I.C.T-MV350

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

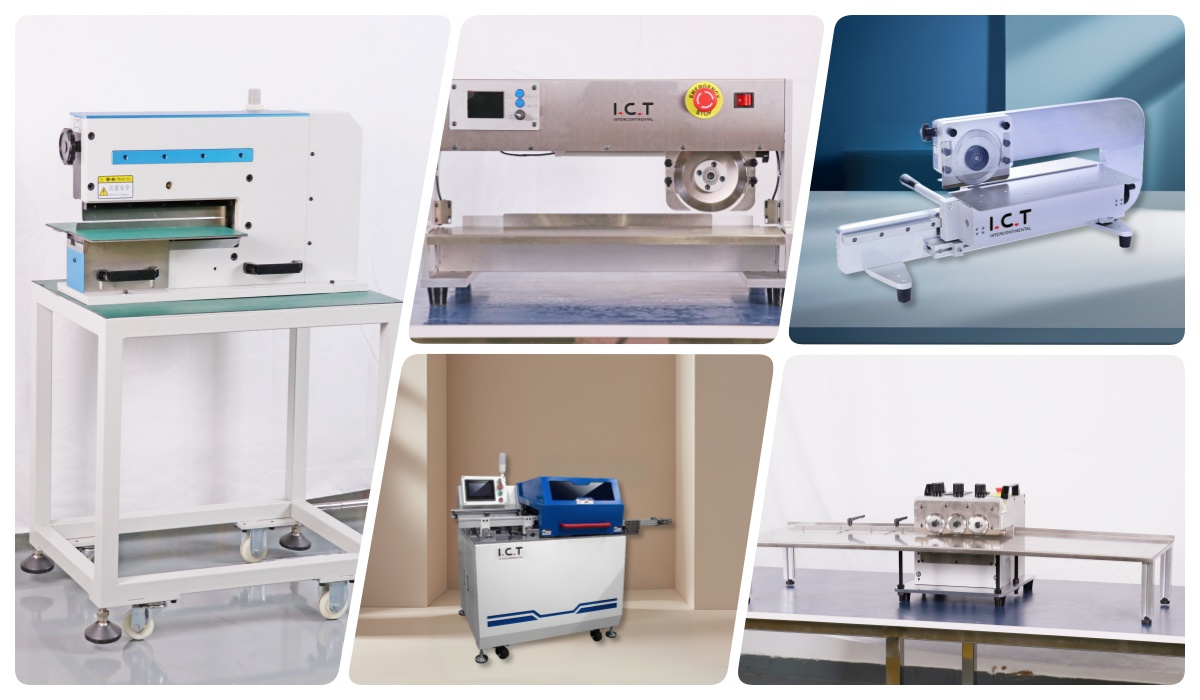

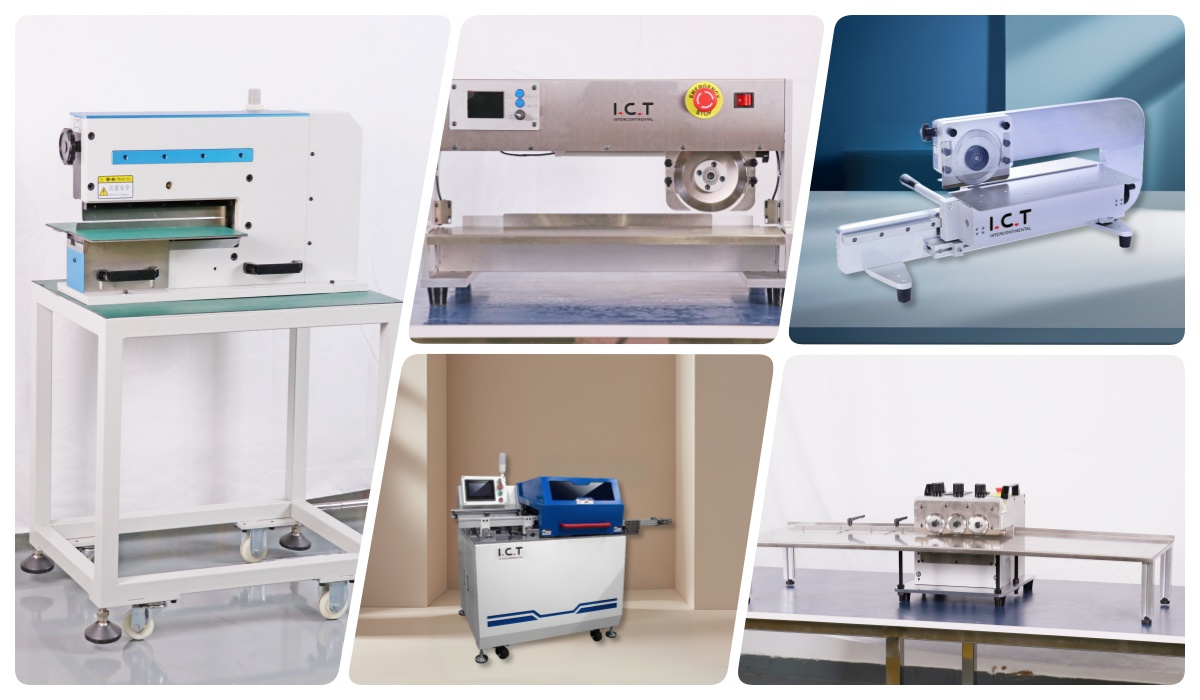

| Controlled Cutting for Reliable LED PCBs

The LED PCB Cutting Machine is developed to ensure safe and consistent separation of LED circuit boards after assembly. During depaneling, uncontrolled force can cause hidden cracks, solder joint damage, or early product failure. This machine focuses on stable board positioning and controlled cutting motion to reduce these risks. It can be used as a manual PCB depanelizer or integrated into a semi-automatic workflow, depending on production needs. By improving edge quality and reducing internal stress, the LED PCB Cutting Machine helps manufacturers maintain product reliability throughout testing, aging, and final assembly.

Function and application overview:

PCB depaneling prepares LED boards for electrical testing;

Commonly used in LED lighting and driver board production;

Different cutting structures match different PCB designs.

| Feature

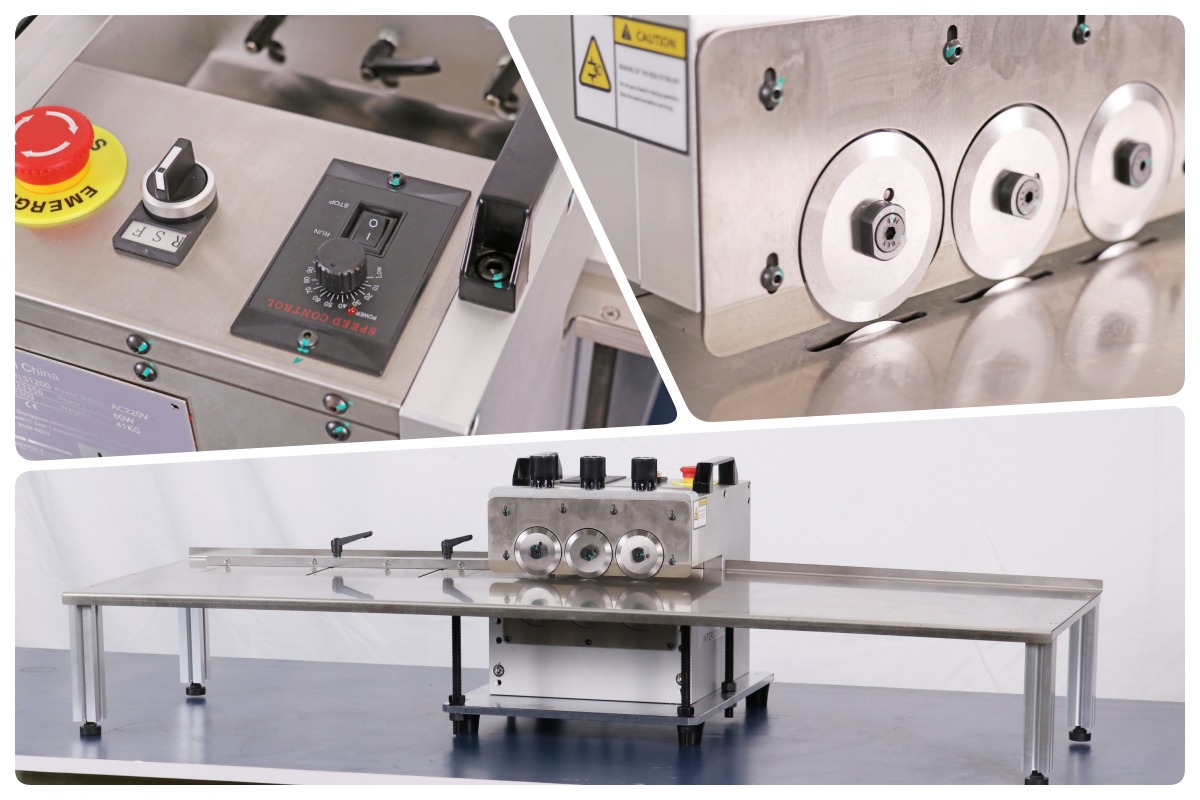

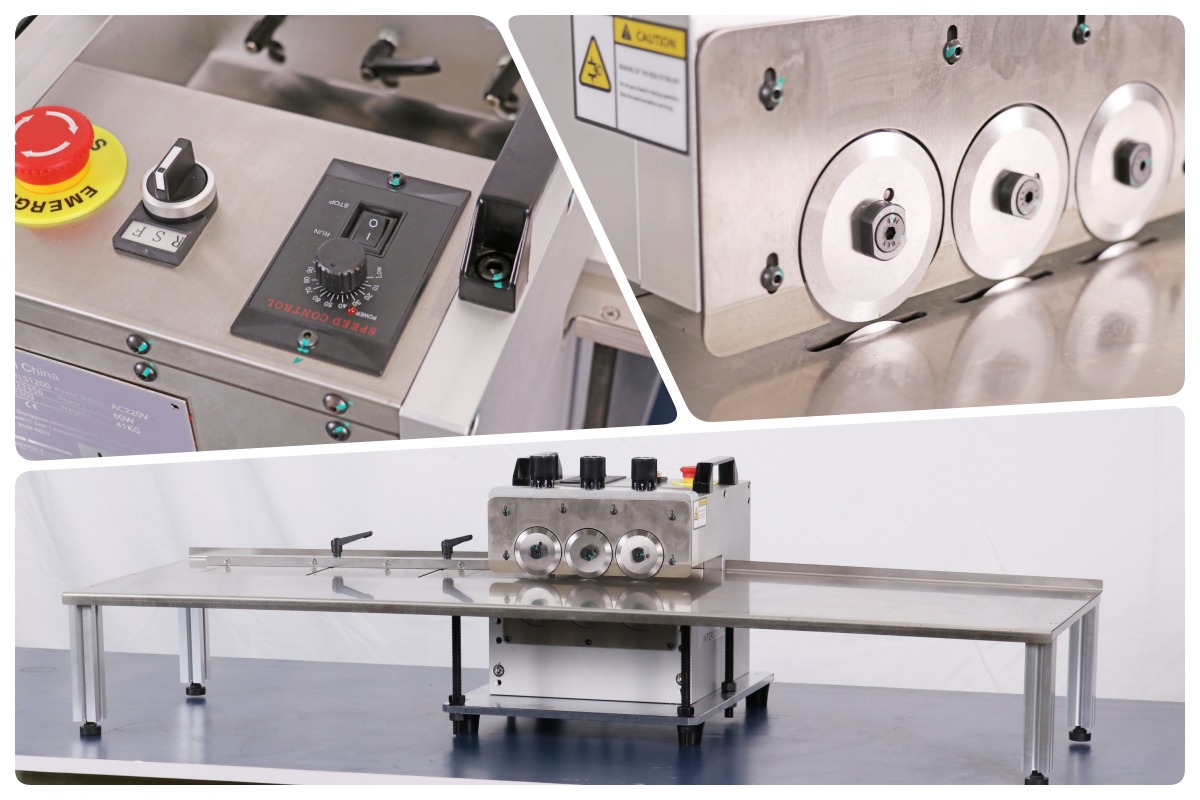

Multi-Blades LED Separator

The Multi-Blades LED Separator is mainly applied in LED strip and light bar production where PCBs are long and narrow. Multiple circular blades distribute cutting force evenly, reducing localized stress on the board. This is important for LED products where components are often close to the V-groove. As a driver PCB cutting machine, it supports stable and repeatable separation with consistent edge quality. The adjustable blade spacing allows the machine to adapt to different panel widths, making it suitable for batch production with uniform board designs.

Guillotine Type V-Cut Machine

The Guillotine Type V-Cut Machine separates PCBs through a vertical cutting motion along the V-groove. This direct method provides strong and clear separation, making it suitable for thicker boards or rigid materials. It is frequently used as a Semi-Auto Pcb V-Cut solution in workshops where operators need controlled force without complex automation. The simple mechanical structure allows easy training and reliable daily use. Clean edges and stable positioning make it suitable for standard PCB designs.

Move-Blade (Sliding) V-Cut Machine

The Move-Blade V-Cut Machine uses a controlled sliding action to separate PCBs gradually. Instead of applying force at one point, the blade moves along the groove line, reducing sudden impact. This method helps protect sensitive components and solder joints. It is commonly used when PCB length varies or when product designs change frequently. As part of cutting machinery for PCB processing, it offers flexibility and improved edge quality in mixed production environments.

| Specification

| Parameter | Manual Single-Blade V-cut Machine | Multi-Blades LED Separator | Guillotine Type V-cut Machine | Move-Blade (Sliding) V-cut Machine | Multi Group Blades PCB V-cut Machine |

|---|---|---|---|---|---|

| Operation Type | Manual (hand sliding) | Manual (hand push) | Manual (pneumatic foot switch) | Manual (adjustable sliding) | Manual (multi-group push) |

| Blade Setup | 1 circular + 1 straight blade | 6 circular blades (3 groups top/bottom) | Single straight guillotine blade | 1 circular + 1 straight (adjustable gap) | Multiple groups of circular blades (custom multi-knife) |

| PCB Length | 0–350 mm | Unlimited (with 1.2m / 2.4m platforms) | 0–330 mm | 0–350 mm (typical) | Unlimited or very long (platform-dependent) |

| PCB Thickness | 0.8–5 mm | 0.2–5 mm | 0.3–5 mm | 0.8–5 mm | 0.2–5 mm (typical for multi-group) |

| Cutting Method | Single pass sliding | 3-phase (40% + 40% + 20%) | One-shot downward cut | Single pass with adjustable depth | Multi-group sequential cutting |

| Best Application | General PCBs, prototypes, medium volume | Long LED strips, aluminum PCBs, high-volume LED | FR4 boards, clean/dust-free edges | Mixed components, flexible V-depth | Extra-long or wide PCBs, high-efficiency separation |

| SMT Line Equipment List

I.C.T puts together full SMT lines that link loaders, printers, mounters, reflow ovens, AOI units, conveyors, and aluminum PCB cutting machine sections into one working system. Everything matches up right. When space runs tight, U-shaped layouts use the floor well without losing flow. The whole setup raises output, cuts mistakes, and delivers steady quality for automotive parts, LED products, and everyday electronics. Customers get help from start to finish—planning the line, setting it up, and tuning it so production runs smooth and strong from the first day onward.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

In 2025, an I.C.T engineer provided on-site technical support to an automotive electronics manufacturer in Uzbekistan. The customer purchased a complete SMT production line covering printing, placement, reflow soldering, inspection, depaneling, and auxiliary equipment. Due to limited factory space, I.C.T designed a compact U-shaped layout. During the support period, the engineer completed installation, commissioning, and operator training. After handover, the customer successfully ran the entire line independently with stable output.

| Service and Training Support

I.C.T offers comprehensive service that supports customers throughout the entire project. Before delivery, engineers assist with equipment selection and production planning based on PCB design and output targets. During installation, structured training ensures operators understand correct operation and safety procedures. After commissioning, remote technical support provides fast response to daily issues, while on-site service is available when required. This full-service approach helps customers maintain stable production and long-term equipment performance.

| Customer Feedback

Customers often praise I.C.T engineers for their professional attitude and practical experience. Installation guidance is clear and focused on real production needs. Equipment performance is recognized for stable operation and consistent cutting quality. Clients also value the careful packaging methods that protect machines during long-distance transportation. Quick response to technical questions further builds trust and long-term cooperation with I.C.T.

| Certifications and Standards

I.C.T equipment is manufactured under strict quality control systems. All machines comply with CE and RoHS standards to meet international safety and environmental requirements. Production follows ISO9001 management processes to ensure consistency and traceability. In addition, I.C.T holds multiple patents related to PCB depaneling structures and mechanical design. These certifications demonstrate I.C.T’s commitment to reliable engineering and continuous improvement.

| About I.C.T Company and Factory

I.C.T is a professional electronics manufacturing solution provider offering SMT, DIP, assembly, inspection, depaneling, and smart factory systems. With experienced engineers and modern manufacturing facilities, I.C.T focuses on delivering practical equipment for real production environments. Each machine is assembled, tested, and inspected before shipment. I.C.T serves customers worldwide across LED lighting, automotive electronics, industrial control, and consumer electronics industries.

| Controlled Cutting for Reliable LED PCBs

The LED PCB Cutting Machine is developed to ensure safe and consistent separation of LED circuit boards after assembly. During depaneling, uncontrolled force can cause hidden cracks, solder joint damage, or early product failure. This machine focuses on stable board positioning and controlled cutting motion to reduce these risks. It can be used as a manual PCB depanelizer or integrated into a semi-automatic workflow, depending on production needs. By improving edge quality and reducing internal stress, the LED PCB Cutting Machine helps manufacturers maintain product reliability throughout testing, aging, and final assembly.

Function and application overview:

PCB depaneling prepares LED boards for electrical testing;

Commonly used in LED lighting and driver board production;

Different cutting structures match different PCB designs.

| Feature

Multi-Blades LED Separator

The Multi-Blades LED Separator is mainly applied in LED strip and light bar production where PCBs are long and narrow. Multiple circular blades distribute cutting force evenly, reducing localized stress on the board. This is important for LED products where components are often close to the V-groove. As a driver PCB cutting machine, it supports stable and repeatable separation with consistent edge quality. The adjustable blade spacing allows the machine to adapt to different panel widths, making it suitable for batch production with uniform board designs.

Guillotine Type V-Cut Machine

The Guillotine Type V-Cut Machine separates PCBs through a vertical cutting motion along the V-groove. This direct method provides strong and clear separation, making it suitable for thicker boards or rigid materials. It is frequently used as a Semi-Auto Pcb V-Cut solution in workshops where operators need controlled force without complex automation. The simple mechanical structure allows easy training and reliable daily use. Clean edges and stable positioning make it suitable for standard PCB designs.

Move-Blade (Sliding) V-Cut Machine

The Move-Blade V-Cut Machine uses a controlled sliding action to separate PCBs gradually. Instead of applying force at one point, the blade moves along the groove line, reducing sudden impact. This method helps protect sensitive components and solder joints. It is commonly used when PCB length varies or when product designs change frequently. As part of cutting machinery for PCB processing, it offers flexibility and improved edge quality in mixed production environments.

| Specification

| Parameter | Manual Single-Blade V-cut Machine | Multi-Blades LED Separator | Guillotine Type V-cut Machine | Move-Blade (Sliding) V-cut Machine | Multi Group Blades PCB V-cut Machine |

|---|---|---|---|---|---|

| Operation Type | Manual (hand sliding) | Manual (hand push) | Manual (pneumatic foot switch) | Manual (adjustable sliding) | Manual (multi-group push) |

| Blade Setup | 1 circular + 1 straight blade | 6 circular blades (3 groups top/bottom) | Single straight guillotine blade | 1 circular + 1 straight (adjustable gap) | Multiple groups of circular blades (custom multi-knife) |

| PCB Length | 0–350 mm | Unlimited (with 1.2m / 2.4m platforms) | 0–330 mm | 0–350 mm (typical) | Unlimited or very long (platform-dependent) |

| PCB Thickness | 0.8–5 mm | 0.2–5 mm | 0.3–5 mm | 0.8–5 mm | 0.2–5 mm (typical for multi-group) |

| Cutting Method | Single pass sliding | 3-phase (40% + 40% + 20%) | One-shot downward cut | Single pass with adjustable depth | Multi-group sequential cutting |

| Best Application | General PCBs, prototypes, medium volume | Long LED strips, aluminum PCBs, high-volume LED | FR4 boards, clean/dust-free edges | Mixed components, flexible V-depth | Extra-long or wide PCBs, high-efficiency separation |

| SMT Line Equipment List

I.C.T puts together full SMT lines that link loaders, printers, mounters, reflow ovens, AOI units, conveyors, and aluminum PCB cutting machine sections into one working system. Everything matches up right. When space runs tight, U-shaped layouts use the floor well without losing flow. The whole setup raises output, cuts mistakes, and delivers steady quality for automotive parts, LED products, and everyday electronics. Customers get help from start to finish—planning the line, setting it up, and tuning it so production runs smooth and strong from the first day onward.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

In 2025, an I.C.T engineer provided on-site technical support to an automotive electronics manufacturer in Uzbekistan. The customer purchased a complete SMT production line covering printing, placement, reflow soldering, inspection, depaneling, and auxiliary equipment. Due to limited factory space, I.C.T designed a compact U-shaped layout. During the support period, the engineer completed installation, commissioning, and operator training. After handover, the customer successfully ran the entire line independently with stable output.

| Service and Training Support

I.C.T offers comprehensive service that supports customers throughout the entire project. Before delivery, engineers assist with equipment selection and production planning based on PCB design and output targets. During installation, structured training ensures operators understand correct operation and safety procedures. After commissioning, remote technical support provides fast response to daily issues, while on-site service is available when required. This full-service approach helps customers maintain stable production and long-term equipment performance.

| Customer Feedback

Customers often praise I.C.T engineers for their professional attitude and practical experience. Installation guidance is clear and focused on real production needs. Equipment performance is recognized for stable operation and consistent cutting quality. Clients also value the careful packaging methods that protect machines during long-distance transportation. Quick response to technical questions further builds trust and long-term cooperation with I.C.T.

| Certifications and Standards

I.C.T equipment is manufactured under strict quality control systems. All machines comply with CE and RoHS standards to meet international safety and environmental requirements. Production follows ISO9001 management processes to ensure consistency and traceability. In addition, I.C.T holds multiple patents related to PCB depaneling structures and mechanical design. These certifications demonstrate I.C.T’s commitment to reliable engineering and continuous improvement.

| About I.C.T Company and Factory

I.C.T is a professional electronics manufacturing solution provider offering SMT, DIP, assembly, inspection, depaneling, and smart factory systems. With experienced engineers and modern manufacturing facilities, I.C.T focuses on delivering practical equipment for real production environments. Each machine is assembled, tested, and inspected before shipment. I.C.T serves customers worldwide across LED lighting, automotive electronics, industrial control, and consumer electronics industries.