A reliable cleaning machine for PCB board that removes flux residues and improves PCBA reliability after soldering.

a. Efficient removal of flux and solder residues

b. Stable batch cleaning for SMT and THT boards

c. Dual-layer basket for flexible production

d. Closed-loop filtration saves cleaning liquid

e. Controlled drying for moisture-free PCBA

f. Simple operation with PLC control system

g. I.C.T global technical support and service

I.C.T-5600

I.C.T

PCB Cleaning Machine

| Availability: | |

|---|---|

| Quantity: | |

| Offline PCBA Cleaning Solution

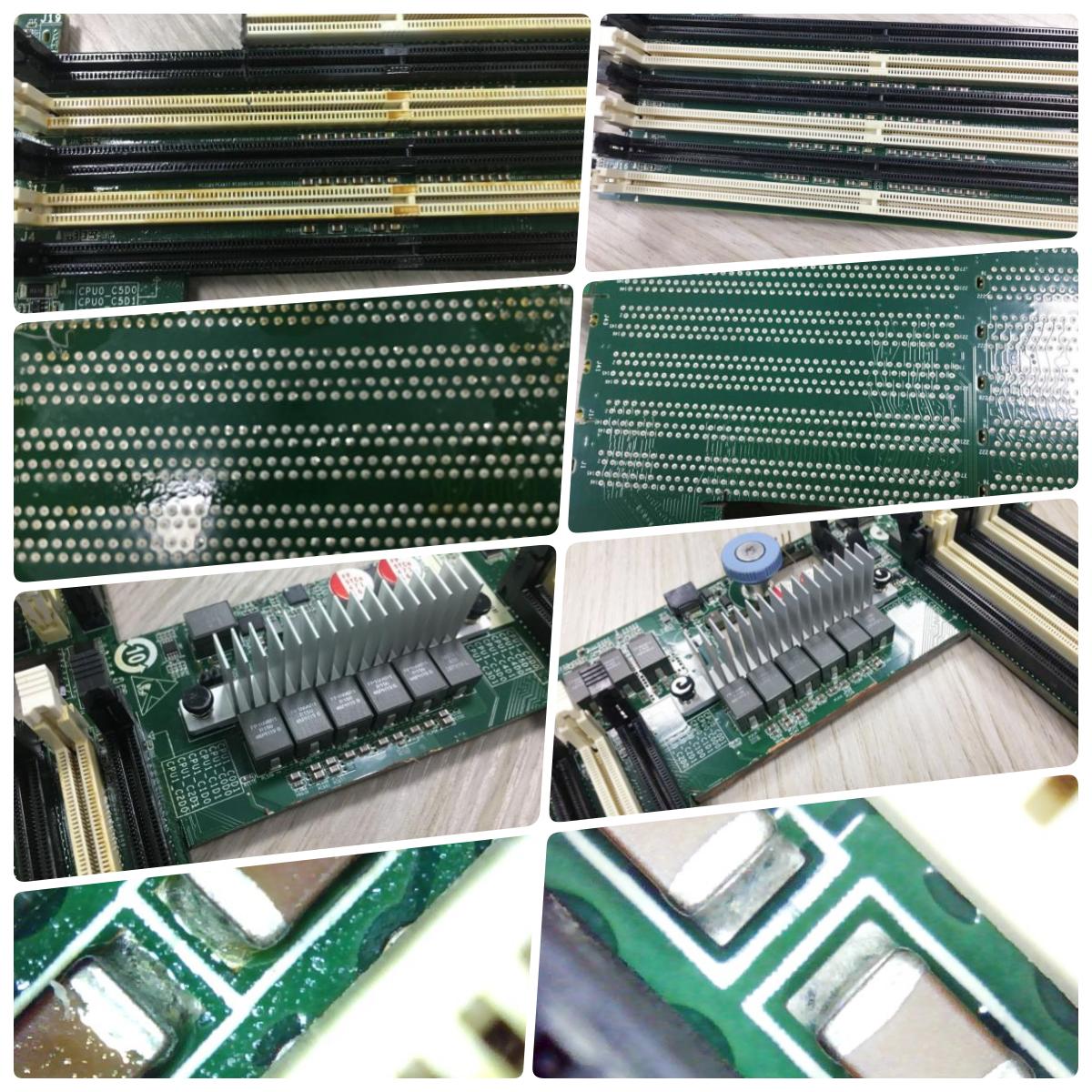

The cleaning machine for PCB board is designed for offline batch cleaning after SMT or THT soldering. It effectively removes rosin flux, water-soluble flux, no-clean flux, solder paste, and other contaminants from PCBA surfaces. This PCBA Cleaning Machine is ideal for high-mix, low-to-medium volume production where flexibility and cleanliness are critical. With a compact footprint and stainless-steel structure, the machine delivers stable cleaning, rinsing, and drying performance while reducing chemical consumption. It is widely used in automotive electronics, medical devices, aerospace, and consumer electronics manufacturing. The system focuses on process stability, easy maintenance, and consistent cleaning results that meet international cleanliness standards.

| Feature

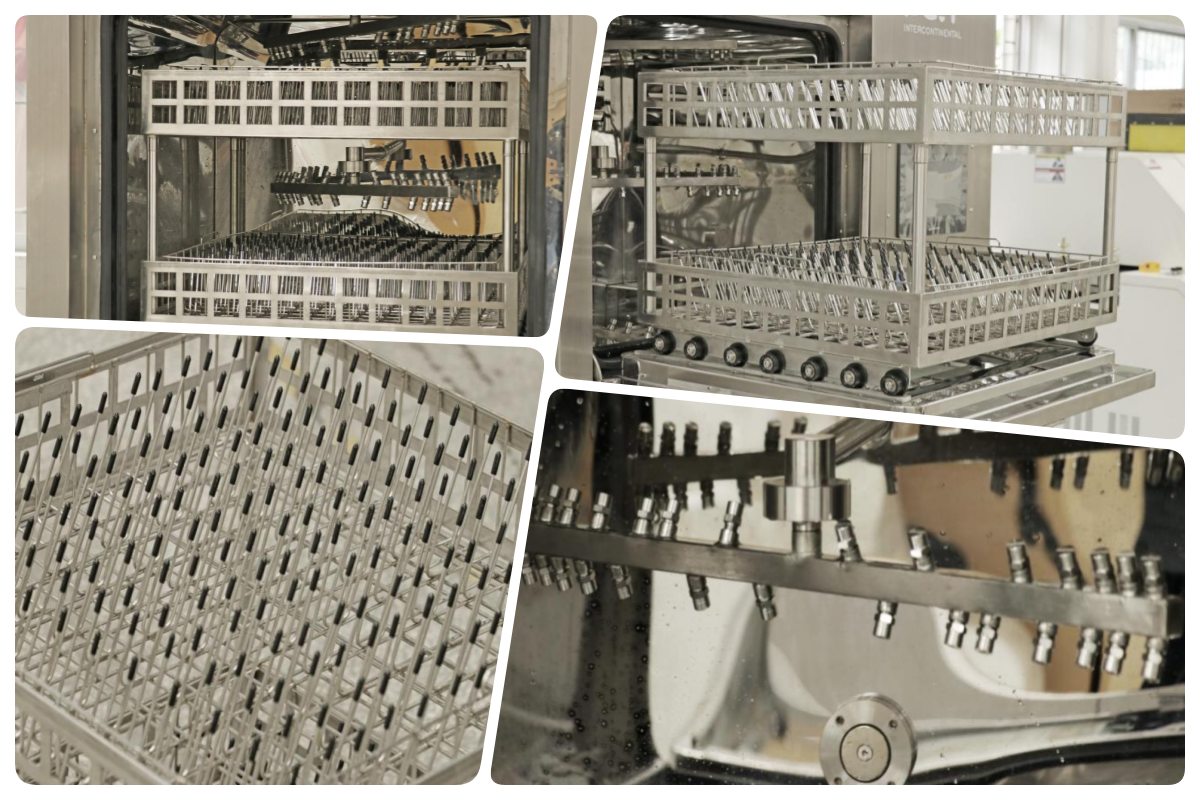

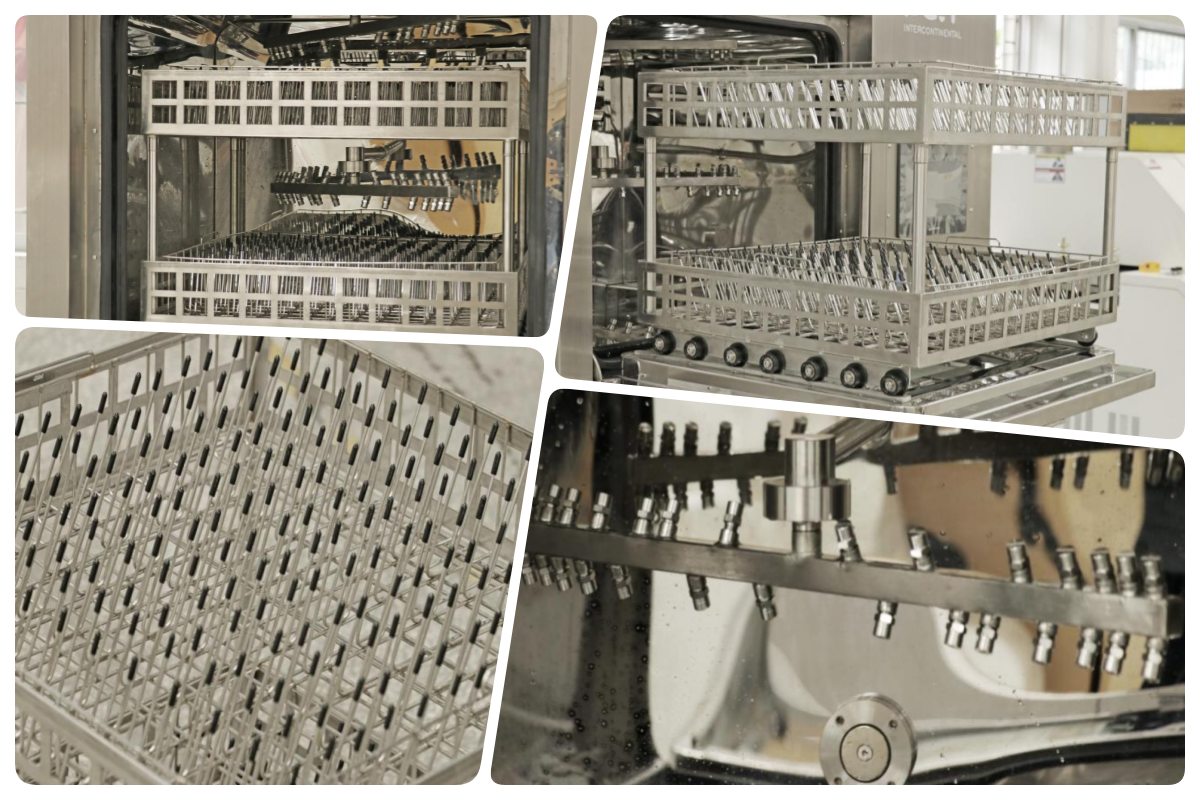

The cleaning room is fully constructed with SUS304 stainless steel, ensuring long service life and strong chemical resistance. A dual-layer cleaning basket allows multiple PCBAs to be processed in one cycle, improving efficiency without increasing space requirements. The spray system uses carefully designed nozzle spacing to ensure full coverage, even in complex PCBA areas. During operation, the cleaning basket moves smoothly to enhance spray penetration. A large observation window allows operators to visually monitor the cleaning process in real time, improving process control and confidence in cleaning results.

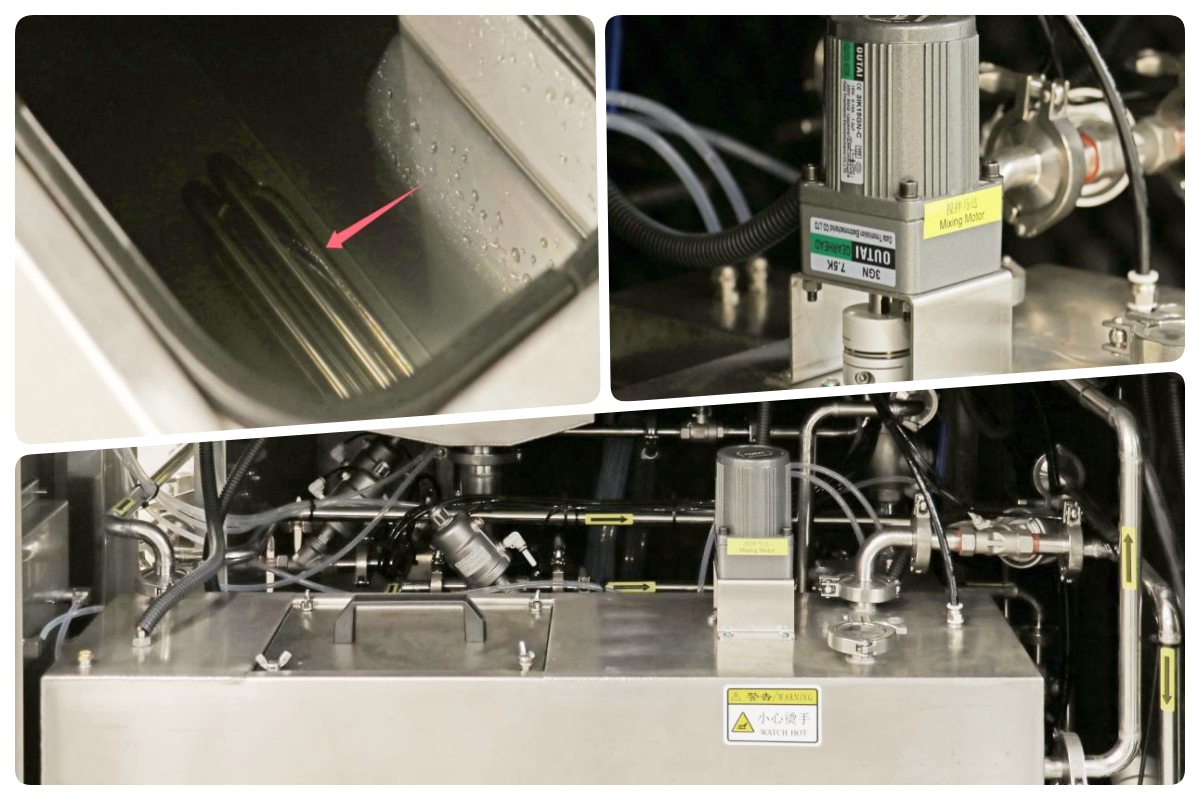

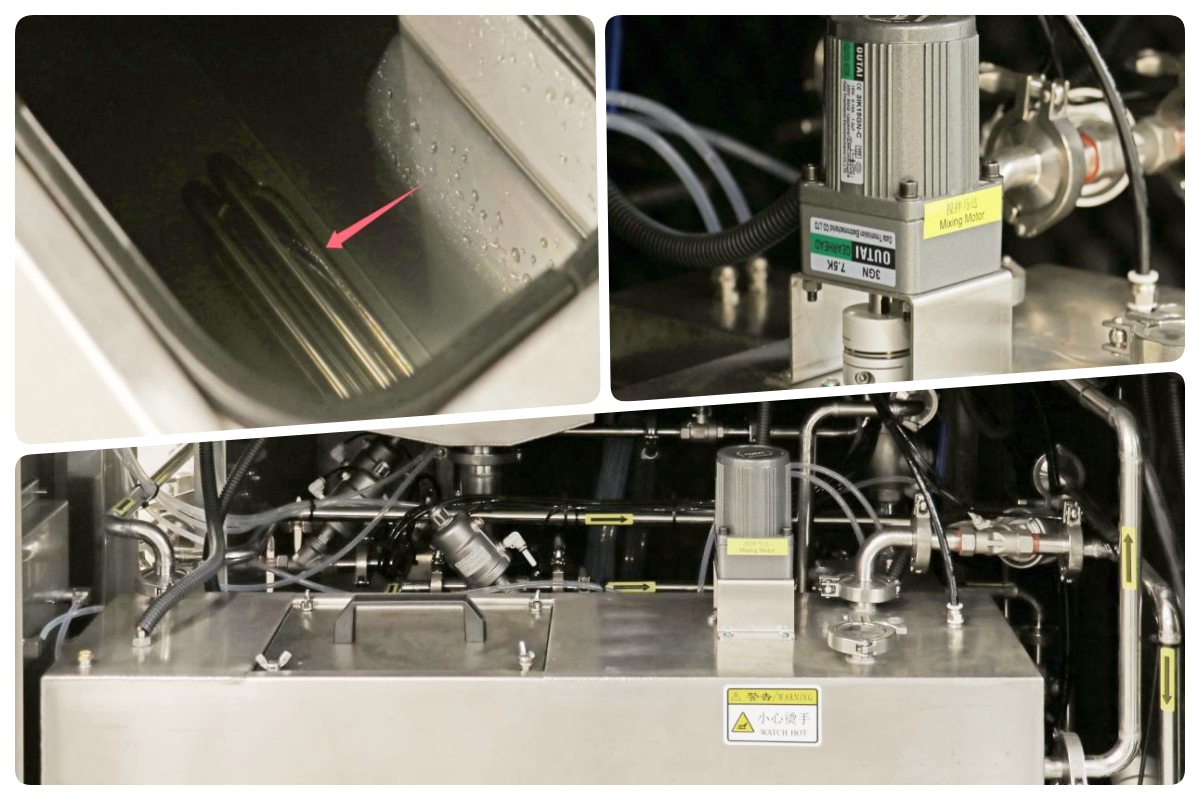

The circulation pipe system is designed for high efficiency and space optimization. A high-power diaphragm pump provides stable pressure, ensuring consistent spray performance throughout the cleaning cycle. The system includes dual-stage filtration, allowing cleaning liquid to be reused multiple times, significantly reducing operating costs. Quick-connect pipe interfaces make maintenance and replacement fast and simple. This design improves reliability while minimizing downtime. The closed circulation structure also supports environmentally friendly operation by reducing waste and chemical loss during daily production.

The washer fluid tank features a large-capacity design, reducing the frequency of liquid refilling during production. A built-in stirring motor ensures uniform mixing of cleaning agent and DI water, maintaining stable cleaning performance. The heating module raises the cleaning liquid temperature to improve cleaning efficiency and shorten cycle time. A high-precision liquid level sensor continuously monitors fluid status, while an external window allows operators to easily check levels. This system helps maintain consistent cleaning quality while ensuring safe and controlled operation.

The drying module uses powerful hot air blowers to fully remove moisture from the PCBA after rinsing. Multiple air outlets are arranged to cover the entire cleaning chamber, ensuring even drying without dead zones. An air inlet filter prevents dust and particles from entering the chamber during drying, protecting sensitive electronic components. Drying temperature and time can be precisely controlled to match different board requirements. This ensures PCBAs exit the machine clean, dry, and ready for the next production step.

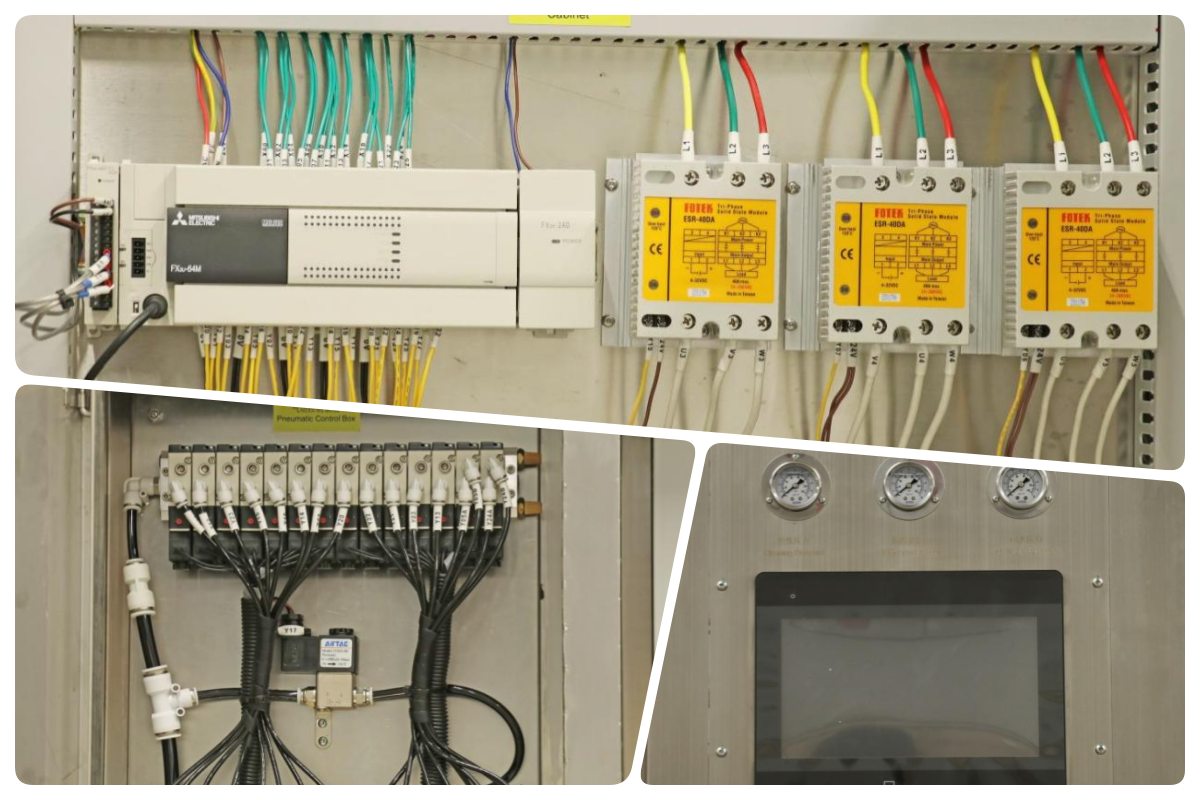

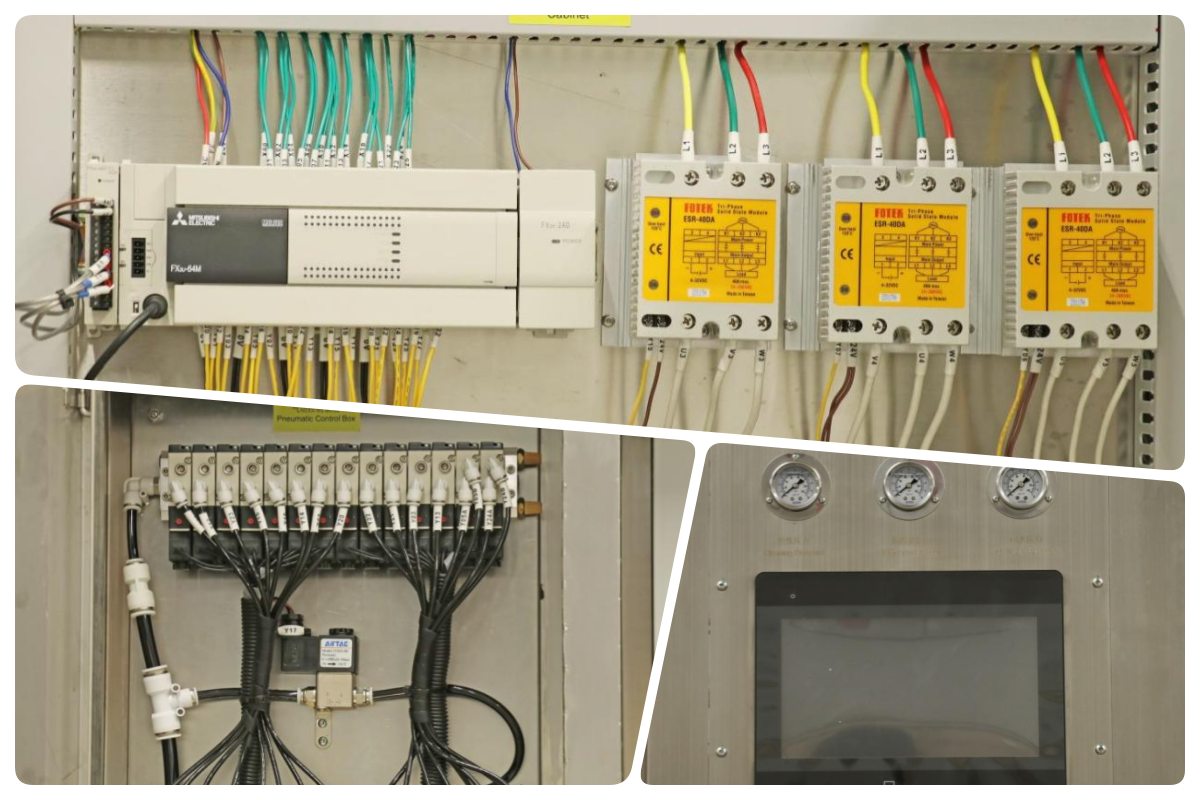

The control system is based on a reliable PLC platform with a user-friendly human-machine interface. Operators can easily set cleaning, rinsing, and drying parameters according to different product requirements. Multiple password levels help protect process settings and prevent unauthorized changes. Electrical and pneumatic systems are separated to reduce interference and improve long-term stability. The system complies with CE safety standards and is designed for simple maintenance, making it suitable for continuous factory operation.

| Comparison Before and After

| Specification

| Parameter | I.C.T-5600 (Offline) | I.C.T-6300 (Online) |

|---|---|---|

| Cleaning Type | Offline batch, basket loading | Online continuous, belt conveyor |

| PCBA/Basket Size | 610 × 560 × 100 mm × 2 layers | Up to 600 × 400 × 100 mm (max conveyor width) |

| Cleaning Method | Multi-spray with heating, rinse, hot air dry | High-pressure spray, chemical + DI rinse + hot air dry |

| Tank Capacity (Diluent/Clean) | 60L (dilution) / 17L (spray tank) | 240L (clean liquid tank) |

| Concentrate Tank | 30-32L | Equipped with concentrated tank + auto add/discharge |

| Power Supply | Not specified (typically lower, ~30-50 kW est.) | 380V 3P 50/60Hz, 110-122 kW |

| Machine Dimensions | Compact (exact not listed, smaller footprint) | 5200 × 1750 × 1650-1700 mm |

| Drying | Hot air dry 10-30 min | Multi-stage hot air dry (dry 1 & dry 2) |

| Control System | Touch screen, easy parameters, password | PC + PLC, English software, adjustable pressures |

| DI Water Resistivity Monitoring | Yes, real-time | Yes, monitoring system |

| Typical Use | Small-multi variety, high-mix batches | High-volume batch, inline SMT lines |

| SMT Line Equipment List

I.C.T constructs multiple SMT production line that complement the PCB board cleaning machine seamlessly. Typical builds incorporate PCB laser marking system for traceability, printers plus SPI for accurate paste application, JUKI placement machines for rapid assembly, reflow ovens for strong solder joints, AOI scanners for thorough inspection, and conveyors for fluid transfer. Automated solder paste storage systems preserve material quality. Selective wave soldering options handle through-hole requirements. Each piece integrates expertly to form productive, customized lines. I.C.T experts guide equipment choices and installation for optimal results throughout the process.

| Customer Success Video

In this project, I.C.T successfully supported a North American beauty device manufacturer with the overseas installation and FAT of two SMT production lines. The production lines included laser marking systems, SMT printers with SPI, Panasonic pick-and-place machines, Heller reflow ovens, AOI inspection equipment, PCB handling conveyors, a PCBA cleaning machine, and a fully automatic solder paste storage and warming system. I.C.T engineers provided on-site installation, debugging, and process verification support. The lines passed production acceptance smoothly, helping the customer achieve stable, high-quality PCBA manufacturing for beauty device products.

| Service and Training

I.C.T provides comprehensive service and training support for every cleaning machine for PCB board we deliver. Our engineers assist with installation, parameter setup, and process optimization to ensure stable operation from the first day. Training covers machine operation, routine maintenance, and basic troubleshooting, helping customers build internal technical capability. Remote support and fast-response service channels are also available to minimize downtime. With experience supporting customers across many countries, I.C.T ensures reliable long-term operation and continuous improvement for your production line.

| Customer Reviews

Customers consistently praise I.C.T for professional engineers, stable equipment performance, and well-organized packaging during shipment. The machines arrive safely and are ready for quick installation. Many customers highlight our fast response to technical questions and clear communication throughout the project. The cleaning performance, system stability, and ease of operation are highly valued. These positive experiences help customers improve product quality while reducing operational risk.

| Our Certification

I.C.T equipment is designed and manufactured according to strict quality standards. Our products comply with CE and RoHS requirements and are produced under an ISO9001 quality management system. Multiple patented technologies are applied to improve reliability, safety, and performance. Each machine undergoes inspection and functional testing before delivery. These certifications reflect our commitment to consistent quality and long-term customer trust.

| About Us and Factory

I.C.T is an experienced electronic manufacturing equipment provider with strong capabilities in research, design, and production. We have a professional engineering team and a growing manufacturing base that supports rapid product development. Over the years, I.C.T has served customers in many countries and regions worldwide, delivering complete SMT and PCBA solutions. Our factory follows strict inspection procedures and a structured quality management system to ensure stable product performance. Continuous growth and technical improvement allow I.C.T to support customers with reliable equipment and long-term partnership value.

| Offline PCBA Cleaning Solution

The cleaning machine for PCB board is designed for offline batch cleaning after SMT or THT soldering. It effectively removes rosin flux, water-soluble flux, no-clean flux, solder paste, and other contaminants from PCBA surfaces. This PCBA Cleaning Machine is ideal for high-mix, low-to-medium volume production where flexibility and cleanliness are critical. With a compact footprint and stainless-steel structure, the machine delivers stable cleaning, rinsing, and drying performance while reducing chemical consumption. It is widely used in automotive electronics, medical devices, aerospace, and consumer electronics manufacturing. The system focuses on process stability, easy maintenance, and consistent cleaning results that meet international cleanliness standards.

| Feature

The cleaning room is fully constructed with SUS304 stainless steel, ensuring long service life and strong chemical resistance. A dual-layer cleaning basket allows multiple PCBAs to be processed in one cycle, improving efficiency without increasing space requirements. The spray system uses carefully designed nozzle spacing to ensure full coverage, even in complex PCBA areas. During operation, the cleaning basket moves smoothly to enhance spray penetration. A large observation window allows operators to visually monitor the cleaning process in real time, improving process control and confidence in cleaning results.

The circulation pipe system is designed for high efficiency and space optimization. A high-power diaphragm pump provides stable pressure, ensuring consistent spray performance throughout the cleaning cycle. The system includes dual-stage filtration, allowing cleaning liquid to be reused multiple times, significantly reducing operating costs. Quick-connect pipe interfaces make maintenance and replacement fast and simple. This design improves reliability while minimizing downtime. The closed circulation structure also supports environmentally friendly operation by reducing waste and chemical loss during daily production.

The washer fluid tank features a large-capacity design, reducing the frequency of liquid refilling during production. A built-in stirring motor ensures uniform mixing of cleaning agent and DI water, maintaining stable cleaning performance. The heating module raises the cleaning liquid temperature to improve cleaning efficiency and shorten cycle time. A high-precision liquid level sensor continuously monitors fluid status, while an external window allows operators to easily check levels. This system helps maintain consistent cleaning quality while ensuring safe and controlled operation.

The drying module uses powerful hot air blowers to fully remove moisture from the PCBA after rinsing. Multiple air outlets are arranged to cover the entire cleaning chamber, ensuring even drying without dead zones. An air inlet filter prevents dust and particles from entering the chamber during drying, protecting sensitive electronic components. Drying temperature and time can be precisely controlled to match different board requirements. This ensures PCBAs exit the machine clean, dry, and ready for the next production step.

The control system is based on a reliable PLC platform with a user-friendly human-machine interface. Operators can easily set cleaning, rinsing, and drying parameters according to different product requirements. Multiple password levels help protect process settings and prevent unauthorized changes. Electrical and pneumatic systems are separated to reduce interference and improve long-term stability. The system complies with CE safety standards and is designed for simple maintenance, making it suitable for continuous factory operation.

| Comparison Before and After

| Specification

| Parameter | I.C.T-5600 (Offline) | I.C.T-6300 (Online) |

|---|---|---|

| Cleaning Type | Offline batch, basket loading | Online continuous, belt conveyor |

| PCBA/Basket Size | 610 × 560 × 100 mm × 2 layers | Up to 600 × 400 × 100 mm (max conveyor width) |

| Cleaning Method | Multi-spray with heating, rinse, hot air dry | High-pressure spray, chemical + DI rinse + hot air dry |

| Tank Capacity (Diluent/Clean) | 60L (dilution) / 17L (spray tank) | 240L (clean liquid tank) |

| Concentrate Tank | 30-32L | Equipped with concentrated tank + auto add/discharge |

| Power Supply | Not specified (typically lower, ~30-50 kW est.) | 380V 3P 50/60Hz, 110-122 kW |

| Machine Dimensions | Compact (exact not listed, smaller footprint) | 5200 × 1750 × 1650-1700 mm |

| Drying | Hot air dry 10-30 min | Multi-stage hot air dry (dry 1 & dry 2) |

| Control System | Touch screen, easy parameters, password | PC + PLC, English software, adjustable pressures |

| DI Water Resistivity Monitoring | Yes, real-time | Yes, monitoring system |

| Typical Use | Small-multi variety, high-mix batches | High-volume batch, inline SMT lines |

| SMT Line Equipment List

I.C.T constructs multiple SMT production line that complement the PCB board cleaning machine seamlessly. Typical builds incorporate PCB laser marking system for traceability, printers plus SPI for accurate paste application, JUKI placement machines for rapid assembly, reflow ovens for strong solder joints, AOI scanners for thorough inspection, and conveyors for fluid transfer. Automated solder paste storage systems preserve material quality. Selective wave soldering options handle through-hole requirements. Each piece integrates expertly to form productive, customized lines. I.C.T experts guide equipment choices and installation for optimal results throughout the process.

| Customer Success Video

In this project, I.C.T successfully supported a North American beauty device manufacturer with the overseas installation and FAT of two SMT production lines. The production lines included laser marking systems, SMT printers with SPI, Panasonic pick-and-place machines, Heller reflow ovens, AOI inspection equipment, PCB handling conveyors, a PCBA cleaning machine, and a fully automatic solder paste storage and warming system. I.C.T engineers provided on-site installation, debugging, and process verification support. The lines passed production acceptance smoothly, helping the customer achieve stable, high-quality PCBA manufacturing for beauty device products.

| Service and Training

I.C.T provides comprehensive service and training support for every cleaning machine for PCB board we deliver. Our engineers assist with installation, parameter setup, and process optimization to ensure stable operation from the first day. Training covers machine operation, routine maintenance, and basic troubleshooting, helping customers build internal technical capability. Remote support and fast-response service channels are also available to minimize downtime. With experience supporting customers across many countries, I.C.T ensures reliable long-term operation and continuous improvement for your production line.

| Customer Reviews

Customers consistently praise I.C.T for professional engineers, stable equipment performance, and well-organized packaging during shipment. The machines arrive safely and are ready for quick installation. Many customers highlight our fast response to technical questions and clear communication throughout the project. The cleaning performance, system stability, and ease of operation are highly valued. These positive experiences help customers improve product quality while reducing operational risk.

| Our Certification

I.C.T equipment is designed and manufactured according to strict quality standards. Our products comply with CE and RoHS requirements and are produced under an ISO9001 quality management system. Multiple patented technologies are applied to improve reliability, safety, and performance. Each machine undergoes inspection and functional testing before delivery. These certifications reflect our commitment to consistent quality and long-term customer trust.

| About Us and Factory

I.C.T is an experienced electronic manufacturing equipment provider with strong capabilities in research, design, and production. We have a professional engineering team and a growing manufacturing base that supports rapid product development. Over the years, I.C.T has served customers in many countries and regions worldwide, delivering complete SMT and PCBA solutions. Our factory follows strict inspection procedures and a structured quality management system to ensure stable product performance. Continuous growth and technical improvement allow I.C.T to support customers with reliable equipment and long-term partnership value.

FAQ

FAQ