I.C.T-5700

I.C.T

PCB Auto Depanelizer Machine

| Availability: | |

|---|---|

| Quantity: | |

| Offline PCB Auto Depanelizer Machine

The I.C.T-5700 PCB Auto Depanelizer Machine serves as a dedicated solution for separating assembled PCBs with controlled accuracy and reduced mechanical stress. It finds application across smartphones, smart wearables, tablets, automotive electronics, medical equipment, aerospace components, and military-grade products. Available in models supporting PCB sizes from 340×380 mm up to 450×600 mm, with thicknesses ranging from 0.5 to 5.0 mm, the machine accommodates diverse production requirements. Its dual-platform configuration enables concurrent handling of different board types or combination into a single large working area for flexibility. The spindle reaches speeds of 60,000 rpm while keeping cutting forces low. Advanced CCD vision identifies marks and performs automatic positional correction. Ionization removes static buildup, and the separate high-efficiency vacuum system extracts dust with minimal noise. Operator-friendly controls, comprehensive safety features, and full data traceability support reliable daily operation. This off line PCBA router contributes directly to higher yield and consistent quality in final depaneling stages.

| Feature

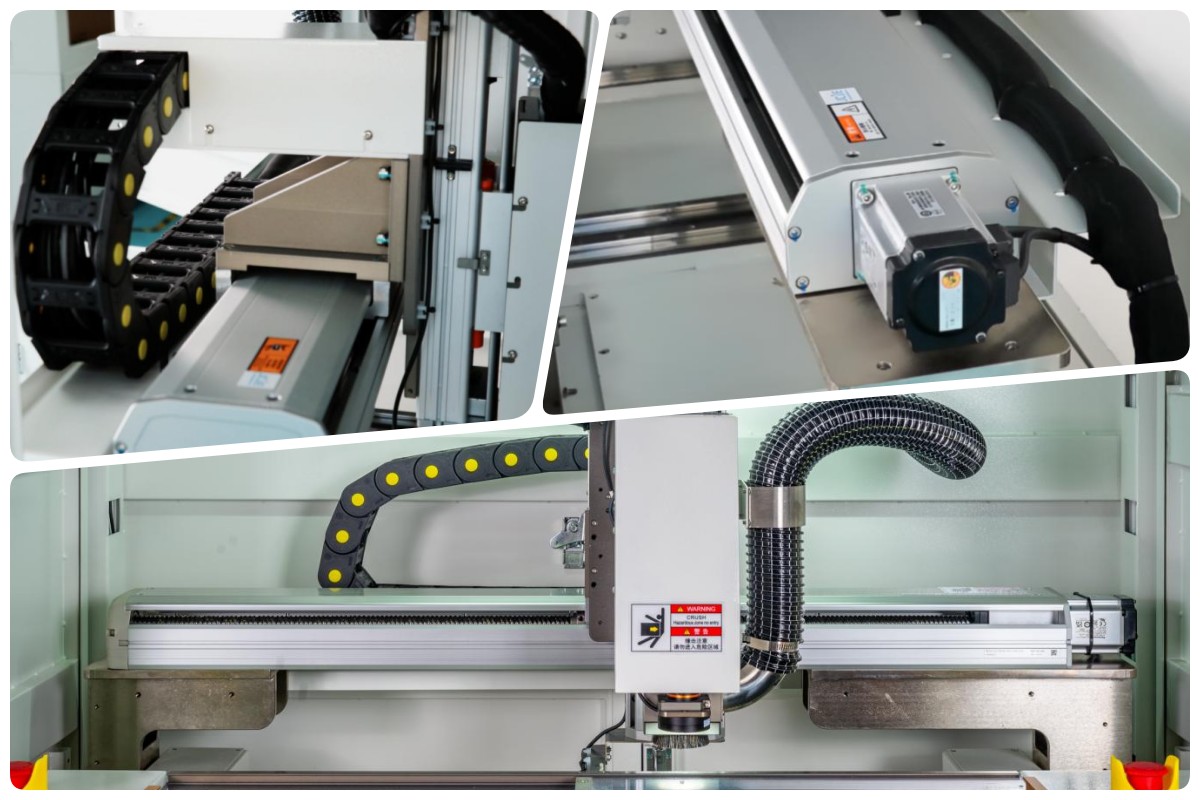

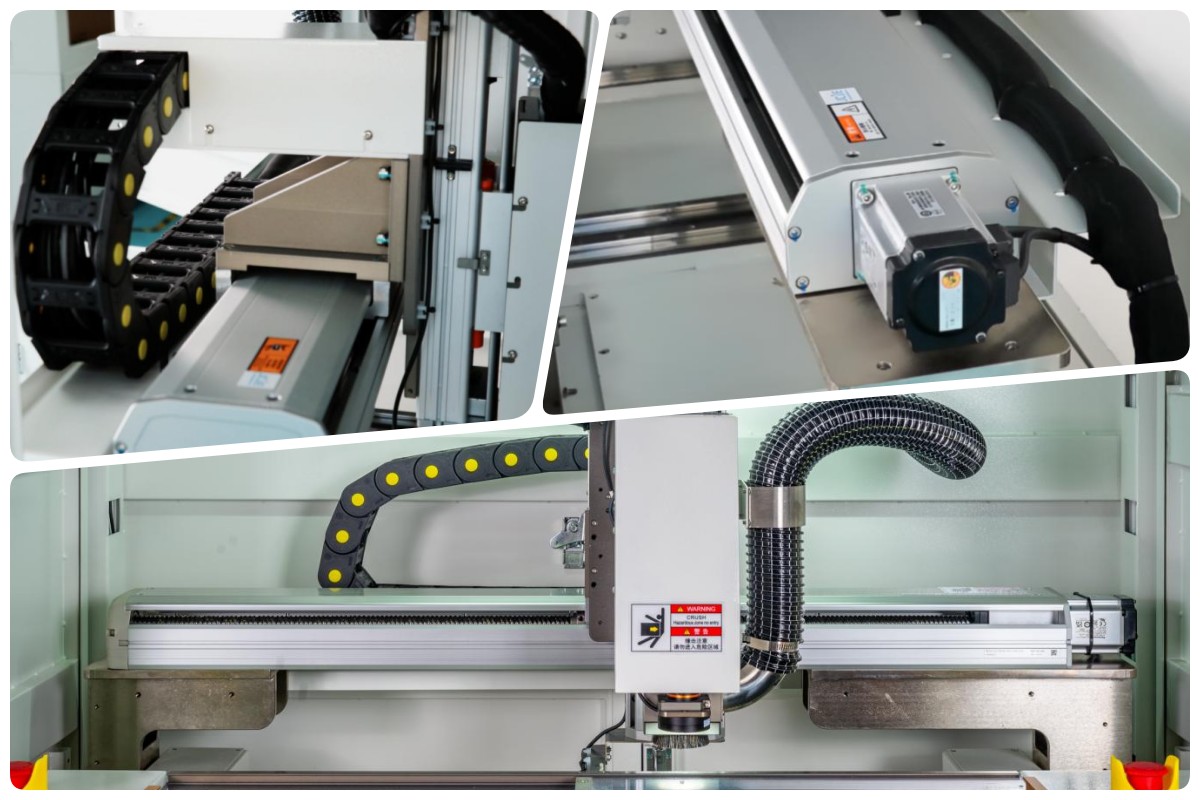

Transmission System

The transmission relies on imported Panasonic servo motors paired with high-precision screw rods to guarantee exact motion control across all axes. The mechanical framework incorporates thicker structural elements that significantly enhance operational stability, even under continuous heavy-duty cycles. Flexible tank chains route cables in an organized manner, eliminating any risk of interference with dynamic components while preserving a clean aesthetic. The X-axis module features a specialized dust-proof enclosure that effectively blocks contaminants, thereby extending service intervals and reducing overall maintenance expenses. Positioning repeatability consistently achieves ±0.01 mm, with maximum cutting speeds reaching 100 mm per second. The entire system operates with noticeably low vibration and noise levels, allowing operators to maintain focus during extended shifts. These engineering choices collectively ensure the PCB Auto Depanelizer Machine delivers dependable performance in high-volume manufacturing settings where precision cannot be compromised.

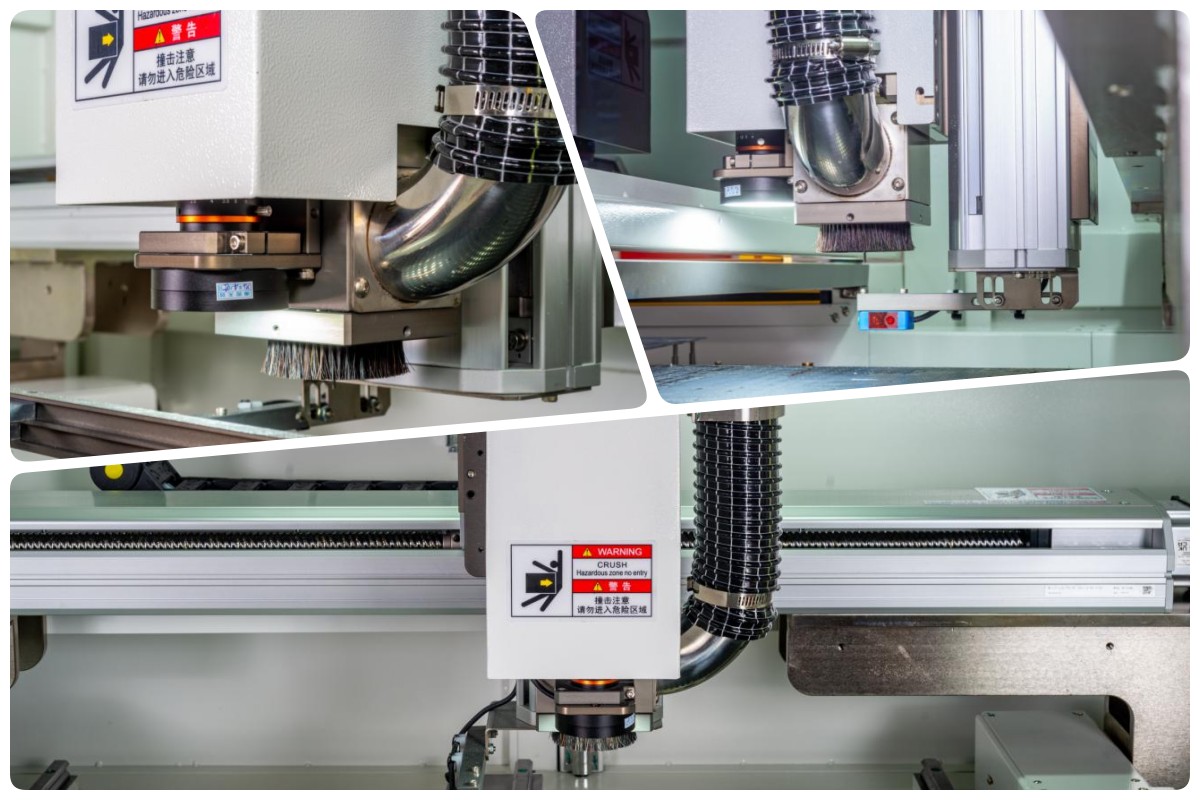

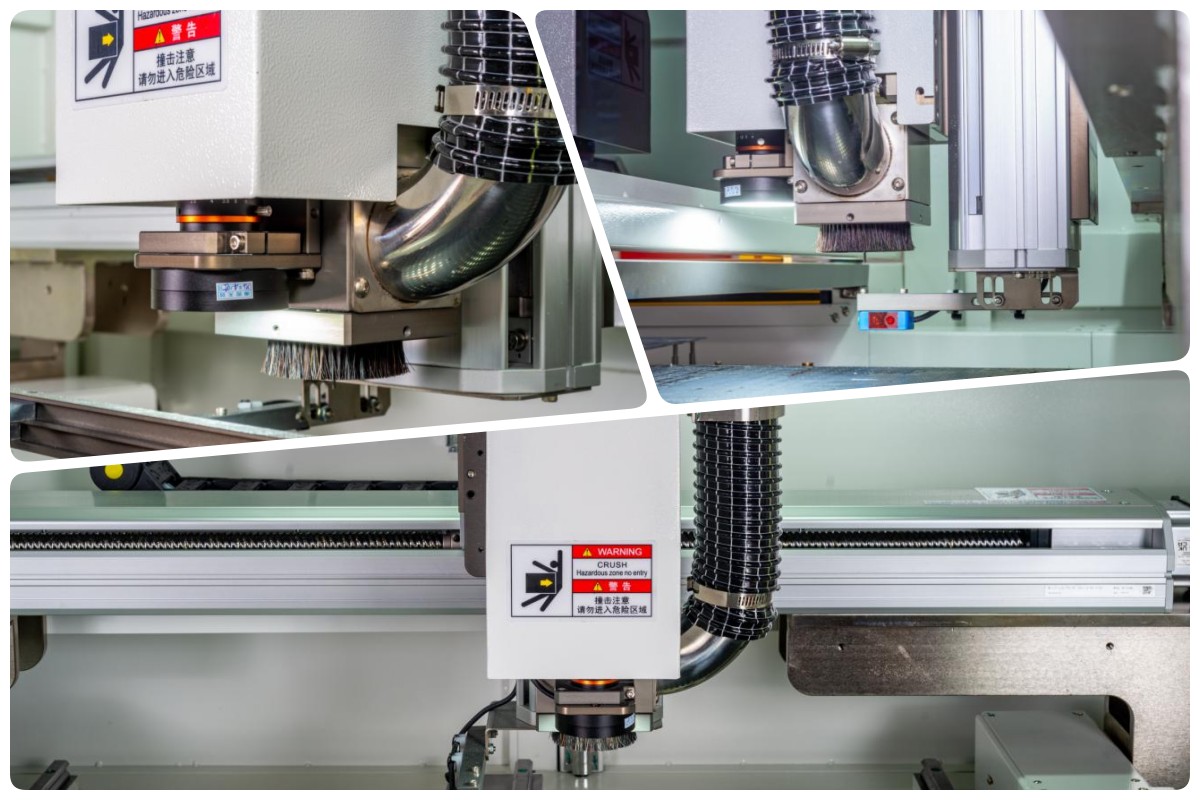

Router System

A high-definition vision system aligns coaxially with the milling cutter, simplifying calibration procedures and ensuring consistent accuracy. Built-in tool breakage detection continuously monitors cutter condition, issuing an immediate alarm to halt operation before further damage occurs. The optional automatic tool-changing mechanism enables seamless continuation of production without manual intervention, thereby maximizing uptime. An integrated ion air gun systematically neutralizes static electricity on PCB surfaces, effectively preventing particulate adhesion that could compromise cut quality. Imported high-speed spindles operate with markedly reduced cutting stress, maintain exceptional precision, exhibit low inertia, and provide rapid response characteristics. Supported cutter sizes range from 0.8 to 3 mm, accommodating a broad spectrum of board complexities. The accompanying vacuum system removes debris efficiently. This configuration makes the Pcb Router Separator particularly effective for intricate pcb depanel tasks.

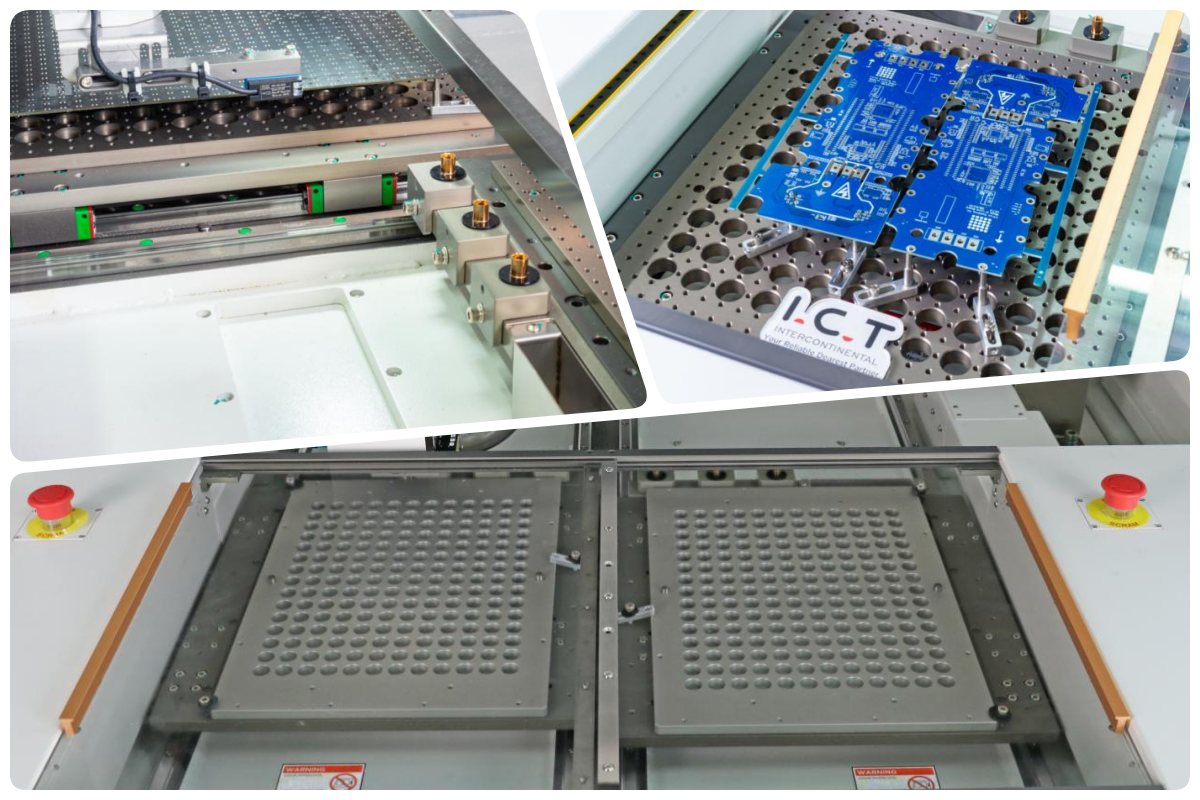

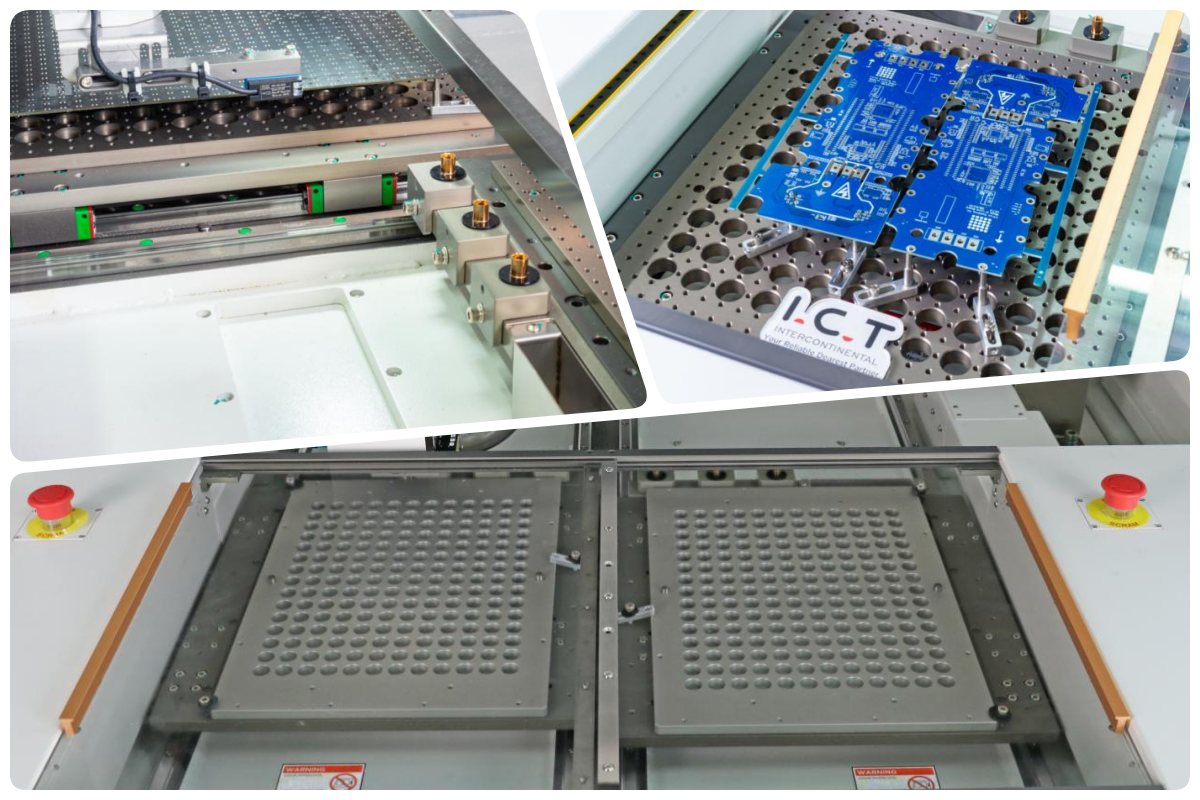

Platform System

Y-axis movement is managed through precision slide rails and servo motor control, resulting in highly stable platform positioning. Dual emergency stop buttons, positioned for easy access from either side, contribute to layered safety protocols. Standard protective covers combined with safety light curtains create comprehensive operator safeguards. Dual start buttons require simultaneous activation to initiate machine cycles, incorporating a deliberate two-hand control measure that minimizes accidental starts. The honeycomb porous base plate offers broad compatibility with multifunctional and custom fixtures. The dual-platform architecture supports independent processing of separate jobs or unification into a single extended workspace. Full compliance with CE and UL standards is maintained throughout the design. Cutting accuracy remains at ±0.05 mm under normal operation, providing confidence in sensitive applications such as automotive and medical electronics.

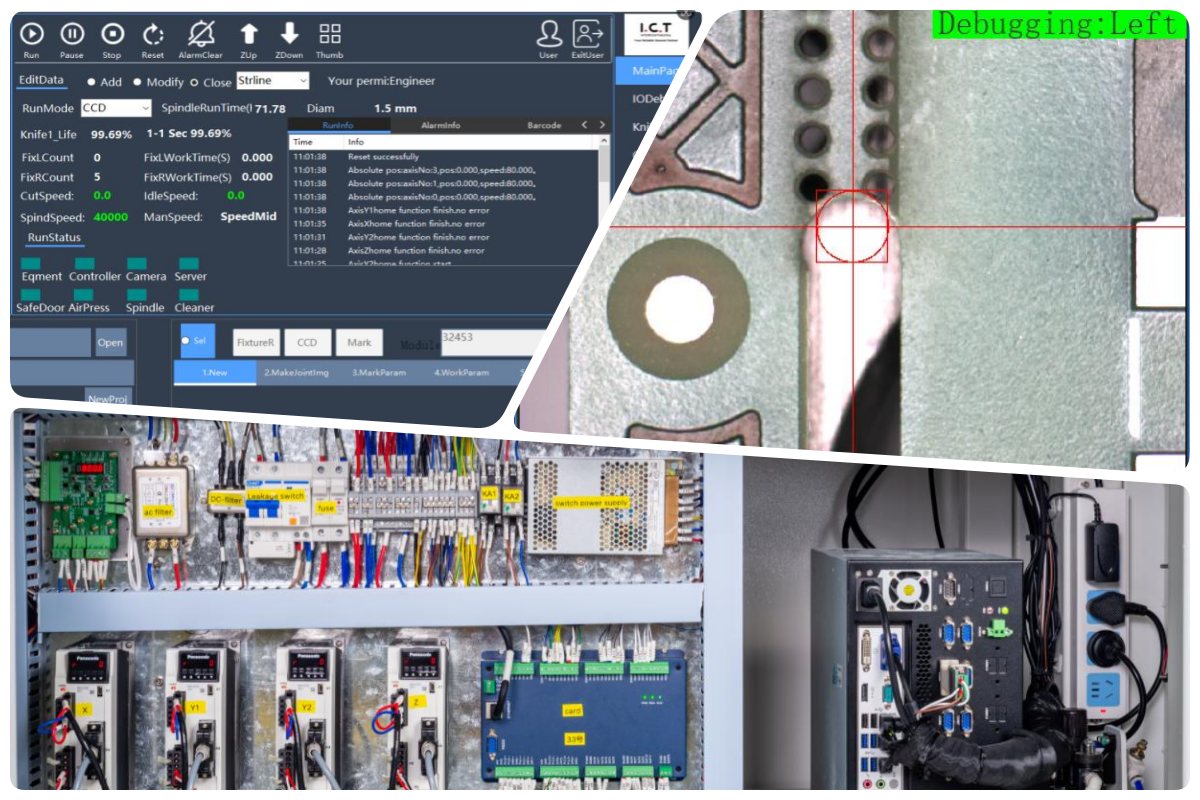

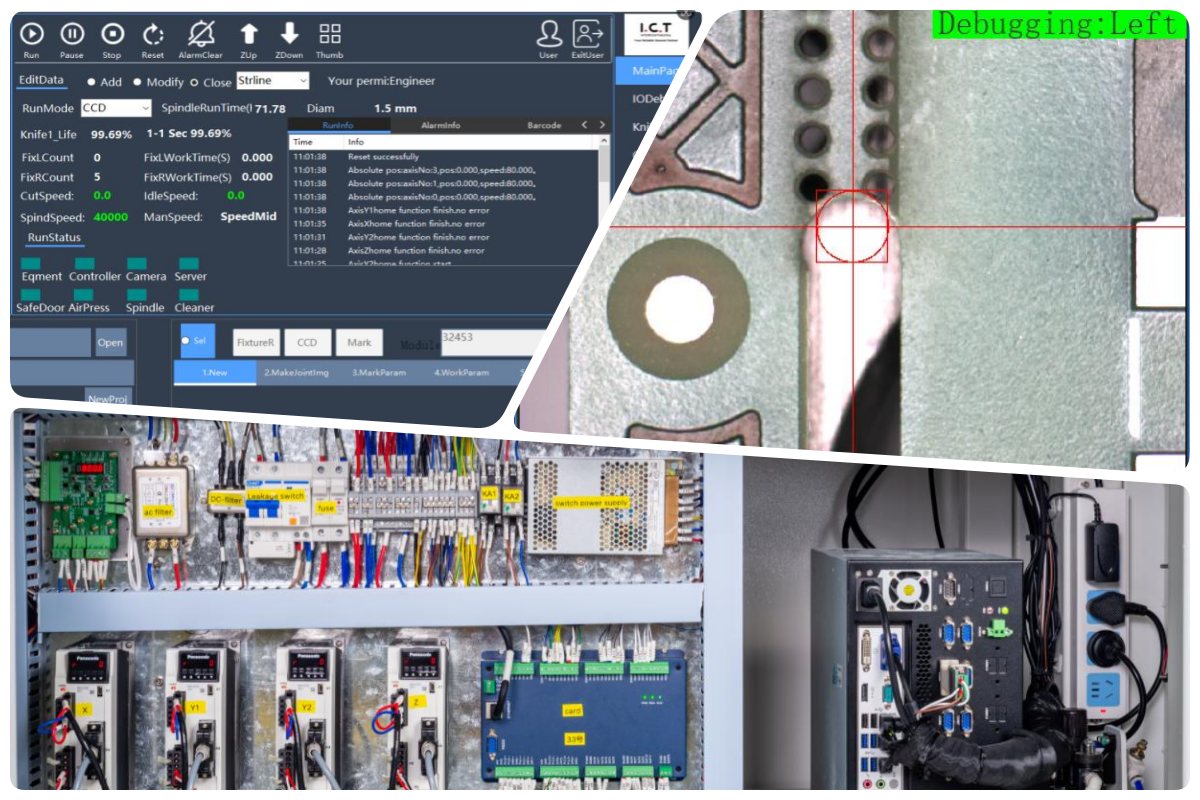

Control System

Control is managed via an industrial-grade computer interfaced with a dedicated control card, delivering superior accuracy alongside robust long-term stability. All production parameters and events are logged automatically, enabling generation of comprehensive traceability reports on demand. The physical layout adheres strictly to CE and UL electrical and safety standards. The user interface employs straightforward navigation, allowing operators to master basic functions quickly and execute product program changes with minimal delay. A coaxial CCD camera supplies continuous real-time visual monitoring for precise alignment verification. CNC-based controllers demonstrate strong resistance to electromagnetic interference. Standard integrated breakage and slip detection features add further layers of process protection. Operating at 1.5 kW on standard 220 V supply, the system integrates readily into existing SMT environments.

Detail Display

Critical subsystems are readily observable: convection fans regulate internal temperatures, side-door safety sensors enhance enclosure security, and ESD interfaces provide essential grounding protection. The automatic tool changer minimizes manual handling time. Broken-knife detection sensors deliver prompt alerts. Self-locking pneumatic struts facilitate safe, controlled access during maintenance. Component sourcing includes Panasonic servomotors (Japan), RSK/NSK spindles (China/Japan), HIKVISION CCD (China), PMI/HIWIN guide rails (Taiwan), TBI ball screws (Taiwan), Delta power supplies (Taiwan), Omron sensors (Japan), and NSK bearings (Japan). This deliberate selection of proven brands contributes to extended operational life and reduced unplanned downtime. Optional upper vacuuming further optimizes dust extraction performance.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

A feature phone production facility in Algeria arranged an on-site verification visit, arriving with more than ten distinct board types and accompanying materials. Our engineers configured a complete SMT production line immediately. The demonstration proceeded sequentially: automatic solder paste printing, SPI paste inspection, component placement via RX-8 for small parts and RS-1R for larger components, tray-fed shielding cover application, reflow soldering, AOI optical verification, and final separation using the PCB Auto Depanelizer Machine. Throughout the process, the client observed closely. The resulting boards exhibited clean, precise edges with negligible defect rates. The line demonstrated consistent stability and throughput. This practical, hands-on validation left the team fully convinced of the equipment's suitability for integration into their existing manufacturing operations.

| Service and Training Support

I.C.T delivers end-to-end service beginning with on-site installation and commissioning of the PCB auto depanelizer. Experienced engineers conduct structured training programs covering machine operation, program creation, routine maintenance, and troubleshooting procedures. Training accommodates operators at varying experience levels. Remote technical assistance ensures rapid response to queries. Spare parts logistics maintain high availability to limit production interruptions. Drawing on more than 25 years of electronics manufacturing expertise, the support team addresses practical factory challenges effectively. Clients in 72 countries benefit from uniform professional service. Ongoing process optimization and upgrade recommendations occur as production requirements evolve. The overarching goal is to provide dependable, worry-free equipment performance.

| Client Testimonials

Customers consistently appreciate the clarity and responsiveness of our engineers during installation and commissioning. They frequently highlight the PCB Router Separator for its reliable precision and smooth performance across extended production runs. Many specifically mention the careful, professional packaging that ensures the machine arrives undamaged after international shipping. Rapid handling of technical questions and issues reinforces trust. Overall, the combination of equipment quality and attentive support enables factories to meet demanding schedules without unnecessary complications.

| Certifications and Standards

I.C.T equipment carries CE, RoHS, and ISO9001 certifications, supplemented by multiple registered patents. These certifications verify that the off line PCBA router satisfies stringent international requirements for safety, environmental responsibility, and manufacturing quality. Each machine undergoes rigorous factory testing. Customers can proceed with confidence in documented compliance and proven performance.

| About I.C.T Company and Factory

Founded in 2012, I.C.T maintains a 12,000 square meter production facility staffed by 89 employees, including 20 specialized engineers focused on research and development. In-house design, manufacturing, and quality control drive continuous product advancement. Steady growth has resulted in service to over 1,600 customers across 72 countries. Strict inspection protocols are enforced at every production stage. A comprehensive quality management system ensures consistent standards from component receipt through final assembly. This operational framework supports reliable delivery of full SMT solutions while fostering long-term global partnerships.

| Offline PCB Auto Depanelizer Machine

The I.C.T-5700 PCB Auto Depanelizer Machine serves as a dedicated solution for separating assembled PCBs with controlled accuracy and reduced mechanical stress. It finds application across smartphones, smart wearables, tablets, automotive electronics, medical equipment, aerospace components, and military-grade products. Available in models supporting PCB sizes from 340×380 mm up to 450×600 mm, with thicknesses ranging from 0.5 to 5.0 mm, the machine accommodates diverse production requirements. Its dual-platform configuration enables concurrent handling of different board types or combination into a single large working area for flexibility. The spindle reaches speeds of 60,000 rpm while keeping cutting forces low. Advanced CCD vision identifies marks and performs automatic positional correction. Ionization removes static buildup, and the separate high-efficiency vacuum system extracts dust with minimal noise. Operator-friendly controls, comprehensive safety features, and full data traceability support reliable daily operation. This off line PCBA router contributes directly to higher yield and consistent quality in final depaneling stages.

| Feature

Transmission System

The transmission relies on imported Panasonic servo motors paired with high-precision screw rods to guarantee exact motion control across all axes. The mechanical framework incorporates thicker structural elements that significantly enhance operational stability, even under continuous heavy-duty cycles. Flexible tank chains route cables in an organized manner, eliminating any risk of interference with dynamic components while preserving a clean aesthetic. The X-axis module features a specialized dust-proof enclosure that effectively blocks contaminants, thereby extending service intervals and reducing overall maintenance expenses. Positioning repeatability consistently achieves ±0.01 mm, with maximum cutting speeds reaching 100 mm per second. The entire system operates with noticeably low vibration and noise levels, allowing operators to maintain focus during extended shifts. These engineering choices collectively ensure the PCB Auto Depanelizer Machine delivers dependable performance in high-volume manufacturing settings where precision cannot be compromised.

Router System

A high-definition vision system aligns coaxially with the milling cutter, simplifying calibration procedures and ensuring consistent accuracy. Built-in tool breakage detection continuously monitors cutter condition, issuing an immediate alarm to halt operation before further damage occurs. The optional automatic tool-changing mechanism enables seamless continuation of production without manual intervention, thereby maximizing uptime. An integrated ion air gun systematically neutralizes static electricity on PCB surfaces, effectively preventing particulate adhesion that could compromise cut quality. Imported high-speed spindles operate with markedly reduced cutting stress, maintain exceptional precision, exhibit low inertia, and provide rapid response characteristics. Supported cutter sizes range from 0.8 to 3 mm, accommodating a broad spectrum of board complexities. The accompanying vacuum system removes debris efficiently. This configuration makes the Pcb Router Separator particularly effective for intricate pcb depanel tasks.

Platform System

Y-axis movement is managed through precision slide rails and servo motor control, resulting in highly stable platform positioning. Dual emergency stop buttons, positioned for easy access from either side, contribute to layered safety protocols. Standard protective covers combined with safety light curtains create comprehensive operator safeguards. Dual start buttons require simultaneous activation to initiate machine cycles, incorporating a deliberate two-hand control measure that minimizes accidental starts. The honeycomb porous base plate offers broad compatibility with multifunctional and custom fixtures. The dual-platform architecture supports independent processing of separate jobs or unification into a single extended workspace. Full compliance with CE and UL standards is maintained throughout the design. Cutting accuracy remains at ±0.05 mm under normal operation, providing confidence in sensitive applications such as automotive and medical electronics.

Control System

Control is managed via an industrial-grade computer interfaced with a dedicated control card, delivering superior accuracy alongside robust long-term stability. All production parameters and events are logged automatically, enabling generation of comprehensive traceability reports on demand. The physical layout adheres strictly to CE and UL electrical and safety standards. The user interface employs straightforward navigation, allowing operators to master basic functions quickly and execute product program changes with minimal delay. A coaxial CCD camera supplies continuous real-time visual monitoring for precise alignment verification. CNC-based controllers demonstrate strong resistance to electromagnetic interference. Standard integrated breakage and slip detection features add further layers of process protection. Operating at 1.5 kW on standard 220 V supply, the system integrates readily into existing SMT environments.

Detail Display

Critical subsystems are readily observable: convection fans regulate internal temperatures, side-door safety sensors enhance enclosure security, and ESD interfaces provide essential grounding protection. The automatic tool changer minimizes manual handling time. Broken-knife detection sensors deliver prompt alerts. Self-locking pneumatic struts facilitate safe, controlled access during maintenance. Component sourcing includes Panasonic servomotors (Japan), RSK/NSK spindles (China/Japan), HIKVISION CCD (China), PMI/HIWIN guide rails (Taiwan), TBI ball screws (Taiwan), Delta power supplies (Taiwan), Omron sensors (Japan), and NSK bearings (Japan). This deliberate selection of proven brands contributes to extended operational life and reduced unplanned downtime. Optional upper vacuuming further optimizes dust extraction performance.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

A feature phone production facility in Algeria arranged an on-site verification visit, arriving with more than ten distinct board types and accompanying materials. Our engineers configured a complete SMT production line immediately. The demonstration proceeded sequentially: automatic solder paste printing, SPI paste inspection, component placement via RX-8 for small parts and RS-1R for larger components, tray-fed shielding cover application, reflow soldering, AOI optical verification, and final separation using the PCB Auto Depanelizer Machine. Throughout the process, the client observed closely. The resulting boards exhibited clean, precise edges with negligible defect rates. The line demonstrated consistent stability and throughput. This practical, hands-on validation left the team fully convinced of the equipment's suitability for integration into their existing manufacturing operations.

| Service and Training Support

I.C.T delivers end-to-end service beginning with on-site installation and commissioning of the PCB auto depanelizer. Experienced engineers conduct structured training programs covering machine operation, program creation, routine maintenance, and troubleshooting procedures. Training accommodates operators at varying experience levels. Remote technical assistance ensures rapid response to queries. Spare parts logistics maintain high availability to limit production interruptions. Drawing on more than 25 years of electronics manufacturing expertise, the support team addresses practical factory challenges effectively. Clients in 72 countries benefit from uniform professional service. Ongoing process optimization and upgrade recommendations occur as production requirements evolve. The overarching goal is to provide dependable, worry-free equipment performance.

| Client Testimonials

Customers consistently appreciate the clarity and responsiveness of our engineers during installation and commissioning. They frequently highlight the PCB Router Separator for its reliable precision and smooth performance across extended production runs. Many specifically mention the careful, professional packaging that ensures the machine arrives undamaged after international shipping. Rapid handling of technical questions and issues reinforces trust. Overall, the combination of equipment quality and attentive support enables factories to meet demanding schedules without unnecessary complications.

| Certifications and Standards

I.C.T equipment carries CE, RoHS, and ISO9001 certifications, supplemented by multiple registered patents. These certifications verify that the off line PCBA router satisfies stringent international requirements for safety, environmental responsibility, and manufacturing quality. Each machine undergoes rigorous factory testing. Customers can proceed with confidence in documented compliance and proven performance.

| About I.C.T Company and Factory

Founded in 2012, I.C.T maintains a 12,000 square meter production facility staffed by 89 employees, including 20 specialized engineers focused on research and development. In-house design, manufacturing, and quality control drive continuous product advancement. Steady growth has resulted in service to over 1,600 customers across 72 countries. Strict inspection protocols are enforced at every production stage. A comprehensive quality management system ensures consistent standards from component receipt through final assembly. This operational framework supports reliable delivery of full SMT solutions while fostering long-term global partnerships.