LD-L

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

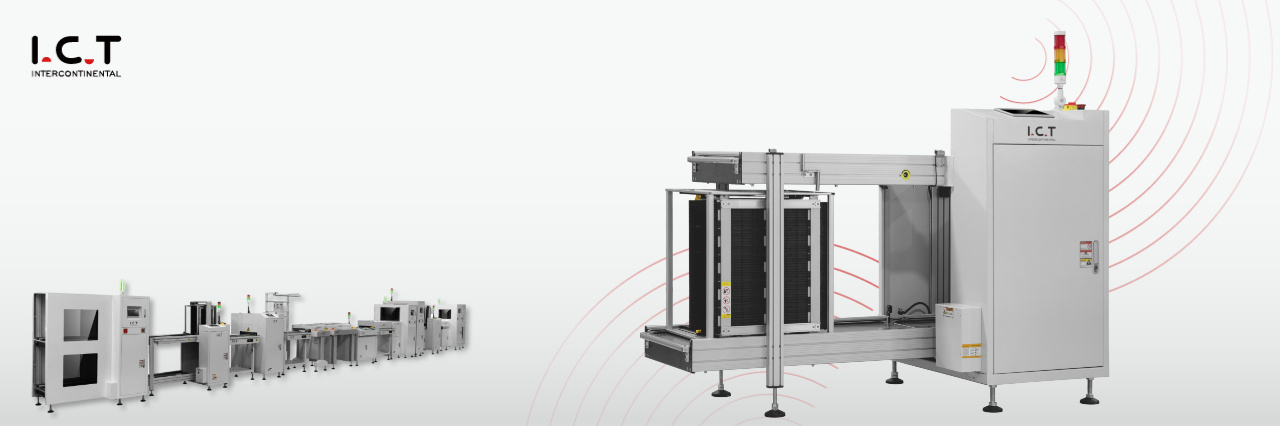

| PCB Unloader Loader – Real pcb multi rack loader

The I.C.T PCB Unloader Loader sits at both ends of the line. It feeds bare boards from magazines at the front. It catches finished boards and stacks them clean at the back. This pcb multi rack loader switches modes in seconds. Standard or full CE version—both come with thicker steel, better sensors, smarter software. The PCB Unloader Loader cuts operators in half, pushes daily numbers up, runs three shifts straight. It shakes hands with any printer, placer, or reflow on day one.

| Detailed Product Features

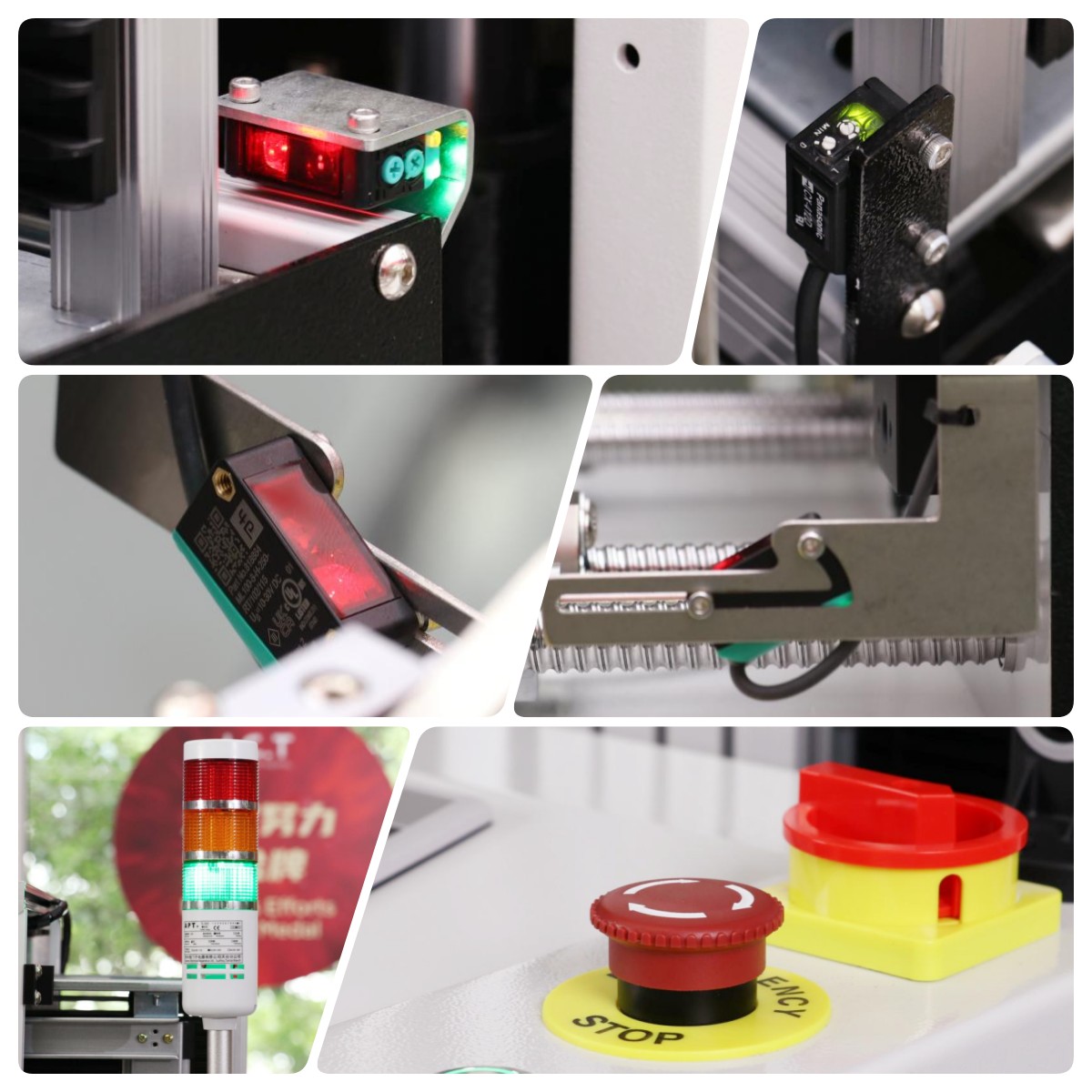

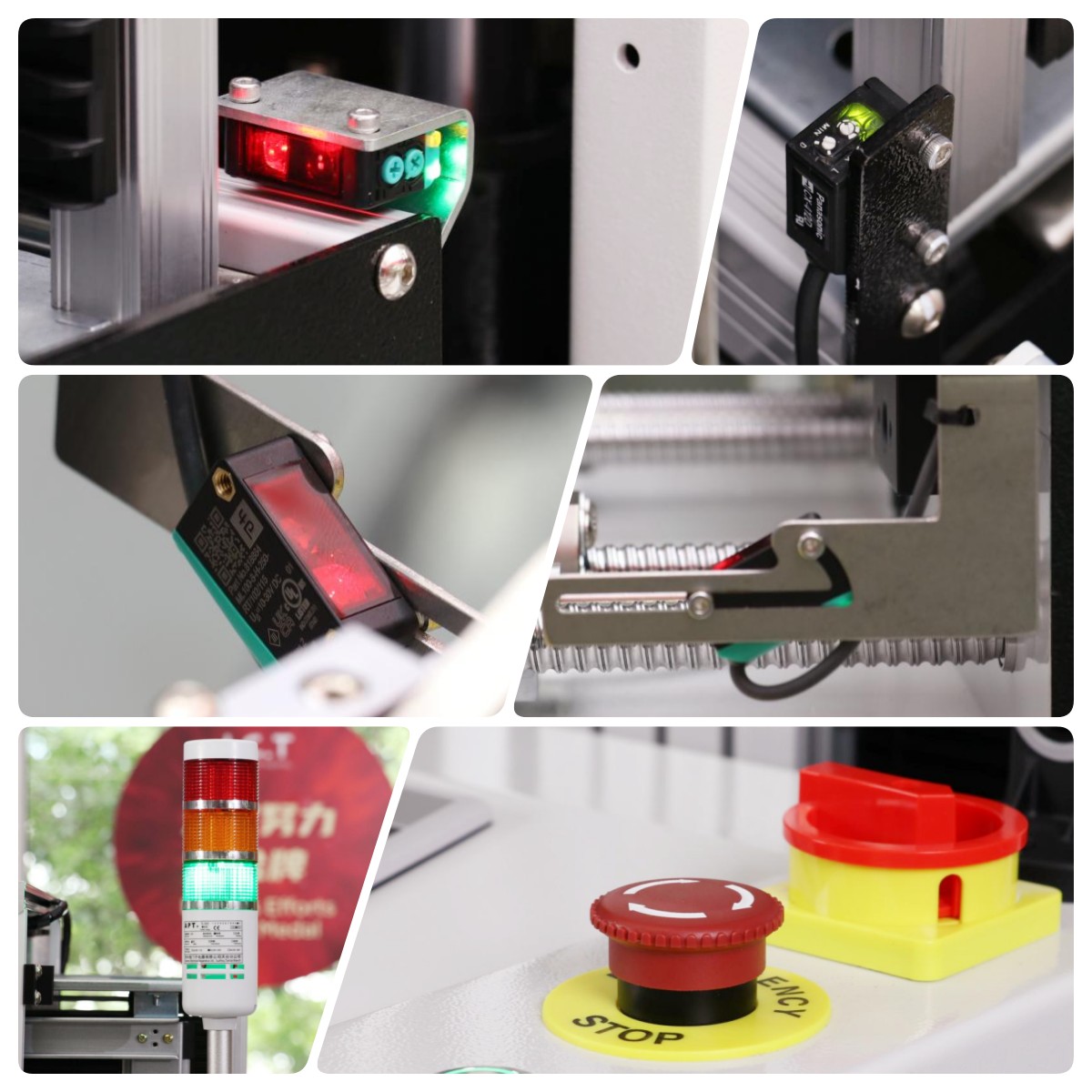

Steel beams are thicker. Rails are heavier. Base is bolted solid. The PCB Unloader Loader meets full CE and ISO marks. Vibration is gone. Maintenance takes five minutes with basic tools. The machine keeps running for ten straight years.

Sensors fire the second a board moves. Tower lights burn bright red or green. Buttons slam and respond instantly. The PCB Unloader Loader knows exactly where every board is—loading or unloading. Operators read the lights and trust what they see. No false stops. No missed boards. Production stays at full speed.

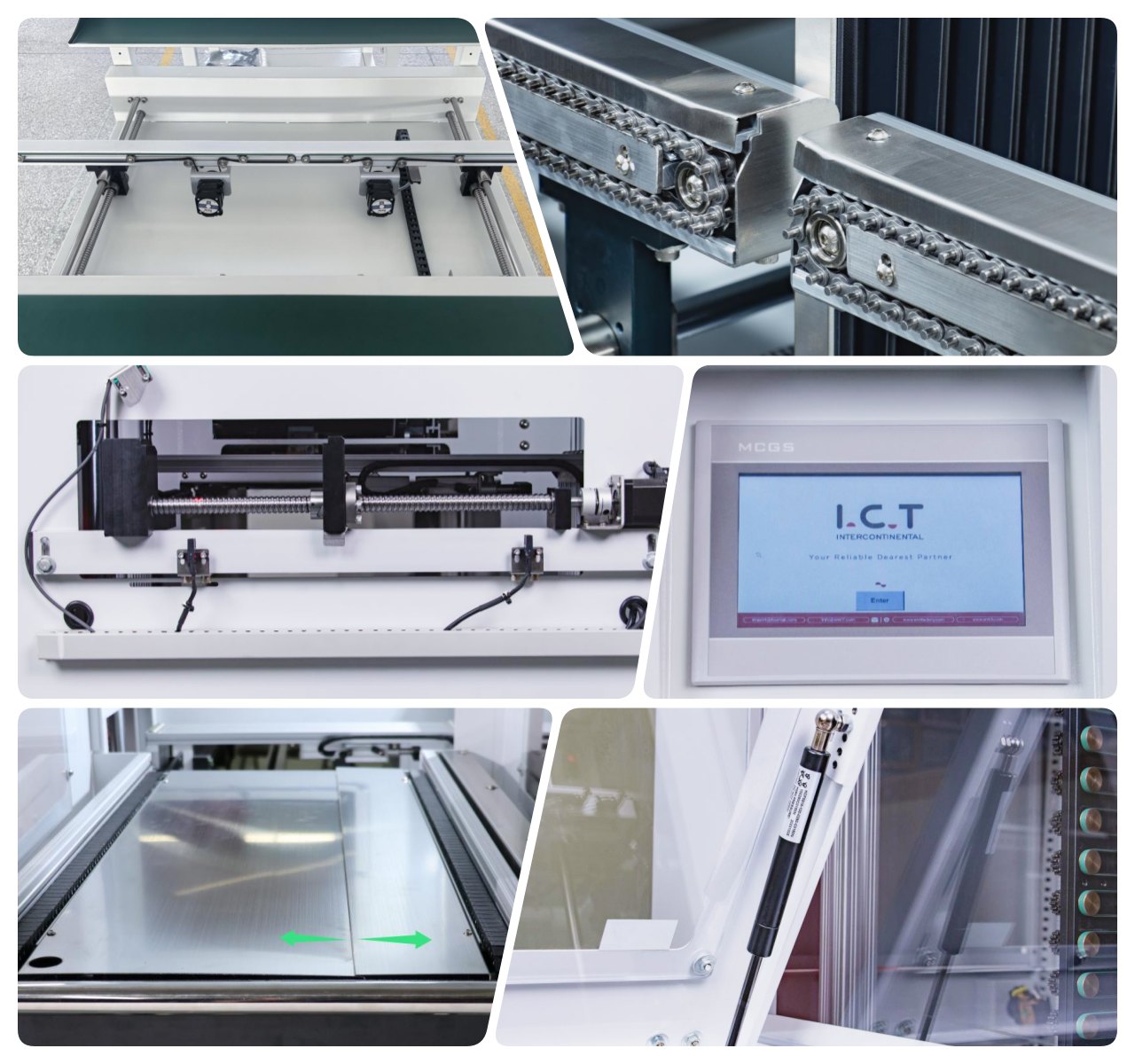

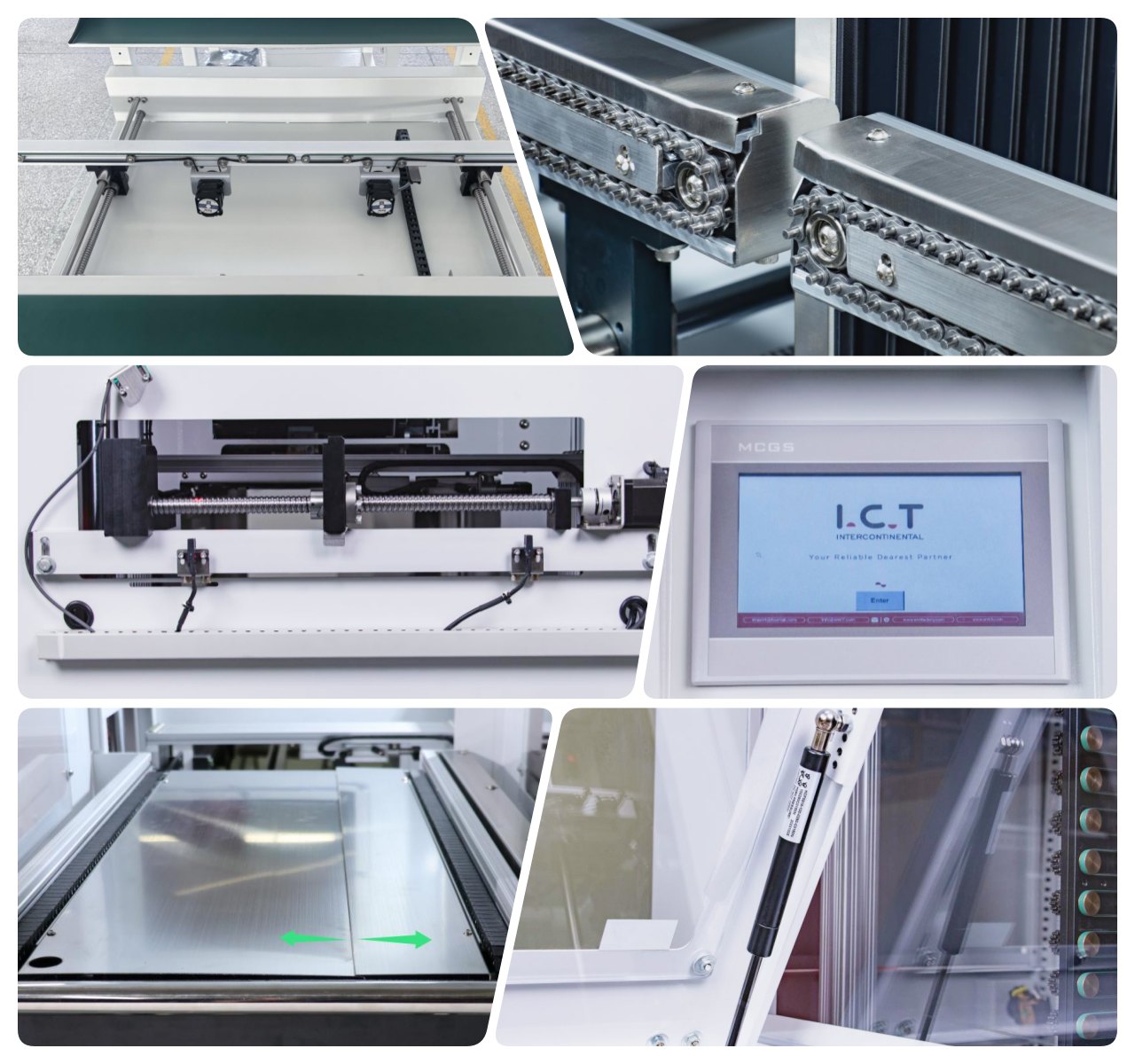

Industry 4.0 software is standard. IPC-CFX, Hermes, and SEMI SMT-ELS protocols load as options. New product files drop in under two minutes. The PCB Unloader Loader talks live to the factory MES, adjusts magazine height automatically, and switches between load and unload mode without stopping the line.

Lifters drop slow and sure. Pushers slide with exact pressure. The PCB Unloader Loader feeds bare boards or stacks finished ones—thousands of cycles, not one scratch, not one jam, not one misfeed. Quality stays perfect from first board to last.

SMEMA cables are live out of the crate. Smart protocols wait ready. The PCB Unloader Loader grabs boards from the printer, releases boards to reflow, or stacks them after AOI—changeover happens in thirty seconds while the rest of the line keeps moving

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Turnkey means bare board in, finished panel out, no babysitting. The PCB Unloader Loader feeds clean at the front, catches clean at the back. Printer hits perfect paste. Placer drops every component dead-center. Reflow solders solid. AOI checks everything. All stations stay locked in sync. Labor stays thin. First-pass yield stays north of 99.5 %. Uptime stays brutal. Automotive, medical, consumer, LED—standards crushed, costs crushed.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Depaneling Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automatic driver locking screw robot machine and soldering for efficient SMT assembly. |

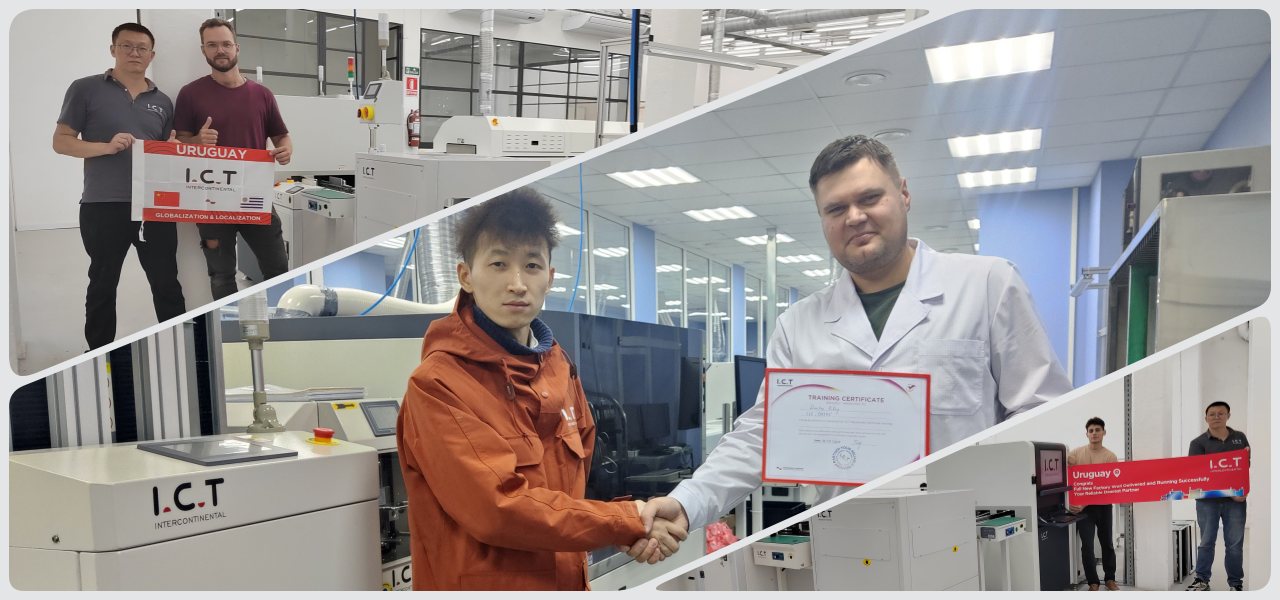

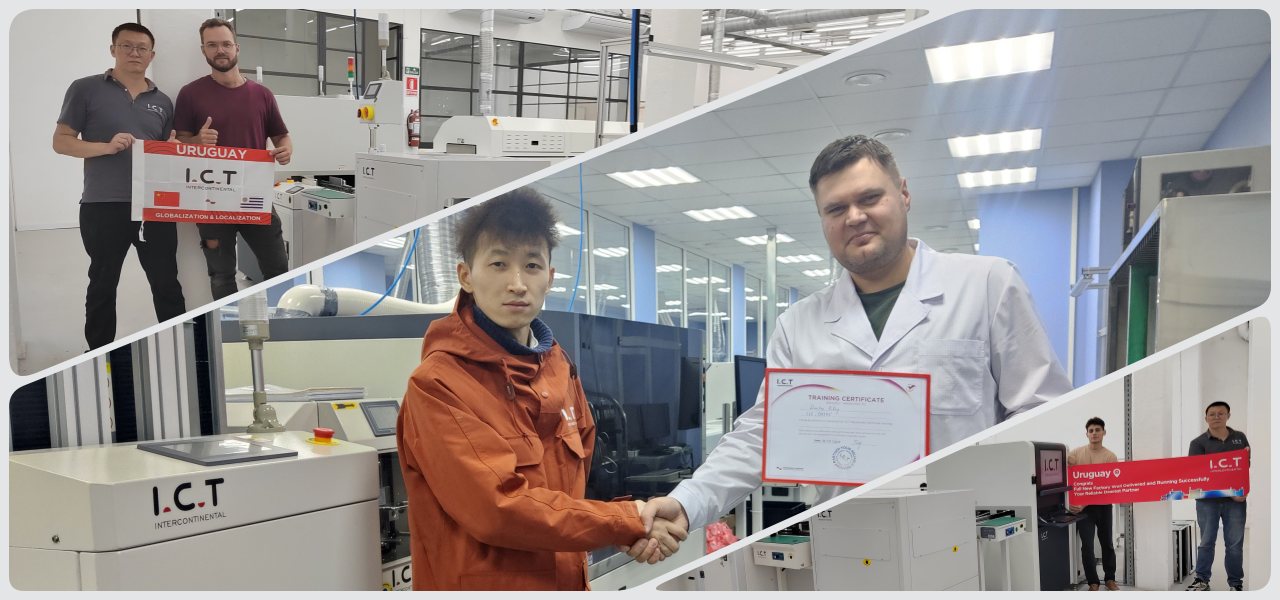

| Customer Success Story

Finland. I.C.T crew lands in Helsinki. Full LED panel line for the biggest lighting company in Europe. PCB Unloader Loader, 1.5 m printer, SM482PLUS placer, L8 reflow, vertical buffers, conveyors, board splitter, solder-paste mixer. Five days total—install, debug, full operator and technician training. Day six they hit target speed. Zero defects all week. Customer stares at the PCB Unloader Loader and says it never once stopped or scratched a board. European audit walks the floor—clean pass, no remarks. Same month they sign for a second identical line.

| Professional Training & Support

Remote diagnostic check before the crate even leaves China. Engineers on site for commissioning. Free two-day training—operators and maintenance techs. Real 24/7 hotline with engineers who speak English. Spare-parts warehouses in Europe, America, and Asia. Scheduled preventive visits twice a year. The PCB Unloader Loader almost never sits dead when it should be running.

| Customer Praise

“Your engineer fixed it at 3 a.m. their time—best support on the planet!” “Forty-five days at sea and the crate arrived perfect—no damage.” “My PCB SMT Unloader machine has run three shifts for 20 straight months—no failures.” “After one day of training our newest operators ran the whole line alone.”

| Our Certification

CE mark. RoHS compliant. ISO9001 certified. Multiple exclusive patents registered. Every PCB Unloader Loader finishes a full 72-hour loaded burn-in plus final line inspection before it ships. Customers open the crate knowing the machine is already proven, compliant, and ready to make money from hour one.

| About Us and Factory

Started 2012. 12,000 m² factory. Ninety employees. Full in-house R&D lab. Every cut, every weld, every wire, every test done under one roof with zero shortcuts. Over 1,600 customers in 72 countries—from one PCB Unloader Loader to complete turnkey factories. I.C.T ships what it promises.

| PCB Unloader Loader – Real pcb multi rack loader

The I.C.T PCB Unloader Loader sits at both ends of the line. It feeds bare boards from magazines at the front. It catches finished boards and stacks them clean at the back. This pcb multi rack loader switches modes in seconds. Standard or full CE version—both come with thicker steel, better sensors, smarter software. The PCB Unloader Loader cuts operators in half, pushes daily numbers up, runs three shifts straight. It shakes hands with any printer, placer, or reflow on day one.

| Detailed Product Features

Steel beams are thicker. Rails are heavier. Base is bolted solid. The PCB Unloader Loader meets full CE and ISO marks. Vibration is gone. Maintenance takes five minutes with basic tools. The machine keeps running for ten straight years.

Sensors fire the second a board moves. Tower lights burn bright red or green. Buttons slam and respond instantly. The PCB Unloader Loader knows exactly where every board is—loading or unloading. Operators read the lights and trust what they see. No false stops. No missed boards. Production stays at full speed.

Industry 4.0 software is standard. IPC-CFX, Hermes, and SEMI SMT-ELS protocols load as options. New product files drop in under two minutes. The PCB Unloader Loader talks live to the factory MES, adjusts magazine height automatically, and switches between load and unload mode without stopping the line.

Lifters drop slow and sure. Pushers slide with exact pressure. The PCB Unloader Loader feeds bare boards or stacks finished ones—thousands of cycles, not one scratch, not one jam, not one misfeed. Quality stays perfect from first board to last.

SMEMA cables are live out of the crate. Smart protocols wait ready. The PCB Unloader Loader grabs boards from the printer, releases boards to reflow, or stacks them after AOI—changeover happens in thirty seconds while the rest of the line keeps moving

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Turnkey means bare board in, finished panel out, no babysitting. The PCB Unloader Loader feeds clean at the front, catches clean at the back. Printer hits perfect paste. Placer drops every component dead-center. Reflow solders solid. AOI checks everything. All stations stay locked in sync. Labor stays thin. First-pass yield stays north of 99.5 %. Uptime stays brutal. Automotive, medical, consumer, LED—standards crushed, costs crushed.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Depaneling Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automatic driver locking screw robot machine and soldering for efficient SMT assembly. |

| Customer Success Story

Finland. I.C.T crew lands in Helsinki. Full LED panel line for the biggest lighting company in Europe. PCB Unloader Loader, 1.5 m printer, SM482PLUS placer, L8 reflow, vertical buffers, conveyors, board splitter, solder-paste mixer. Five days total—install, debug, full operator and technician training. Day six they hit target speed. Zero defects all week. Customer stares at the PCB Unloader Loader and says it never once stopped or scratched a board. European audit walks the floor—clean pass, no remarks. Same month they sign for a second identical line.

| Professional Training & Support

Remote diagnostic check before the crate even leaves China. Engineers on site for commissioning. Free two-day training—operators and maintenance techs. Real 24/7 hotline with engineers who speak English. Spare-parts warehouses in Europe, America, and Asia. Scheduled preventive visits twice a year. The PCB Unloader Loader almost never sits dead when it should be running.

| Customer Praise

“Your engineer fixed it at 3 a.m. their time—best support on the planet!” “Forty-five days at sea and the crate arrived perfect—no damage.” “My PCB SMT Unloader machine has run three shifts for 20 straight months—no failures.” “After one day of training our newest operators ran the whole line alone.”

| Our Certification

CE mark. RoHS compliant. ISO9001 certified. Multiple exclusive patents registered. Every PCB Unloader Loader finishes a full 72-hour loaded burn-in plus final line inspection before it ships. Customers open the crate knowing the machine is already proven, compliant, and ready to make money from hour one.

| About Us and Factory

Started 2012. 12,000 m² factory. Ninety employees. Full in-house R&D lab. Every cut, every weld, every wire, every test done under one roof with zero shortcuts. Over 1,600 customers in 72 countries—from one PCB Unloader Loader to complete turnkey factories. I.C.T ships what it promises.