RS-1R

JUKI

| Availability: | |

|---|---|

| Quantity: | |

| SMT IC Mounting Machine

The SMT pnp machine from Juki does the plain work of setting components on circuit boards in real factories. It runs steady, places tiny chips and bigger pieces where they belong. RS models give solid speed and handle different board sizes without fuss. RX models pack more power into less room, good when space runs short. Heads move quick, cameras check every pick, software keeps track easy. Plants use them for car parts, lights, phones—whatever needs boards done right. I.C.T comes in early, sets the line up, stays around to fix what needs fixing. Lines run longer, output stays even.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

The RS-1R goes 47,000 CPH optimum, keeps accuracy at ±35µm. Boards fit up to 650×370mm single, bigger with double clamp. The RS-1XL opens to 650×560mm, takes wider work like LED strips. Both carry Takumi heads that switch jobs smooth. Parts run from 0201 to 74mm square or long ones. Feeders max out at 112. Machines sit compact so lines line up easy. Vision catches mistakes early, force control keeps things gentle. They fit shops that change jobs often, need speed without losing board size. I.C.T tunes them to the floor, makes sure they run quiet and steady.

RX-7R / RX-8 Series Features

The RX-7R runs 75,000 CPH on small chips, uses P16 heads, holds accuracy near ±0.04mm. It places 03015 parts up to 25mm square. Boards go 510×450mm single lane. The RX-8 pushes 100,000 CPH with P20 head, built for tight, high-count work. Both stay 998mm wide, fit where older ones took more room. Dual lanes move boards quick, monitoring shows what slows down. Low-impact placement saves parts and boards. These handle big runs of small stuff—phones, lights, auto electronics—when every inch and second matters. The build gives high output without spreading out.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T sets up plain PCB assembly lines that work without drama. Vacuum loader brings boards in clean. Auto SMT printer puts paste down exact. SMT pnp machine drops chips where they go. Reflow oven heats solder even across zones. AOI looks close, finds bad spots fast. Conveyors keep boards moving, no pile-up. Yield goes up, costs come down. No long stops, no rework pile. Lines take on car power supplies, LED boards, tough daily runs. Boards come off ready, no loose ends. I.C.T stands by the whole thing from day one.

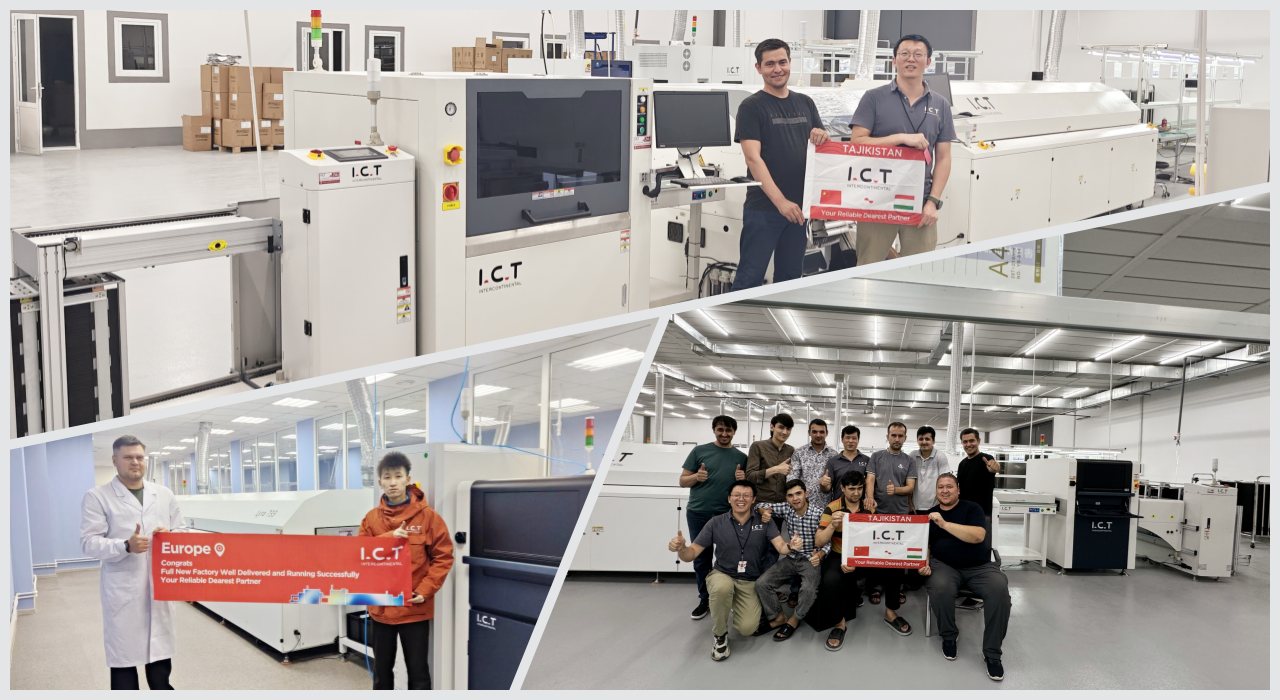

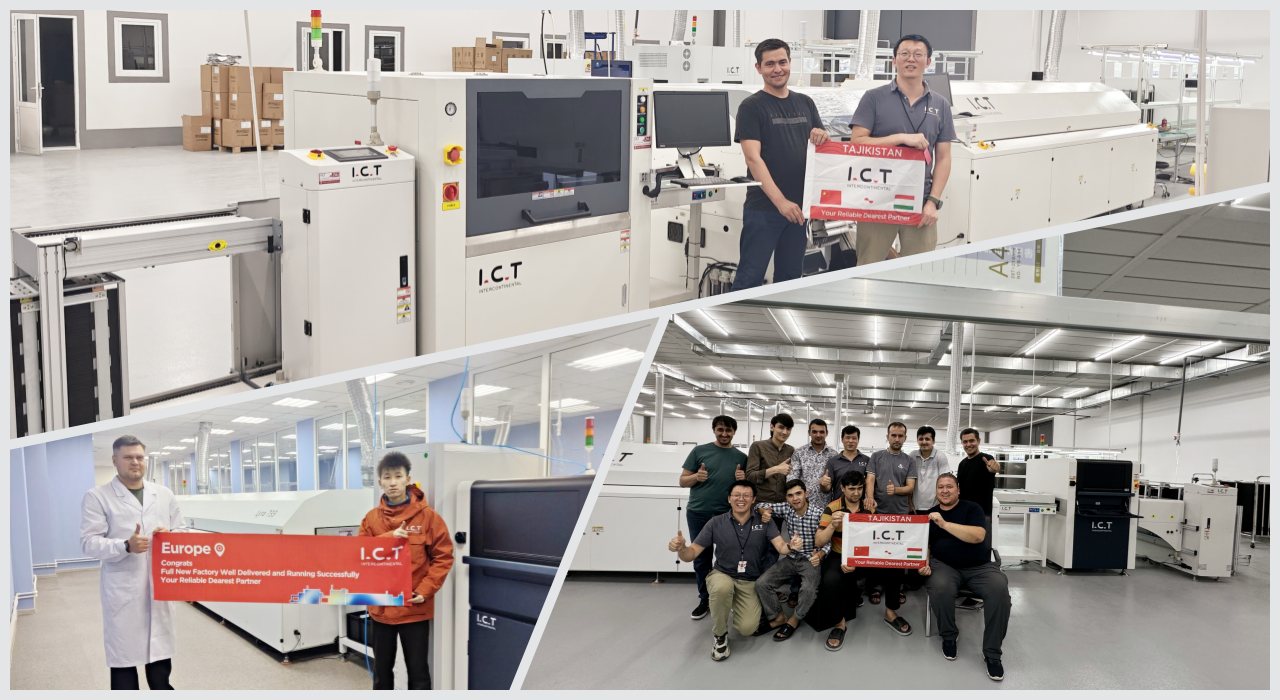

| Customer Success Video

The video lets a customer talk straight about their SMT and DIP lines running automotive power supplies. Loader feeds boards clean, cleaner wipes them, printer lays paste, then the SMT IC mounting machine places parts quick and dead-on. Conveyors take boards to reflow, cooling buffer, AOI scan, unloaders. DIP runs wave solder, flipper turns boards, ICT checks connections. Footage shows it all—machines hum steady, boards travel smooth, placement sits right. The customer says errors stay low, pace holds even. Quality meets car specs, downtime barely shows up. The line just keeps going in their shop.

| Service and Training Support

I.C.T sends people right to the floor for SMT pnp machine install and startup. They show operators the daily checks, how to build programs, how to handle small fixes. Remote help comes fast when something stops. Service plans keep machines clean and running long. Teams shift lines or add jobs without big breaks. Offices sit around the world so help shows up soon. Customers learn quick, keep boards coming steady. This turns machines into tools that last, no big surprises.

| Customer Feedback

Customers say engineers show up knowing the job and fix things fast. They talk about the SMT pnp machine running smooth shift after shift, no fuss. Packing holds up—machines arrive straight after the trip. Questions get answered same day, lines stay moving. Many note the setup works better than they figured, fewer stops, cleaner boards. Trust comes from gear that holds and people who back it. Shops count on I.C.T to keep production plain and steady.

| Certifications and Standards

I.C.T keeps its own people working on new SMT designs. The factory runs large, checks every step from parts in to machines out. Staff grew quick since 2012. We reach over 1600 customers in more than 72 countries now. Branch offices sit close for fast help. Quality steps track each build so machines hold up under real work. I.C.T gives full lines—from first plan to later changes—helping shops stay steady in electronics.

| About I.C.T Company and Factory

I.C.T keeps its own research crews busy inventing better SMT gear. Big modern factories turn those ideas into real machines. Every station has tough checks to catch problems early. Team and offices have grown fast lately. We now look after more than 1600 customers spread across 72 countries with full electronics line solutions. Strong quality systems make sure each Smart Placement machine stands up to hard daily work and keeps performing year after year.

| SMT IC Mounting Machine

The SMT pnp machine from Juki does the plain work of setting components on circuit boards in real factories. It runs steady, places tiny chips and bigger pieces where they belong. RS models give solid speed and handle different board sizes without fuss. RX models pack more power into less room, good when space runs short. Heads move quick, cameras check every pick, software keeps track easy. Plants use them for car parts, lights, phones—whatever needs boards done right. I.C.T comes in early, sets the line up, stays around to fix what needs fixing. Lines run longer, output stays even.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

The RS-1R goes 47,000 CPH optimum, keeps accuracy at ±35µm. Boards fit up to 650×370mm single, bigger with double clamp. The RS-1XL opens to 650×560mm, takes wider work like LED strips. Both carry Takumi heads that switch jobs smooth. Parts run from 0201 to 74mm square or long ones. Feeders max out at 112. Machines sit compact so lines line up easy. Vision catches mistakes early, force control keeps things gentle. They fit shops that change jobs often, need speed without losing board size. I.C.T tunes them to the floor, makes sure they run quiet and steady.

RX-7R / RX-8 Series Features

The RX-7R runs 75,000 CPH on small chips, uses P16 heads, holds accuracy near ±0.04mm. It places 03015 parts up to 25mm square. Boards go 510×450mm single lane. The RX-8 pushes 100,000 CPH with P20 head, built for tight, high-count work. Both stay 998mm wide, fit where older ones took more room. Dual lanes move boards quick, monitoring shows what slows down. Low-impact placement saves parts and boards. These handle big runs of small stuff—phones, lights, auto electronics—when every inch and second matters. The build gives high output without spreading out.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T sets up plain PCB assembly lines that work without drama. Vacuum loader brings boards in clean. Auto SMT printer puts paste down exact. SMT pnp machine drops chips where they go. Reflow oven heats solder even across zones. AOI looks close, finds bad spots fast. Conveyors keep boards moving, no pile-up. Yield goes up, costs come down. No long stops, no rework pile. Lines take on car power supplies, LED boards, tough daily runs. Boards come off ready, no loose ends. I.C.T stands by the whole thing from day one.

| Customer Success Video

The video lets a customer talk straight about their SMT and DIP lines running automotive power supplies. Loader feeds boards clean, cleaner wipes them, printer lays paste, then the SMT IC mounting machine places parts quick and dead-on. Conveyors take boards to reflow, cooling buffer, AOI scan, unloaders. DIP runs wave solder, flipper turns boards, ICT checks connections. Footage shows it all—machines hum steady, boards travel smooth, placement sits right. The customer says errors stay low, pace holds even. Quality meets car specs, downtime barely shows up. The line just keeps going in their shop.

| Service and Training Support

I.C.T sends people right to the floor for SMT pnp machine install and startup. They show operators the daily checks, how to build programs, how to handle small fixes. Remote help comes fast when something stops. Service plans keep machines clean and running long. Teams shift lines or add jobs without big breaks. Offices sit around the world so help shows up soon. Customers learn quick, keep boards coming steady. This turns machines into tools that last, no big surprises.

| Customer Feedback

Customers say engineers show up knowing the job and fix things fast. They talk about the SMT pnp machine running smooth shift after shift, no fuss. Packing holds up—machines arrive straight after the trip. Questions get answered same day, lines stay moving. Many note the setup works better than they figured, fewer stops, cleaner boards. Trust comes from gear that holds and people who back it. Shops count on I.C.T to keep production plain and steady.

| Certifications and Standards

I.C.T keeps its own people working on new SMT designs. The factory runs large, checks every step from parts in to machines out. Staff grew quick since 2012. We reach over 1600 customers in more than 72 countries now. Branch offices sit close for fast help. Quality steps track each build so machines hold up under real work. I.C.T gives full lines—from first plan to later changes—helping shops stay steady in electronics.

| About I.C.T Company and Factory

I.C.T keeps its own research crews busy inventing better SMT gear. Big modern factories turn those ideas into real machines. Every station has tough checks to catch problems early. Team and offices have grown fast lately. We now look after more than 1600 customers spread across 72 countries with full electronics line solutions. Strong quality systems make sure each Smart Placement machine stands up to hard daily work and keeps performing year after year.