D600 (LENS)

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Reliable PCB Dispensing Machine SMT Production Lines

Operators require equipment that functions without constant attention. The PCB Dispensing machine meets this need. Three-axis gantry moves at measured speeds. Vision system identifies reference points and adjusts for variations. Dispense valve releases controlled amounts. Preheating maintains material properties. Multiple syringe options load quickly. The Automatic Glue Dispenser Machine SMT connects to conveyor systems and operates continuously. Applications include electronics assembly, lens attachment, and medical device production. Performance records from various sites show minimal downtime and high output quality. Support teams respond promptly to inquiries.

| Detailed Product Features

The dispense valve releases glue in measured quantities. Servo motor and precision screw ensure repetition. Preheating stabilizes flow characteristics. Various adhesive types perform equally. Syringe changes occur efficiently. Automatic cleaning prevents blockages. Resulting bonds maintain strength across production batches. The PCB Dispensing machine achieves required accuracy without operator intervention.

Boards enter on anti-static belts driven by separate motors. Adjustable stop positions the board accurately. Width adjustment maintains rail alignment. System handles boards from small to large formats, up to five kilograms. Transport occurs smoothly in required directions. The Automatic Glue Dispenser Machine SMT integrates without interrupting line flow.

Cleaning activates automatically. Short cycle removes residue from valve. Temperature regulation preserves adhesive condition. Minimal maintenance time results. The PCB Dispensing machine returns to operation quickly after each run.

Control combines PLC and computer processing. Selected components include Panasonic servos and Omron relays. Compliance with CE standards documented. Design supports future additions like detection modules. Interface allows straightforward programming. The Automatic Glue Dispenser Machine SMT operates reliably under standard factory conditions.

| Specification

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

| SMT Line Equipment List

Boards enter from loader. PCB Dispensing machine applies adhesive pattern at specified speed. Placement equipment positions components on fresh glue. Curing oven completes bond formation rapidly. Inspection station verifies results when required. Stations connect seamlessly. Minimal operators needed. Yield rates remain high. Applications span automotive, medical, and LED sectors. Complete Automatic Glue Dispenser Machine SMT line supplied under unified responsibility.

| Product Name | Purpose in Glue Dispensing Line |

|---|---|

| Glue Dispensing Machine | Delivers high-speed, ultra-precise glue dispensing |

| Conformal Coating Machine | Applies final protective coating for reliability |

| Pick and Place Machine | Accurately places components onto fresh glue |

| Curing Oven | Rapidly cures glue with IR or UV technology |

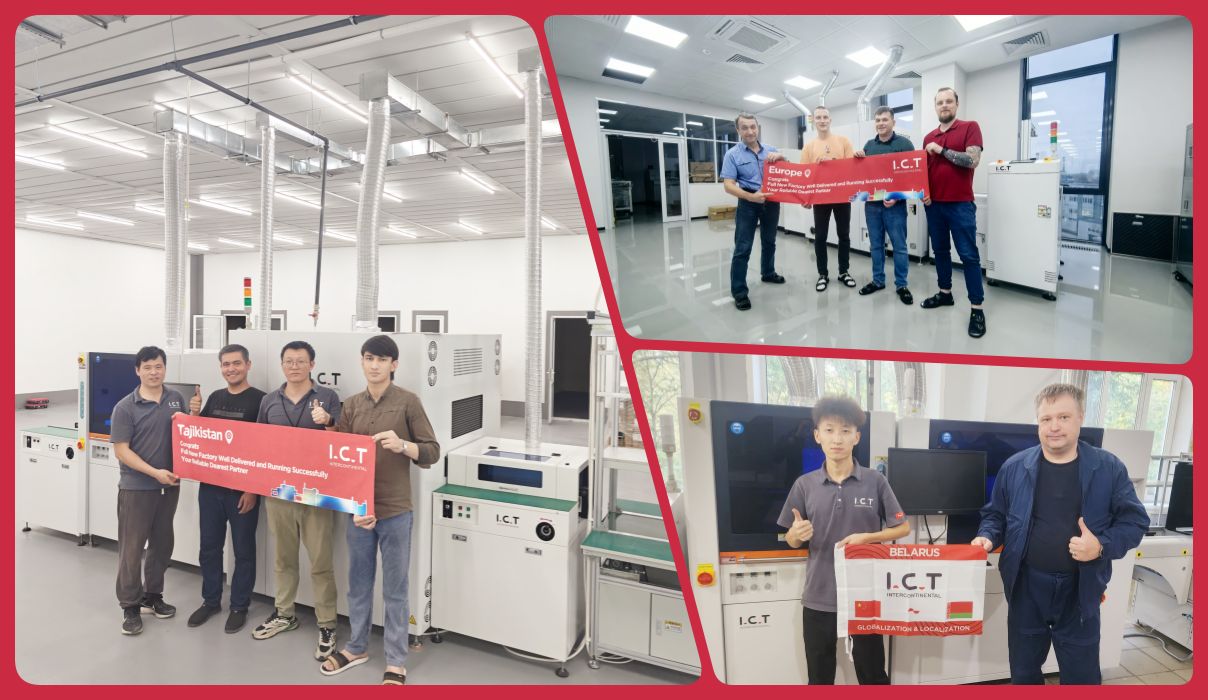

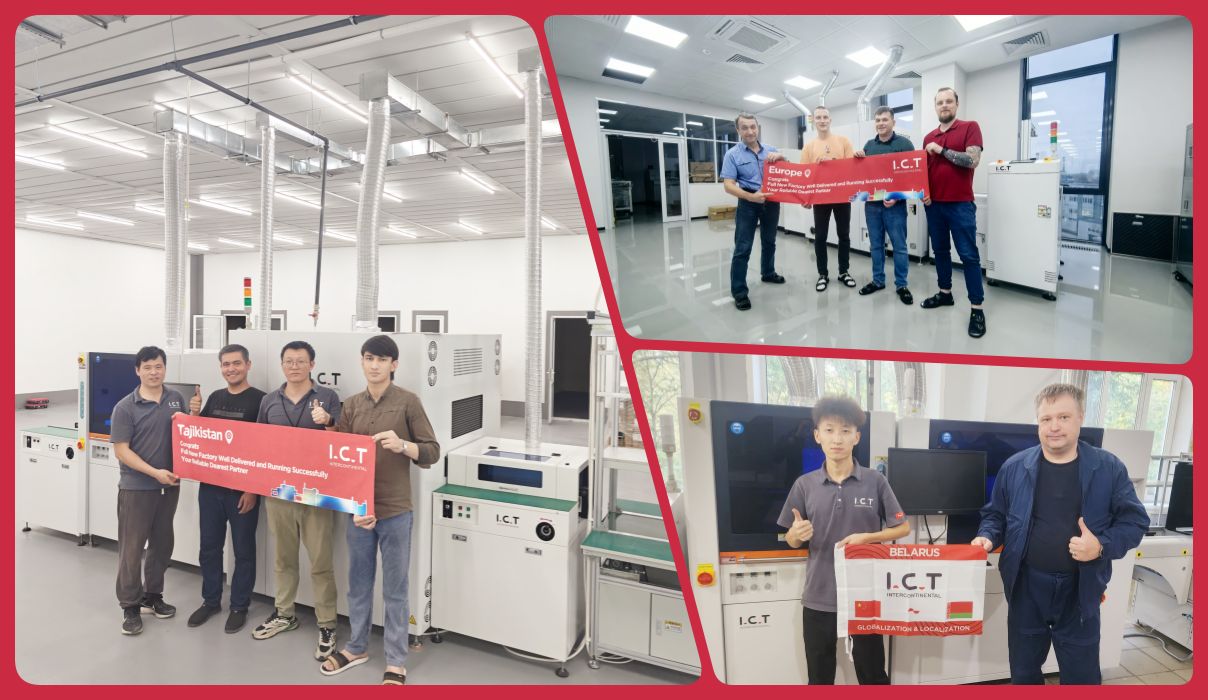

| Customer Success Story

Our two engineers traveled to Tajikistan following equipment delivery. Customer had acquired multiple production lines including SMT, DIP, coating, glue dispensing, and LED bulb assembly. Engineers completed installation and testing. PCB Dispensing machine demonstrated required placement accuracy from initial operation. Local personnel received training over several days. Production reached full capacity. Customer recorded proceedings and expressed satisfaction with results achieved.

| Professional Training & Support

Technical personnel accompany each PCB Dispensing machine delivery. Training continues until customer staff operate independently. Remote diagnostics address many issues rapidly. Spare components ship from multiple locations. On-site attendance arranged within specified timeframes. Software enhancements supplied ongoing. The Automatic Glue Dispenser Machine SMT contributes to production goals from early stages.

| Customer Praise

Customers note engineer proficiency during setup. Equipment reliability receives positive comment. Packaging protects contents during long transport. Response times to technical questions satisfy requirements. Overall performance meets or exceeds expectations.

| Our Certification

CE marking applied. RoHS requirements fulfilled. ISO9001 certification maintained. Patents protect key technologies. Each PCB Dispensing machine carries documentation confirming standards compliance.

| About Us and Factory

Company maintains research, development, and manufacturing in Dongguan facility covering 12 000 m². Staff totals 89 including 20 engineers. Capital registered at USD 30 million. Operations began 2012. Current customer installations exceed 1 600 across 72 countries. Strict testing protocols and quality systems govern production.

| Reliable PCB Dispensing Machine SMT Production Lines

Operators require equipment that functions without constant attention. The PCB Dispensing machine meets this need. Three-axis gantry moves at measured speeds. Vision system identifies reference points and adjusts for variations. Dispense valve releases controlled amounts. Preheating maintains material properties. Multiple syringe options load quickly. The Automatic Glue Dispenser Machine SMT connects to conveyor systems and operates continuously. Applications include electronics assembly, lens attachment, and medical device production. Performance records from various sites show minimal downtime and high output quality. Support teams respond promptly to inquiries.

| Detailed Product Features

The dispense valve releases glue in measured quantities. Servo motor and precision screw ensure repetition. Preheating stabilizes flow characteristics. Various adhesive types perform equally. Syringe changes occur efficiently. Automatic cleaning prevents blockages. Resulting bonds maintain strength across production batches. The PCB Dispensing machine achieves required accuracy without operator intervention.

Boards enter on anti-static belts driven by separate motors. Adjustable stop positions the board accurately. Width adjustment maintains rail alignment. System handles boards from small to large formats, up to five kilograms. Transport occurs smoothly in required directions. The Automatic Glue Dispenser Machine SMT integrates without interrupting line flow.

Cleaning activates automatically. Short cycle removes residue from valve. Temperature regulation preserves adhesive condition. Minimal maintenance time results. The PCB Dispensing machine returns to operation quickly after each run.

Control combines PLC and computer processing. Selected components include Panasonic servos and Omron relays. Compliance with CE standards documented. Design supports future additions like detection modules. Interface allows straightforward programming. The Automatic Glue Dispenser Machine SMT operates reliably under standard factory conditions.

| Specification

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

| SMT Line Equipment List

Boards enter from loader. PCB Dispensing machine applies adhesive pattern at specified speed. Placement equipment positions components on fresh glue. Curing oven completes bond formation rapidly. Inspection station verifies results when required. Stations connect seamlessly. Minimal operators needed. Yield rates remain high. Applications span automotive, medical, and LED sectors. Complete Automatic Glue Dispenser Machine SMT line supplied under unified responsibility.

| Product Name | Purpose in Glue Dispensing Line |

|---|---|

| Glue Dispensing Machine | Delivers high-speed, ultra-precise glue dispensing |

| Conformal Coating Machine | Applies final protective coating for reliability |

| Pick and Place Machine | Accurately places components onto fresh glue |

| Curing Oven | Rapidly cures glue with IR or UV technology |

| Customer Success Story

Our two engineers traveled to Tajikistan following equipment delivery. Customer had acquired multiple production lines including SMT, DIP, coating, glue dispensing, and LED bulb assembly. Engineers completed installation and testing. PCB Dispensing machine demonstrated required placement accuracy from initial operation. Local personnel received training over several days. Production reached full capacity. Customer recorded proceedings and expressed satisfaction with results achieved.

| Professional Training & Support

Technical personnel accompany each PCB Dispensing machine delivery. Training continues until customer staff operate independently. Remote diagnostics address many issues rapidly. Spare components ship from multiple locations. On-site attendance arranged within specified timeframes. Software enhancements supplied ongoing. The Automatic Glue Dispenser Machine SMT contributes to production goals from early stages.

| Customer Praise

Customers note engineer proficiency during setup. Equipment reliability receives positive comment. Packaging protects contents during long transport. Response times to technical questions satisfy requirements. Overall performance meets or exceeds expectations.

| Our Certification

CE marking applied. RoHS requirements fulfilled. ISO9001 certification maintained. Patents protect key technologies. Each PCB Dispensing machine carries documentation confirming standards compliance.

| About Us and Factory

Company maintains research, development, and manufacturing in Dongguan facility covering 12 000 m². Staff totals 89 including 20 engineers. Capital registered at USD 30 million. Operations began 2012. Current customer installations exceed 1 600 across 72 countries. Strict testing protocols and quality systems govern production.