The I.C.T PCB Separator Routing Machine offers gentle, high-accuracy separation that protects delicate boards while boosting production speed in electronics factories.

a. Dual platforms adapt to any production flow.I.C.T-5700

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Precision PCB Separator Routing Machine

Across factories building smartphones, smart wearables, automotive controls, medical tools, and aerospace electronics, this PCB Separator Routing Machine stands ready. It handles boards from 340×380mm up to 450×600mm and thicknesses of 0.5 to 5.0mm with ease. Fresh CCD vision reads every mark clearly and adjusts position automatically. The spindle spins at 80,000rpm, delivering clean cuts while keeping stress very low. Dual platforms work on different jobs together or combine into one big surface when needed. An ion air gun gently removes static so dust never clings. Sensors keep constant watch over the cutter. Quiet, strong dust collection clears the air. Simple controls feel natural from the first day.

| Feature

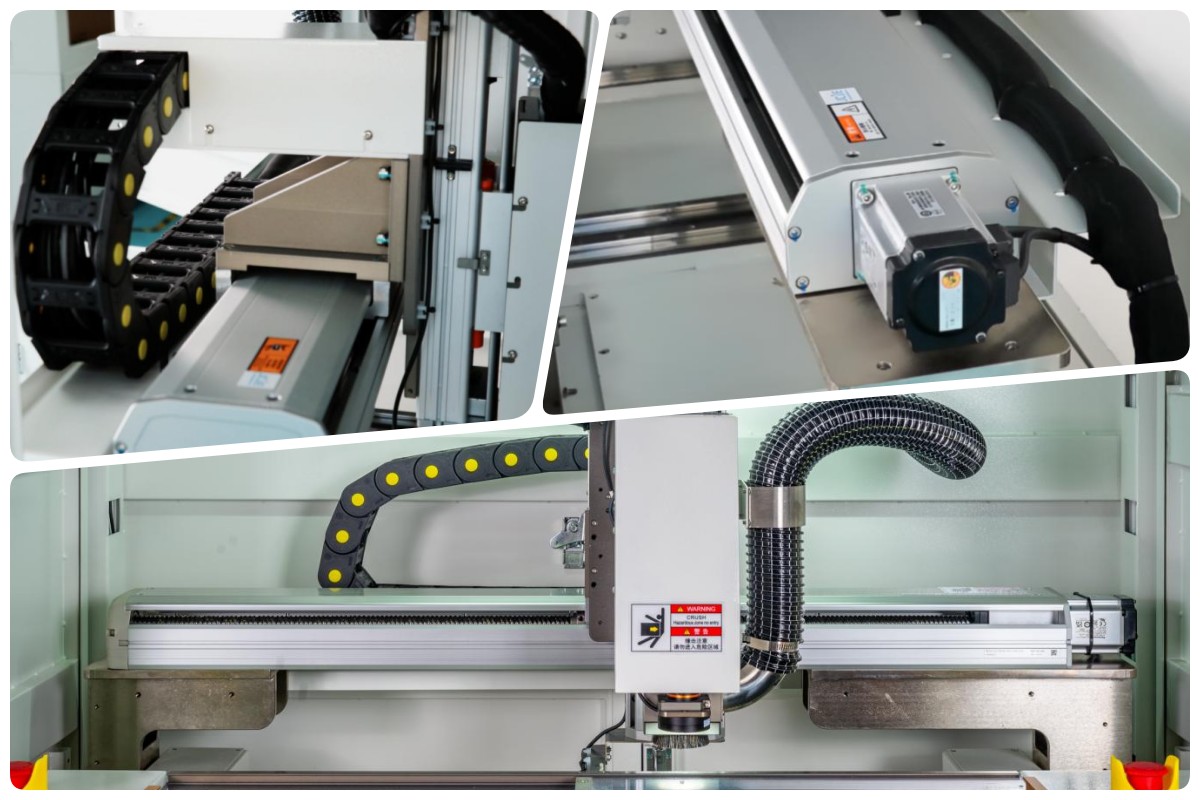

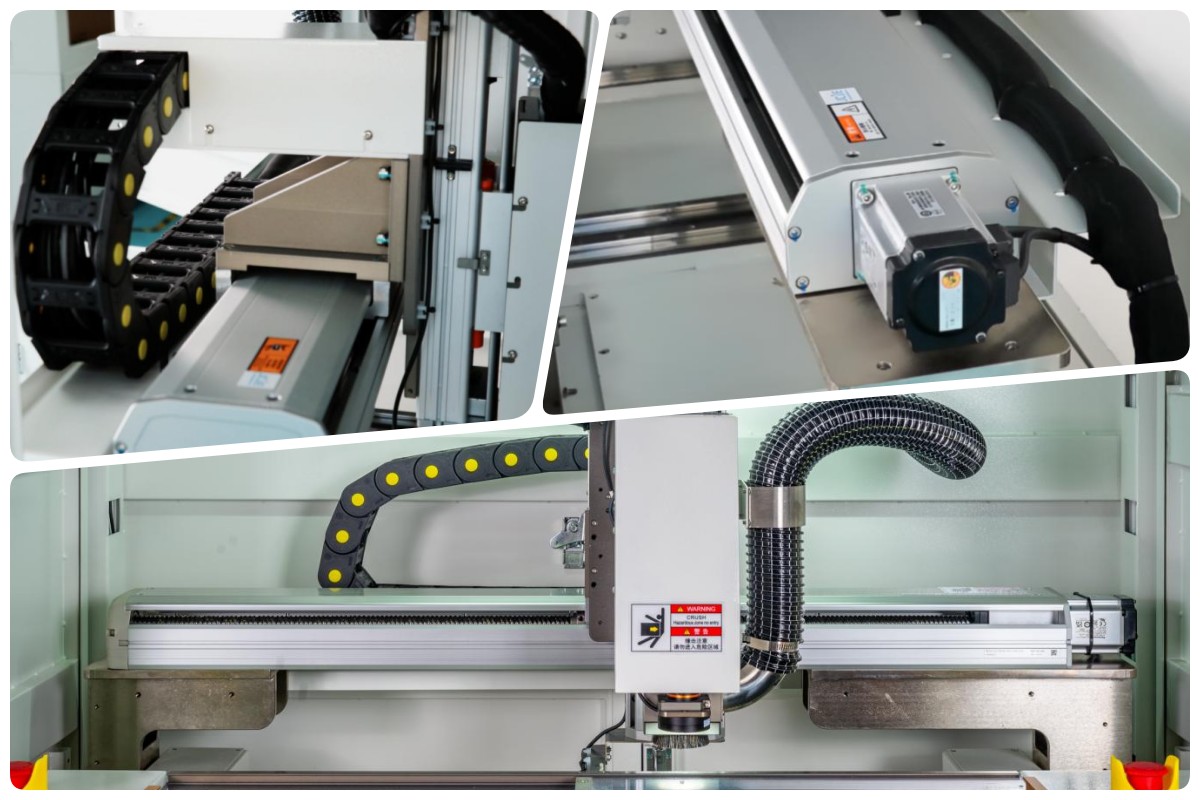

Transmission System

Thick, solid framing carries the weight of daily work without shaking. Flexible tank chains guide cables smoothly, never tangling with moving pieces. A clever dust-proof shield covers the X-axis, keeping dirt out and repairs rare. Panasonic servo motors from Japan, matched with high-precision screws and Taiwan guide rails, create motion that feels alive yet perfectly controlled. Every shift, the system moves boards with steady grace. These honest parts give the PCB Separator Routing Machine in China lasting strength and keep maintenance simple while holding the tight accuracy modern electronics demand.

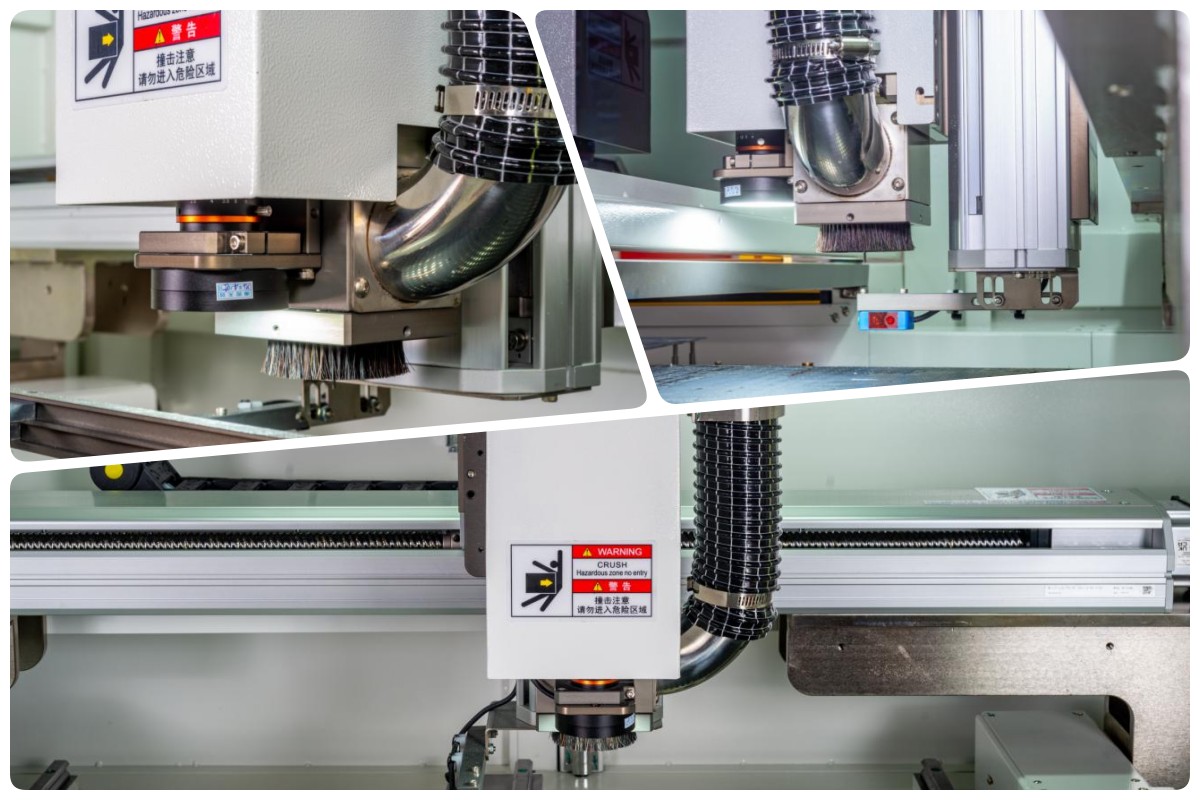

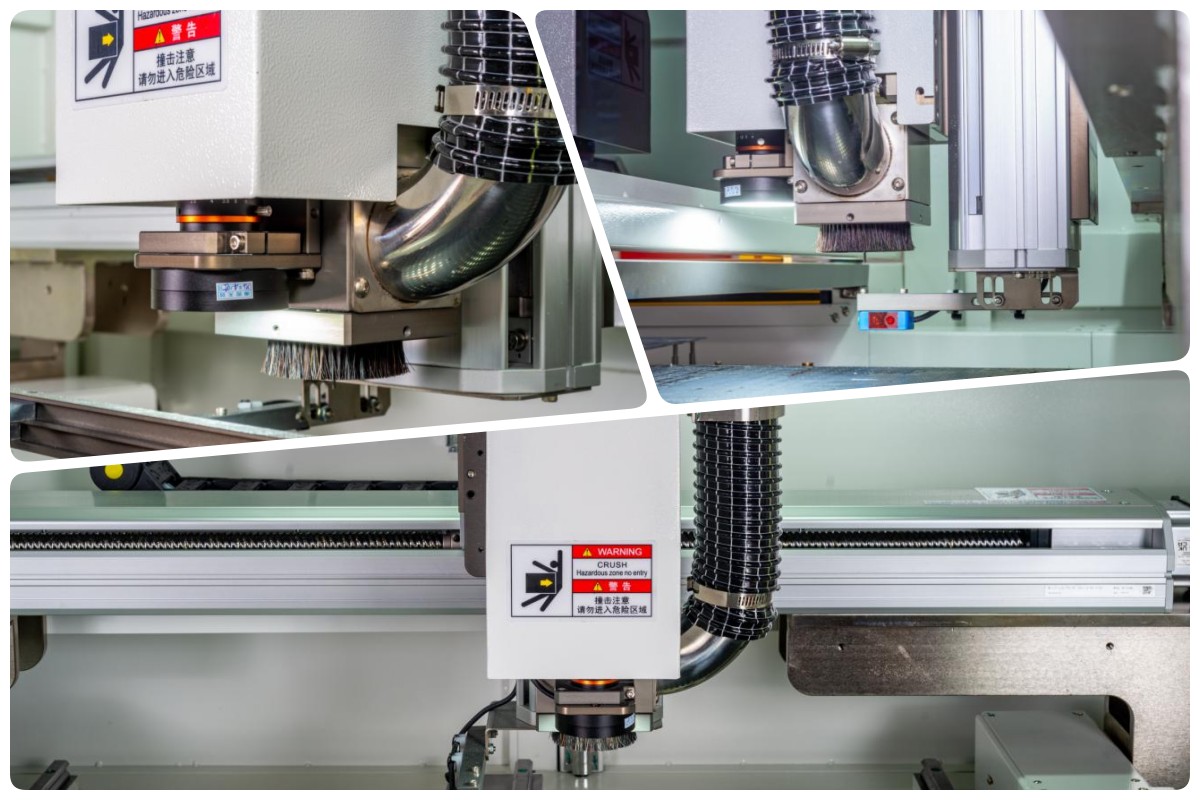

Router System

High-definition vision sits right beside the cutter, making calibration quick and sure. Built-in breakage detection calls out the moment a cutter weakens. Optional automatic tool change keeps the rhythm unbroken for higher daily output. The ion air gun breathes softly across each board, lifting static away so dust stays distant. Imported high-speed spindle works with gentle force, high precision, low inertia, and swift response. Every cut feels careful and exact on this router separator machine PCB, protecting boards while delivering clean edges time after time.

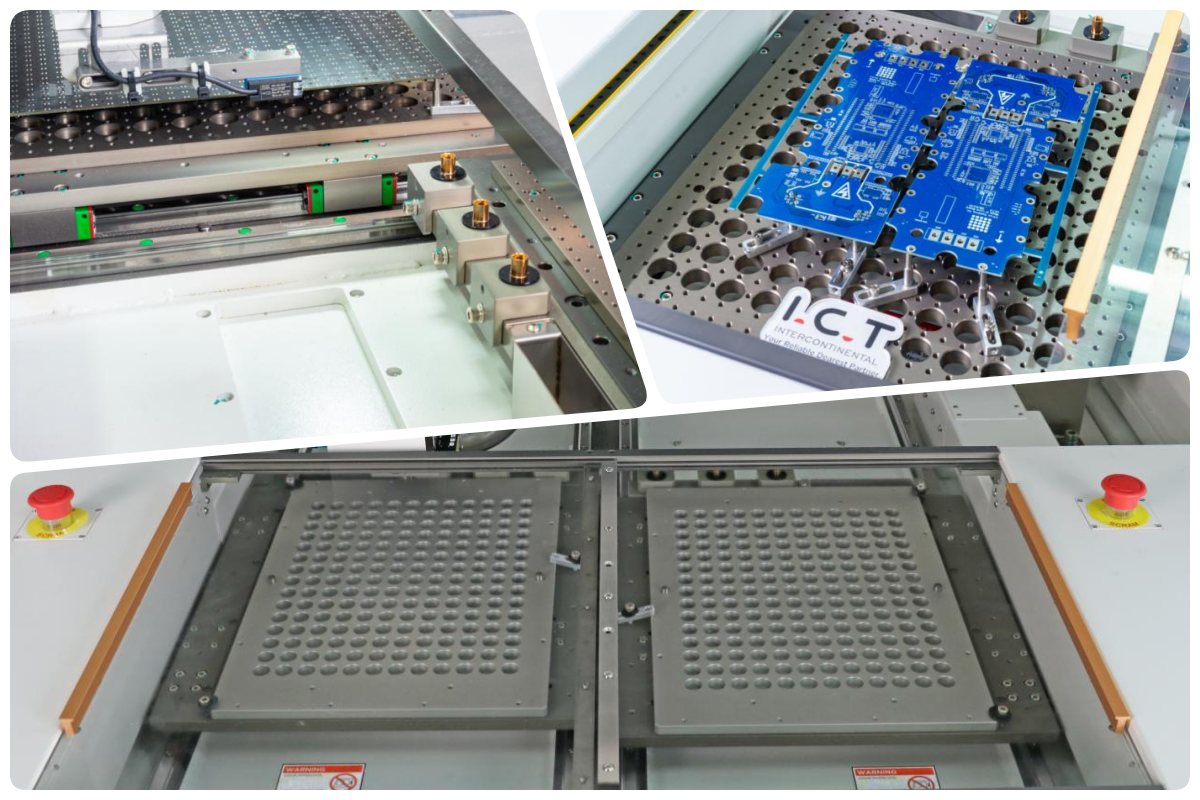

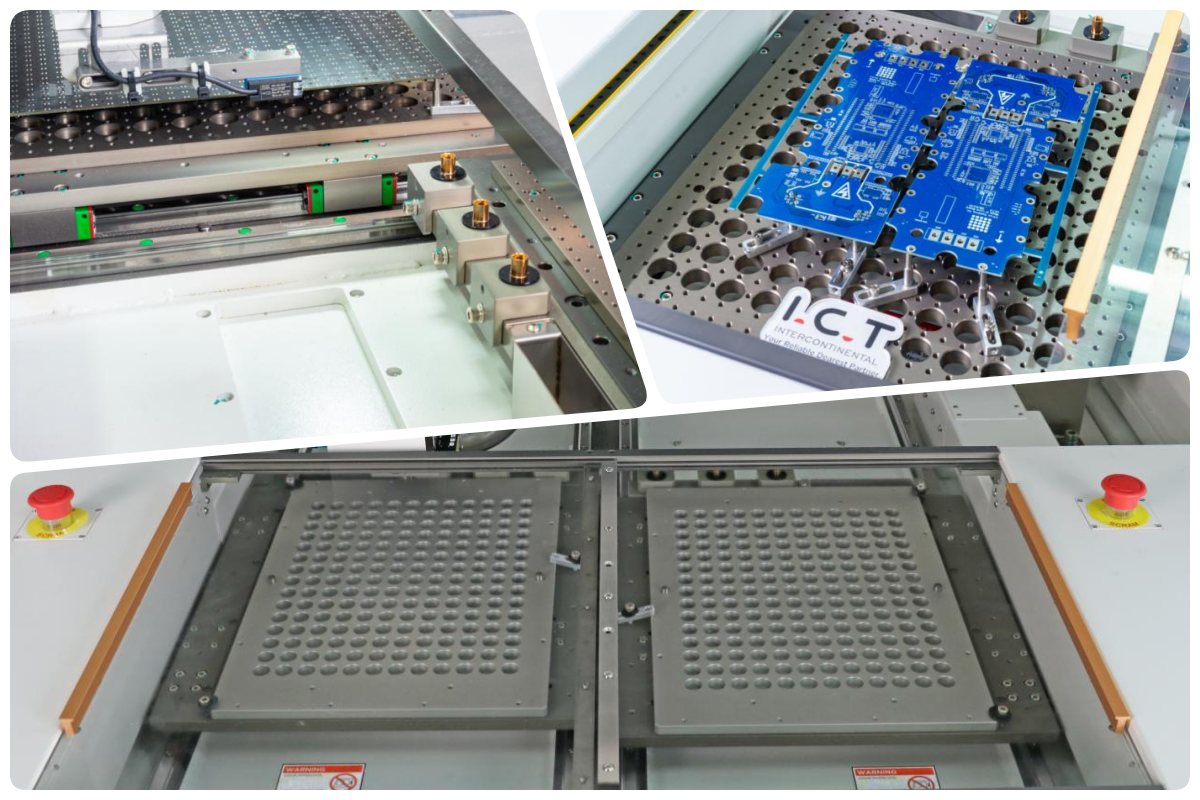

Platform System

Servo motors and strong slide rails guide the Y-axis with calm stability. Emergency stops wait on both sides, safety covers close in, and light curtains watch every movement. Dual start buttons demand both hands, keeping operators safe by design. The honeycomb base grips boards firmly and welcomes many fixture types. Dual platforms shift between jobs or join as one large workspace. This thoughtful arrangement makes the PCB routing mashine safe, adaptable, and comfortable for long hours on busy floors.

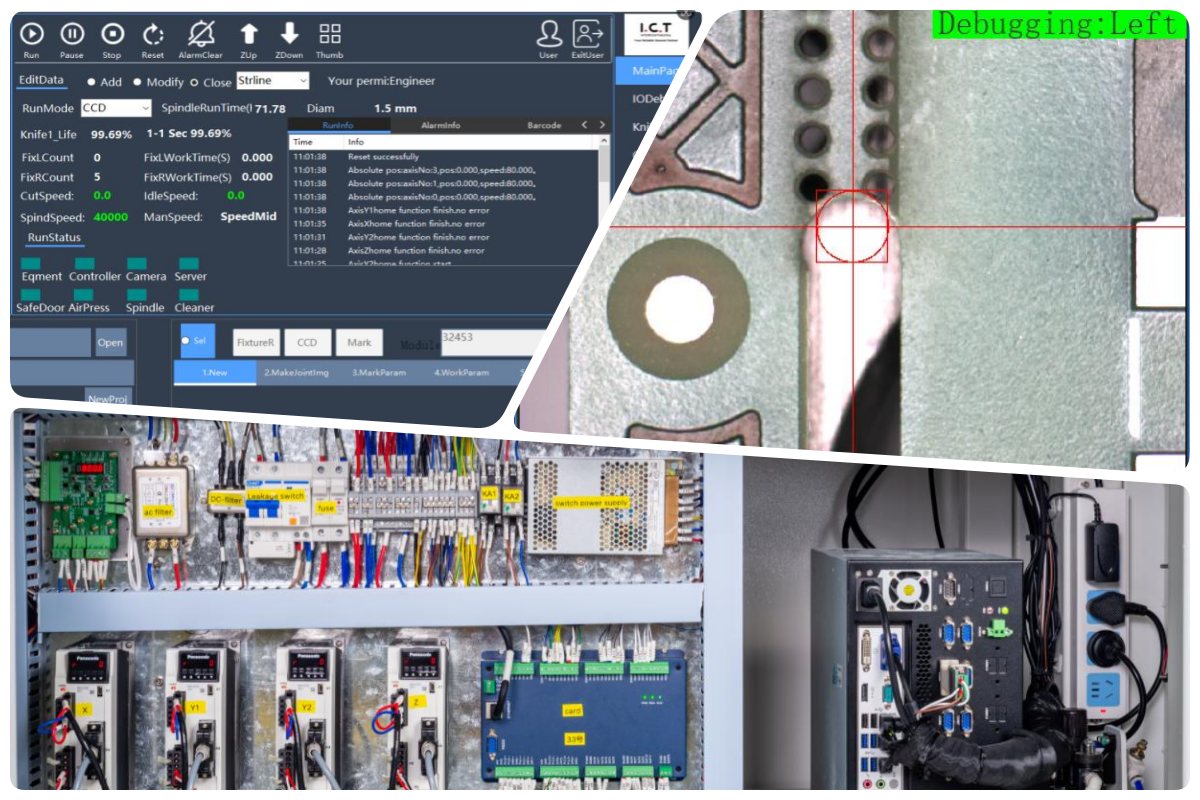

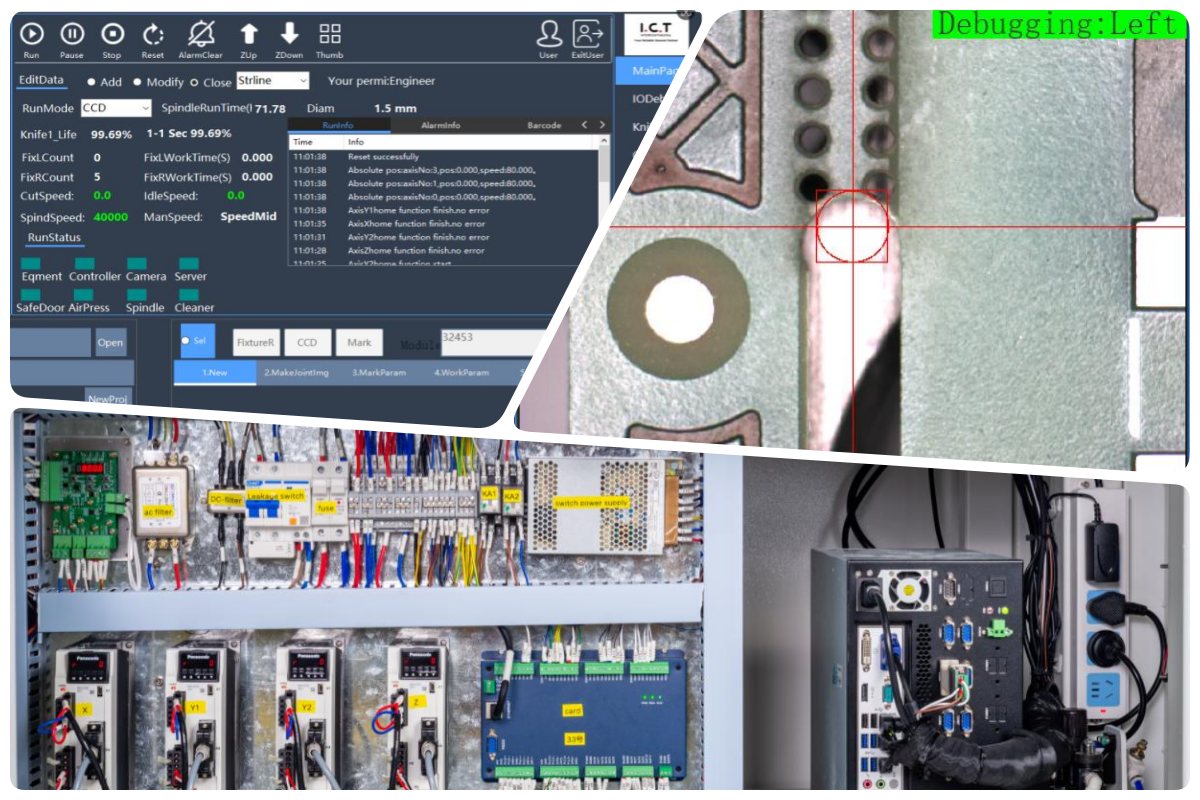

Control System

Industrial computer and dedicated CNC controller stand strong against factory electrical noise. Full logs capture every job for clear quality records. The friendly interface meets CE rules and lets programs change quickly. Coaxial CCD shows real-time views of the cutting path. Operators learn fast and trust the steady results day after day. These reliable elements turn the PCB Separator Routing Machine into an easy partner for production teams everywhere.

Detail Display

Self-locking pneumatic struts hold doors open like patient hands. Broken-knife sensor quietly checks the cutter’s health every moment. Optional auto tool changer swaps bits while work continues. ESD interface shields sensitive parts from hidden static. Side door sensors stop everything if safety opens. Convection fan keeps gentle, even cooling inside. Each small touch adds warmth, safety, and ease to daily life with this PCB Separator Routing Machine.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

An Algerian team making feature phones came to our factory carrying more than ten PCB panels and every needed component. They watched closely as we brought the full SMT line to life: automatic printing laid perfect paste, SPI checked every detail, RX-8 placed tiny parts, RS-1R handled larger ones, tray feeder delivered shield covers, reflow oven bonded everything, AOI inspected quality, and finally the I.C.T PCB Separator Routing Machine separated each board with smooth, precise cuts. The whole line moved like a quiet river, showing high efficiency and gentle handling. The visitors smiled at the clean results and left feeling certain about their choice.

| Service and Training Support

I.C.T brings skilled engineers straight to your factory for careful installation and patient, hands-on training. They teach safe use, easy programming, tool care, and daily routines so your team feels at home with the PCB Separator Routing Machine. Remote help arrives quickly, spare parts ship fast, and worldwide service centers answer calls without delay. Ongoing advice helps fine-tune processes as your needs grow. This warm, thorough support lets customers focus on building products, knowing help is always close and reliable.

| Client Testimonials

Many customers write to thank our engineers for their patient knowledge and quick solutions during setup or questions. They speak warmly about the machine’s steady precision and how gently it treats every board. Secure, thoughtful packing arrives undamaged after long journeys. Fast responses to emails or calls make them feel truly cared for. Overall, people say I.C.T machines and support bring real peace of mind in a busy industry.

| Certifications and Standards

CE marking proves every safety standard is met. RoHS confirms materials respect the environment. ISO9001 shows a deep commitment to quality in every step of production. Multiple patents protect our fresh ideas and careful designs. These respected approvals give customers quiet confidence that the PCB Separator Routing Machine meets the highest global expectations for safety, quality, and responsibility.

| About I.C.T Company and Factory

I.C.T manufacturing facilities in Dongguan, Guangdong, China, where a large team of skilled engineers works every day to create reliable SMT equipment. Since our establishment in 2012, the company has grown rapidly and now serves more than 1600 customers across over 72 countries worldwide. Our production facilities follow strict testing procedures and a complete quality management system at every step to ensure every machine, including the PCB Separator Routing Machine, meets the highest standards before it leaves the factory. With 8 branch offices, a dedicated team of 20 engineers, and a 12,000 square meter workspace, we focus on innovation, fast response, and long-term partnerships to help electronics manufacturers build, upgrade, and optimize their production lines successfully.

| Precision PCB Separator Routing Machine

Across factories building smartphones, smart wearables, automotive controls, medical tools, and aerospace electronics, this PCB Separator Routing Machine stands ready. It handles boards from 340×380mm up to 450×600mm and thicknesses of 0.5 to 5.0mm with ease. Fresh CCD vision reads every mark clearly and adjusts position automatically. The spindle spins at 80,000rpm, delivering clean cuts while keeping stress very low. Dual platforms work on different jobs together or combine into one big surface when needed. An ion air gun gently removes static so dust never clings. Sensors keep constant watch over the cutter. Quiet, strong dust collection clears the air. Simple controls feel natural from the first day.

| Feature

Transmission System

Thick, solid framing carries the weight of daily work without shaking. Flexible tank chains guide cables smoothly, never tangling with moving pieces. A clever dust-proof shield covers the X-axis, keeping dirt out and repairs rare. Panasonic servo motors from Japan, matched with high-precision screws and Taiwan guide rails, create motion that feels alive yet perfectly controlled. Every shift, the system moves boards with steady grace. These honest parts give the PCB Separator Routing Machine in China lasting strength and keep maintenance simple while holding the tight accuracy modern electronics demand.

Router System

High-definition vision sits right beside the cutter, making calibration quick and sure. Built-in breakage detection calls out the moment a cutter weakens. Optional automatic tool change keeps the rhythm unbroken for higher daily output. The ion air gun breathes softly across each board, lifting static away so dust stays distant. Imported high-speed spindle works with gentle force, high precision, low inertia, and swift response. Every cut feels careful and exact on this router separator machine PCB, protecting boards while delivering clean edges time after time.

Platform System

Servo motors and strong slide rails guide the Y-axis with calm stability. Emergency stops wait on both sides, safety covers close in, and light curtains watch every movement. Dual start buttons demand both hands, keeping operators safe by design. The honeycomb base grips boards firmly and welcomes many fixture types. Dual platforms shift between jobs or join as one large workspace. This thoughtful arrangement makes the PCB routing mashine safe, adaptable, and comfortable for long hours on busy floors.

Control System

Industrial computer and dedicated CNC controller stand strong against factory electrical noise. Full logs capture every job for clear quality records. The friendly interface meets CE rules and lets programs change quickly. Coaxial CCD shows real-time views of the cutting path. Operators learn fast and trust the steady results day after day. These reliable elements turn the PCB Separator Routing Machine into an easy partner for production teams everywhere.

Detail Display

Self-locking pneumatic struts hold doors open like patient hands. Broken-knife sensor quietly checks the cutter’s health every moment. Optional auto tool changer swaps bits while work continues. ESD interface shields sensitive parts from hidden static. Side door sensors stop everything if safety opens. Convection fan keeps gentle, even cooling inside. Each small touch adds warmth, safety, and ease to daily life with this PCB Separator Routing Machine.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

An Algerian team making feature phones came to our factory carrying more than ten PCB panels and every needed component. They watched closely as we brought the full SMT line to life: automatic printing laid perfect paste, SPI checked every detail, RX-8 placed tiny parts, RS-1R handled larger ones, tray feeder delivered shield covers, reflow oven bonded everything, AOI inspected quality, and finally the I.C.T PCB Separator Routing Machine separated each board with smooth, precise cuts. The whole line moved like a quiet river, showing high efficiency and gentle handling. The visitors smiled at the clean results and left feeling certain about their choice.

| Service and Training Support

I.C.T brings skilled engineers straight to your factory for careful installation and patient, hands-on training. They teach safe use, easy programming, tool care, and daily routines so your team feels at home with the PCB Separator Routing Machine. Remote help arrives quickly, spare parts ship fast, and worldwide service centers answer calls without delay. Ongoing advice helps fine-tune processes as your needs grow. This warm, thorough support lets customers focus on building products, knowing help is always close and reliable.

| Client Testimonials

Many customers write to thank our engineers for their patient knowledge and quick solutions during setup or questions. They speak warmly about the machine’s steady precision and how gently it treats every board. Secure, thoughtful packing arrives undamaged after long journeys. Fast responses to emails or calls make them feel truly cared for. Overall, people say I.C.T machines and support bring real peace of mind in a busy industry.

| Certifications and Standards

CE marking proves every safety standard is met. RoHS confirms materials respect the environment. ISO9001 shows a deep commitment to quality in every step of production. Multiple patents protect our fresh ideas and careful designs. These respected approvals give customers quiet confidence that the PCB Separator Routing Machine meets the highest global expectations for safety, quality, and responsibility.

| About I.C.T Company and Factory

I.C.T manufacturing facilities in Dongguan, Guangdong, China, where a large team of skilled engineers works every day to create reliable SMT equipment. Since our establishment in 2012, the company has grown rapidly and now serves more than 1600 customers across over 72 countries worldwide. Our production facilities follow strict testing procedures and a complete quality management system at every step to ensure every machine, including the PCB Separator Routing Machine, meets the highest standards before it leaves the factory. With 8 branch offices, a dedicated team of 20 engineers, and a 12,000 square meter workspace, we focus on innovation, fast response, and long-term partnerships to help electronics manufacturers build, upgrade, and optimize their production lines successfully.