I.C.T-6300

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Continuous PCBA Cleaning for SMT Lines

The PCBA On-line Cleaning Machine is designed for manufacturers who require consistent cleaning quality while maintaining uninterrupted SMT production flow. Installed directly after reflow soldering or inspection, the system performs chemical cleaning, rinsing, and drying in a single continuous process. This approach eliminates manual handling and batch delays commonly associated with off-line cleaning. As a PCBA On-line Cleaning Machine, it supports high-volume and high-repeatability manufacturing environments where takt time and stability are critical. The system is widely applied in consumer electronics, LED products, and industrial control assemblies, helping manufacturers control residue-related risks while keeping production efficiency at a predictable level.

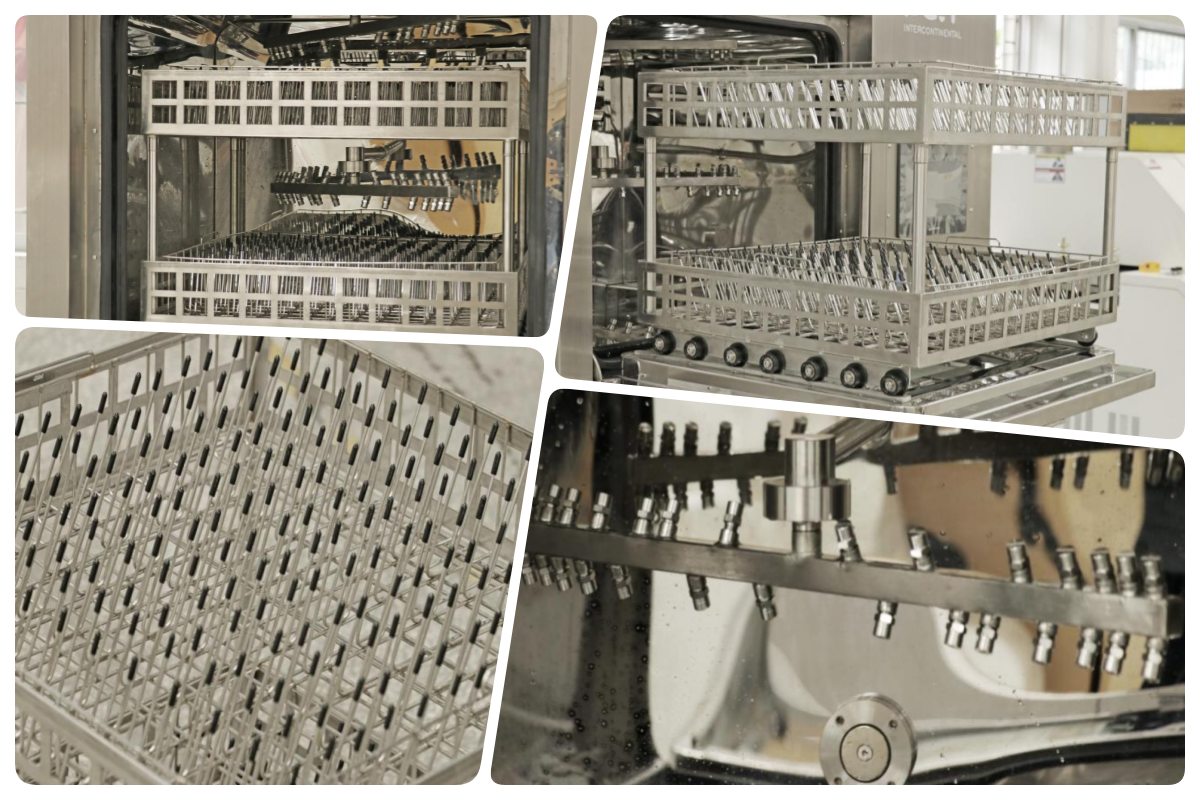

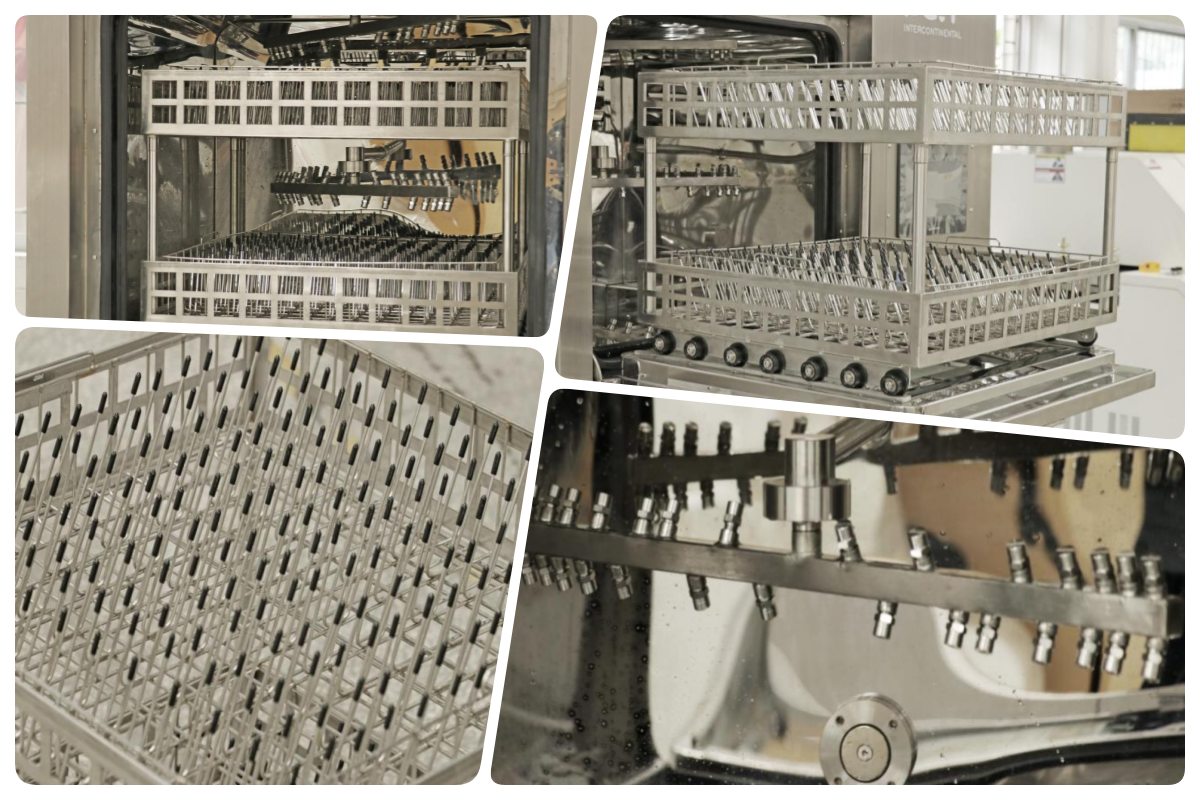

| Feature

The cleaning room is designed as a fully enclosed in-line chamber that supports continuous conveyor-based operation. PCBAs pass through multiple spray zones where cleaning liquid is applied evenly from adjustable nozzles. This structure allows residues beneath components and around solder joints to be removed without interrupting board movement. The enclosed design improves process stability and operator safety while preventing external contamination. For on-line cleaning applications, the cleaning room ensures consistent exposure time and spray coverage, even when board sizes or layouts change frequently in daily production.

The circulation pipe system is designed to maintain stable liquid flow and pressure throughout long production runs. Cleaning liquid is distributed evenly across spray zones and then collected for filtration and reuse. Multiple filtration stages prevent particles and residues from re-entering the cleaning process. This circulation structure supports predictable cleaning performance and reduces liquid consumption. In continuous SMT environments, stable circulation is essential to avoid variation between boards and shifts. The system is engineered to support long-term operation with minimal maintenance interruption.

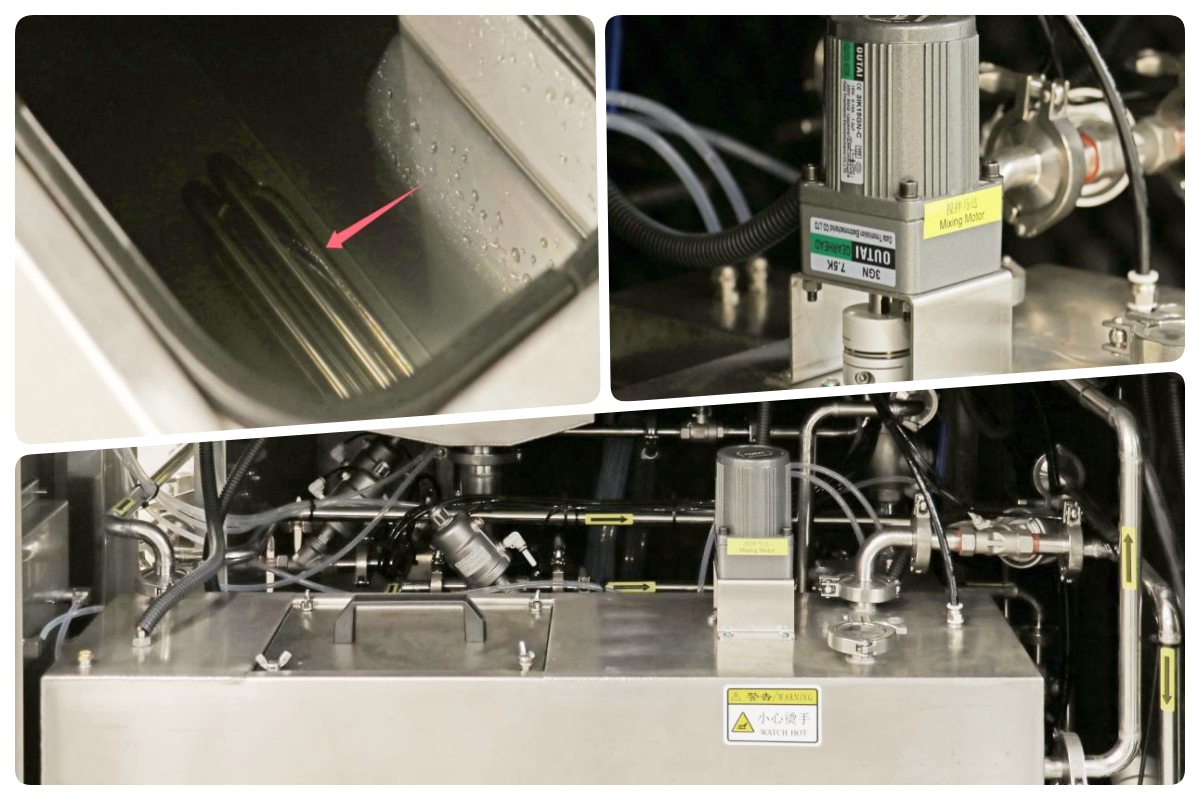

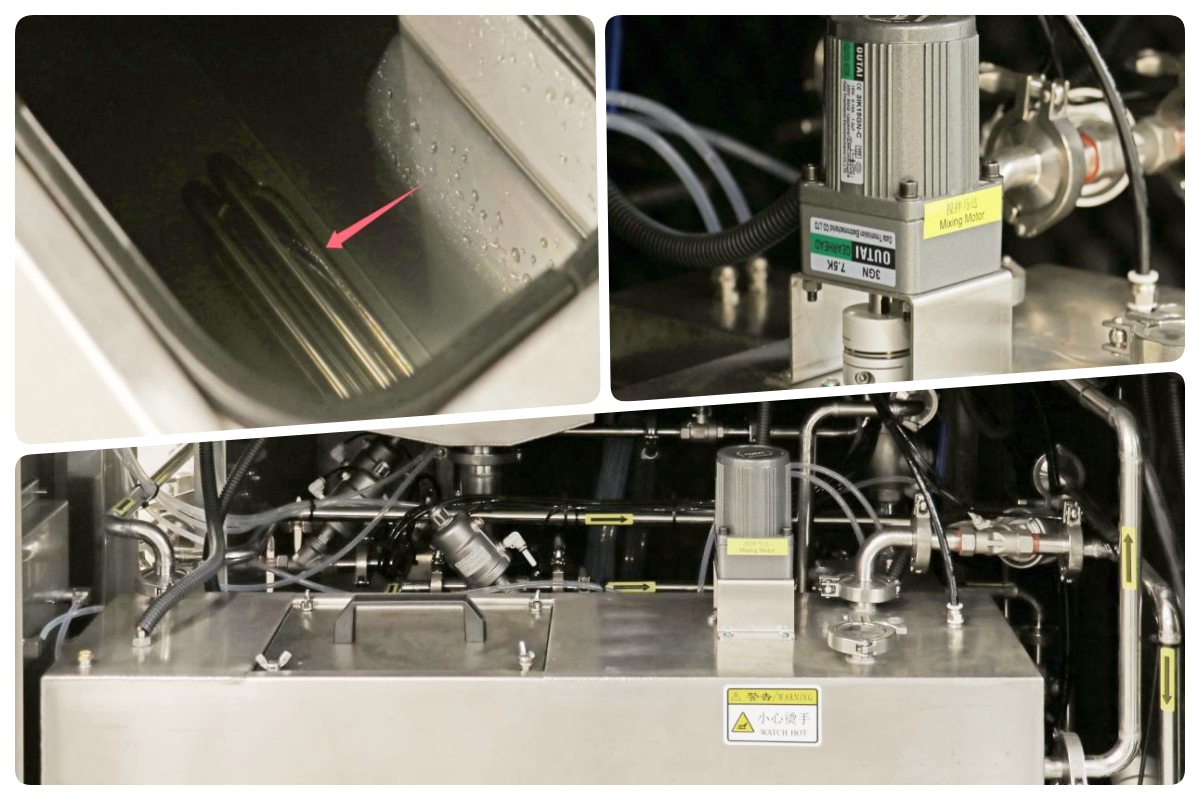

The washer fluid tank manages storage, filtration, and conditioning of the cleaning solution used during on-line operation. Integrated sensors monitor liquid level and condition to ensure stable process control. The tank design supports quick maintenance access while minimizing downtime. For a pcb automatic cleaning machine used in continuous production, proper fluid management is critical to prevent cross-contamination and maintain consistent results. This structure helps manufacturers control operating costs while ensuring reliable cleaning performance across extended production periods.

The drying module is integrated directly after the rinsing stage to ensure PCBAs exit the machine completely dry. A combination of air knives and controlled hot air zones removes residual moisture from board surfaces and component gaps. Drying temperature and airflow are adjustable to match different PCB designs and component densities. This design allows boards to move directly to inspection, testing, or downstream assembly without additional waiting time. In on-line SMT environments, integrated drying supports smooth production flow and reduces handling risks.

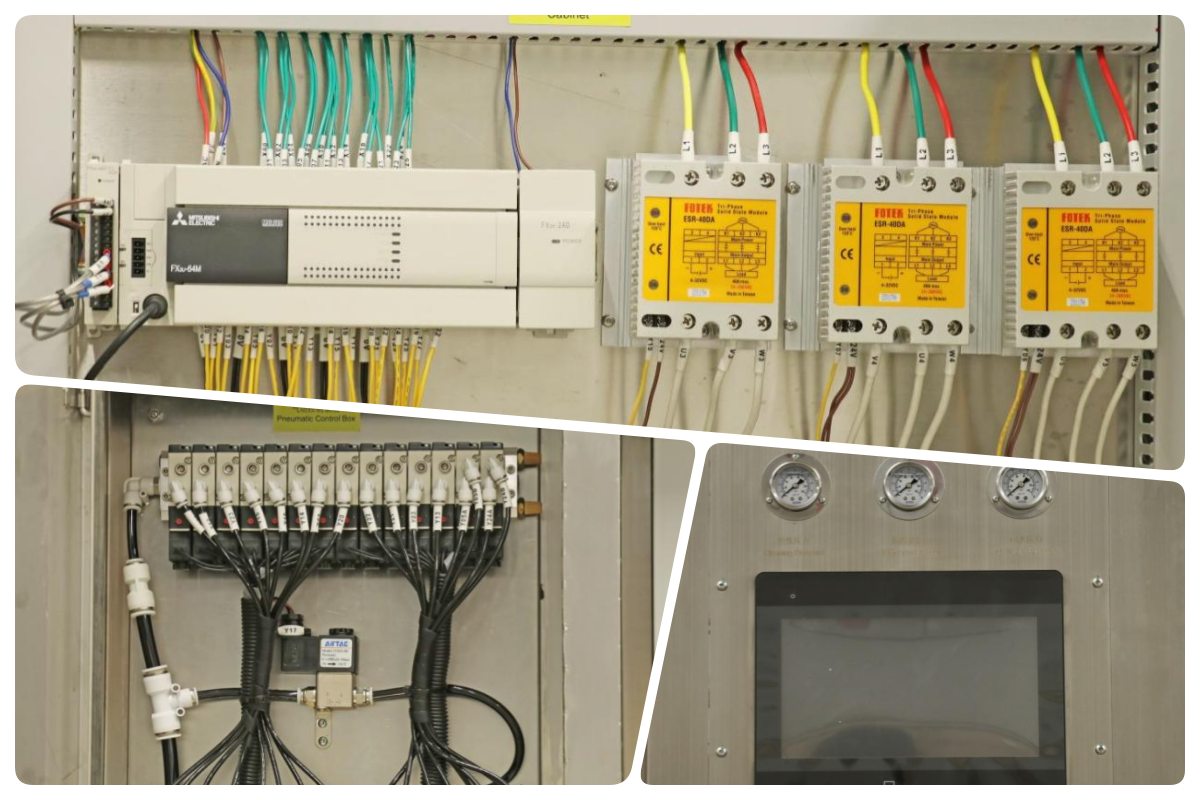

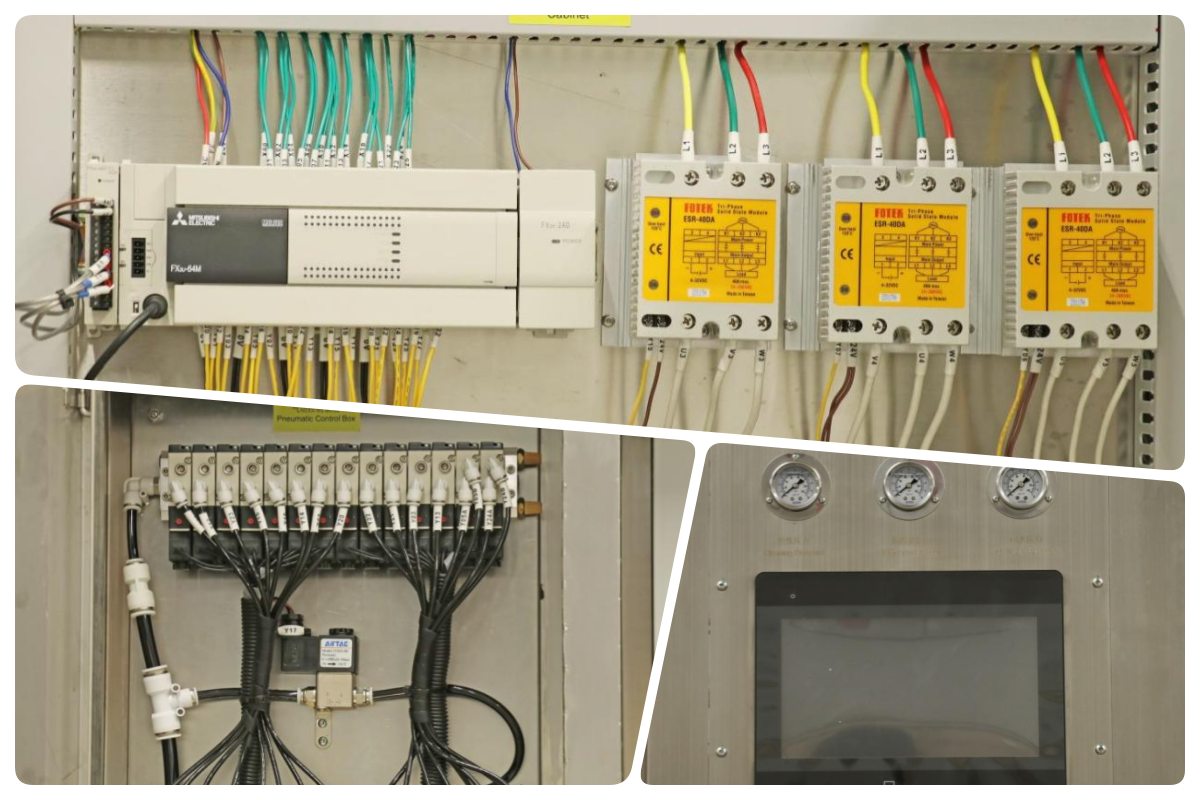

The control system coordinates cleaning, rinsing, and drying processes through a centralized PLC-based interface. Operators can store multiple recipes for different PCB products and switch between them quickly. Real-time monitoring of temperature, pressure, and conveyor speed supports stable operation. Alarm and safety functions protect both equipment and products during continuous operation. Rather than complex automation, the control logic focuses on reliability and repeatability, enabling consistent cleaning standards across shifts and production batches.

| Comparison Before and After

| Specification

| Parameter | I.C.T-5600 (Offline) | I.C.T-6300 (Online) |

|---|---|---|

| Cleaning Type | Offline batch, basket loading | Online continuous, belt conveyor |

| PCBA/Basket Size | 610 × 560 × 100 mm × 2 layers | Up to 600 × 400 × 100 mm (max conveyor width) |

| Cleaning Method | Multi-spray with heating, rinse, hot air dry | High-pressure spray, chemical + DI rinse + hot air dry |

| Tank Capacity (Diluent/Clean) | 60L (dilution) / 17L (spray tank) | 240L (clean liquid tank) |

| Concentrate Tank | 30-32L | Equipped with concentrated tank + auto add/discharge |

| Power Supply | Not specified (typically lower, ~30-50 kW est.) | 380V 3P 50/60Hz, 110-122 kW |

| Machine Dimensions | Compact (exact not listed, smaller footprint) | 5200 × 1750 × 1650-1700 mm |

| Drying | Hot air dry 10-30 min | Multi-stage hot air dry (dry 1 & dry 2) |

| Control System | Touch screen, easy parameters, password | PC + PLC, English software, adjustable pressures |

| DI Water Resistivity Monitoring | Yes, real-time | Yes, monitoring system |

| Typical Use | Small-multi variety, high-mix batches | High-volume batch, inline SMT lines |

| SMT Line Equipment List

I.C.T constructs multiple SMT production line that complement the PCB board cleaning machine seamlessly. Typical builds incorporate PCB laser marking system for traceability, printers plus SPI for accurate paste application, JUKI placement machines for rapid assembly, reflow ovens for strong solder joints, AOI scanners for thorough inspection, and conveyors for fluid transfer. Automated solder paste storage systems preserve material quality. Selective wave soldering options handle through-hole requirements. Each piece integrates expertly to form productive, customized lines. I.C.T experts guide equipment choices and installation for optimal results throughout the process.

| Customer Success Video

I.C.T successfully completed overseas installation and FAT support for two SMT production lines for a North American beauty device manufacturer. The project included laser marking systems, solder paste printers with SPI inspection, Panasonic placement machines, Heller reflow ovens, AOI inspection equipment, PCB handling systems, PCBA cleaning machines, and fully automatic solder paste storage and warming cabinets. I.C.T engineers supported installation, process setup, and trial production. Both SMT lines passed production acceptance smoothly, enabling stable mass production with improved cleanliness and process consistency.

| Service and Training

I.C.T provides service and training from a complete SMT line perspective rather than focusing on individual machines. Support includes line layout planning, equipment integration, process coordination, and on-site training. Cleaning parameters are defined in relation to soldering quality and downstream inspection requirements. Training emphasizes process understanding, preventive maintenance, and long-term stability. This approach helps customers maintain continuous production, reduce quality risks, and achieve consistent output across automated SMT lines.

| Customer Reviews

Customers consistently recognize I.C.T for its engineering professionalism and reliable delivery capability. Feedback highlights stable equipment performance, clear technical communication, and effective on-site support during overseas projects. The ability to integrate cleaning systems smoothly into existing SMT lines is frequently mentioned as a key advantage. Customers also value careful packaging and well-managed logistics. Fast response to technical questions further strengthens confidence in I.C.T as a long-term manufacturing partner.

| Our Certification

I.C.T equipment is designed and manufactured in compliance with global standards. Certifications include CE and RoHS, supporting safety and environmental requirements, as well as ISO9001 for quality management systems. Multiple patents demonstrate continuous technical improvement. These certifications help customers meet regulatory requirements and support stable deployment of equipment across different regions and markets.

| About I.C.T and SMT Factory

I.C.T is a professional manufacturer and solution provider specializing in SMT, DIP, and electronic assembly production lines. With strong in-house research, engineering, and manufacturing capabilities, the company supports customers worldwide. I.C.T employs a large technical team and continues to expand globally. Strict inspection and quality control processes ensure reliable equipment performance. Through extensive project experience, I.C.T helps customers build efficient, scalable, and stable manufacturing systems.

| Continuous PCBA Cleaning for SMT Lines

The PCBA On-line Cleaning Machine is designed for manufacturers who require consistent cleaning quality while maintaining uninterrupted SMT production flow. Installed directly after reflow soldering or inspection, the system performs chemical cleaning, rinsing, and drying in a single continuous process. This approach eliminates manual handling and batch delays commonly associated with off-line cleaning. As a PCBA On-line Cleaning Machine, it supports high-volume and high-repeatability manufacturing environments where takt time and stability are critical. The system is widely applied in consumer electronics, LED products, and industrial control assemblies, helping manufacturers control residue-related risks while keeping production efficiency at a predictable level.

| Feature

The cleaning room is designed as a fully enclosed in-line chamber that supports continuous conveyor-based operation. PCBAs pass through multiple spray zones where cleaning liquid is applied evenly from adjustable nozzles. This structure allows residues beneath components and around solder joints to be removed without interrupting board movement. The enclosed design improves process stability and operator safety while preventing external contamination. For on-line cleaning applications, the cleaning room ensures consistent exposure time and spray coverage, even when board sizes or layouts change frequently in daily production.

The circulation pipe system is designed to maintain stable liquid flow and pressure throughout long production runs. Cleaning liquid is distributed evenly across spray zones and then collected for filtration and reuse. Multiple filtration stages prevent particles and residues from re-entering the cleaning process. This circulation structure supports predictable cleaning performance and reduces liquid consumption. In continuous SMT environments, stable circulation is essential to avoid variation between boards and shifts. The system is engineered to support long-term operation with minimal maintenance interruption.

The washer fluid tank manages storage, filtration, and conditioning of the cleaning solution used during on-line operation. Integrated sensors monitor liquid level and condition to ensure stable process control. The tank design supports quick maintenance access while minimizing downtime. For a pcb automatic cleaning machine used in continuous production, proper fluid management is critical to prevent cross-contamination and maintain consistent results. This structure helps manufacturers control operating costs while ensuring reliable cleaning performance across extended production periods.

The drying module is integrated directly after the rinsing stage to ensure PCBAs exit the machine completely dry. A combination of air knives and controlled hot air zones removes residual moisture from board surfaces and component gaps. Drying temperature and airflow are adjustable to match different PCB designs and component densities. This design allows boards to move directly to inspection, testing, or downstream assembly without additional waiting time. In on-line SMT environments, integrated drying supports smooth production flow and reduces handling risks.

The control system coordinates cleaning, rinsing, and drying processes through a centralized PLC-based interface. Operators can store multiple recipes for different PCB products and switch between them quickly. Real-time monitoring of temperature, pressure, and conveyor speed supports stable operation. Alarm and safety functions protect both equipment and products during continuous operation. Rather than complex automation, the control logic focuses on reliability and repeatability, enabling consistent cleaning standards across shifts and production batches.

| Comparison Before and After

| Specification

| Parameter | I.C.T-5600 (Offline) | I.C.T-6300 (Online) |

|---|---|---|

| Cleaning Type | Offline batch, basket loading | Online continuous, belt conveyor |

| PCBA/Basket Size | 610 × 560 × 100 mm × 2 layers | Up to 600 × 400 × 100 mm (max conveyor width) |

| Cleaning Method | Multi-spray with heating, rinse, hot air dry | High-pressure spray, chemical + DI rinse + hot air dry |

| Tank Capacity (Diluent/Clean) | 60L (dilution) / 17L (spray tank) | 240L (clean liquid tank) |

| Concentrate Tank | 30-32L | Equipped with concentrated tank + auto add/discharge |

| Power Supply | Not specified (typically lower, ~30-50 kW est.) | 380V 3P 50/60Hz, 110-122 kW |

| Machine Dimensions | Compact (exact not listed, smaller footprint) | 5200 × 1750 × 1650-1700 mm |

| Drying | Hot air dry 10-30 min | Multi-stage hot air dry (dry 1 & dry 2) |

| Control System | Touch screen, easy parameters, password | PC + PLC, English software, adjustable pressures |

| DI Water Resistivity Monitoring | Yes, real-time | Yes, monitoring system |

| Typical Use | Small-multi variety, high-mix batches | High-volume batch, inline SMT lines |

| SMT Line Equipment List

I.C.T constructs multiple SMT production line that complement the PCB board cleaning machine seamlessly. Typical builds incorporate PCB laser marking system for traceability, printers plus SPI for accurate paste application, JUKI placement machines for rapid assembly, reflow ovens for strong solder joints, AOI scanners for thorough inspection, and conveyors for fluid transfer. Automated solder paste storage systems preserve material quality. Selective wave soldering options handle through-hole requirements. Each piece integrates expertly to form productive, customized lines. I.C.T experts guide equipment choices and installation for optimal results throughout the process.

| Customer Success Video

I.C.T successfully completed overseas installation and FAT support for two SMT production lines for a North American beauty device manufacturer. The project included laser marking systems, solder paste printers with SPI inspection, Panasonic placement machines, Heller reflow ovens, AOI inspection equipment, PCB handling systems, PCBA cleaning machines, and fully automatic solder paste storage and warming cabinets. I.C.T engineers supported installation, process setup, and trial production. Both SMT lines passed production acceptance smoothly, enabling stable mass production with improved cleanliness and process consistency.

| Service and Training

I.C.T provides service and training from a complete SMT line perspective rather than focusing on individual machines. Support includes line layout planning, equipment integration, process coordination, and on-site training. Cleaning parameters are defined in relation to soldering quality and downstream inspection requirements. Training emphasizes process understanding, preventive maintenance, and long-term stability. This approach helps customers maintain continuous production, reduce quality risks, and achieve consistent output across automated SMT lines.

| Customer Reviews

Customers consistently recognize I.C.T for its engineering professionalism and reliable delivery capability. Feedback highlights stable equipment performance, clear technical communication, and effective on-site support during overseas projects. The ability to integrate cleaning systems smoothly into existing SMT lines is frequently mentioned as a key advantage. Customers also value careful packaging and well-managed logistics. Fast response to technical questions further strengthens confidence in I.C.T as a long-term manufacturing partner.

| Our Certification

I.C.T equipment is designed and manufactured in compliance with global standards. Certifications include CE and RoHS, supporting safety and environmental requirements, as well as ISO9001 for quality management systems. Multiple patents demonstrate continuous technical improvement. These certifications help customers meet regulatory requirements and support stable deployment of equipment across different regions and markets.

| About I.C.T and SMT Factory

I.C.T is a professional manufacturer and solution provider specializing in SMT, DIP, and electronic assembly production lines. With strong in-house research, engineering, and manufacturing capabilities, the company supports customers worldwide. I.C.T employs a large technical team and continues to expand globally. Strict inspection and quality control processes ensure reliable equipment performance. Through extensive project experience, I.C.T helps customers build efficient, scalable, and stable manufacturing systems.