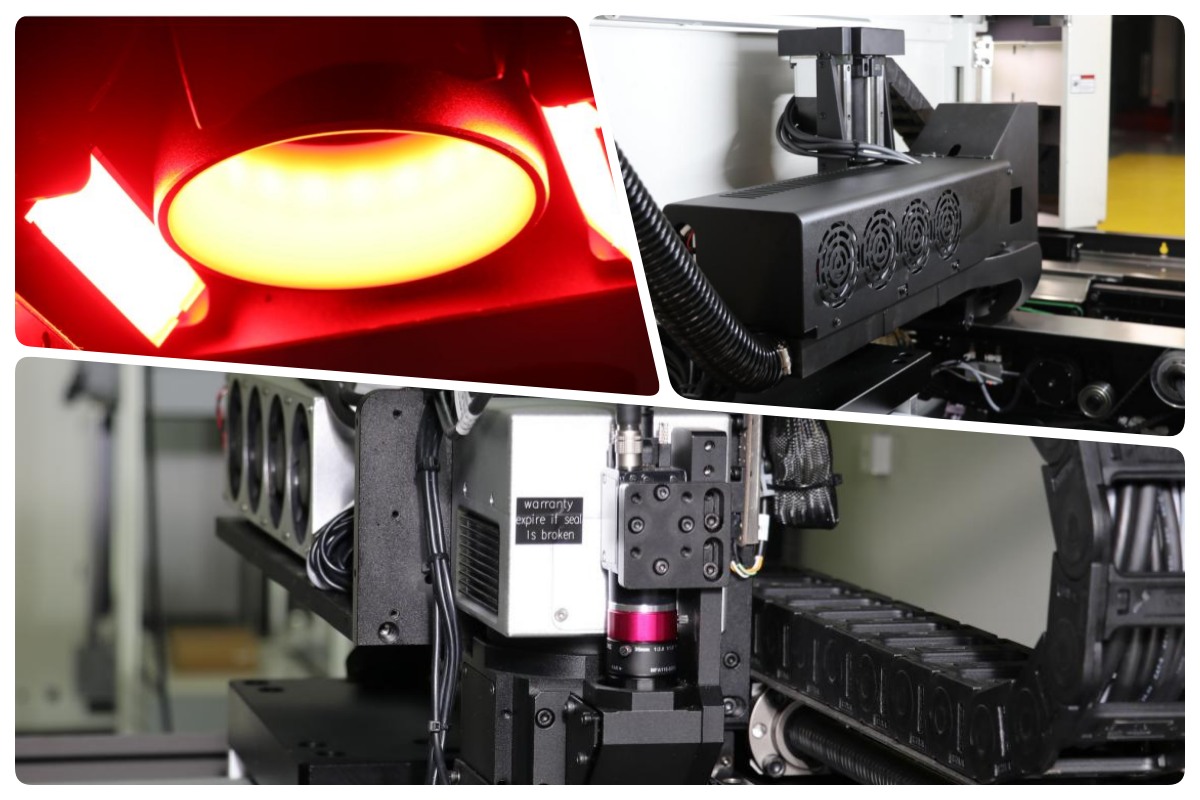

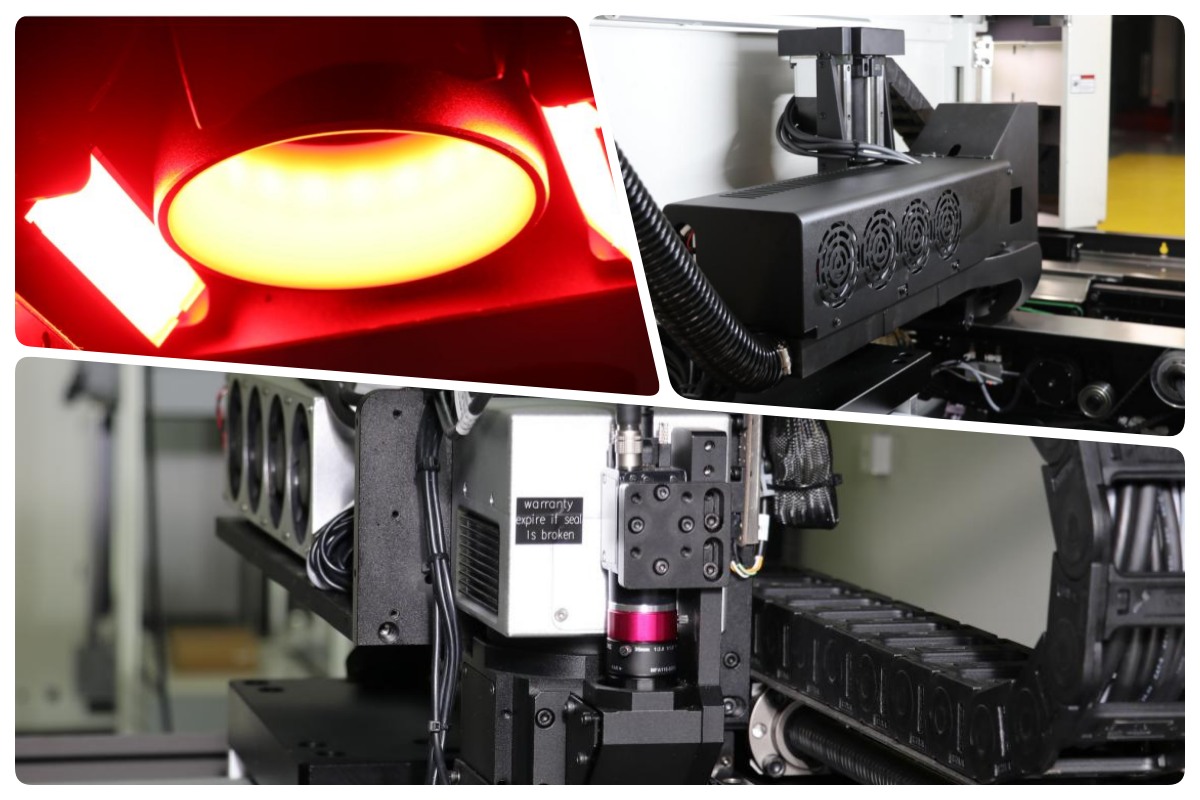

Dependable Marking System

Choose your laser—UV, green, fiber, or CO₂—to fit the boards you make. Each type keeps a steady beam, lasts many years, and focuses sharp. The factory sets the focal point before shipping, so no tweaking is needed; the Z axis lifts on its own. Cooling matches whatever laser you pick, keeping it cool under load. Extra beam shapes handle odd surfaces or tight spots. Day in and day out, this system puts clean, readable marks on every PCB without fail, even when the line runs full speed.

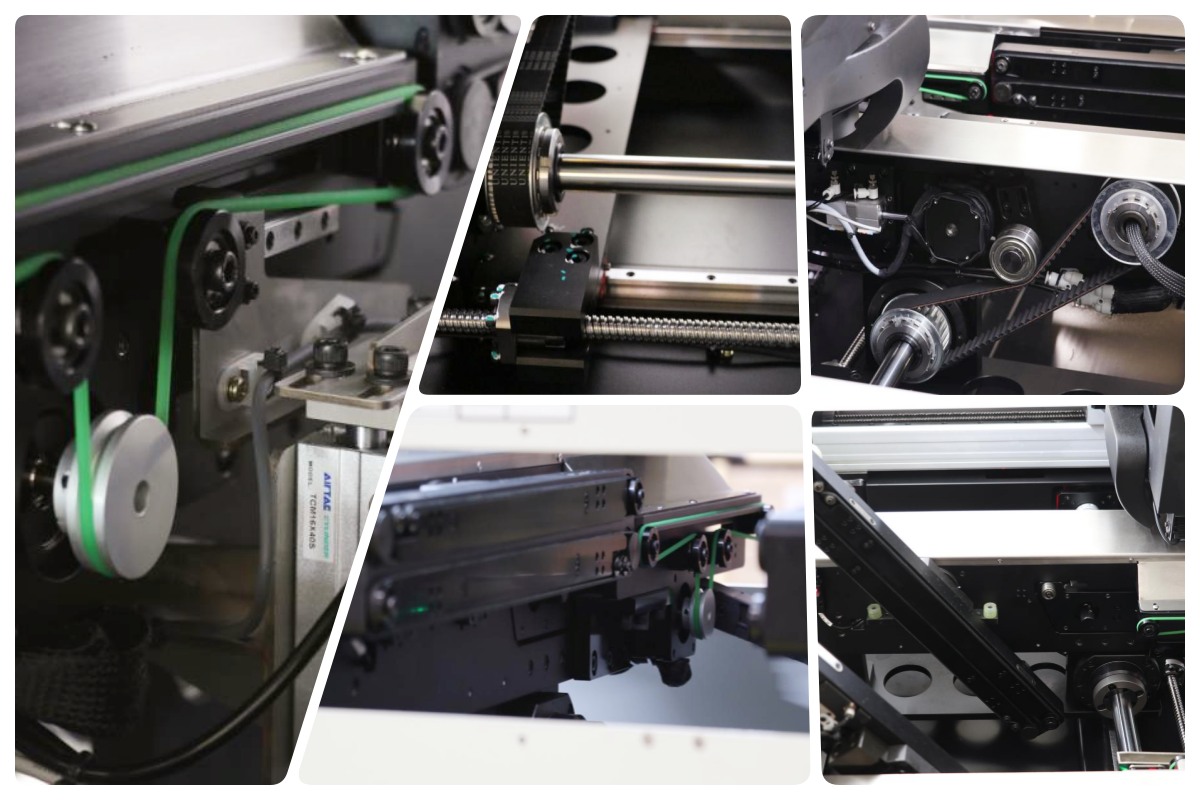

Careful Transport Through the Machine

A built-in flip turns double-sided boards without extra steps when you need it. Rails come in sections with ESD belts that stop static from hurting parts. Strong synchronous belts let you set the speed just right for the line. Tension stays even with special adjusters, so belts never slip or wear uneven. Ball screws and solid shafts widen or narrow rails together, keeping everything straight front to back. Cylinder stops fine-tune where boards halt. This path moves PCBs gently and sure, no jams, no scratches.

Straightforward Control Setup

Everything inside is laid out clean with clear wiring, so checks and fixes go quick. High-grade servo motors and drives keep motion smooth and repeat the same way every time. Air flows through to cool parts naturally during long runs. Our own control board runs steady with few problems and easy service. A separate safety switch trips if power goes wrong, meeting CE and UL rules worldwide. In real factories, this keeps the machine going without surprises or long stops.

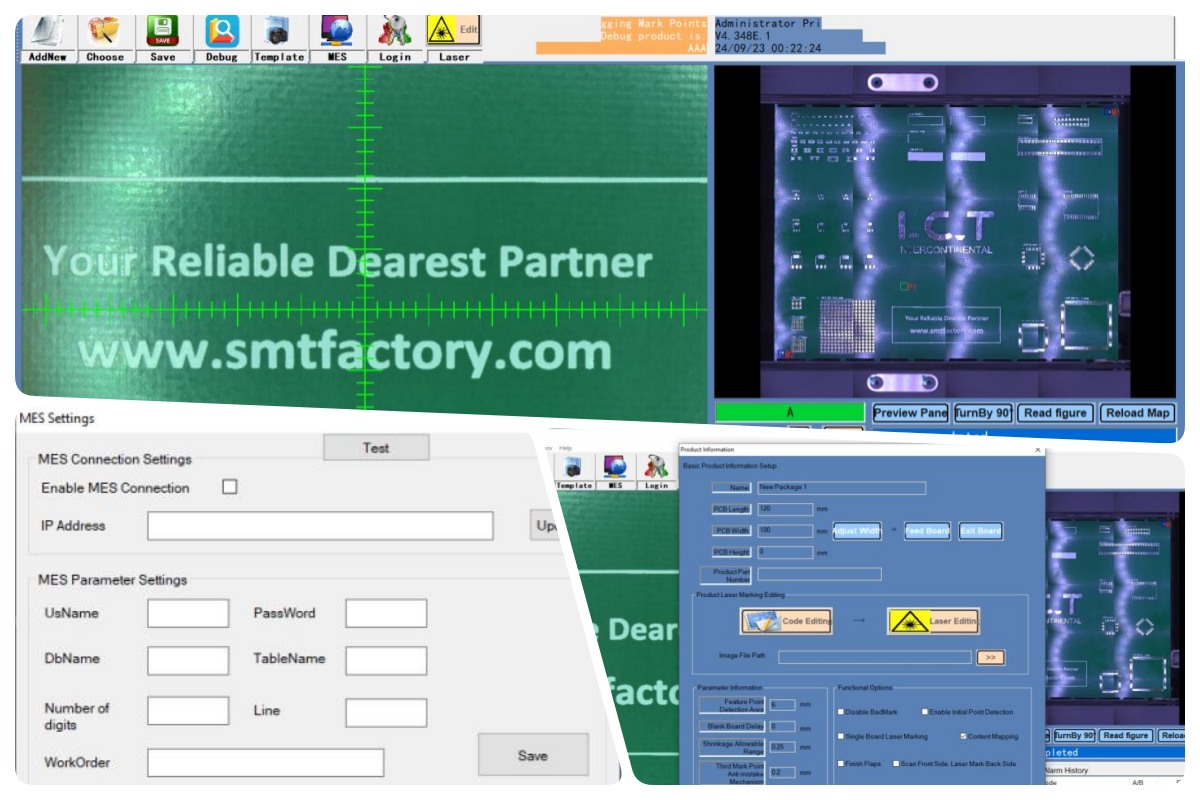

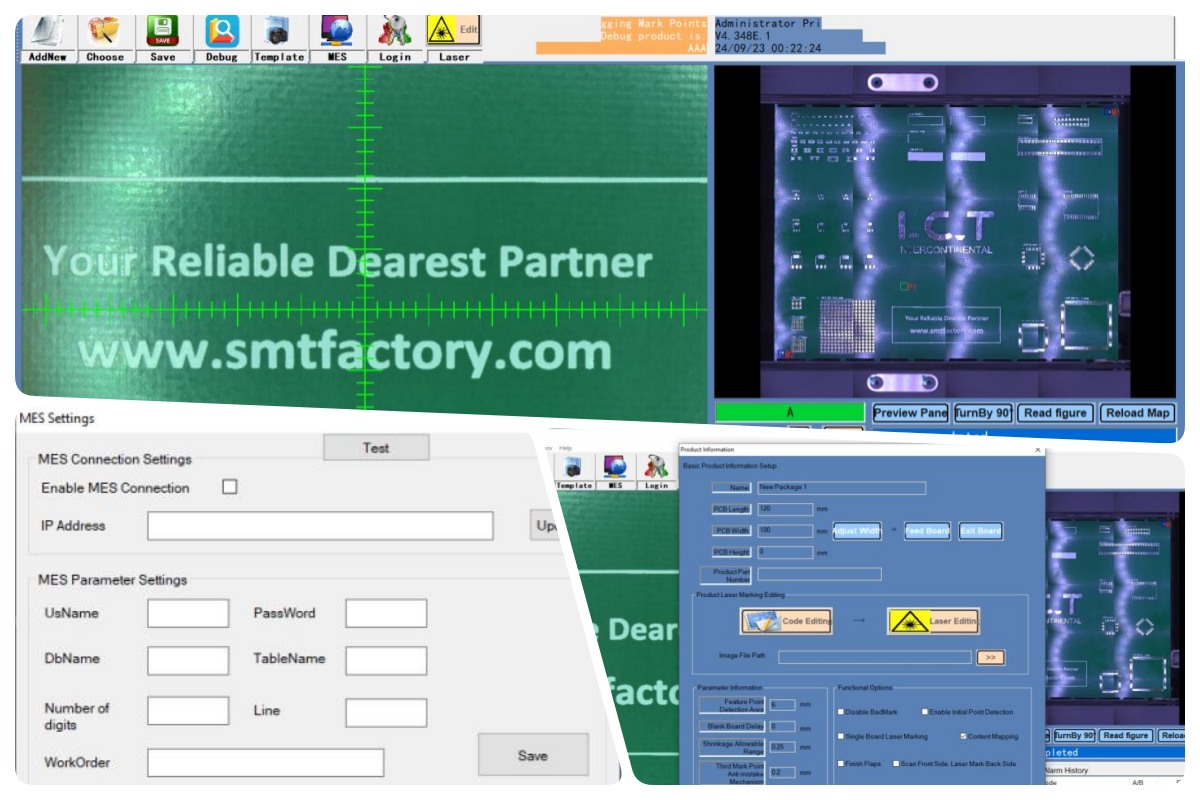

Simple Operator Controls

The screen shows plain steps that new people pick up fast. It uses real Windows and holds many job files, so switching products takes little time. Scanning fills the whole frame and shows the layout right there for easy setup. The camera sits coaxial—no need for separate alignment work. Standard ports hook to MES, and custom ones fit special systems. Operators spend less time learning and more time running boards, keeping the line moving steady.

| Specification

| Parameter | I.C.T-400 | I.C.T-460 | I.C.T-510 | I.C.T-510L |

|---|---|---|---|---|

| Max PCB Size | 380 × 380 mm | 510 × 450 mm | 510 × 400 mm | 510 × 460 mm |

| Marking Range | 280 × 380 mm | 460 × 450 mm | 430 × 400 mm | 510 × 460 mm |

| PCB Flip Function | Yes (built-in flipper) | Yes (built-in flipper) | No | No |

| Machine Dimension | 835 × 1488 × 1566 mm | 974 × 1528 × 1616 mm | 1054 × 1568 × 1523 mm | 1054 × 1470 × 1523 mm |

| Machine Weight | 700 kg | 800 kg | 750 kg | 800 kg |

| Marking Precision | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) |

| PCB Thickness | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) |

| Marking Speed | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) |

| Laser Types Supported | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) |

| PCB Safety Height | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) |

How to choose the Laser:

UV laser (355nm): Best for heat-sensitive PCBs, FR4 solder mask, flexible circuits. Cold marking, minimal damage, high contrast.

Green laser (532nm): Ideal for plastics, silicon wafers, ceramics, reflective coatings. Excellent absorption, ultra-fine marks, low heat impact.

Fiber laser (1064nm): Perfect for metals, copper/aluminum traces, metallic PCBs. Deep, permanent, fast, high-contrast marks.

CO₂ laser (10600nm): Suitable for standard FR4, solder mask, organic coatings. Stable, good contrast, cost-effective for rigid boards.

| Full SMT Line Setup for Real Production

I.C.T puts together complete PCBA lines that work hard in automotive, medical, and everyday electronics plants. Boards enter clean through PCB Magezine loaders, get exact paste from auto printers checked by SPI, take components from SMT placers at high speed, solder solid in Heller ovens with even heat zones. AOI spots flaws early, conveyors carry boards without trouble, cleaners wash off leftover flux for stronger joints, and automatic paste boxes hold and warm material just right. The laser mug printing machine starts the chain with clear tracking. This whole setup raises output, drops defects, lowers cost, and runs reliable with I.C.T standing behind it.

| Customer Project Case

I.C.T sent engineers overseas to install and test two full SMT lines at a North American beauty device maker. Both passed factory acceptance and started production clean. Each line ran our 30 watt fiber laser marking machine for permanent codes, plus SMT printer and SPI, Panasonic mounter, Heller reflow, AOI checker, PCB conveyors, PCBA cleaner, and auto solder paste warmer. Our team set up machines, trained operators, tuned processes, and stayed until everything ran smooth. Now the customer builds steady, high-quality units with full tracking and no holdups.

| Global Service and Training Support

I.C.T handles the whole job—installation at your plant, startup checks, and hands-on training for your crew. Engineers show how to run programs, fix small issues, clean daily, and keep uptime high. We tune settings to fit your boards and goals. After startup, quick calls or visits solve problems fast, and parts stay ready. This support gets lines running right away and keeps them going strong for years in tough production.

| Customer Experience and Operational Benefits

People talk about our engineers—knowledgeable, patient, quick to fix things during setup and training. They like how the machine marks clean and steady, fits lines without trouble. Shipping comes packed tight, arrives safe after long trips. When questions come up, answers arrive fast and work. Customers trust the equipment and the help behind it to keep their production solid and on time.

| Standards, Control and Production Discipline

Our machines carry CE for safe electric use, RoHS to limit harmful materials, and ISO9001 for steady quality control. Several patents cover smart designs in laser work and SMT handling. These marks show the world we build safe, clean-running, dependable tools that meet rules everywhere.

| About I.C.T Company and Factory

I.C.T runs its own design and build shop in Dongguan, China—12,000 square meters, 89 people working, 20 engineers on staff. Started in 2012, it grew fast and now helps over 1,600 customers in 72 countries. Every machine goes through careful checks from parts to final test, backed by a full quality system. We plan whole factories, supply gear, train teams, and tune lines so customers start strong and grow steady.

| Solid PCB Marking with Laser Technology

This laser mug printing machine marks PCBs permanently with barcodes, QR codes, text, or patterns in the electronics world. Built for SMT lines, it links up easily and sends data to MES systems in real time. Four models cover board sizes up to 510 by 460 mm, holding tight precision at ±0.05 mm. Pick UV, green, fiber, or CO₂ lasers depending on what material you run—FR4, metals, plastics, or sensitive coatings. The 30 watt fiber laser marking machine option gives strong, lasting results on metals and traces. No ink, no labels, no reprints by mistake. It cuts costs, keeps the shop cleaner, and meets tough rules for product tracking in busy manufacturing.

| Feature

Built-to-Last Driving System

The machine stands on an arch bridge frame with ball screws and heavy guides from reliable makers like TBI and HIWIN. Two separate servo motors run the X and Y axes on their own, giving steady, exact moves across the work area. Closed tank chains bend without catching, and extra profiles keep motion even. A simple dust cover blocks grit and cuts how often you need to clean or fix things. Workers in hard-running SMT plants count on this setup day after day—it holds position true and asks little in return over long shifts.

Dependable Marking System

Choose your laser—UV, green, fiber, or CO₂—to fit the boards you make. Each type keeps a steady beam, lasts many years, and focuses sharp. The factory sets the focal point before shipping, so no tweaking is needed; the Z axis lifts on its own. Cooling matches whatever laser you pick, keeping it cool under load. Extra beam shapes handle odd surfaces or tight spots. Day in and day out, this system puts clean, readable marks on every PCB without fail, even when the line runs full speed.

Careful Transport Through the Machine

A built-in flip turns double-sided boards without extra steps when you need it. Rails come in sections with ESD belts that stop static from hurting parts. Strong synchronous belts let you set the speed just right for the line. Tension stays even with special adjusters, so belts never slip or wear uneven. Ball screws and solid shafts widen or narrow rails together, keeping everything straight front to back. Cylinder stops fine-tune where boards halt. This path moves PCBs gently and sure, no jams, no scratches.

Straightforward Control Setup

Everything inside is laid out clean with clear wiring, so checks and fixes go quick. High-grade servo motors and drives keep motion smooth and repeat the same way every time. Air flows through to cool parts naturally during long runs. Our own control board runs steady with few problems and easy service. A separate safety switch trips if power goes wrong, meeting CE and UL rules worldwide. In real factories, this keeps the machine going without surprises or long stops.

Simple Operator Controls

The screen shows plain steps that new people pick up fast. It uses real Windows and holds many job files, so switching products takes little time. Scanning fills the whole frame and shows the layout right there for easy setup. The camera sits coaxial—no need for separate alignment work. Standard ports hook to MES, and custom ones fit special systems. Operators spend less time learning and more time running boards, keeping the line moving steady.

| Specification

| Parameter | I.C.T-400 | I.C.T-460 | I.C.T-510 | I.C.T-510L |

|---|---|---|---|---|

| Max PCB Size | 380 × 380 mm | 510 × 450 mm | 510 × 400 mm | 510 × 460 mm |

| Marking Range | 280 × 380 mm | 460 × 450 mm | 430 × 400 mm | 510 × 460 mm |

| PCB Flip Function | Yes (built-in flipper) | Yes (built-in flipper) | No | No |

| Machine Dimension | 835 × 1488 × 1566 mm | 974 × 1528 × 1616 mm | 1054 × 1568 × 1523 mm | 1054 × 1470 × 1523 mm |

| Machine Weight | 700 kg | 800 kg | 750 kg | 800 kg |

| Marking Precision | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) |

| PCB Thickness | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) |

| Marking Speed | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) |

| Laser Types Supported | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) |

| PCB Safety Height | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) |

How to choose the Laser:

UV laser (355nm): Best for heat-sensitive PCBs, FR4 solder mask, flexible circuits. Cold marking, minimal damage, high contrast.

Green laser (532nm): Ideal for plastics, silicon wafers, ceramics, reflective coatings. Excellent absorption, ultra-fine marks, low heat impact.

Fiber laser (1064nm): Perfect for metals, copper/aluminum traces, metallic PCBs. Deep, permanent, fast, high-contrast marks.

CO₂ laser (10600nm): Suitable for standard FR4, solder mask, organic coatings. Stable, good contrast, cost-effective for rigid boards.

| Full SMT Line Setup for Real Production

I.C.T puts together complete PCBA lines that work hard in automotive, medical, and everyday electronics plants. Boards enter clean through PCB Magezine loaders, get exact paste from auto printers checked by SPI, take components from SMT placers at high speed, solder solid in Heller ovens with even heat zones. AOI spots flaws early, conveyors carry boards without trouble, cleaners wash off leftover flux for stronger joints, and automatic paste boxes hold and warm material just right. The laser mug printing machine starts the chain with clear tracking. This whole setup raises output, drops defects, lowers cost, and runs reliable with I.C.T standing behind it.

| Customer Project Case

I.C.T sent engineers overseas to install and test two full SMT lines at a North American beauty device maker. Both passed factory acceptance and started production clean. Each line ran our 30 watt fiber laser marking machine for permanent codes, plus SMT printer and SPI, Panasonic mounter, Heller reflow, AOI checker, PCB conveyors, PCBA cleaner, and auto solder paste warmer. Our team set up machines, trained operators, tuned processes, and stayed until everything ran smooth. Now the customer builds steady, high-quality units with full tracking and no holdups.

| Global Service and Training Support

I.C.T handles the whole job—installation at your plant, startup checks, and hands-on training for your crew. Engineers show how to run programs, fix small issues, clean daily, and keep uptime high. We tune settings to fit your boards and goals. After startup, quick calls or visits solve problems fast, and parts stay ready. This support gets lines running right away and keeps them going strong for years in tough production.

| Customer Experience and Operational Benefits

People talk about our engineers—knowledgeable, patient, quick to fix things during setup and training. They like how the machine marks clean and steady, fits lines without trouble. Shipping comes packed tight, arrives safe after long trips. When questions come up, answers arrive fast and work. Customers trust the equipment and the help behind it to keep their production solid and on time.

| Standards, Control and Production Discipline

Our machines carry CE for safe electric use, RoHS to limit harmful materials, and ISO9001 for steady quality control. Several patents cover smart designs in laser work and SMT handling. These marks show the world we build safe, clean-running, dependable tools that meet rules everywhere.

| About I.C.T Company and Factory

I.C.T runs its own design and build shop in Dongguan, China—12,000 square meters, 89 people working, 20 engineers on staff. Started in 2012, it grew fast and now helps over 1,600 customers in 72 countries. Every machine goes through careful checks from parts to final test, backed by a full quality system. We plan whole factories, supply gear, train teams, and tune lines so customers start strong and grow steady.