I.C.T

| Availability: | |

|---|---|

| Quantity: | |

The SMT Cooling Conveyor receives boards directly from the reflow oven, where residual heat must be reduced in a controlled manner to avoid thermal stress or solder joint failure. It applies uniform airflow through adjustable fans while the belt advances at steady speed. The system permits one-button width synchronization across connected machines. Transmission options include standard ESD belt or chain for heavier loads. Built according to standardized procedures, it operates without deviation, ensuring each board emerges at acceptable temperature for subsequent inspection or assembly. Factories rely on this conveyor to complete the thermal cycle without introducing variables or interruptions.

| Complete Conveyor Series Including Advanced Cooling Models

I.C.T produces more than ten conveyor variants. Linking models connect machines in sequence. Inspection models include illumination for examination. Gate models permit passage when required. Buffer models retain boards in reserve. The SMT linking conveyor is available in various lengths and configurations. Chain drive is provided for increased capacity. Cooling options eliminate excess heat. Each variant can be adjusted in size or function to conform to the line's requirements. The system complies without objection. The conveyor fulfills its designated role.

| Detailed Product Features

Aluminum rails, machined to exact dimension, maintain alignment under thermal load. Thicker base plates and calibrated screws prevent any shift during extended operation. Ergonomic placement of access points follows established maintenance protocols. The assembly complies with ISO and CE requirements, remaining functional over prolonged cycles with minimal adjustment.

Photoelectric sensors register board entry and exit with measured accuracy. Tower lights display operational state in predefined colors, visible across the production floor. High-frequency buttons respond reliably under repeated use. ESD grounding protects boards throughout transit. The wiring configuration adheres to safety norms, ensuring uninterrupted signal transmission.

The PLC executes commands in sequence, displayed on a 7-inch touch screen with clear status fields. Operators modify speed or width through direct input. Optional Industry 4.0 interface permits protocol integration when required. Software updates occur without halting production, maintaining system conformity.

The ESD belt advances boards at constant velocity, minimizing noise. Chain transmission engages for boards retaining higher mass or heat. Both mechanisms coordinate with fan operation to achieve required cooling profile. Transition between types follows established procedure on site.

| PCB Conveyor Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Conveyor | Automatically transportation bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data. |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

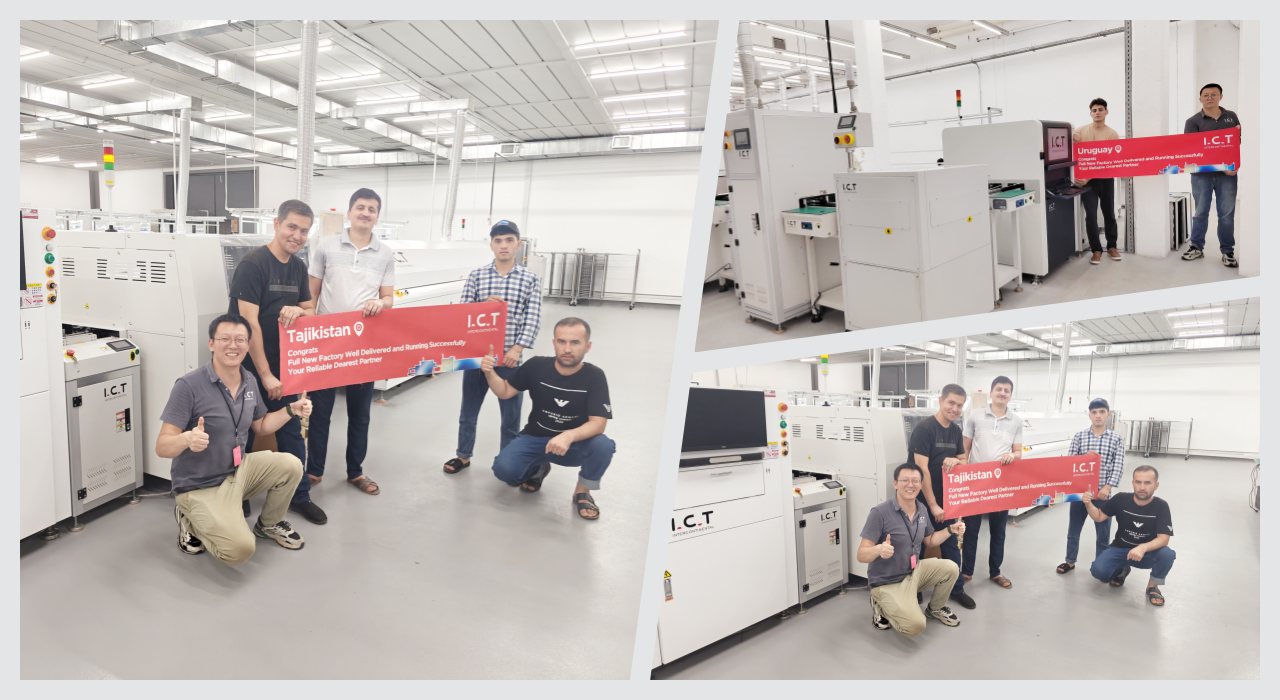

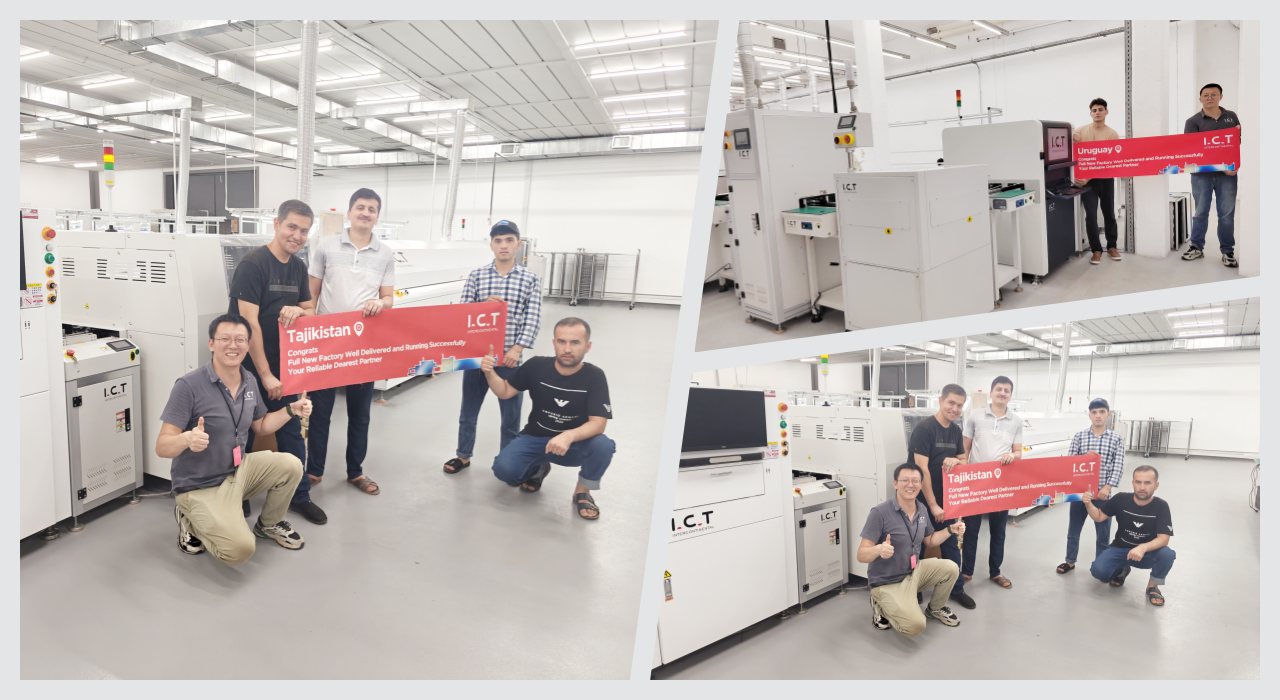

| Customer Success Story

Two I.C.T engineers proceeded to Uruguay to oversee the commissioning of a smart electric meter production line. The customer had procured magazine loader, 471 and 481 printers, Lyra622 mounter, AOI, turning conveyor, reflow oven W2, several SMT Cooling Conveyors, magazine belt lines, roller lines, and bull-eye workstations. The team executed installation, calibrated cooling parameters, and conducted operator training within seven days. The line now maintains consistent temperature reduction post-reflow, with boards proceeding without thermal defects. The customer acknowledged the conveyor's orderly performance and the engineers' methodical, punctual assistance.

| World-Class Service & Training

I.C.T maintains continuous oversight from initial layout to operational stability. Training occurs on site or remotely, following defined curricula. Software updates remain available without charge. Remote diagnostics function around the clock. Engineers deploy within 48 hours when required. Spare parts reside in eight warehouses for immediate dispatch. Support persists until the line conforms to production specifications.

| Customer Praise

“The SMT Cooling Conveyor reduces temperature uniformly—no defects noted.”

“Engineers followed procedures precisely during commissioning.”

“Packing secured all components through transit.”

“Response to inquiries arrives promptly.”

“Training was structured and thorough.”

| Our Certification

Machines bear CE, RoHS, and ISO9001 certification, accompanied by multiple patents. Each SMT Cooling Conveyor undergoes 48-hour full-load testing prior to release. These verifications confirm adherence to safety, environmental, and performance standards.

| About Us and Factory

Since 2012, I.C.T has expanded to nearly 90 personnel within a 12,000 m² facility in Dongguan, China. Research, design, and production occur internally under regulated quality protocols. More than 1,600 customers in 72 countries operate our equipment. Eight overseas offices facilitate ongoing support. Strict inspection processes and management systems ensure consistent output.

The SMT Cooling Conveyor receives boards directly from the reflow oven, where residual heat must be reduced in a controlled manner to avoid thermal stress or solder joint failure. It applies uniform airflow through adjustable fans while the belt advances at steady speed. The system permits one-button width synchronization across connected machines. Transmission options include standard ESD belt or chain for heavier loads. Built according to standardized procedures, it operates without deviation, ensuring each board emerges at acceptable temperature for subsequent inspection or assembly. Factories rely on this conveyor to complete the thermal cycle without introducing variables or interruptions.

| Complete Conveyor Series Including Advanced Cooling Models

I.C.T produces more than ten conveyor variants. Linking models connect machines in sequence. Inspection models include illumination for examination. Gate models permit passage when required. Buffer models retain boards in reserve. The SMT linking conveyor is available in various lengths and configurations. Chain drive is provided for increased capacity. Cooling options eliminate excess heat. Each variant can be adjusted in size or function to conform to the line's requirements. The system complies without objection. The conveyor fulfills its designated role.

| Detailed Product Features

Aluminum rails, machined to exact dimension, maintain alignment under thermal load. Thicker base plates and calibrated screws prevent any shift during extended operation. Ergonomic placement of access points follows established maintenance protocols. The assembly complies with ISO and CE requirements, remaining functional over prolonged cycles with minimal adjustment.

Photoelectric sensors register board entry and exit with measured accuracy. Tower lights display operational state in predefined colors, visible across the production floor. High-frequency buttons respond reliably under repeated use. ESD grounding protects boards throughout transit. The wiring configuration adheres to safety norms, ensuring uninterrupted signal transmission.

The PLC executes commands in sequence, displayed on a 7-inch touch screen with clear status fields. Operators modify speed or width through direct input. Optional Industry 4.0 interface permits protocol integration when required. Software updates occur without halting production, maintaining system conformity.

The ESD belt advances boards at constant velocity, minimizing noise. Chain transmission engages for boards retaining higher mass or heat. Both mechanisms coordinate with fan operation to achieve required cooling profile. Transition between types follows established procedure on site.

| PCB Conveyor Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Conveyor | Automatically transportation bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data. |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Story

Two I.C.T engineers proceeded to Uruguay to oversee the commissioning of a smart electric meter production line. The customer had procured magazine loader, 471 and 481 printers, Lyra622 mounter, AOI, turning conveyor, reflow oven W2, several SMT Cooling Conveyors, magazine belt lines, roller lines, and bull-eye workstations. The team executed installation, calibrated cooling parameters, and conducted operator training within seven days. The line now maintains consistent temperature reduction post-reflow, with boards proceeding without thermal defects. The customer acknowledged the conveyor's orderly performance and the engineers' methodical, punctual assistance.

| World-Class Service & Training

I.C.T maintains continuous oversight from initial layout to operational stability. Training occurs on site or remotely, following defined curricula. Software updates remain available without charge. Remote diagnostics function around the clock. Engineers deploy within 48 hours when required. Spare parts reside in eight warehouses for immediate dispatch. Support persists until the line conforms to production specifications.

| Customer Praise

“The SMT Cooling Conveyor reduces temperature uniformly—no defects noted.”

“Engineers followed procedures precisely during commissioning.”

“Packing secured all components through transit.”

“Response to inquiries arrives promptly.”

“Training was structured and thorough.”

| Our Certification

Machines bear CE, RoHS, and ISO9001 certification, accompanied by multiple patents. Each SMT Cooling Conveyor undergoes 48-hour full-load testing prior to release. These verifications confirm adherence to safety, environmental, and performance standards.

| About Us and Factory

Since 2012, I.C.T has expanded to nearly 90 personnel within a 12,000 m² facility in Dongguan, China. Research, design, and production occur internally under regulated quality protocols. More than 1,600 customers in 72 countries operate our equipment. Eight overseas offices facilitate ongoing support. Strict inspection processes and management systems ensure consistent output.