Views: 0 Author: Site Editor Publish Time: 2026-01-22 Origin: Site

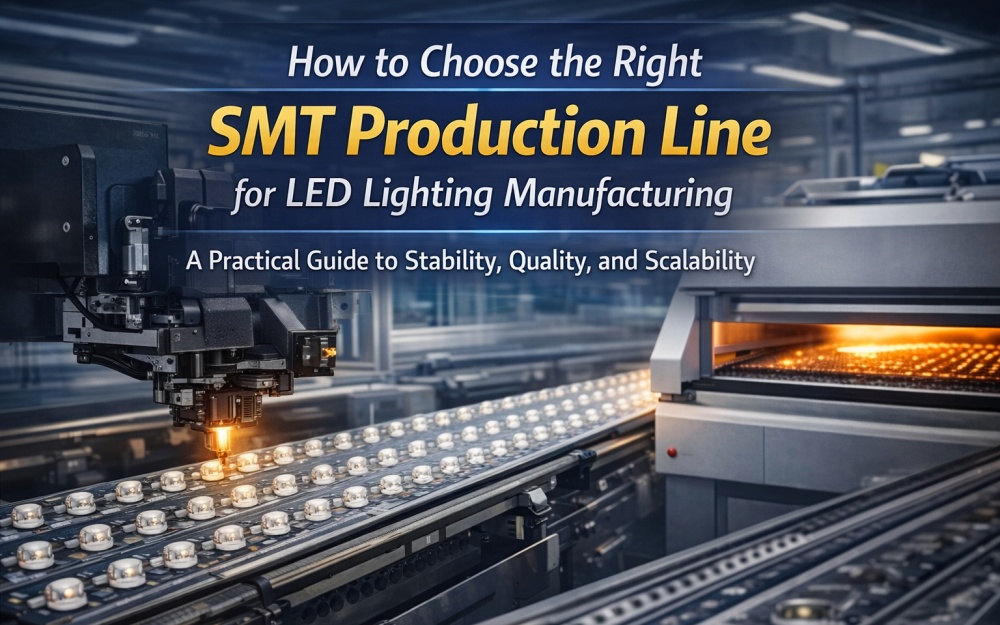

Choosing an SMT production line for LED lighting manufacturing is not just an equipment purchase—it is a long-term manufacturing decision that directly affects product reliability, light consistency, and operational cost.

Many LED manufacturers initially assume that LED PCB assembly is simpler than consumer electronics because of relatively low component variety. In reality, LED lighting introduces a unique set of challenges: long and thin PCB boards, strict thermal requirements, sensitivity to soldering consistency, and high expectations for long-term stability. A poorly configured SMT line may run acceptably in early production but gradually lead to color deviation, premature light decay, or rising rework rates after months of operation.

This article provides a practical, engineering-oriented guide to choosing the right SMT production line for LED lighting manufacturing—focused on stability, consistency, scalability, and cost control rather than headline speed alone.

For manufacturers planning long-term growth, selecting the right LED SMT production line configuration is not only about current output targets, but also about ensuring stable quality, consistent performance, and scalability for future product upgrades.

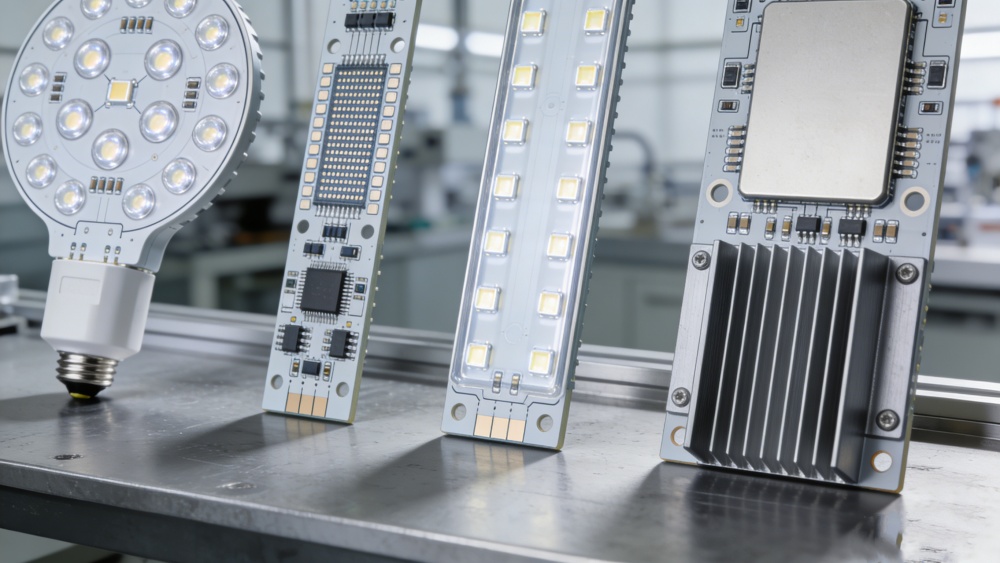

Unlike smartphones or compact consumer electronics, LED lighting products often use long, narrow, and relatively thin PCBs. Linear lights, panel lights, and outdoor luminaires commonly exceed standard PCB lengths and are prone to warpage during thermal processes.

These characteristics place higher demands on:

Board support during printing and placement

Conveyor width and transport stability

Thermal uniformity during reflow soldering

Ignoring these factors can result in solder joint stress, uneven heating, and gradual reliability issues that are difficult to detect during initial inspection.

LED lighting PCBs typically consist of:

Large quantities of LED chips

Resistors and capacitors in repetitive patterns

Limited package diversity compared to smartphones or wearables

While the layout appears simple, the challenge lies in maintaining placement and soldering consistency across thousands—or millions—of identical components. Minor variations in solder volume or placement pressure can accumulate into visible brightness inconsistency across finished products.

For LED manufacturing, repeatability and process control matter more than extreme placement speed.

LED performance is directly linked to solder joint quality and thermal behavior. Poor soldering can lead to:

Increased junction temperature

Faster lumen depreciation

Color shift over time

Unlike short-life consumer products, LED lighting is expected to operate reliably for years. SMT decisions made during line configuration will have a direct impact on field performance long after production begins.

In practice, SMT solutions for LED lighting manufacturing must be adapted to product structure, PCB size, and thermal requirements rather than using a one-size-fits-all approach.

LED bulbs and tubes are typically high-volume products with moderate PCB sizes. Key SMT priorities include:

Stable printing for consistent solder volume

Reliable placement at moderate speeds

Reflow processes focused on uniform heating rather than maximum throughput

For these applications, a well-balanced SMT line emphasizing uptime and yield often delivers better ROI than ultra-high-speed configurations.

Panel lights and linear luminaires introduce additional complexity due to board length and mechanical stress. SMT lines for these products should emphasize:

Enhanced PCB support during printing and placement

Conveyors designed for long-board handling

Reflow ovens with proven temperature uniformity across wide and long PCBs

Inadequate handling or uneven heating can cause subtle solder joint fatigue that only appears after prolonged operation.

High-power and outdoor LED products demand the highest soldering reliability. These applications often require:

Strict thermal profile control

Optional nitrogen reflow environments

Conservative process margins to ensure long-term durability

In such cases, investing in thermal stability and process control upfront significantly reduces warranty and maintenance costs later.

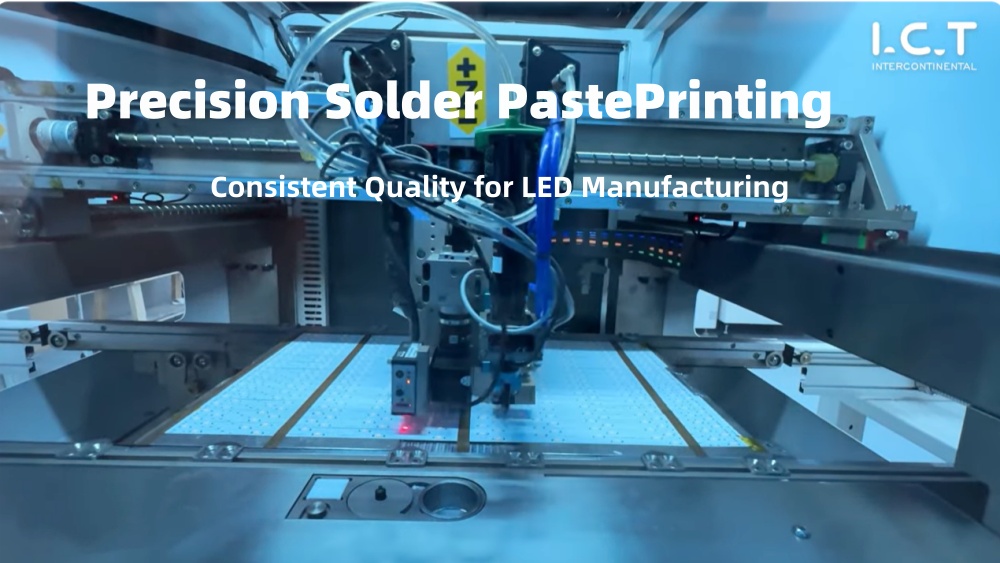

Solder paste printing is the starting point of LED SMT quality. Common challenges include:

Uneven solder volume on large LED pads

Paste slumping or insufficient release on long boards

Variations caused by inconsistent board support

Even minor solder volume deviations can lead to LED tilt, insufficient heat dissipation, or long-term reliability issues.

When selecting a solder paste printer for LED manufacturing, priority should be given to:

Stable frame and repeatable alignment

Effective underside board support for long PCBs

Consistent squeegee pressure across the entire print area

Speed is rarely the limiting factor. A slightly slower but more stable printer often delivers superior long-term results in LED production.

A stable and repeatable solder paste printing process for LED PCBs is often more valuable than higher printing speed, especially for long boards and large LED pads.

Solder Paste Inspection (SPI) is not mandatory for every LED factory, but it becomes increasingly valuable when:

Producing medium to high volumes

Manufacturing high-power or export-grade LED products

Struggling with solder-related defects or brightness inconsistency

SPI provides early detection of solder volume variation before placement and reflow amplify the problem.

LED components are sensitive to mechanical stress. Excessive placement force can damage chips internally without visible defects during AOI.

Key considerations include:

Adjustable placement force control

Stable nozzle alignment

Consistent placement behavior across long production runs

For LED SMT, gentle and repeatable placement often outweighs peak placement speed.

While high CPH figures may appear attractive, LED manufacturing benefits more from:

Stable placement accuracy over time

Minimal drift during long production shifts

Low defect rates rather than maximum output

A machine running slightly slower but consistently often yields higher effective productivity due to reduced rework.

When evaluating SMT pick and place machines for LED assembly, long-term placement stability and force control are often more important than headline CPH figures.

Many LED boards combine LED chips with standard resistors, capacitors, or connectors. Pick and place systems should:

Handle mixed component sizes smoothly

Support quick program changes for different product variants

Maintain accuracy without frequent recalibration

Flexibility is increasingly important as LED product lines diversify.

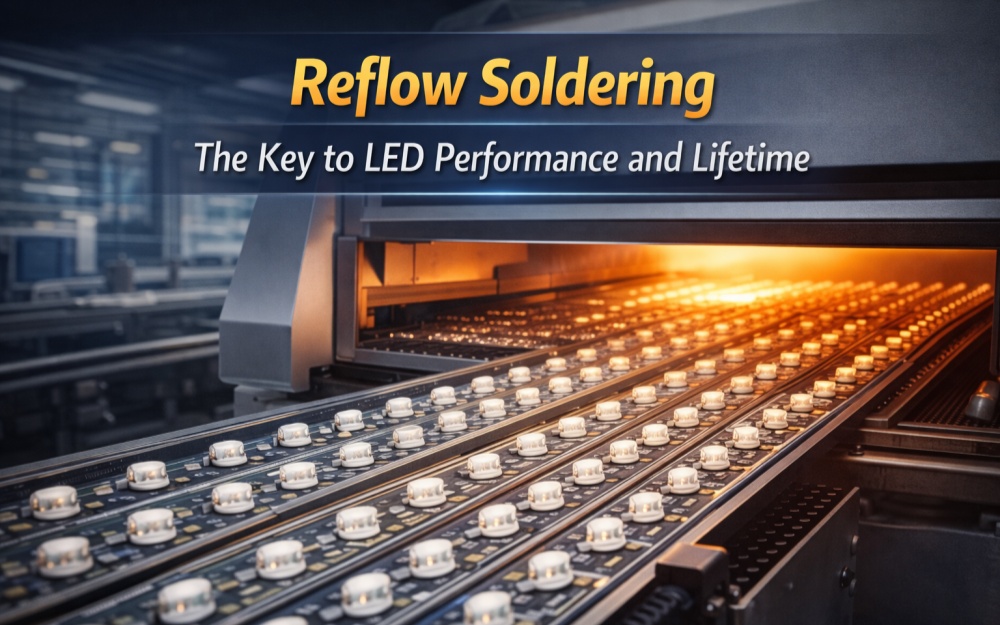

Selecting suitable reflow soldering solutions for LED lighting plays a decisive role in solder joint integrity, thermal consistency, and long-term LED performance.

Reflow soldering is the most critical process for LED reliability. Common challenges include:

Uneven heating across long PCBs

Inconsistent soak and peak temperatures

Excessive thermal stress leading to solder fatigue

A stable and repeatable thermal profile is essential for consistent light output and long service life.

Nitrogen reflow can offer benefits for certain LED applications:

Reduced oxidation

Improved solder wetting

More consistent joint formation

However, it also increases operating cost. For many standard LED products, a well-controlled air reflow process is sufficient. Nitrogen is typically justified for high-power or premium-grade LED manufacturing.

For long LED boards, reflow oven design becomes critical. Key factors include:

Adequate heating zone length

Stable airflow design

Proven temperature uniformity across board width and length

Short-term test results may appear acceptable, but long-term consistency determines real manufacturing success.

LED SMT defects differ from those in dense consumer electronics. Typical issues include:

LED misalignment or tilt

Insufficient or excessive solder

Polarity errors

Missing components

Inspection strategies should be tailored to these defect types rather than generic high-density PCB requirements.

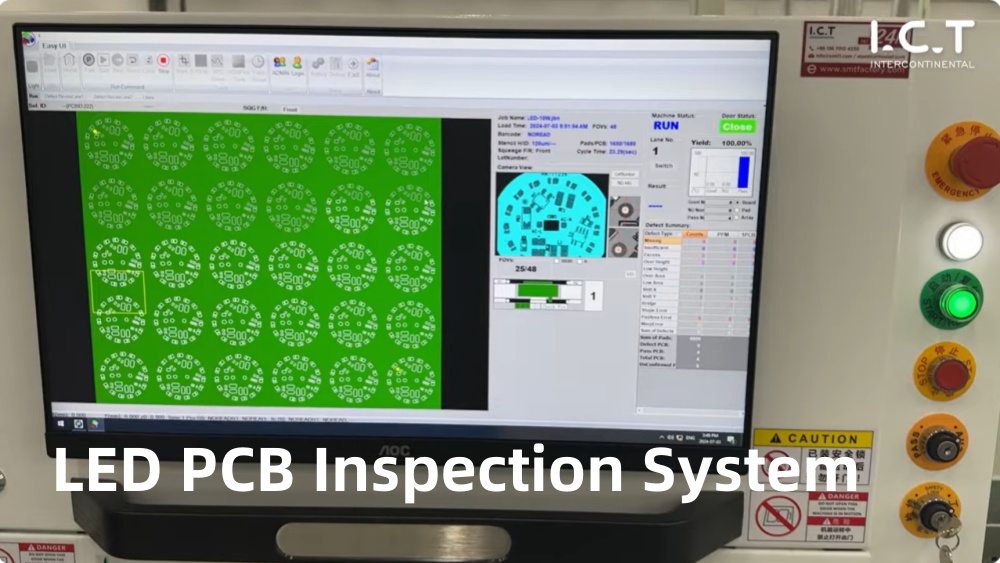

Automated Optical Inspection (AOI) is widely used in LED SMT lines. Effective AOI setups focus on:

LED position accuracy

Solder joint shape rather than micro-defect detection

High inspection speed without unnecessary complexity

Overly complex AOI programming often adds cost without improving yield.

Proper AOI inspection for LED PCB assembly should focus on alignment, polarity, and solder appearance rather than overly complex defect classification.

Not every LED factory needs full SPI and AOI coverage from day one. A practical approach is:

Start with AOI for placement and polarity control

Introduce SPI as volume or quality requirements increase

Inspection investment should grow alongside production scale and customer expectations.

Many LED manufacturers begin with a single SMT line. The key is ensuring that the initial configuration:

Does not limit future expansion

Allows additional equipment to be integrated smoothly

Avoids early obsolescence

Modular planning reduces risk and protects capital investment.

In LED SMT lines, certain equipment benefits from higher initial specification:

Reflow ovens with stable thermal performance

Printers with strong mechanical stability

Conveying systems capable of handling longer boards

Other elements, such as inspection depth or placement speed, can often be upgraded later.

Over-specifying equipment can be as problematic as under-investing. Common mistakes include:

Buying excessive speed for simple LED layouts

Investing in inspection beyond actual needs

Copying smartphone SMT configurations without adjustment

Balanced planning ensures optimal cost-performance over the entire product lifecycle.

Some recurring errors include:

Prioritizing speed over stability

Underestimating the impact of thermal consistency

Ignoring long PCB handling challenges

Treating LED SMT as identical to consumer electronics assembly

Avoiding these mistakes early saves significant cost and operational stress later.

For manufacturers seeking long-term stability, a complete SMT production line for LED lighting should be designed as an integrated system rather than a collection of individual machines.

Choosing the right SMT production line for LED lighting manufacturing requires a mindset shift. Success is not defined by maximum speed or lowest initial cost, but by long-term consistency, reliability, and scalability.

A well-designed LED SMT line delivers:

Stable soldering quality

Consistent light performance

Lower rework and warranty risk

Sustainable manufacturing growth

By focusing on real process requirements rather than headline specifications, LED manufacturers can build SMT production lines that support both current needs and future expansion with confidence.

content is empty!