SMT Line Solutions for IFPD

I.C.T

SMT Line Solutions for IFPD

| Availability: | |

|---|---|

| Quantity: | |

| SMT Line Solutions for IFPD Details

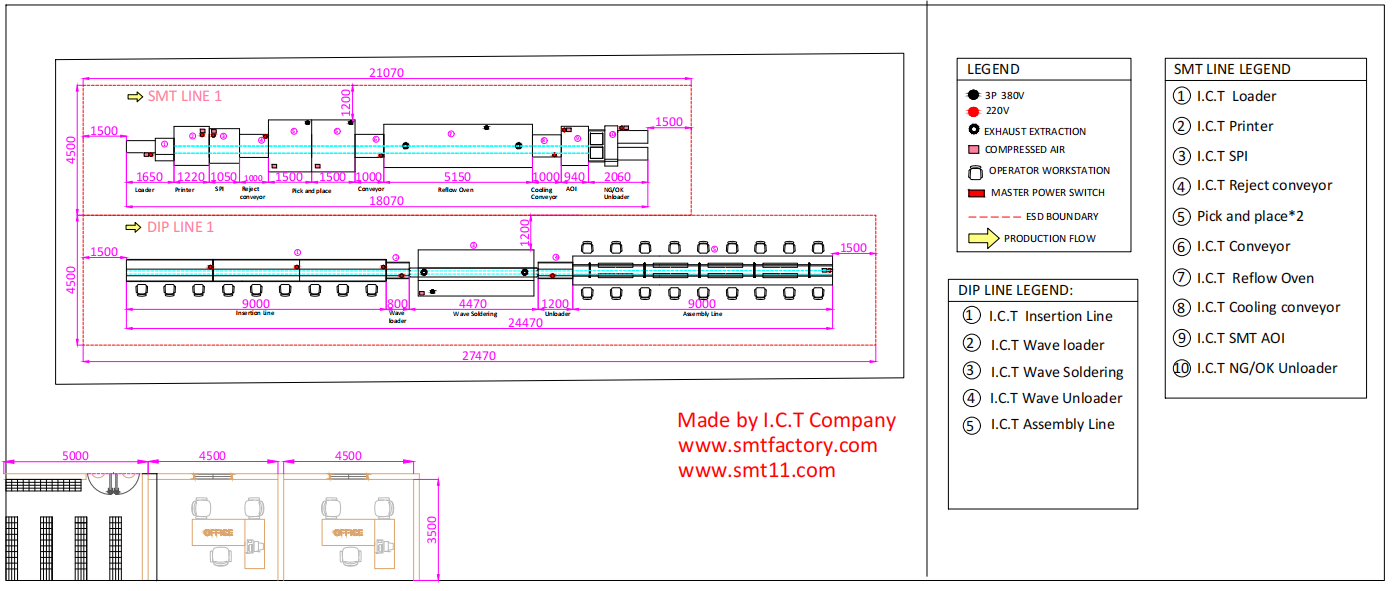

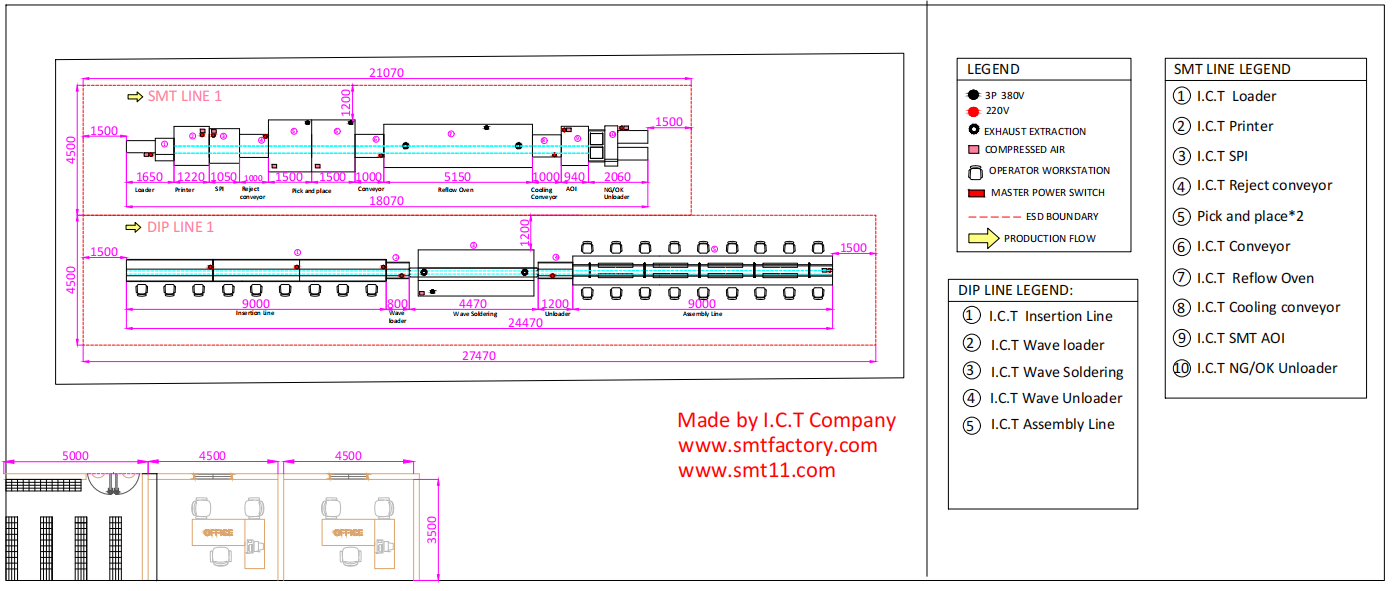

I.C.T delivers Comprehensive SMT Line Solutions for IFPD through three wholly-owned factories and over 22 years of specialized SMT/DIP expertise. We provide end-to-end factory planning, detailed layout drawings, accurate labor cost forecasts, and comprehensive ROI calculations to ensure seamless integration.

Our solutions cover semi-automatic and fully automatic lines featuring auto loaders, high-precision printers, advanced placers, multi-zone reflow ovens, inline AOI systems, and smart unloaders. A single operator can efficiently manage the entire shift with minimal intervention. The low 18Kw/H power consumption promotes eco-friendly operations and cost savings. We serve a wide range of global clients in education technology, conference systems, digital signage, and related fields worldwide.

Installation is completed in just 3 days, including full verification of air circuits, electrical layouts, exhaust systems, lighting, and temperature controls. Training spans 7-15 days, covering software programming, daily maintenance, safety protocols, and troubleshooting techniques.

With 15 years of proven overseas service experience, we guarantee maximum uptime and quick issue resolution. IFPD Smart Factory Solutions incorporate data analytics, predictive maintenance, and seamless connectivity for modern, zero-downtime manufacturing environments. This turnkey approach simplifies factory setup and accelerates time-to-market for new IFPD producers.

| Feature

Connected Factory Operations

SMT Line Solutions for IFPD fully synchronize all stations using advanced cloud MES software for live OEE tracking, production scheduling, and performance analytics. The auto loader dynamically adjusts to board sizes ranging from 55 to 100 inches or more, ensuring compatibility with various IFPD models. The printer employs cutting-edge 3D vision systems for precise paste application on intricate LED arrays and fine-pitch components.

The placer efficiently handles ultra-small 01005 chips at high speeds while maintaining placement accuracy. The reflow oven sustains temperature stability within ±1.4°C across multiple zones for consistent bonding without defects. Inline AOI utilizes AI algorithms to identify even the smallest micro-defects in real time. The unloader automatically directs boards to testing or packaging stations. This integrated setup can increase overall yield by up to 25% in Comprehensive SMT Line Solutions for IFPD.

It is highly scalable to support 4K, 8K, or future ultra-high-resolution panels. Conveyors include buffer zones to handle peak loads, and the system supports remote access for global oversight. Additional features like automatic recipe switching and material traceability enhance flexibility for high-mix, low-volume production runs common in IFPD manufacturing.

Advanced Paste Application

The printer within SMT Line Solutions for IFPD achieves sub-micron alignment accuracy using oversized stencil frames designed specifically for large interactive displays. It supports quick-change mechanisms for minimal downtime during product switches. Automatic paste dispensing and under-stencil wiping ensure consistent deposition cycles.

Integrated 3D SPI scans verify paste volume and height to prevent voids or bridges before reflow. This is particularly crucial for high-brightness IFPD backlights with dense LED configurations. The system accommodates various solder pastes, including low-temperature options for sensitive components. Vision-guided squeegees adapt pressure dynamically for uniform coverage on uneven surfaces.

Precise Thermal Management

The reflow oven in SMT Line Solutions for IFPD includes up to 12 independent convection zones with precise top and bottom heating controls. A nitrogen atmosphere option creates bright, void-free solder joints essential for display reliability.

Profiles are auto-optimized based on panel size, thickness, and component density. Rapid cooling zones prevent delamination or warpage in large-format boards. The design incorporates heat recovery systems to achieve the efficient 18Kw/H rating. Touchscreen interfaces allow storage of hundreds of recipes with easy retrieval. This thermal process is a cornerstone of IFPD Smart Factory Solutions, ensuring long-term durability in demanding environments like classrooms or conference rooms. Conveyor speeds are adjustable in real time via the MES.

Intelligent Defect Detection

The inline AOI system captures ultra-high-resolution 8K images at full line speed for comprehensive scanning. It detects issues such as panel warpage, LED misalignment, solder inconsistencies, or foreign materials. Advanced AI continuously learns from production data to improve detection accuracy over time.

Inspection results feed back to upstream stations, like the placer, for automatic corrections and process optimization. This proactive approach significantly reduces defect escapes in Comprehensive SMT Line Solutions for IFPD. The system generates detailed reports and dashboards for quality management. Reject handling includes automated rework routing.

Expansion and Customization

Begin with a semi-automatic configuration and seamlessly upgrade to full automation by adding plug-in modules without major disruptions. Factory drawings incorporate reserved spaces for future additions like extra SPI units, buffers, or IoT hubs. We provide detailed labor models that predict up to 70% savings in manpower through automation. Customization options include cleanroom compatibility, ESD protection, and integration with existing ERP systems.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

An Algerian client specializing in functional mobile phones visited our facility for machine acceptance testing. They brought over a dozen PCB boards along with all necessary components and materials. Our team demonstrated live production on a fully configured line to showcase real-world performance and reliability. The process began with the full automatic printer applying solder paste precisely. Next, SPI inspected paste deposition for volume and alignment accuracy. The RX-8 placement machine handled small components like resistors and chips at high speed. The RS-1R took care of larger parts including connectors and IC with equal efficiency.

A tray feeder supplied shield covers automatically without interrupting the flow. Boards then entered the reflow oven for solid soldering under controlled conditions. AOI scanned for any defects post-reflow to ensure quality. Finally, the 5700 board separator divided multi-panel arrays cleanly. The entire run completed smoothly with zero errors, impressing the client with output speed and precision. This hands-on demo highlighted how SMT Line Solutions for IFPD principles apply to mobile PCBA, proving versatility. The client confirmed all boards met specifications and praised the seamless integration. They left confident in scaling their production using similar setups back home.

| Service and Training Support

I.C.T assigns a dedicated project manager to every SMT Line Solutions for IFPD implementation, overseeing from initial consultation to long-term optimization.

The 3-day on-site service includes complete system validation, pilot production runs, and fine-tuning of all parameters. The 7-15 day training program is customized for IFPD, covering MES software setup, large-panel handling techniques, defect analysis tools, preventive maintenance schedules, and emergency protocols.

Cloud-based diagnostics enable predictive failure alerts and remote troubleshooting. Spare parts are readily available from our network of 8 global warehouses to minimize delays. With a 15-year track record in overseas installations, our multilingual engineers ensure cultural and technical alignment. Annual health checks include software upgrades, performance audits, and process improvements to keep the line at peak efficiency.

| Client Testimonials

Clients consistently praise the rapid 2-hour remote resolution for any issues in SMT Line Solutions for IFPD, often preventing minor glitches from escalating. The large-capacity ovens operate reliably 24/7 with no temperature drift, even during extended production runs.

Custom packaging ensures all components arrive undamaged, regardless of air or sea freight challenges. Service response times consistently beat agreed SLAs, building strong trust. Comprehensive SMT Line Solutions for IFPD have enabled clients to produce over 1 million panels annually without quality compromises. Users appreciate the intuitive interfaces that allow quick onboarding of new staff.

| Certifications and Standards

CE certification verifies full compliance with international electrical safety standards for all equipment. RoHS ensures the use of environmentally friendly, non-hazardous materials throughout the supply chain. ISO9001 provides a robust framework for consistent quality management and continuous improvement. Multiple patents protect innovative features like large-board conveyor designs and AI inspection algorithms. These credentials collectively validate the reliability and global acceptability of SMT Line Solutions for IFPD. Every system undergoes rigorous pre-shipment testing in our facilities.

| About I.C.T Company and Factory

I.C.T operates three state-of-the-art factories totaling 12000m², equipped with the latest automation for in-house production. Our team of 89 dedicated professionals includes 20 highly skilled engineers focused on R&D and innovation. Over 25 years of continuous growth, we have successfully served 1600 satisfied clients across 72 countries worldwide.

Internal R&D teams develop custom IFPD Smart Factory Solutions, from specialized software to hardware adaptations. Multi-stage quality control starts with incoming material inspections, proceeds through in-process checks, and ends with final functional testing before shipment. Global infrastructure includes sales centers, service hubs, warehouses, and branch offices for localized support. Our mission is to evolve into a leading cross-value platform, integrating electronics manufacturing with intelligent systems for the future.

| SMT Line Solutions for IFPD Details

I.C.T delivers Comprehensive SMT Line Solutions for IFPD through three wholly-owned factories and over 22 years of specialized SMT/DIP expertise. We provide end-to-end factory planning, detailed layout drawings, accurate labor cost forecasts, and comprehensive ROI calculations to ensure seamless integration.

Our solutions cover semi-automatic and fully automatic lines featuring auto loaders, high-precision printers, advanced placers, multi-zone reflow ovens, inline AOI systems, and smart unloaders. A single operator can efficiently manage the entire shift with minimal intervention. The low 18Kw/H power consumption promotes eco-friendly operations and cost savings. We serve a wide range of global clients in education technology, conference systems, digital signage, and related fields worldwide.

Installation is completed in just 3 days, including full verification of air circuits, electrical layouts, exhaust systems, lighting, and temperature controls. Training spans 7-15 days, covering software programming, daily maintenance, safety protocols, and troubleshooting techniques.

With 15 years of proven overseas service experience, we guarantee maximum uptime and quick issue resolution. IFPD Smart Factory Solutions incorporate data analytics, predictive maintenance, and seamless connectivity for modern, zero-downtime manufacturing environments. This turnkey approach simplifies factory setup and accelerates time-to-market for new IFPD producers.

| Feature

Connected Factory Operations

SMT Line Solutions for IFPD fully synchronize all stations using advanced cloud MES software for live OEE tracking, production scheduling, and performance analytics. The auto loader dynamically adjusts to board sizes ranging from 55 to 100 inches or more, ensuring compatibility with various IFPD models. The printer employs cutting-edge 3D vision systems for precise paste application on intricate LED arrays and fine-pitch components.

The placer efficiently handles ultra-small 01005 chips at high speeds while maintaining placement accuracy. The reflow oven sustains temperature stability within ±1.4°C across multiple zones for consistent bonding without defects. Inline AOI utilizes AI algorithms to identify even the smallest micro-defects in real time. The unloader automatically directs boards to testing or packaging stations. This integrated setup can increase overall yield by up to 25% in Comprehensive SMT Line Solutions for IFPD.

It is highly scalable to support 4K, 8K, or future ultra-high-resolution panels. Conveyors include buffer zones to handle peak loads, and the system supports remote access for global oversight. Additional features like automatic recipe switching and material traceability enhance flexibility for high-mix, low-volume production runs common in IFPD manufacturing.

Advanced Paste Application

The printer within SMT Line Solutions for IFPD achieves sub-micron alignment accuracy using oversized stencil frames designed specifically for large interactive displays. It supports quick-change mechanisms for minimal downtime during product switches. Automatic paste dispensing and under-stencil wiping ensure consistent deposition cycles.

Integrated 3D SPI scans verify paste volume and height to prevent voids or bridges before reflow. This is particularly crucial for high-brightness IFPD backlights with dense LED configurations. The system accommodates various solder pastes, including low-temperature options for sensitive components. Vision-guided squeegees adapt pressure dynamically for uniform coverage on uneven surfaces.

Precise Thermal Management

The reflow oven in SMT Line Solutions for IFPD includes up to 12 independent convection zones with precise top and bottom heating controls. A nitrogen atmosphere option creates bright, void-free solder joints essential for display reliability.

Profiles are auto-optimized based on panel size, thickness, and component density. Rapid cooling zones prevent delamination or warpage in large-format boards. The design incorporates heat recovery systems to achieve the efficient 18Kw/H rating. Touchscreen interfaces allow storage of hundreds of recipes with easy retrieval. This thermal process is a cornerstone of IFPD Smart Factory Solutions, ensuring long-term durability in demanding environments like classrooms or conference rooms. Conveyor speeds are adjustable in real time via the MES.

Intelligent Defect Detection

The inline AOI system captures ultra-high-resolution 8K images at full line speed for comprehensive scanning. It detects issues such as panel warpage, LED misalignment, solder inconsistencies, or foreign materials. Advanced AI continuously learns from production data to improve detection accuracy over time.

Inspection results feed back to upstream stations, like the placer, for automatic corrections and process optimization. This proactive approach significantly reduces defect escapes in Comprehensive SMT Line Solutions for IFPD. The system generates detailed reports and dashboards for quality management. Reject handling includes automated rework routing.

Expansion and Customization

Begin with a semi-automatic configuration and seamlessly upgrade to full automation by adding plug-in modules without major disruptions. Factory drawings incorporate reserved spaces for future additions like extra SPI units, buffers, or IoT hubs. We provide detailed labor models that predict up to 70% savings in manpower through automation. Customization options include cleanroom compatibility, ESD protection, and integration with existing ERP systems.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

An Algerian client specializing in functional mobile phones visited our facility for machine acceptance testing. They brought over a dozen PCB boards along with all necessary components and materials. Our team demonstrated live production on a fully configured line to showcase real-world performance and reliability. The process began with the full automatic printer applying solder paste precisely. Next, SPI inspected paste deposition for volume and alignment accuracy. The RX-8 placement machine handled small components like resistors and chips at high speed. The RS-1R took care of larger parts including connectors and IC with equal efficiency.

A tray feeder supplied shield covers automatically without interrupting the flow. Boards then entered the reflow oven for solid soldering under controlled conditions. AOI scanned for any defects post-reflow to ensure quality. Finally, the 5700 board separator divided multi-panel arrays cleanly. The entire run completed smoothly with zero errors, impressing the client with output speed and precision. This hands-on demo highlighted how SMT Line Solutions for IFPD principles apply to mobile PCBA, proving versatility. The client confirmed all boards met specifications and praised the seamless integration. They left confident in scaling their production using similar setups back home.

| Service and Training Support

I.C.T assigns a dedicated project manager to every SMT Line Solutions for IFPD implementation, overseeing from initial consultation to long-term optimization.

The 3-day on-site service includes complete system validation, pilot production runs, and fine-tuning of all parameters. The 7-15 day training program is customized for IFPD, covering MES software setup, large-panel handling techniques, defect analysis tools, preventive maintenance schedules, and emergency protocols.

Cloud-based diagnostics enable predictive failure alerts and remote troubleshooting. Spare parts are readily available from our network of 8 global warehouses to minimize delays. With a 15-year track record in overseas installations, our multilingual engineers ensure cultural and technical alignment. Annual health checks include software upgrades, performance audits, and process improvements to keep the line at peak efficiency.

| Client Testimonials

Clients consistently praise the rapid 2-hour remote resolution for any issues in SMT Line Solutions for IFPD, often preventing minor glitches from escalating. The large-capacity ovens operate reliably 24/7 with no temperature drift, even during extended production runs.

Custom packaging ensures all components arrive undamaged, regardless of air or sea freight challenges. Service response times consistently beat agreed SLAs, building strong trust. Comprehensive SMT Line Solutions for IFPD have enabled clients to produce over 1 million panels annually without quality compromises. Users appreciate the intuitive interfaces that allow quick onboarding of new staff.

| Certifications and Standards

CE certification verifies full compliance with international electrical safety standards for all equipment. RoHS ensures the use of environmentally friendly, non-hazardous materials throughout the supply chain. ISO9001 provides a robust framework for consistent quality management and continuous improvement. Multiple patents protect innovative features like large-board conveyor designs and AI inspection algorithms. These credentials collectively validate the reliability and global acceptability of SMT Line Solutions for IFPD. Every system undergoes rigorous pre-shipment testing in our facilities.

| About I.C.T Company and Factory

I.C.T operates three state-of-the-art factories totaling 12000m², equipped with the latest automation for in-house production. Our team of 89 dedicated professionals includes 20 highly skilled engineers focused on R&D and innovation. Over 25 years of continuous growth, we have successfully served 1600 satisfied clients across 72 countries worldwide.

Internal R&D teams develop custom IFPD Smart Factory Solutions, from specialized software to hardware adaptations. Multi-stage quality control starts with incoming material inspections, proceeds through in-process checks, and ends with final functional testing before shipment. Global infrastructure includes sales centers, service hubs, warehouses, and branch offices for localized support. Our mission is to evolve into a leading cross-value platform, integrating electronics manufacturing with intelligent systems for the future.