I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| The Ultimate SMT Glue Dispenser Machine

Guy walks into a factory, says, “I need glue on lenses and boards, fast and perfect.” We roll in the SMT glue dispenser machine. Panasonic servos hum. Vision camera snaps Mark points. Valve drops glue like it’s got eyes. Preheats itself. Syringes click in and out. The automated glue dispensing systems for SMT run all day, no babysitting. Customer checks the first pallet, nods, says, “Ship me two more.” That’s how it usually goes.

| Detailed Product Features

Valve opens, glue lands, same weight every shot. Servo and screw make sure of that. Preheating keeps it flowing right. Red glue, UV, underfill—pick your poison. Syringe swap takes one minute flat. Auto-purge keeps the tip clean. No strings, no mess. Lenses stay put forever. The SMT glue dispenser machine doesn’t guess. It knows.

Board slides in, belts grab it, motors keep it straight. Stop bar drops—bam—dead center. Rails stay parallel while width changes on the fly. Handles everything from 50×50 mm to 600×600 mm, five kilos no sweat. Runs any direction at 300 mm/s. The automated glue dispensing systems for SMT never let a board wander off the reservation.

End of run. Operator taps one button. Eight seconds later the valve’s clean. Temperature stays locked so tomorrow’s glue acts exactly like today’s. No scraping, no swearing. The SMT glue dispenser machine is ready before the next shift even shows up.

PLC and PC talk quiet and fast. Panasonic servos, Omron relays, Schneider breakers—good parts, no cheap stuff. CE stamp, Industry 4.0 ready, MES port wide open. Want 3D height check next year? Plug it in, software smiles. Screen is big, buttons are simple. New guy runs it after one coffee. The automated glue dispensing systems for SMT keep the line moving like money in the bank.

| Specification

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

| SMT Line Equipment List

Magazine in. Loader kicks. SMT glue dispenser machine fires perfect dots at 800 mm/s. Pick-and-place drops lenses or parts on wet glue. IR or UV oven hardens it rock-solid in seconds. Optional AOI checks every dot. All machines handshake SMEMA, run like a chain gang. One or two operators watch the show. Yield stays north of 99.5 %. Uptime brutal. Automotive, medical, LED—standards met, costs killed, profits fat. One complete automated glue dispensing systems for SMT line. You turn it on, money rolls in.

| Product Name | Purpose in Glue Dispensing Line |

|---|---|

| Glue Dispensing Machine | Delivers high-speed, ultra-precise glue dispensing |

| Conformal Coating Machine | Applies final protective coating for reliability |

| Pick and Place Machine | Accurately places components onto fresh glue |

| Vertical Curing Oven | Rapidly cures glue with IR or UV technology |

| Customer Success Story

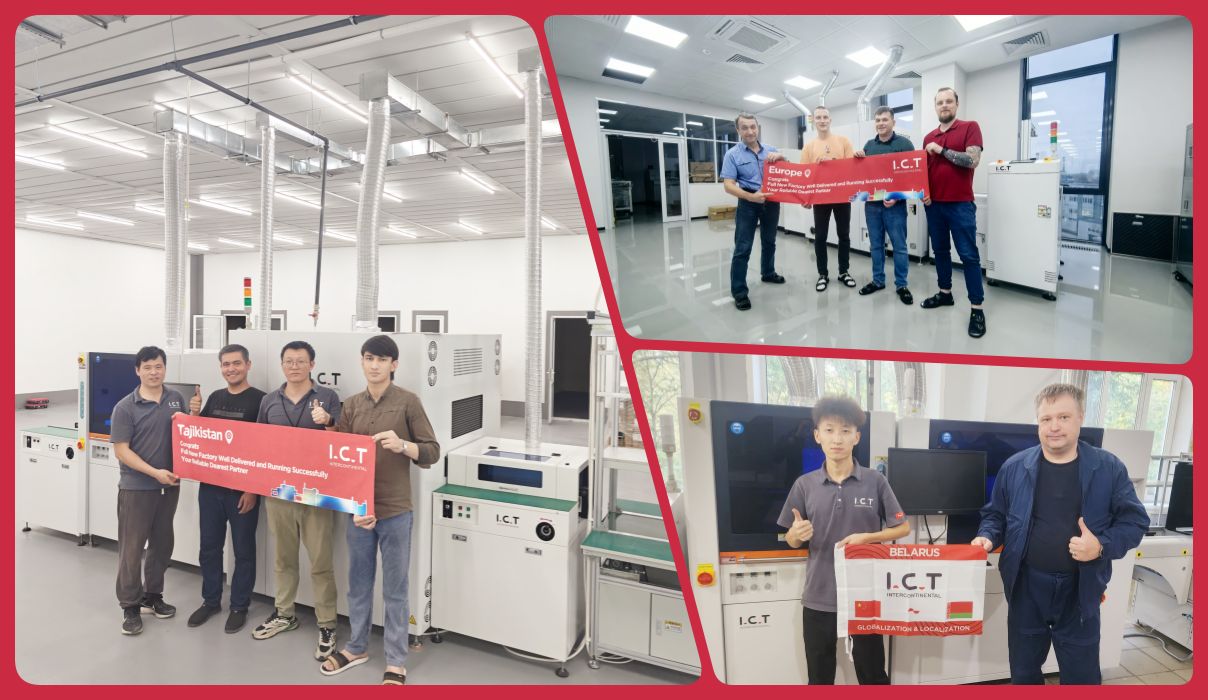

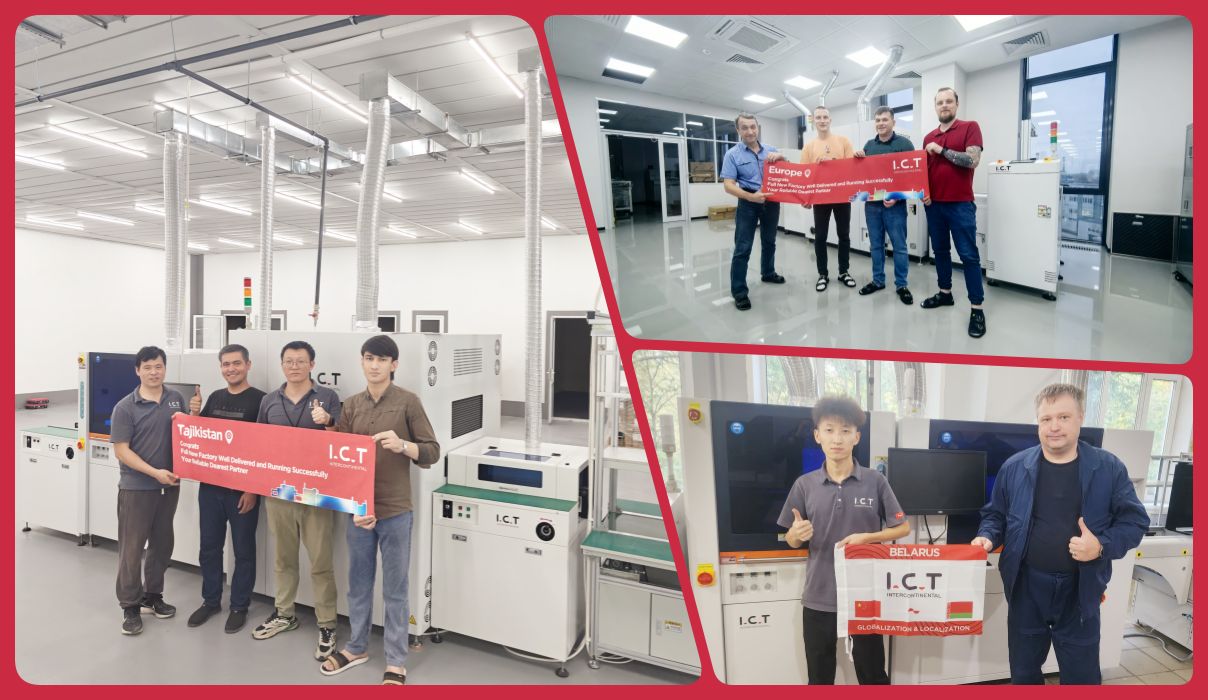

Two of our engineers land in Dushanbe. Customer already paid for two SMT lines, one DIP, one coating, one glue line, one full LED bulb line. They crack the crates, bolt everything down, fire it up. SMT glue dispenser machine lays perfect dots. Pick-and-place sets lenses. Ovens cure. AOI passes. Ten days later the local crew runs the whole show solo. Customer grabs the camera, grins: “I.C.T said it, I.C.T did it.”

| Professional Training & Support

We show up with the SMT glue dispenser machine and don’t leave until your people tell us to get lost. Remote team fixes most calls before you finish your donut. Parts ship same day. On-site guy lands in 48 hours, anywhere. Software updates forever, no invoice. The automated glue dispensing systems for SMT start paying for themselves the first week.

| Customer Praise

“Engineers knew every screw.” “Glue dots never move.” “Wooden crates survived 8 000 km without a scratch.” “Remote team fixed the alarm at 2 a.m. my time.” “Line has not stopped in fourteen months.” Same words, different countries, same SMT glue machine.

| Our Certification

CE. RoHS. ISO9001. Patents locked and loaded. Every SMT glue dispenser machine leaves with full test report and serial number. Customs waves you through—Europe, States, Japan—no hassle.

| About Us and Factory

Dongguan. 12 000 m². 89 people. 20 engineers. $30 million capital. Started 2012. 1 600 customers. 72 countries. Every SMT glue dispenser machine runs full torture test before it ships. Quality doesn’t take vacations.

| The Ultimate SMT Glue Dispenser Machine

Guy walks into a factory, says, “I need glue on lenses and boards, fast and perfect.” We roll in the SMT glue dispenser machine. Panasonic servos hum. Vision camera snaps Mark points. Valve drops glue like it’s got eyes. Preheats itself. Syringes click in and out. The automated glue dispensing systems for SMT run all day, no babysitting. Customer checks the first pallet, nods, says, “Ship me two more.” That’s how it usually goes.

| Detailed Product Features

Valve opens, glue lands, same weight every shot. Servo and screw make sure of that. Preheating keeps it flowing right. Red glue, UV, underfill—pick your poison. Syringe swap takes one minute flat. Auto-purge keeps the tip clean. No strings, no mess. Lenses stay put forever. The SMT glue dispenser machine doesn’t guess. It knows.

Board slides in, belts grab it, motors keep it straight. Stop bar drops—bam—dead center. Rails stay parallel while width changes on the fly. Handles everything from 50×50 mm to 600×600 mm, five kilos no sweat. Runs any direction at 300 mm/s. The automated glue dispensing systems for SMT never let a board wander off the reservation.

End of run. Operator taps one button. Eight seconds later the valve’s clean. Temperature stays locked so tomorrow’s glue acts exactly like today’s. No scraping, no swearing. The SMT glue dispenser machine is ready before the next shift even shows up.

PLC and PC talk quiet and fast. Panasonic servos, Omron relays, Schneider breakers—good parts, no cheap stuff. CE stamp, Industry 4.0 ready, MES port wide open. Want 3D height check next year? Plug it in, software smiles. Screen is big, buttons are simple. New guy runs it after one coffee. The automated glue dispensing systems for SMT keep the line moving like money in the bank.

| Specification

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

| SMT Line Equipment List

Magazine in. Loader kicks. SMT glue dispenser machine fires perfect dots at 800 mm/s. Pick-and-place drops lenses or parts on wet glue. IR or UV oven hardens it rock-solid in seconds. Optional AOI checks every dot. All machines handshake SMEMA, run like a chain gang. One or two operators watch the show. Yield stays north of 99.5 %. Uptime brutal. Automotive, medical, LED—standards met, costs killed, profits fat. One complete automated glue dispensing systems for SMT line. You turn it on, money rolls in.

| Product Name | Purpose in Glue Dispensing Line |

|---|---|

| Glue Dispensing Machine | Delivers high-speed, ultra-precise glue dispensing |

| Conformal Coating Machine | Applies final protective coating for reliability |

| Pick and Place Machine | Accurately places components onto fresh glue |

| Vertical Curing Oven | Rapidly cures glue with IR or UV technology |

| Customer Success Story

Two of our engineers land in Dushanbe. Customer already paid for two SMT lines, one DIP, one coating, one glue line, one full LED bulb line. They crack the crates, bolt everything down, fire it up. SMT glue dispenser machine lays perfect dots. Pick-and-place sets lenses. Ovens cure. AOI passes. Ten days later the local crew runs the whole show solo. Customer grabs the camera, grins: “I.C.T said it, I.C.T did it.”

| Professional Training & Support

We show up with the SMT glue dispenser machine and don’t leave until your people tell us to get lost. Remote team fixes most calls before you finish your donut. Parts ship same day. On-site guy lands in 48 hours, anywhere. Software updates forever, no invoice. The automated glue dispensing systems for SMT start paying for themselves the first week.

| Customer Praise

“Engineers knew every screw.” “Glue dots never move.” “Wooden crates survived 8 000 km without a scratch.” “Remote team fixed the alarm at 2 a.m. my time.” “Line has not stopped in fourteen months.” Same words, different countries, same SMT glue machine.

| Our Certification

CE. RoHS. ISO9001. Patents locked and loaded. Every SMT glue dispenser machine leaves with full test report and serial number. Customs waves you through—Europe, States, Japan—no hassle.

| About Us and Factory

Dongguan. 12 000 m². 89 people. 20 engineers. $30 million capital. Started 2012. 1 600 customers. 72 countries. Every SMT glue dispenser machine runs full torture test before it ships. Quality doesn’t take vacations.