SMT Production Line

I.C.T

Turnkey Drones SMT Production Line

| Availability: | |

|---|---|

| Quantity: | |

| Turnkey Drones Production Line Essentials

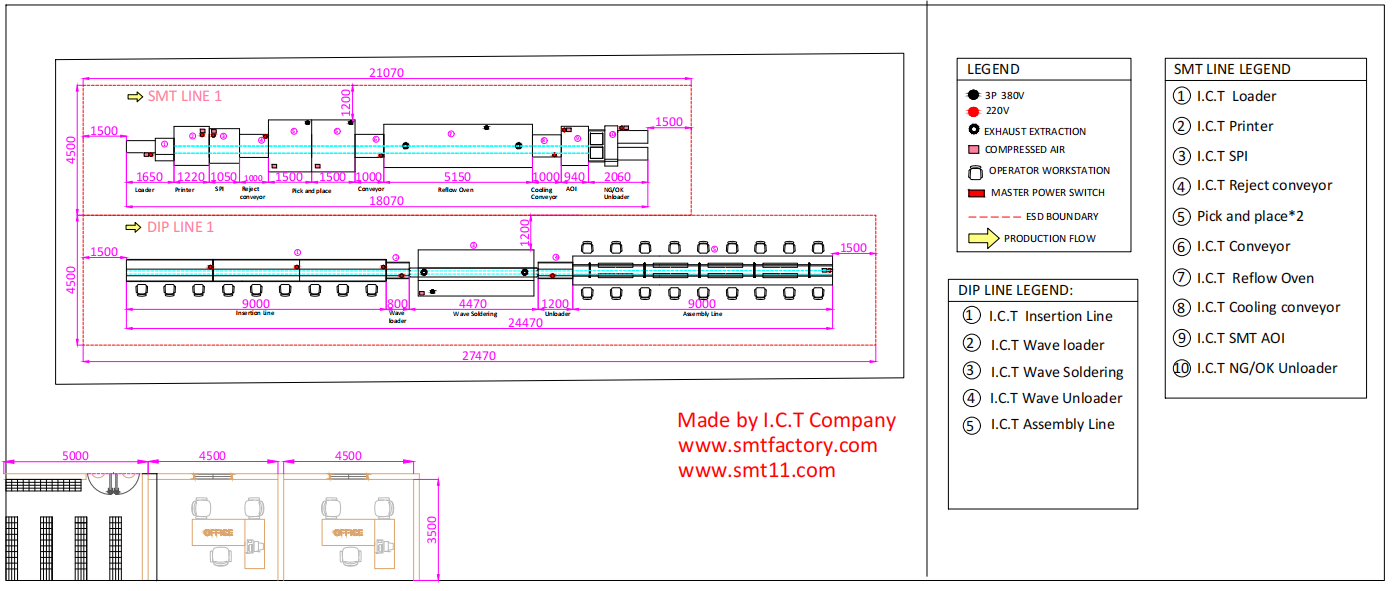

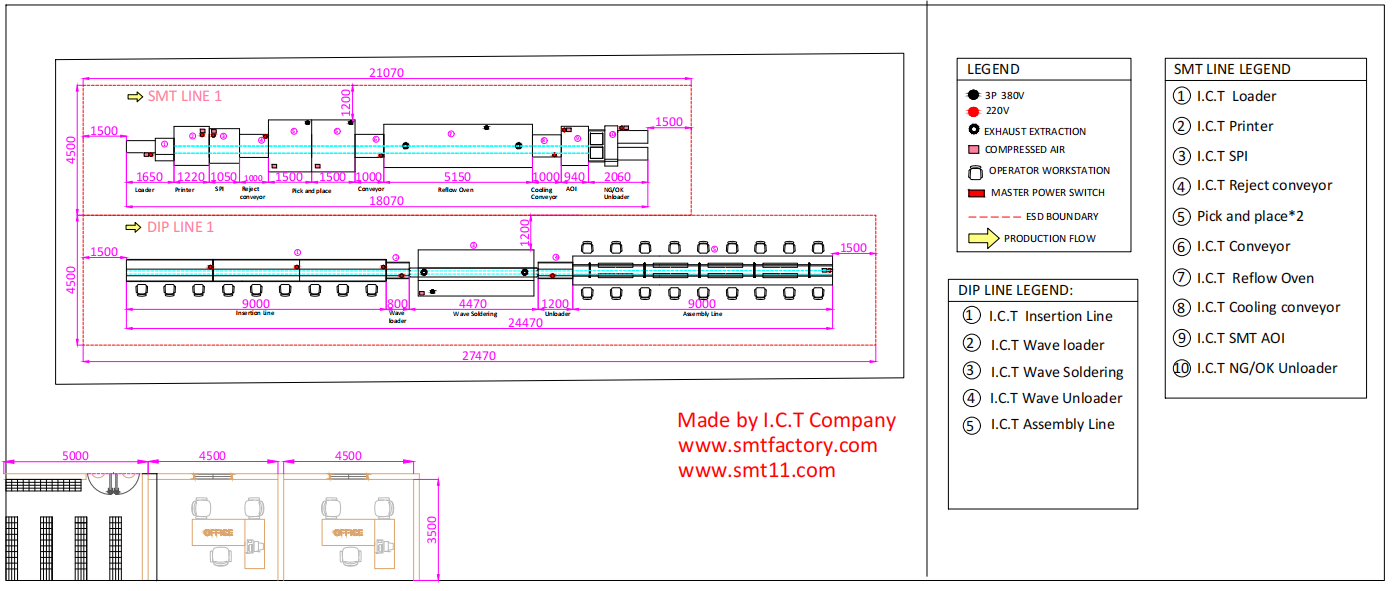

I.C.T launches Turnkey Drones Production Line via three owned factories and 22+ years SMT/DIP expertise, delivering factory planning, layouts, labor forecasts, ROI models for unmanned aerial vehicles and set-top boxes. Semi-auto or full-auto setups include loaders, printers, placers, reflow ovens, AOI, unloaders. Single operator per shift. 18Kw/H for sustainable ops. Serves drone makers, TV providers, EMS globally. 3-day install verifies air, power, exhaust, lighting, 23±1.5°C stability. 7-15 days teach software, upkeep, safety, fixes. 15+ years service worldwide. Full Auto SMT Line for STB Production adds MES, IoT for smart, high-yield factories. Plug-and-play accelerates drone/STB launches with scalability and minimal risks for new or expanding producers in competitive markets.

| Feature

Seamless Automation Flow

Turnkey Drones Production Line links machines through MES for real-time data, yield boosts, process tweaks in drone PCBA. Loaders adapt to small drone boards up to STB sizes. Printers use vision for paste on fine drone sensors or STB chips. Placers handle tiny 01005 parts at speed. Reflow keeps ±1.5°C for solid joints. AOI detects flaws instantly with AI.

Unloaders sort to next steps. Yields rise 25%+ in STB Production Line. Fits compact drone frames or larger STB panels. Buffers balance loads, remote tools oversee, auto recipes switch fast, traceability covers materials for varied drone/STB mixes, cutting changes, ensuring compliance and efficiency in high-volume runs with added flexibility for custom configurations.

Accurate Paste System

Printers in Turnkey Drones Production Line align stencils micron-precise, supporting compact frames for drone efficiency. Fast swaps reduce downtime. Auto dispense/clean cycles maintain quality. 3D SPI checks paste to prevent issues early. Key for dense drone flight controls or STB tuners. Handles multiple pastes, low-melt for heat-sensitive drone batteries. Squeegee adapts for even coverage on irregular boards, boosting print consistency, reducing defects, and supporting rapid prototyping in evolving drone designs with reliable results every time.

Reliable Reflow Process

Ovens offer 12+ zones with convection controls for uniform heating in Full Auto SMT Line for STB Production. Nitrogen for strong joints in drone motors or STB ports. Profiles auto-fit board types. Cooling avoids damage in small formats. Recovery systems hit 18Kw/H. Screens hold many recipes. Essential for durable drone/STB in field use. Conveyors sync via MES for smooth pacing, adjustable speeds, and integrated monitoring to prevent bottlenecks in continuous operations.

Smart Inspection Tools

AOI grabs 8K scans at speed, spotting misplacements or solder errors in drones/STB. AI learns from data for better accuracy. Feedback corrects placers live. Lowers escapes in Turnkey Drones Production Line. Analytics drive improvements. Auto rejects route without halts, logging details for audits and quick rework in mixed production environments.

Flexible Scaling Options

Semi-auto start with full-auto upgrades via modular additions. Layouts reserve for SPI, buffers, IoT. Models show 70% labor efficiency gains. Options include cleanroom, ESD, ERP connectivity.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T SMT led production line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB loader unloader | Automatically loads bare PCBs to the line. |

| Automatic stencil printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| SMT chip mounter | Mounts components onto PCB precisely. |

| Nitrogen Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| Solder paste inspection machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: SMT PCB laser printer/Label Mounter/Inkjet Printer |

| SMT stencil cleaning machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB V-cut machine | Cut the PCBA into the final product |

| Customer Success Video

Algerian functional phone team visited for verification demo. They supplied 10+ PCBs and parts; we ran live on configured line. Auto printer applied paste accurately. SPI validated deposits fully. RX-8 placed small components rapidly. RS-1R managed larger ones precisely. Tray feeder added shields smoothly. Reflow fused everything solidly. AOI confirmed no defects. 5700 separated panels cleanly. Perfect run showcased speed, accuracy for phone-like drone/STB apps. Mirrors Full Auto SMT Line for STB Production adaptability. Clients approved outputs, admired flow, plan similar Turnkey Drones Production Line setups with STB Production Line elements back home for efficient scaling.

| End-to-End Support System

Assigned managers oversee Turnkey Drones Production Line from start to upgrades. 3-day onsite: checks, trials, optimizations. 7-15 day program: MES, drone/STB handling, diagnostics, maintenance, safety. IoT predicts issues, enables remote help. Parts from 8 warehouses fast. 15-year expertise, multilingual teams. Yearly checks, updates keep peak performance for long-term drone/STB reliability and output growth.

| User Feedback Highlights

Praise for 2-hour remote fixes on Turnkey Drones Production Line. Ovens run 24/7 stably. Packaging survives shipping. Responses exceed expectations. Full Auto SMT Line for STB Production hits high volumes flawlessly. Easy interfaces speed staff training in drone/STB contexts.

| Quality Standards Met

CE ensures safety compliance. RoHS for green materials. ISO9001 quality processes. Patents on key tech. Proves Turnkey Drones Production Line trustworthiness globally. Extensive pre-ship tests included for every unit.

| About I.C.T Company and Factory

Three factories span 12000m² total. 89 staff include 20 engineers. 25 years serving 1600 clients in 72 countries. R&D creates tailored STB Production Line solutions. QC covers all stages rigorously. Global sales, service, warehouses, branches ensure quick support. Aim: leading cross-value electronics manufacturing platform with innovation focus.

| Turnkey Drones Production Line Essentials

I.C.T launches Turnkey Drones Production Line via three owned factories and 22+ years SMT/DIP expertise, delivering factory planning, layouts, labor forecasts, ROI models for unmanned aerial vehicles and set-top boxes. Semi-auto or full-auto setups include loaders, printers, placers, reflow ovens, AOI, unloaders. Single operator per shift. 18Kw/H for sustainable ops. Serves drone makers, TV providers, EMS globally. 3-day install verifies air, power, exhaust, lighting, 23±1.5°C stability. 7-15 days teach software, upkeep, safety, fixes. 15+ years service worldwide. Full Auto SMT Line for STB Production adds MES, IoT for smart, high-yield factories. Plug-and-play accelerates drone/STB launches with scalability and minimal risks for new or expanding producers in competitive markets.

| Feature

Seamless Automation Flow

Turnkey Drones Production Line links machines through MES for real-time data, yield boosts, process tweaks in drone PCBA. Loaders adapt to small drone boards up to STB sizes. Printers use vision for paste on fine drone sensors or STB chips. Placers handle tiny 01005 parts at speed. Reflow keeps ±1.5°C for solid joints. AOI detects flaws instantly with AI.

Unloaders sort to next steps. Yields rise 25%+ in STB Production Line. Fits compact drone frames or larger STB panels. Buffers balance loads, remote tools oversee, auto recipes switch fast, traceability covers materials for varied drone/STB mixes, cutting changes, ensuring compliance and efficiency in high-volume runs with added flexibility for custom configurations.

Accurate Paste System

Printers in Turnkey Drones Production Line align stencils micron-precise, supporting compact frames for drone efficiency. Fast swaps reduce downtime. Auto dispense/clean cycles maintain quality. 3D SPI checks paste to prevent issues early. Key for dense drone flight controls or STB tuners. Handles multiple pastes, low-melt for heat-sensitive drone batteries. Squeegee adapts for even coverage on irregular boards, boosting print consistency, reducing defects, and supporting rapid prototyping in evolving drone designs with reliable results every time.

Reliable Reflow Process

Ovens offer 12+ zones with convection controls for uniform heating in Full Auto SMT Line for STB Production. Nitrogen for strong joints in drone motors or STB ports. Profiles auto-fit board types. Cooling avoids damage in small formats. Recovery systems hit 18Kw/H. Screens hold many recipes. Essential for durable drone/STB in field use. Conveyors sync via MES for smooth pacing, adjustable speeds, and integrated monitoring to prevent bottlenecks in continuous operations.

Smart Inspection Tools

AOI grabs 8K scans at speed, spotting misplacements or solder errors in drones/STB. AI learns from data for better accuracy. Feedback corrects placers live. Lowers escapes in Turnkey Drones Production Line. Analytics drive improvements. Auto rejects route without halts, logging details for audits and quick rework in mixed production environments.

Flexible Scaling Options

Semi-auto start with full-auto upgrades via modular additions. Layouts reserve for SPI, buffers, IoT. Models show 70% labor efficiency gains. Options include cleanroom, ESD, ERP connectivity.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T SMT led production line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB loader unloader | Automatically loads bare PCBs to the line. |

| Automatic stencil printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| SMT chip mounter | Mounts components onto PCB precisely. |

| Nitrogen Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| Solder paste inspection machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: SMT PCB laser printer/Label Mounter/Inkjet Printer |

| SMT stencil cleaning machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB V-cut machine | Cut the PCBA into the final product |

| Customer Success Video

Algerian functional phone team visited for verification demo. They supplied 10+ PCBs and parts; we ran live on configured line. Auto printer applied paste accurately. SPI validated deposits fully. RX-8 placed small components rapidly. RS-1R managed larger ones precisely. Tray feeder added shields smoothly. Reflow fused everything solidly. AOI confirmed no defects. 5700 separated panels cleanly. Perfect run showcased speed, accuracy for phone-like drone/STB apps. Mirrors Full Auto SMT Line for STB Production adaptability. Clients approved outputs, admired flow, plan similar Turnkey Drones Production Line setups with STB Production Line elements back home for efficient scaling.

| End-to-End Support System

Assigned managers oversee Turnkey Drones Production Line from start to upgrades. 3-day onsite: checks, trials, optimizations. 7-15 day program: MES, drone/STB handling, diagnostics, maintenance, safety. IoT predicts issues, enables remote help. Parts from 8 warehouses fast. 15-year expertise, multilingual teams. Yearly checks, updates keep peak performance for long-term drone/STB reliability and output growth.

| User Feedback Highlights

Praise for 2-hour remote fixes on Turnkey Drones Production Line. Ovens run 24/7 stably. Packaging survives shipping. Responses exceed expectations. Full Auto SMT Line for STB Production hits high volumes flawlessly. Easy interfaces speed staff training in drone/STB contexts.

| Quality Standards Met

CE ensures safety compliance. RoHS for green materials. ISO9001 quality processes. Patents on key tech. Proves Turnkey Drones Production Line trustworthiness globally. Extensive pre-ship tests included for every unit.

| About I.C.T Company and Factory

Three factories span 12000m² total. 89 staff include 20 engineers. 25 years serving 1600 clients in 72 countries. R&D creates tailored STB Production Line solutions. QC covers all stages rigorously. Global sales, service, warehouses, branches ensure quick support. Aim: leading cross-value electronics manufacturing platform with innovation focus.

How does a turnkey drone SMT production line differ from traditional assembly methods?

Answer: A turnkey drone SMT (Surface Mount Technology) production line integrates automated assembly processes, including soldering, component placement, and inspection, into a seamless workflow. Unlike traditional methods, which may involve manual labor and multiple stages of assembly, a turnkey SMT production line streamlines the manufacturing process, leading to higher efficiency, consistency, and quality control.

What are the key components required for setting up a turnkey drone SMT production line?

Answer: Setting up a turnkey drone SMT production line requires several key components, including SMT placement machines, soldering equipment (such as reflow ovens), conveyors for material handling, inspection systems (such as AOI - Automated Optical Inspection), and software for programming and control. Additionally, auxiliary equipment like stencil printers, solder paste inspection machines, and component feeders are essential for a complete and efficient assembly line.

What are the benefits of investing in a turnkey drone SMT production line for drone manufacturing companies?

Answer: Investing in a turnkey drone SMT production line offers several benefits for drone manufacturing companies. These include increased production speed and capacity, improved product quality and consistency, reduced labor costs, enhanced flexibility in production processes, and better adaptability to changes in product design or specifications. Additionally, the automated nature of the SMT production line minimizes the risk of human error and ensures a more precise and reliable assembly process.

How does a turnkey drone SMT production line differ from traditional assembly methods?

Answer: A turnkey drone SMT (Surface Mount Technology) production line integrates automated assembly processes, including soldering, component placement, and inspection, into a seamless workflow. Unlike traditional methods, which may involve manual labor and multiple stages of assembly, a turnkey SMT production line streamlines the manufacturing process, leading to higher efficiency, consistency, and quality control.

What are the key components required for setting up a turnkey drone SMT production line?

Answer: Setting up a turnkey drone SMT production line requires several key components, including SMT placement machines, soldering equipment (such as reflow ovens), conveyors for material handling, inspection systems (such as AOI - Automated Optical Inspection), and software for programming and control. Additionally, auxiliary equipment like stencil printers, solder paste inspection machines, and component feeders are essential for a complete and efficient assembly line.

What are the benefits of investing in a turnkey drone SMT production line for drone manufacturing companies?

Answer: Investing in a turnkey drone SMT production line offers several benefits for drone manufacturing companies. These include increased production speed and capacity, improved product quality and consistency, reduced labor costs, enhanced flexibility in production processes, and better adaptability to changes in product design or specifications. Additionally, the automated nature of the SMT production line minimizes the risk of human error and ensures a more precise and reliable assembly process.