Semiconductor Expertise:

Versatility Across Industries:

Battery Brilliance:

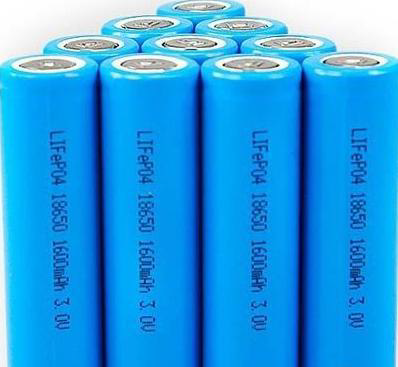

Powerful Battery Inspection: Detect defects in various battery types, including power batteries, cylinders, flexible packaging, square shells, and laminates.

X-8000

I.C.T

Semiconductor X Ray Inspection System

| Availability: | |

|---|---|

| Quantity: | |

Powerful Battery Inspection: Detect defects in various battery types, including power batteries, cylinders, flexible packaging, square shells, and laminates.

Joystick Control

Programming Control

Optional: Digital HD X-RAY flat detector

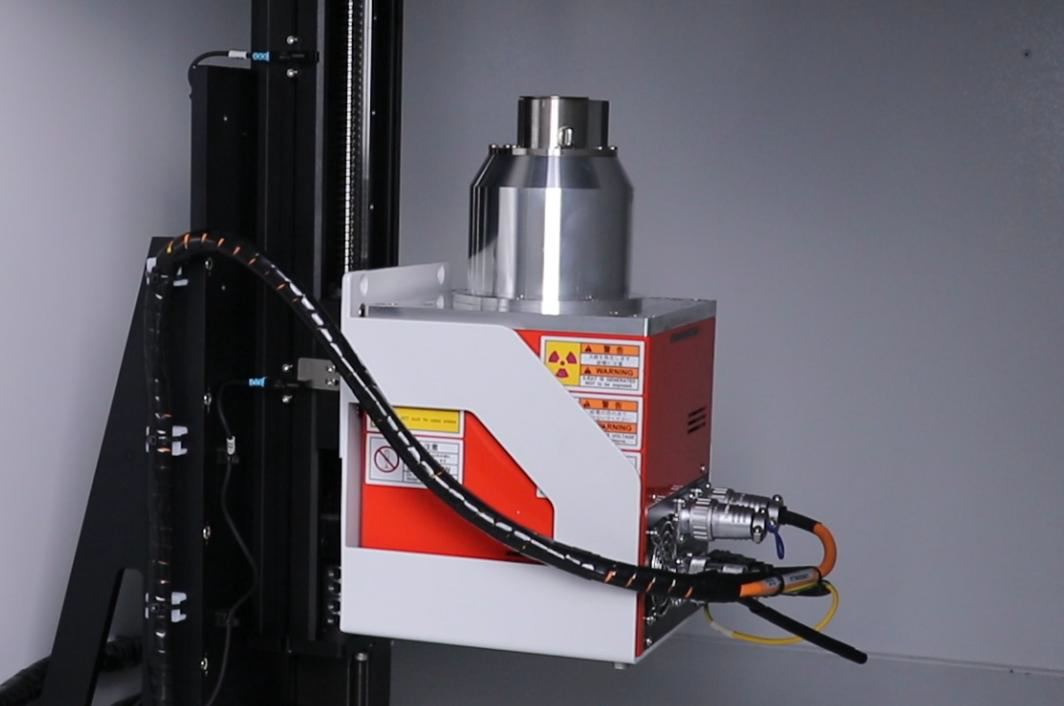

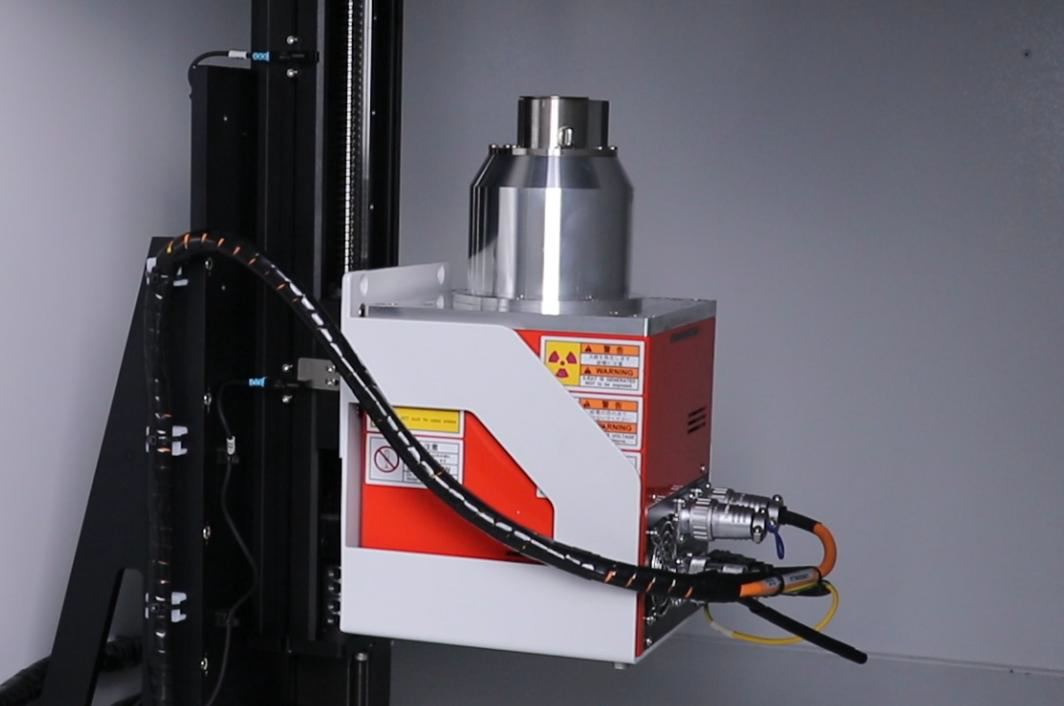

XRAY Tube

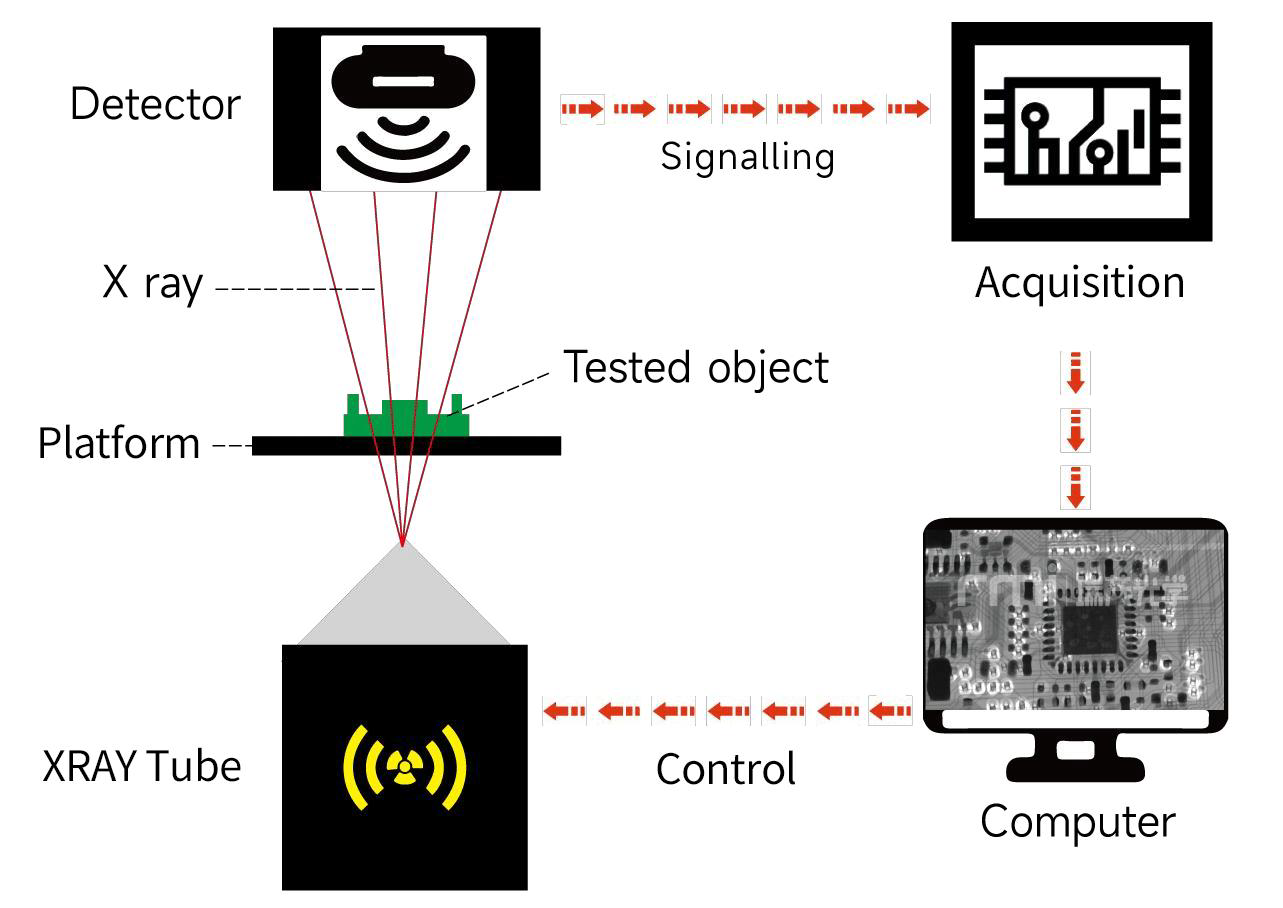

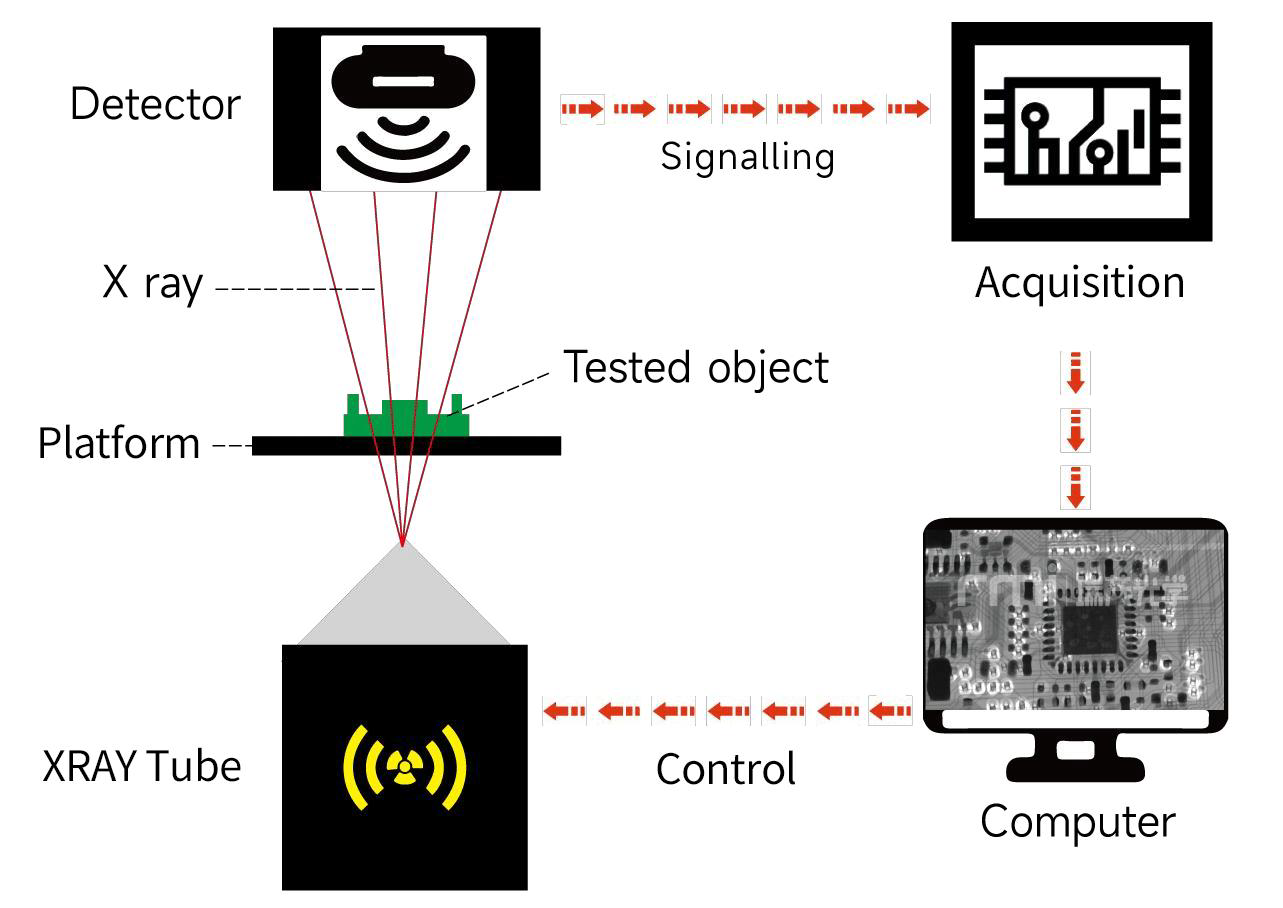

The computer controls the intensity of the XRAY tube emitted by the XRAY, penetrates the Tested object, reaches the Detector, and the Image Acquisition card converts the signal and sends it back to the computer.

SMT, BGA, CSP, Flip Chip, MINI LED package, PCBA assembly, Semiconductor packaging, Lithium battery, Electronic components, Automotive parts, Photo-voltaic, Aluminium die-casting, Moulding plastic, Ceramics, other special industries.

Semiconductor packaging

PCBA

Electronic harness

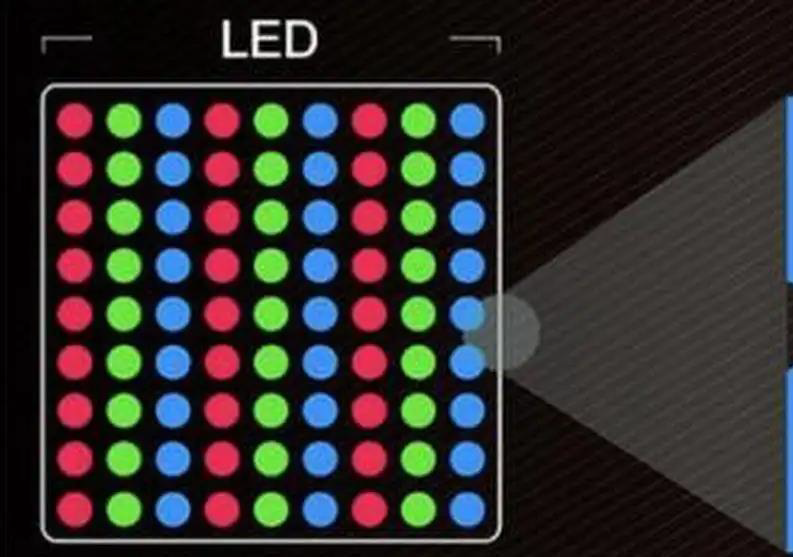

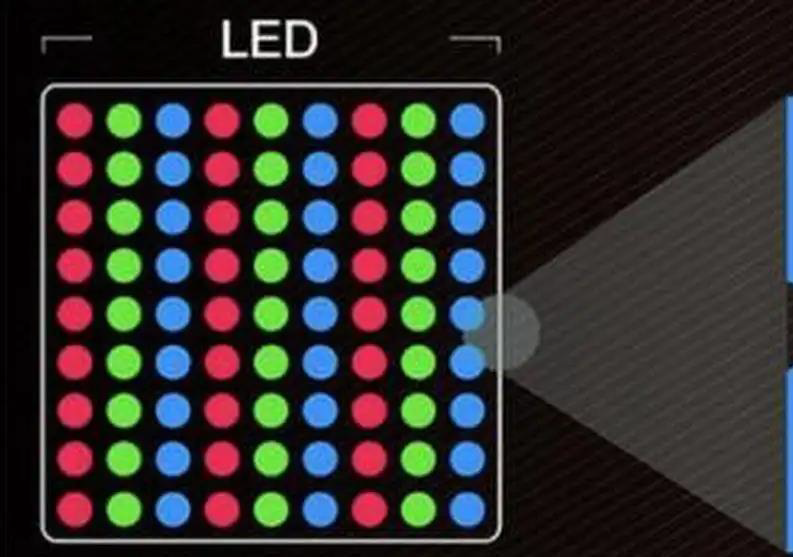

MINI LED Package

Cable

Car sensor

Lithium battery

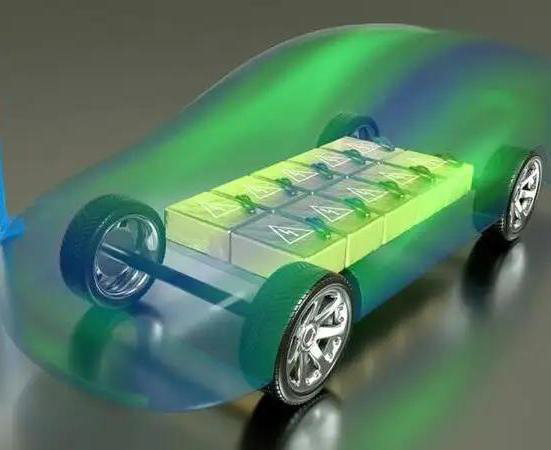

Power Battery

| Item | Model | I.C.T X-8000 |

| X-Ray Tube | Type | Enclosed reflective target microfocus X-ray source |

| Voltage | 130kV | |

| Electric current | 300uA | |

| Focal spot size | 3μm | |

| Maximum input power | 39W | |

| X-ray beam angle (cone) | 105 degree | |

| Distance from focus to object | 10mm | |

| Flat panel | Imaging area | 160mm*160mm |

| Photosensitive unit size | 85μm | |

| Resolution | 1644*1648px | |

| Detector tilt angle | 0-60° | |

| Image frame rate (1×1) | 30fps | |

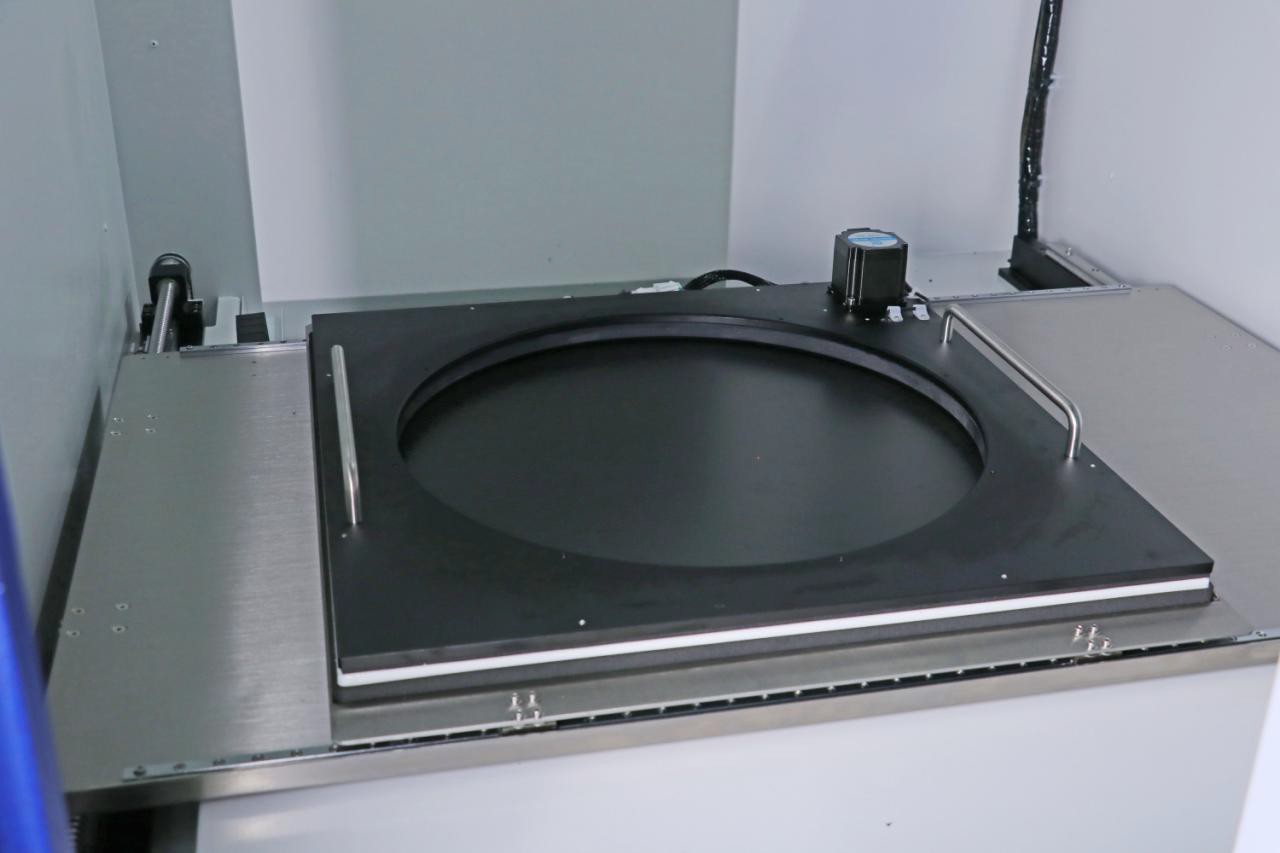

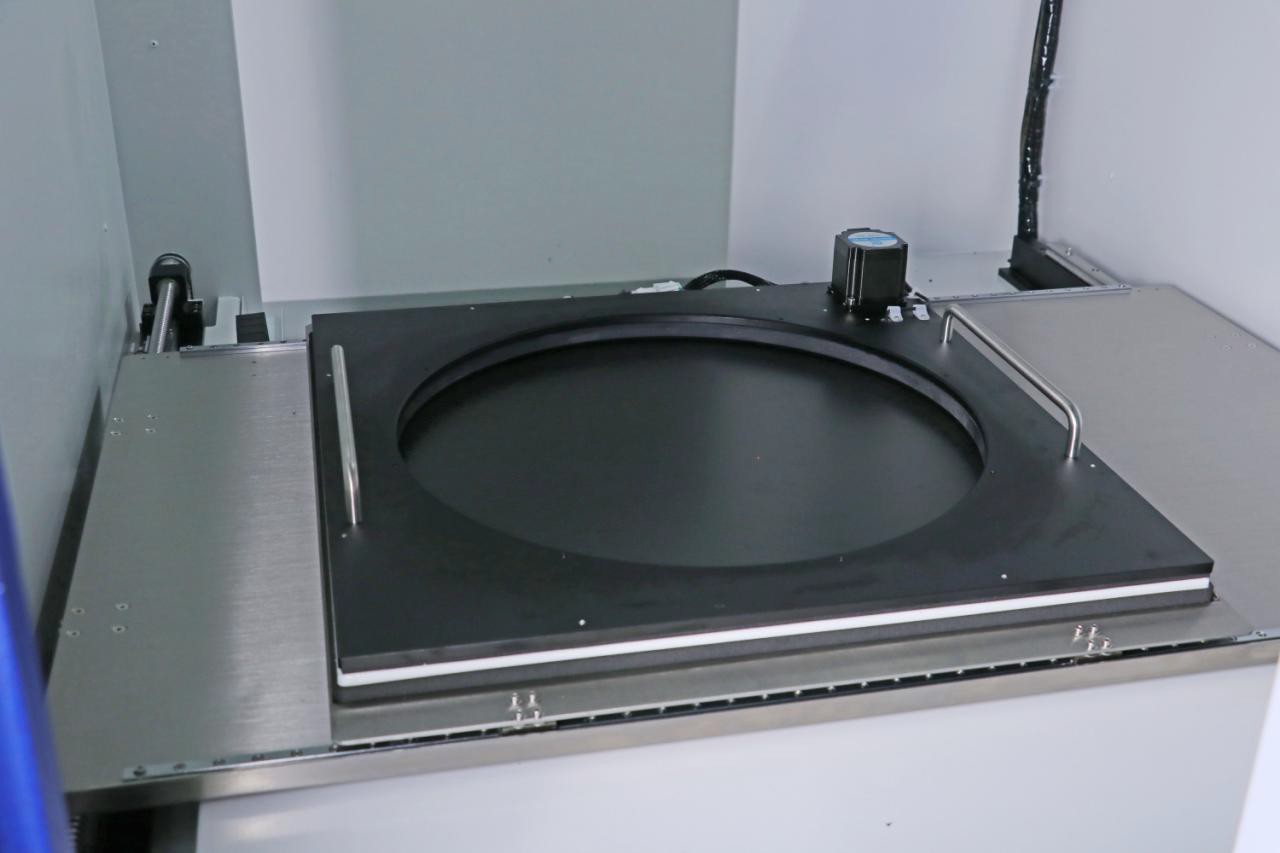

| Platform | Max. Loading size | 540mm*540mm |

| Max. Inspection area | 510mm*510mm | |

| Max. Loading weight | 10kg | |

| Platform rotation | 360° platform rotation (Optional) | |

| Machine | Inner lead sheet | 5mm thick lead plate (isolation radiation) |

| Dimension | 1110mm(L)*1350mm(W)*2000mm(H) | |

| Weight | 1050KG | |

| Computer | 24-inch widescreen LCD monitor/I5 processor/4G memory/250G hard disk | |

| Power | AC110/220V, 10A, 1300W |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

Powerful Battery Inspection: Detect defects in various battery types, including power batteries, cylinders, flexible packaging, square shells, and laminates.

Joystick Control

Programming Control

Optional: Digital HD X-RAY flat detector

XRAY Tube

The computer controls the intensity of the XRAY tube emitted by the XRAY, penetrates the Tested object, reaches the Detector, and the Image Acquisition card converts the signal and sends it back to the computer.

SMT, BGA, CSP, Flip Chip, MINI LED package, PCBA assembly, Semiconductor packaging, Lithium battery, Electronic components, Automotive parts, Photo-voltaic, Aluminium die-casting, Moulding plastic, Ceramics, other special industries.

Semiconductor packaging

PCBA

Electronic harness

MINI LED Package

Cable

Car sensor

Lithium battery

Power Battery

| Item | Model | I.C.T X-8000 |

| X-Ray Tube | Type | Enclosed reflective target microfocus X-ray source |

| Voltage | 130kV | |

| Electric current | 300uA | |

| Focal spot size | 3μm | |

| Maximum input power | 39W | |

| X-ray beam angle (cone) | 105 degree | |

| Distance from focus to object | 10mm | |

| Flat panel | Imaging area | 160mm*160mm |

| Photosensitive unit size | 85μm | |

| Resolution | 1644*1648px | |

| Detector tilt angle | 0-60° | |

| Image frame rate (1×1) | 30fps | |

| Platform | Max. Loading size | 540mm*540mm |

| Max. Inspection area | 510mm*510mm | |

| Max. Loading weight | 10kg | |

| Platform rotation | 360° platform rotation (Optional) | |

| Machine | Inner lead sheet | 5mm thick lead plate (isolation radiation) |

| Dimension | 1110mm(L)*1350mm(W)*2000mm(H) | |

| Weight | 1050KG | |

| Computer | 24-inch widescreen LCD monitor/I5 processor/4G memory/250G hard disk | |

| Power | AC110/220V, 10A, 1300W |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT