I.C.T

| Availability: | |

|---|---|

| Quantity: | |

The SMT Inspection Conveyor moves PCBs forward in the line, yet it also pauses, holding them beneath soft, even light so that the operator may see clearly—solder joints, misplaced components, traces that whisper of imperfection—before the board continues its journey. The machine itself remains unobtrusive, its aluminum rails steady, its belt quiet, its sensors attentive without intrusion. Width adjusts with a single touch across the line; belt or chain chosen according to need. In the flow of production, it becomes a moment of stillness amid motion, helping factories catch flaws early, protect quality, and maintain the rhythm of steady output.

| Complete Conveyor Series Including Advanced Cooling Models

| Detailed Product Features

Aluminum rails rise smooth and firm, catching light as boards glide along, while thicker base plates beneath absorb any tremor of vibration. Precision screws remain tight through endless cycles; ergonomic design places controls within easy reach. The frame follows ISO and CE without deviation, enduring years of quiet service, never hurrying, never faltering, simply present as each board arrives and departs.

Sensors register the board's arrival with patient precision, signaling the light to brighten, the belt to pause if needed. Tower lights glow—green for continuation, red for pause—speaking softly across the floor. High-frequency buttons wait beneath fingers; ESD protection flows through everything, guarding what is delicate. Wiring rests orderly, dust stays away, the system remains attentive yet calm in the constant stream of work.

The 7-inch screen glows with simple clarity, showing speed, status, position as if thinking aloud. PLC beneath directs each pause and movement without haste. One touch adjusts width across the line; Industry 4.0 waits optional, ready to speak when the moment arrives. Updates drift in free, remote and gentle, the controls approachable yet deep enough for growing lines.

The ESD belt moves boards quietly, clean for normal inspection. Chain takes heavier loads when required, gripping firmly yet without noise. Both blend with the pause beneath lights. Changing from one to the other feels natural, done quickly on site. Movement stays even, boards travel undisturbed, as the conveyor continues its thoughtful work.

| PCB Conveyor Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Conveyor | Automatically transportation bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data. |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

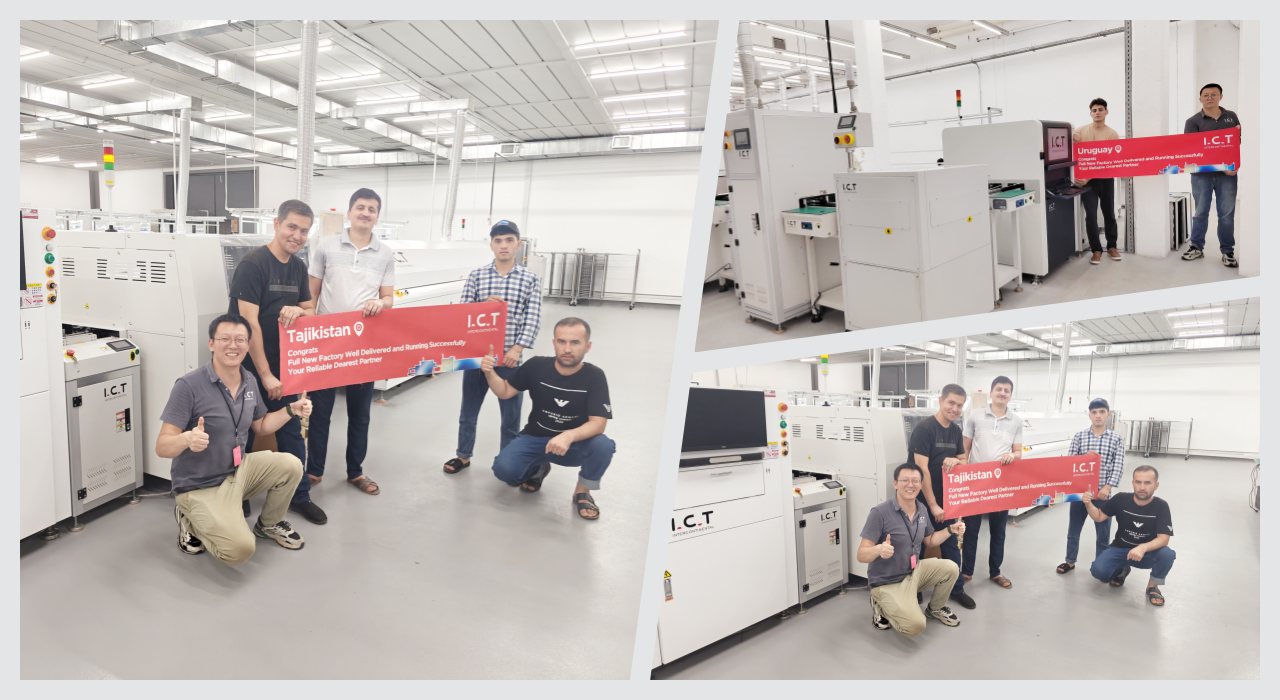

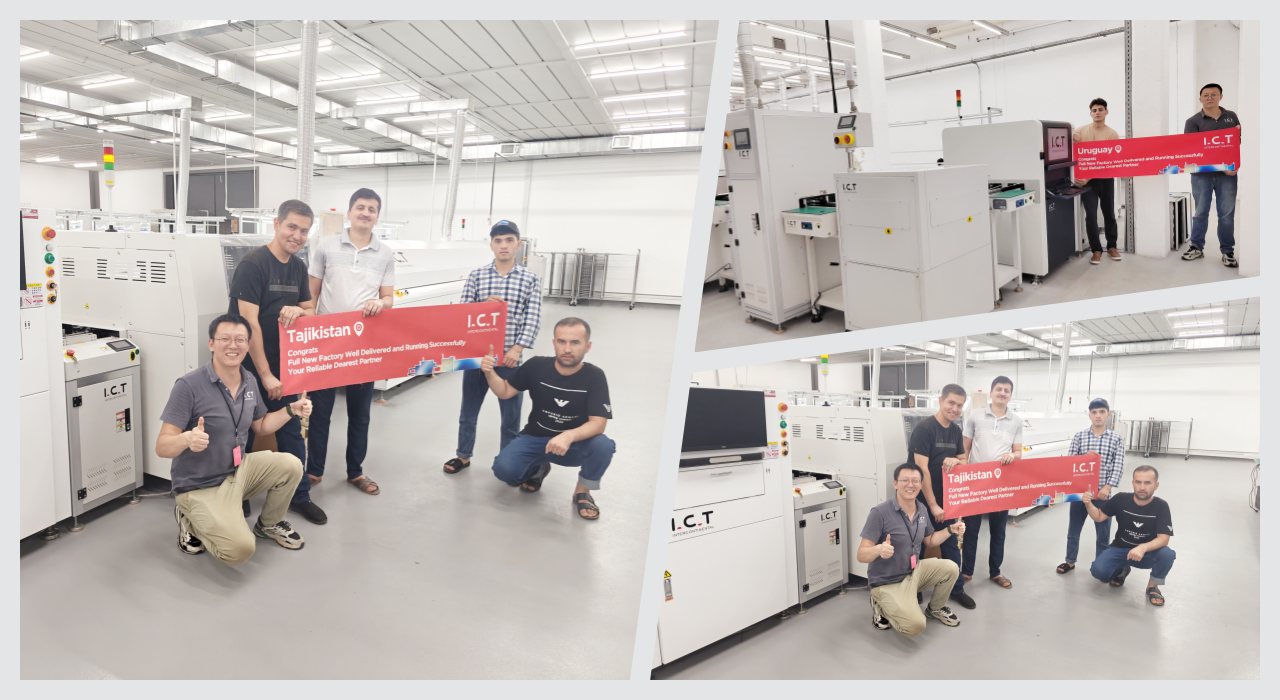

| Customer Success Story

Two I.C.T engineers crossed the distance to Uruguay, entering the smart meter factory with quiet purpose and complete preparation. The line, newly formed, included magazine loader, printers 471 and 481, Lyra622 mounter, AOI, turning conveyor, reflow oven W2, several SMT Inspection Conveyors, magazine belt lines, roller lines, and bull-eye workstations. In seven days they arranged every piece, adjusted the lights and pauses, trained operators who watched and learned. Boards now rest briefly beneath illumination, defects seen and addressed. The manager spoke of the smooth flow, the clear inspection, and the engineers' steady, attentive presence—help given fully, without rush.

| World-Class Service & Training

From the first sketch of layout to the steady hum of production, I.C.T remains near. Training flows naturally—on site or through screens—given with patience and clarity. Software updates arrive without cost, always current. Remote assistance listens 24 hours. When more becomes necessary, engineers travel swiftly, reaching any place within 48 hours. Parts wait ready in eight warehouses. We stay until the line breathes easily on its own.

| Customer Praise

“The SMT Inspection Conveyor lights make defects impossible to miss.”

“Crates arrived perfect after long shipping—no damage.”

“Engineers stayed patient, explained carefully, left us confident.”

“Questions answered quickly, even in quiet hours.”

“Reliable machines, thoughtful people—we trust them fully.”

| Our Certification

CE, RoHS, ISO9001 rest on every machine, joined by patents earned through steady effort. Each SMT Inspection Conveyor endures 48 hours of testing—full load, full speed, full attention to safety. These marks reflect daily care in every detail.

| About Us and Factory

Since 2012, I.C.T has grown quietly to nearly 90 people within a modern 12,000 square meter factory in Dongguan, China. We design and build core parts in-house, under careful standards. More than 1,600 customers in 72 countries feel this care each day. Eight offices reach outward, growth continues gently. We offer reliable equipment and service that lasts.

The SMT Inspection Conveyor moves PCBs forward in the line, yet it also pauses, holding them beneath soft, even light so that the operator may see clearly—solder joints, misplaced components, traces that whisper of imperfection—before the board continues its journey. The machine itself remains unobtrusive, its aluminum rails steady, its belt quiet, its sensors attentive without intrusion. Width adjusts with a single touch across the line; belt or chain chosen according to need. In the flow of production, it becomes a moment of stillness amid motion, helping factories catch flaws early, protect quality, and maintain the rhythm of steady output.

| Complete Conveyor Series Including Advanced Cooling Models

| Detailed Product Features

Aluminum rails rise smooth and firm, catching light as boards glide along, while thicker base plates beneath absorb any tremor of vibration. Precision screws remain tight through endless cycles; ergonomic design places controls within easy reach. The frame follows ISO and CE without deviation, enduring years of quiet service, never hurrying, never faltering, simply present as each board arrives and departs.

Sensors register the board's arrival with patient precision, signaling the light to brighten, the belt to pause if needed. Tower lights glow—green for continuation, red for pause—speaking softly across the floor. High-frequency buttons wait beneath fingers; ESD protection flows through everything, guarding what is delicate. Wiring rests orderly, dust stays away, the system remains attentive yet calm in the constant stream of work.

The 7-inch screen glows with simple clarity, showing speed, status, position as if thinking aloud. PLC beneath directs each pause and movement without haste. One touch adjusts width across the line; Industry 4.0 waits optional, ready to speak when the moment arrives. Updates drift in free, remote and gentle, the controls approachable yet deep enough for growing lines.

The ESD belt moves boards quietly, clean for normal inspection. Chain takes heavier loads when required, gripping firmly yet without noise. Both blend with the pause beneath lights. Changing from one to the other feels natural, done quickly on site. Movement stays even, boards travel undisturbed, as the conveyor continues its thoughtful work.

| PCB Conveyor Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Conveyor | Automatically transportation bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data. |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Story

Two I.C.T engineers crossed the distance to Uruguay, entering the smart meter factory with quiet purpose and complete preparation. The line, newly formed, included magazine loader, printers 471 and 481, Lyra622 mounter, AOI, turning conveyor, reflow oven W2, several SMT Inspection Conveyors, magazine belt lines, roller lines, and bull-eye workstations. In seven days they arranged every piece, adjusted the lights and pauses, trained operators who watched and learned. Boards now rest briefly beneath illumination, defects seen and addressed. The manager spoke of the smooth flow, the clear inspection, and the engineers' steady, attentive presence—help given fully, without rush.

| World-Class Service & Training

From the first sketch of layout to the steady hum of production, I.C.T remains near. Training flows naturally—on site or through screens—given with patience and clarity. Software updates arrive without cost, always current. Remote assistance listens 24 hours. When more becomes necessary, engineers travel swiftly, reaching any place within 48 hours. Parts wait ready in eight warehouses. We stay until the line breathes easily on its own.

| Customer Praise

“The SMT Inspection Conveyor lights make defects impossible to miss.”

“Crates arrived perfect after long shipping—no damage.”

“Engineers stayed patient, explained carefully, left us confident.”

“Questions answered quickly, even in quiet hours.”

“Reliable machines, thoughtful people—we trust them fully.”

| Our Certification

CE, RoHS, ISO9001 rest on every machine, joined by patents earned through steady effort. Each SMT Inspection Conveyor endures 48 hours of testing—full load, full speed, full attention to safety. These marks reflect daily care in every detail.

| About Us and Factory

Since 2012, I.C.T has grown quietly to nearly 90 people within a modern 12,000 square meter factory in Dongguan, China. We design and build core parts in-house, under careful standards. More than 1,600 customers in 72 countries feel this care each day. Eight offices reach outward, growth continues gently. We offer reliable equipment and service that lasts.