I.C.T-X7100

I.C.T

X-RAY machine

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T X-7100 PCB X-ray Inspection Machine

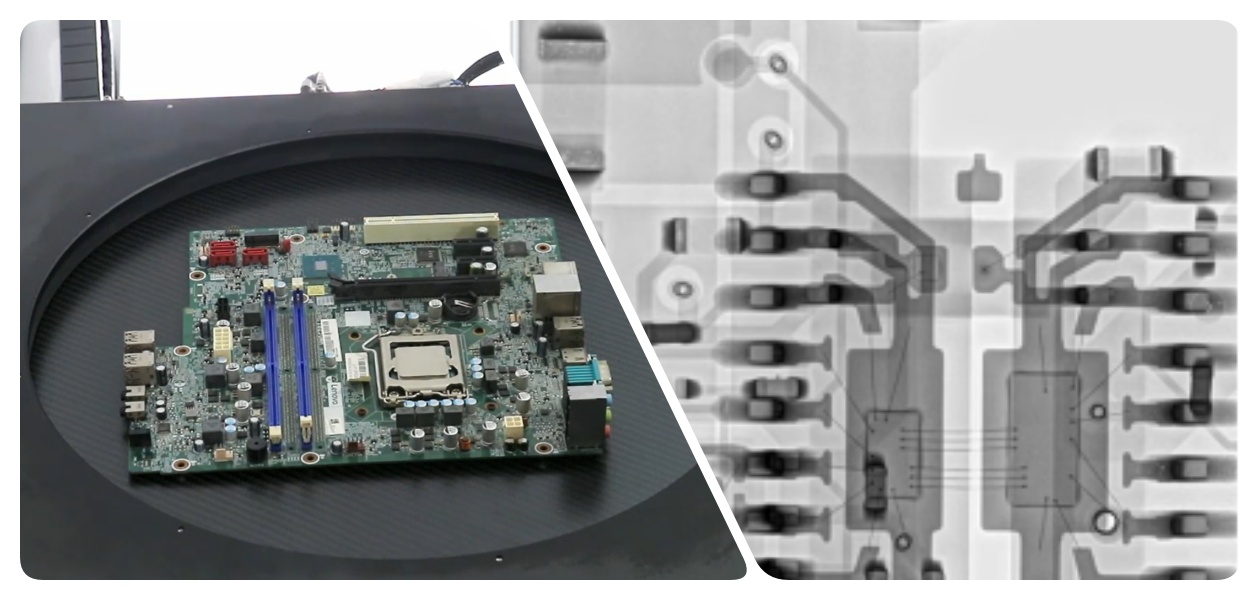

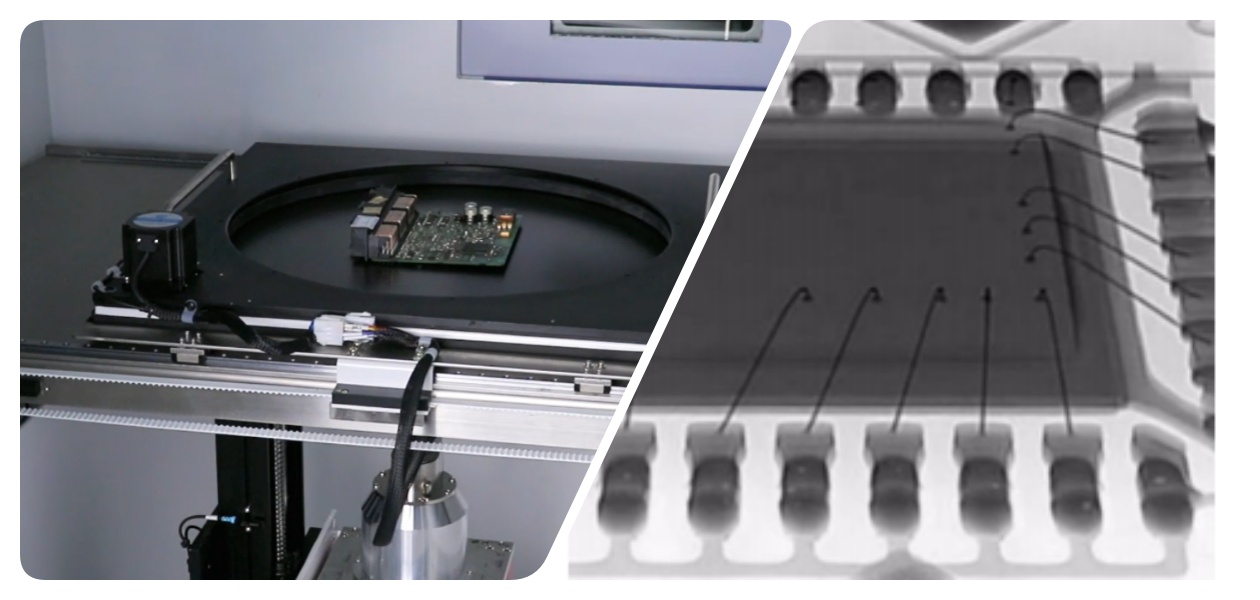

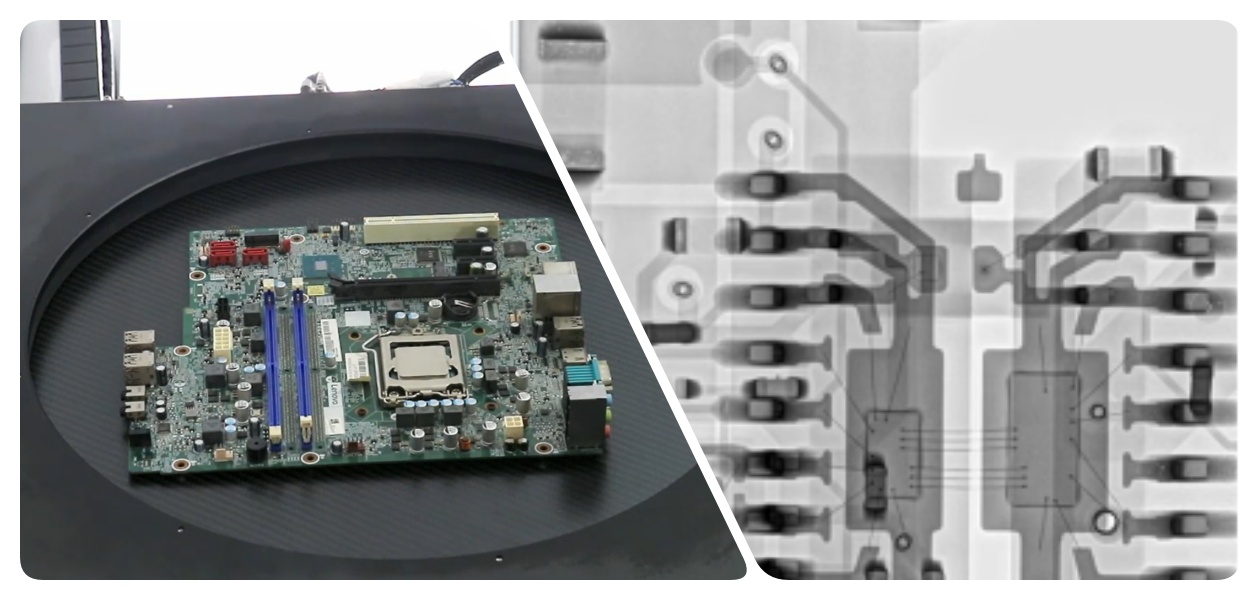

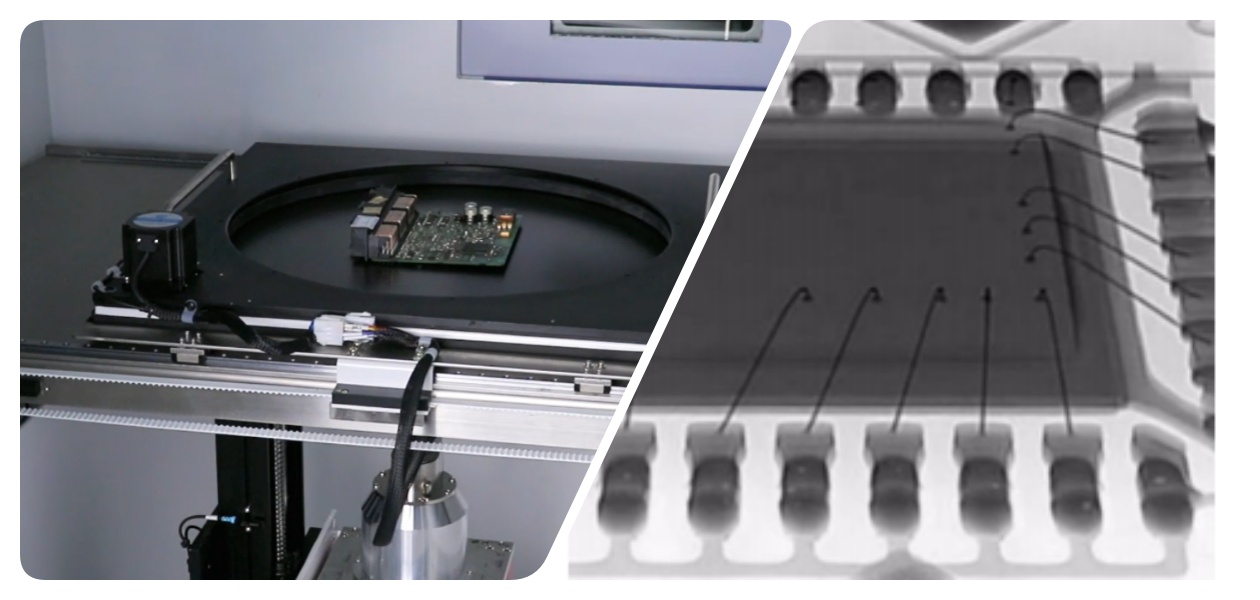

The I.C.T X-7100 is a reliable offline x-ray machin in smt pcba designed for modern electronics manufacturing. This advanced smt x-ray inspection system detects BGA voids, cold solder joints, cracks, wire-bonding failures, missing solder, short circuits, open circuits, and internal foreign objects that standard AOI cannot find. With 1000× system magnification, 60° tilting detector, one-button void analysis, and full CNC automation, operators get sharp, repeatable results with almost no training. Radiation stays safely under 1 µSv/h, and the machine carries CE, RoHS, ISO9001, and AERB certifications for complete global compliance.

| Feature

The x-ray machin in smt pcba features a 1536×1536 digital flat-panel detector paired with Japan’s premium Hamamatsu closed X-ray tube for outstanding clarity and long-term stability. Real-time correction, multiple gain modes, built-in temperature sensors, and passive cooling produce crisp images of tiny solder balls and gold wires even during extended batch runs. Manufacturers worldwide trust this x-ray machin in smt pcba to catch defects early in PCBA, lithium battery, automotive electronics, routers, wire harnesses, displays, and LED production.

A single button activates the intelligent measurement suite inside the x-ray machin in smt pcba, instantly calculating bubble size, void percentage, and solder climb height with color simulation for clear visibility. Intuitive joystick control and visual navigation turn complex internal checks into simple pass/fail decisions in seconds. Factories rely on this smt x-ray inspection feature to meet strict IPC-Class 3 standards and pass customer audits without slowing production.

The detector tilts 0–60° and the stage offers optional 360° rotation, giving the x-ray machin in smt pcba unmatched flexibility to inspect multi-layer PCBs and tall components. Easy-to-use software and precise positioning make advanced angled inspections effortless. This capability makes the X-7100 the top choice for both R&D laboratories and high-mix SMT production floors that demand maximum visibility.

| Specification

| Item | Model | I.C.T X-7100 |

| X-Ray Tube | Type | Closed tube |

| Voltage | 90kV | |

| Electric current | 200uA | |

| Spatial resolution | 5μm | |

| Flat panel | Image capture method | Flat panel digital imaging |

| Imaging accuracy | 85μm | |

| A/D conversion quantized density value | 16bit (65536) | |

| Resolution | 1280*1024px | |

| Acquisition frame rate | 30 FPS | |

| System | Magnification | 200x |

| Operating system | Windows 10 | |

| Power | AC110-220V, 50-60HZ, 1200W | |

| Radiation safety test | <1 uSV/H | |

| Structure | Max. Loading size | 540mm*540mm |

| Max. Inspection area | 510mm*510mm | |

| Max. Loading weight | ≤10kg | |

| Platform rotation angle | 60° | |

| Dimension | 1100*1360*1750mm | |

| Weight | 950kg | |

| Platform movement | Automatic / Manual |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

Inspects internal solder joint integrity and detects hidden defects. | |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Cutting Machine | Cut the PCBA into the final product |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

The official video showcases the I.C.T X-7100 x-ray machin in smt pcba in real factory conditions. It begins with a complete exterior tour highlighting the sleek design and intuitive controls, then opens the cabinet to reveal the premium Hamamatsu tube and digital detector. Live operation follows: automatic batch scanning of PCBA boards, instant void measurement, smooth 60° tilt views of BGA joints, and clear imaging of lithium batteries and wire harnesses. Viewers see exactly how this powerful x-ray machin in smt pcba improves defect detection and quality control.

| Professional Global Training & Support

I.C.T provides comprehensive lifetime support for every x-ray machin in smt pcba. Professional engineers perform on-site installation, detailed operator training, and precise calibration using clear, step-by-step courses. 24/7 spare-parts availability, remote diagnostics, and free software upgrades keep downtime near zero. Regular preventive maintenance programs and global service centers ensure the equipment continues delivering peak performance year after year, protecting the customer’s investment from day one.

| Customer Feedback

Customers consistently praise the rapid expertise and response time of I.C.T engineers whenever support is needed. They love the razor-sharp images, rock-solid reliability, and simple daily operation of the x-ray machin in smt pcba. Many highlight the bullet-proof export packaging and lightning-fast technical assistance that exceed expectations. Overall, buyers describe I.C.T as a true long-term partner that genuinely cares about their success.

| Our Certification

Every I.C.T x-ray machin in smt pcba carries CE, RoHS, ISO9001, AERB radiation certification, and multiple innovation patents. These globally recognized marks prove unwavering commitment to safety, environmental responsibility, and cutting-edge technology. Factories across Europe, America, and Asia accept these certificates without question when approving new SMT equipment for their high-reliability production lines

| About Us and Factory

Since 2012, vestiti I.C.T has grown rapidly with its own 12,000 m² R&D and manufacturing campus in Dongguan, China. Nearly 90 staff members and 20 dedicated engineers design, build, and rigorously test every machine under strict ISO9001 quality systems. The company already serves over 1,600 customers in 72 countries with complete SMT factory solutions. Partnering with I.C.T means working with a proven global leader fully focused on customer success and long-term growth.

| I.C.T X-7100 PCB X-ray Inspection Machine

The I.C.T X-7100 is a reliable offline x-ray machin in smt pcba designed for modern electronics manufacturing. This advanced smt x-ray inspection system detects BGA voids, cold solder joints, cracks, wire-bonding failures, missing solder, short circuits, open circuits, and internal foreign objects that standard AOI cannot find. With 1000× system magnification, 60° tilting detector, one-button void analysis, and full CNC automation, operators get sharp, repeatable results with almost no training. Radiation stays safely under 1 µSv/h, and the machine carries CE, RoHS, ISO9001, and AERB certifications for complete global compliance.

| Feature

The x-ray machin in smt pcba features a 1536×1536 digital flat-panel detector paired with Japan’s premium Hamamatsu closed X-ray tube for outstanding clarity and long-term stability. Real-time correction, multiple gain modes, built-in temperature sensors, and passive cooling produce crisp images of tiny solder balls and gold wires even during extended batch runs. Manufacturers worldwide trust this x-ray machin in smt pcba to catch defects early in PCBA, lithium battery, automotive electronics, routers, wire harnesses, displays, and LED production.

A single button activates the intelligent measurement suite inside the x-ray machin in smt pcba, instantly calculating bubble size, void percentage, and solder climb height with color simulation for clear visibility. Intuitive joystick control and visual navigation turn complex internal checks into simple pass/fail decisions in seconds. Factories rely on this smt x-ray inspection feature to meet strict IPC-Class 3 standards and pass customer audits without slowing production.

The detector tilts 0–60° and the stage offers optional 360° rotation, giving the x-ray machin in smt pcba unmatched flexibility to inspect multi-layer PCBs and tall components. Easy-to-use software and precise positioning make advanced angled inspections effortless. This capability makes the X-7100 the top choice for both R&D laboratories and high-mix SMT production floors that demand maximum visibility.

| Specification

| Item | Model | I.C.T X-7100 |

| X-Ray Tube | Type | Closed tube |

| Voltage | 90kV | |

| Electric current | 200uA | |

| Spatial resolution | 5μm | |

| Flat panel | Image capture method | Flat panel digital imaging |

| Imaging accuracy | 85μm | |

| A/D conversion quantized density value | 16bit (65536) | |

| Resolution | 1280*1024px | |

| Acquisition frame rate | 30 FPS | |

| System | Magnification | 200x |

| Operating system | Windows 10 | |

| Power | AC110-220V, 50-60HZ, 1200W | |

| Radiation safety test | <1 uSV/H | |

| Structure | Max. Loading size | 540mm*540mm |

| Max. Inspection area | 510mm*510mm | |

| Max. Loading weight | ≤10kg | |

| Platform rotation angle | 60° | |

| Dimension | 1100*1360*1750mm | |

| Weight | 950kg | |

| Platform movement | Automatic / Manual |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

Inspects internal solder joint integrity and detects hidden defects. | |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Cutting Machine | Cut the PCBA into the final product |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

The official video showcases the I.C.T X-7100 x-ray machin in smt pcba in real factory conditions. It begins with a complete exterior tour highlighting the sleek design and intuitive controls, then opens the cabinet to reveal the premium Hamamatsu tube and digital detector. Live operation follows: automatic batch scanning of PCBA boards, instant void measurement, smooth 60° tilt views of BGA joints, and clear imaging of lithium batteries and wire harnesses. Viewers see exactly how this powerful x-ray machin in smt pcba improves defect detection and quality control.

| Professional Global Training & Support

I.C.T provides comprehensive lifetime support for every x-ray machin in smt pcba. Professional engineers perform on-site installation, detailed operator training, and precise calibration using clear, step-by-step courses. 24/7 spare-parts availability, remote diagnostics, and free software upgrades keep downtime near zero. Regular preventive maintenance programs and global service centers ensure the equipment continues delivering peak performance year after year, protecting the customer’s investment from day one.

| Customer Feedback

Customers consistently praise the rapid expertise and response time of I.C.T engineers whenever support is needed. They love the razor-sharp images, rock-solid reliability, and simple daily operation of the x-ray machin in smt pcba. Many highlight the bullet-proof export packaging and lightning-fast technical assistance that exceed expectations. Overall, buyers describe I.C.T as a true long-term partner that genuinely cares about their success.

| Our Certification

Every I.C.T x-ray machin in smt pcba carries CE, RoHS, ISO9001, AERB radiation certification, and multiple innovation patents. These globally recognized marks prove unwavering commitment to safety, environmental responsibility, and cutting-edge technology. Factories across Europe, America, and Asia accept these certificates without question when approving new SMT equipment for their high-reliability production lines

| About Us and Factory

Since 2012, vestiti I.C.T has grown rapidly with its own 12,000 m² R&D and manufacturing campus in Dongguan, China. Nearly 90 staff members and 20 dedicated engineers design, build, and rigorously test every machine under strict ISO9001 quality systems. The company already serves over 1,600 customers in 72 countries with complete SMT factory solutions. Partnering with I.C.T means working with a proven global leader fully focused on customer success and long-term growth.