D600 (LENS)

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Precision PCB Board Dispensing Machine

The PCB board dispensing machine arrives on the factory floor. Operators watch it start. Servo motors engage. Vision system locates marks without hesitation. Valve releases glue in exact measures. Preheating keeps flow consistent. Syringes change without pause. Machine continues through shifts. Boards emerge sealed. Lenses fixed. Medical components protected. Red glue lines clean. Output steady. Downtime rare. Managers note the change. Fewer errors. Higher volume. The machine simply performs, day after day, asking nothing in return.

| Detailed Product Features

Glue exits the valve in controlled amounts. Servo and screw maintain repetition. Preheating holds temperature steady. Different adhesives respond the same. Syringe replacement quick. Purge cycle prevents issues. Bonds remain strong across runs. The PCB board dispensing machine delivers results operators trust.

Belts move boards forward. Separate motors ensure smooth travel. Stop device holds position firm. Rails adjust width while staying aligned. Supports various board sizes and weights. Direction changes handled easily. The PCB board dispensing machine keeps material flowing without interruption.

Cleaning starts with one command. Cycle finishes rapidly. Valve stays clear. Temperature control preserves glue quality. Little time lost. The PCB board dispensing machine prepares for next production quickly.

PLC coordinates with computer. Reliable components chosen carefully. Standards met fully. Future upgrades possible. Interface clear for users. The PCB board dispensing machine operates steadily in real conditions.

| Specification

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

| SMT Line Equipment List

Boards load automatically. PCB board dispensing machine applies glue precisely. Components placed on adhesive. Curing hardens bonds quickly. Inspection confirms quality optionally. Line runs coordinated. Few operators required. Yield high consistently. Suitable for automotive, medical, LED uses. Complete system provided with single responsibility.

| Product Name | Purpose in Glue Dispensing Line |

|---|---|

| Glue Dispensing Machine | Delivers high-speed, ultra-precise glue dispensing |

| Conformal Coating Machine | Applies final protective coating for reliability |

| Pick and Place Machine | Accurately places components onto fresh glue |

| Curing Oven | Rapidly cures glue with IR or UV technology |

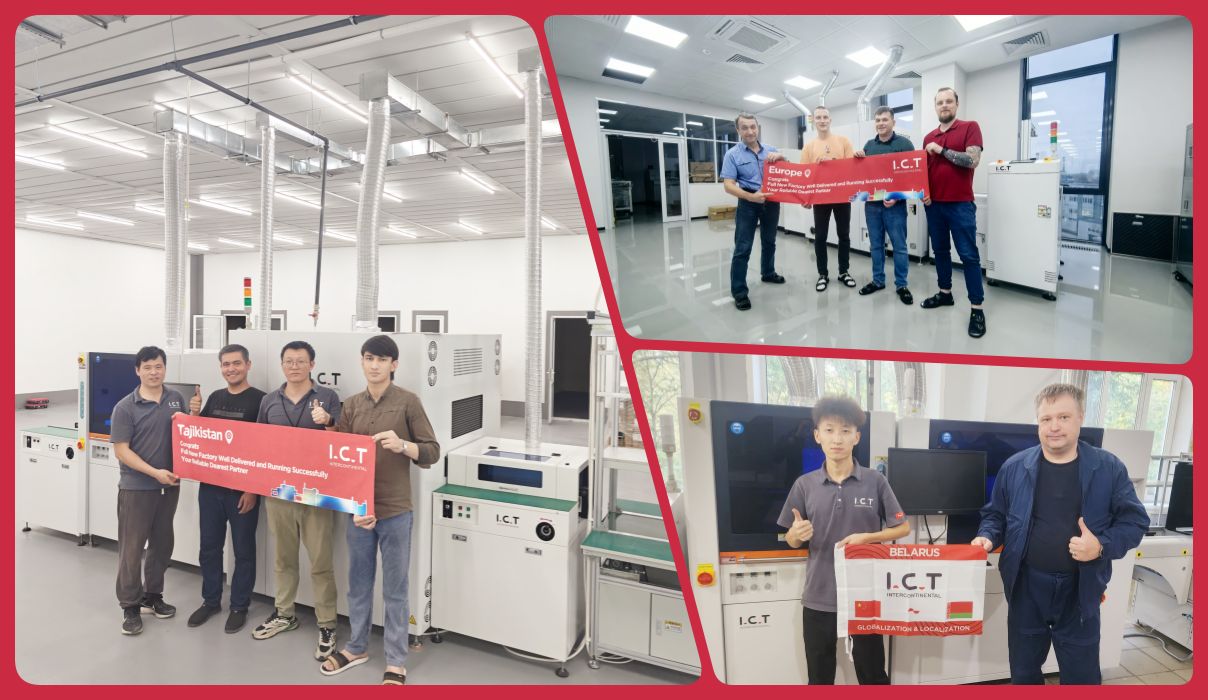

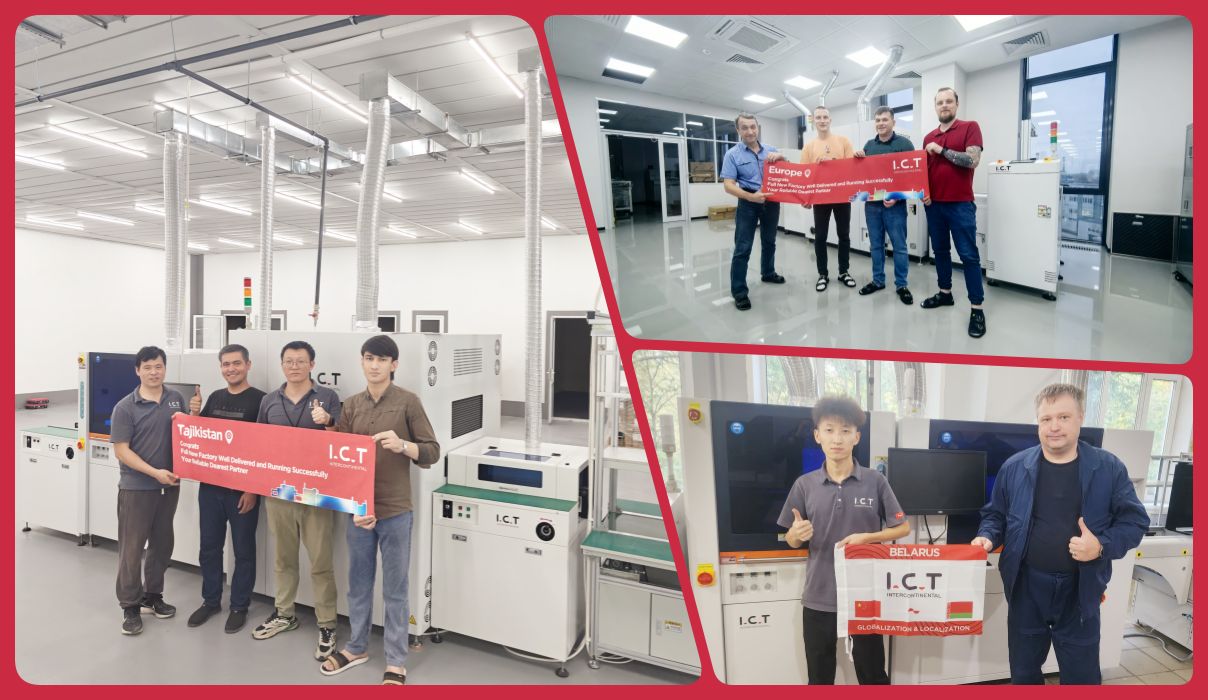

| Customer Success Story

Our engineers arrived in Tajikistan after shipment. Customer purchased multiple lines: two SMT, one DIP, one coating, one dispensing, one LED bulb assembly. Setup completed efficiently. PCB board dispensing machine placed glue accurately from start. Components positioned. Curing finished. Inspection passed. Local staff trained thoroughly. Production began smoothly. Customer documented process and confirmed satisfaction with outcome.

| Professional Training & Support

Support begins with delivery. Engineers train until independence achieved. Remote assistance resolves issues promptly. Parts available globally. On-site help scheduled quickly. Updates provided regularly. The PCB board dispensing machine supports ongoing production needs effectively.

| Customer Praise

Engineers praised for knowledge. Machine noted for consistent performance. Packaging protected during shipment. Responses to questions arrived fast. Overall experience positive.

| Our Certification

CE compliance. RoHS standards. ISO9001 management. Patents secured. PCB board dispensing machine meets international requirements.

| About Us and Factory

Own research and production in Dongguan. Facility spans 12 000 m². Team includes 89 members and 20 engineers. Growth steady since 2012. Serves over 1 600 customers in 72 countries. Testing rigorous. Quality controlled closely.

| Precision PCB Board Dispensing Machine

The PCB board dispensing machine arrives on the factory floor. Operators watch it start. Servo motors engage. Vision system locates marks without hesitation. Valve releases glue in exact measures. Preheating keeps flow consistent. Syringes change without pause. Machine continues through shifts. Boards emerge sealed. Lenses fixed. Medical components protected. Red glue lines clean. Output steady. Downtime rare. Managers note the change. Fewer errors. Higher volume. The machine simply performs, day after day, asking nothing in return.

| Detailed Product Features

Glue exits the valve in controlled amounts. Servo and screw maintain repetition. Preheating holds temperature steady. Different adhesives respond the same. Syringe replacement quick. Purge cycle prevents issues. Bonds remain strong across runs. The PCB board dispensing machine delivers results operators trust.

Belts move boards forward. Separate motors ensure smooth travel. Stop device holds position firm. Rails adjust width while staying aligned. Supports various board sizes and weights. Direction changes handled easily. The PCB board dispensing machine keeps material flowing without interruption.

Cleaning starts with one command. Cycle finishes rapidly. Valve stays clear. Temperature control preserves glue quality. Little time lost. The PCB board dispensing machine prepares for next production quickly.

PLC coordinates with computer. Reliable components chosen carefully. Standards met fully. Future upgrades possible. Interface clear for users. The PCB board dispensing machine operates steadily in real conditions.

| Specification

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

| SMT Line Equipment List

Boards load automatically. PCB board dispensing machine applies glue precisely. Components placed on adhesive. Curing hardens bonds quickly. Inspection confirms quality optionally. Line runs coordinated. Few operators required. Yield high consistently. Suitable for automotive, medical, LED uses. Complete system provided with single responsibility.

| Product Name | Purpose in Glue Dispensing Line |

|---|---|

| Glue Dispensing Machine | Delivers high-speed, ultra-precise glue dispensing |

| Conformal Coating Machine | Applies final protective coating for reliability |

| Pick and Place Machine | Accurately places components onto fresh glue |

| Curing Oven | Rapidly cures glue with IR or UV technology |

| Customer Success Story

Our engineers arrived in Tajikistan after shipment. Customer purchased multiple lines: two SMT, one DIP, one coating, one dispensing, one LED bulb assembly. Setup completed efficiently. PCB board dispensing machine placed glue accurately from start. Components positioned. Curing finished. Inspection passed. Local staff trained thoroughly. Production began smoothly. Customer documented process and confirmed satisfaction with outcome.

| Professional Training & Support

Support begins with delivery. Engineers train until independence achieved. Remote assistance resolves issues promptly. Parts available globally. On-site help scheduled quickly. Updates provided regularly. The PCB board dispensing machine supports ongoing production needs effectively.

| Customer Praise

Engineers praised for knowledge. Machine noted for consistent performance. Packaging protected during shipment. Responses to questions arrived fast. Overall experience positive.

| Our Certification

CE compliance. RoHS standards. ISO9001 management. Patents secured. PCB board dispensing machine meets international requirements.

| About Us and Factory

Own research and production in Dongguan. Facility spans 12 000 m². Team includes 89 members and 20 engineers. Growth steady since 2012. Serves over 1 600 customers in 72 countries. Testing rigorous. Quality controlled closely.