I.C.T-MBV360C

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

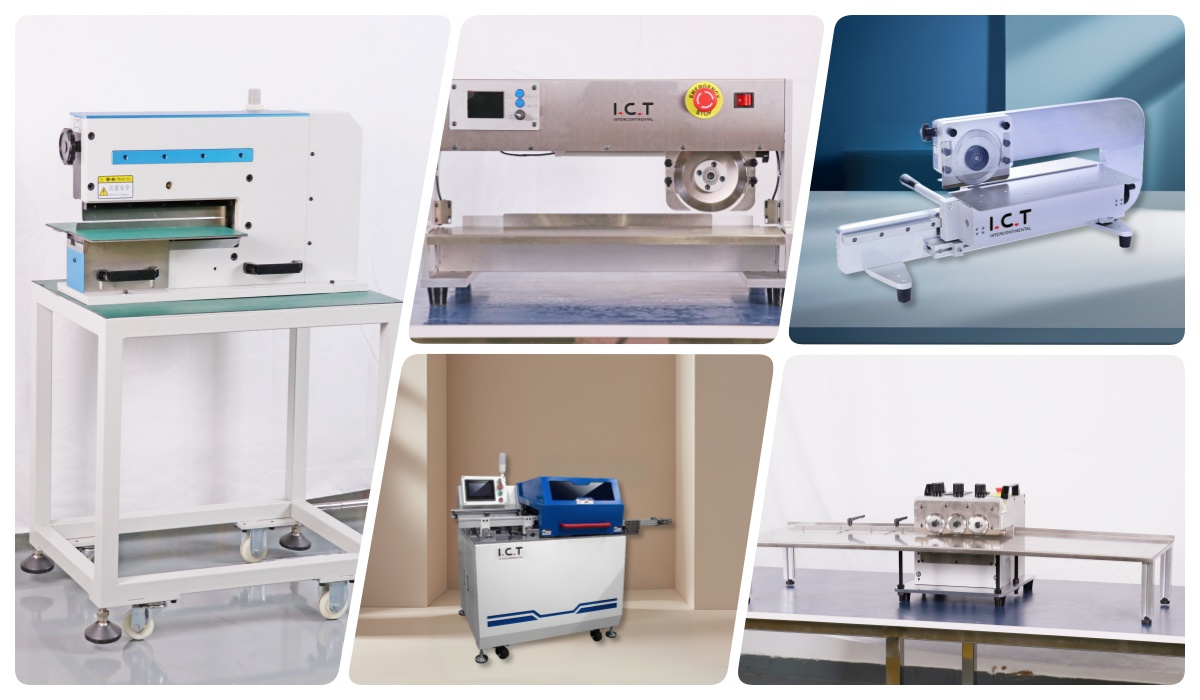

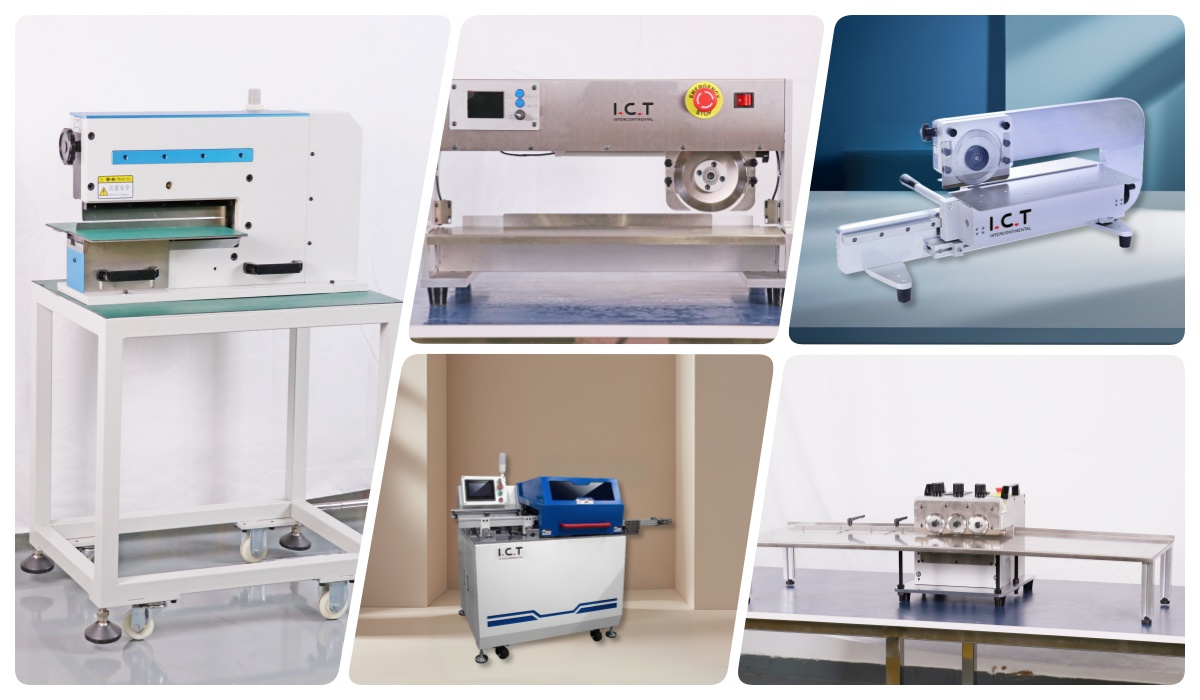

| Precision Cutting for LED Strip PCBs

The LED Strip PCB Depaneling Machine is designed to handle the precise and efficient separation of PCB panels after assembly, especially in LED lighting applications. This machine applies controlled cutting force to separate PCBs along V-grooves or straight cuts, ensuring minimal stress on components during the process. It is ideal for mass production environments where high cutting precision is required. The adjustable cutting speed and blade height provide flexibility for various PCB types, making it suitable for both standard and complex PCB designs. This machine offers reliable and consistent results, ensuring that LED strip and light bar PCBs are separated safely and effectively.

Function and application overview:

The machine is used for depaneling PCBs post-SMT to prepare them for further assembly or testing;

It is especially suitable for LED strip PCBs and light bar applications, where precise cutting is crucial;

The machine ensures clean separation with minimal impact on sensitive components, making it ideal for high-quality LED production

| Feature

Multi-Blades LED Separator

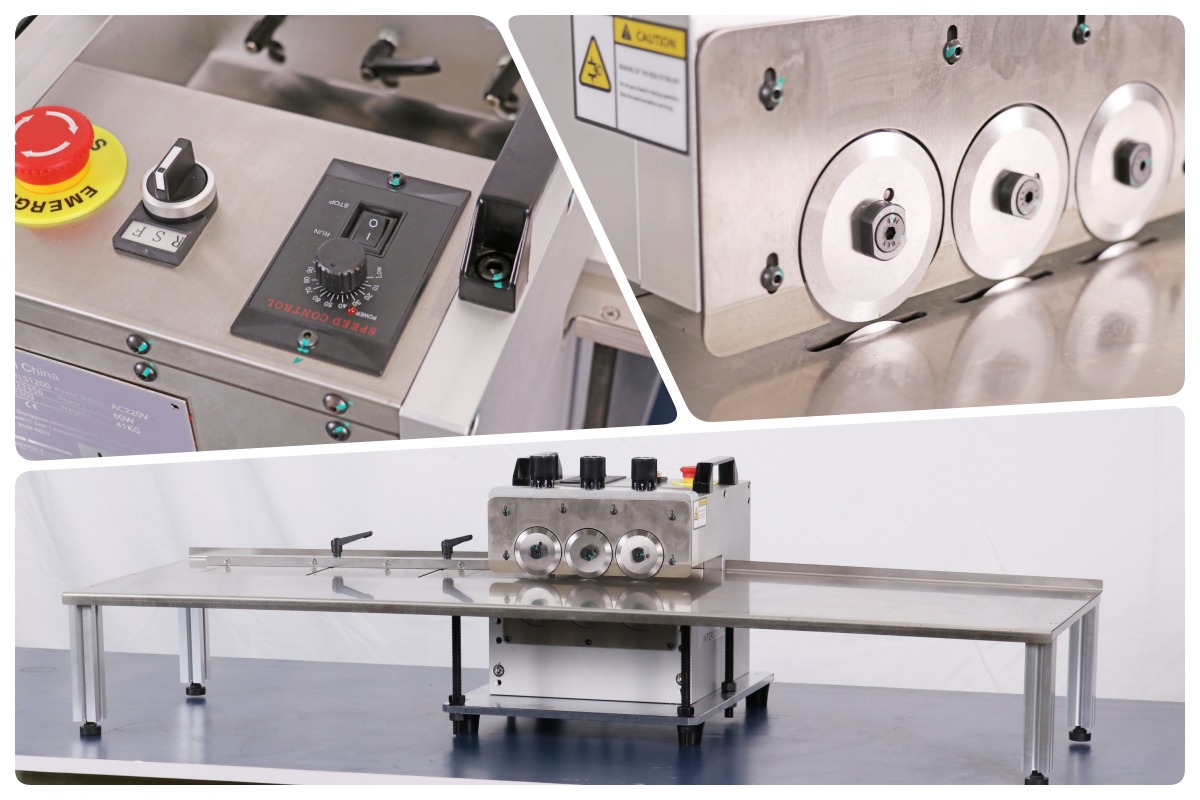

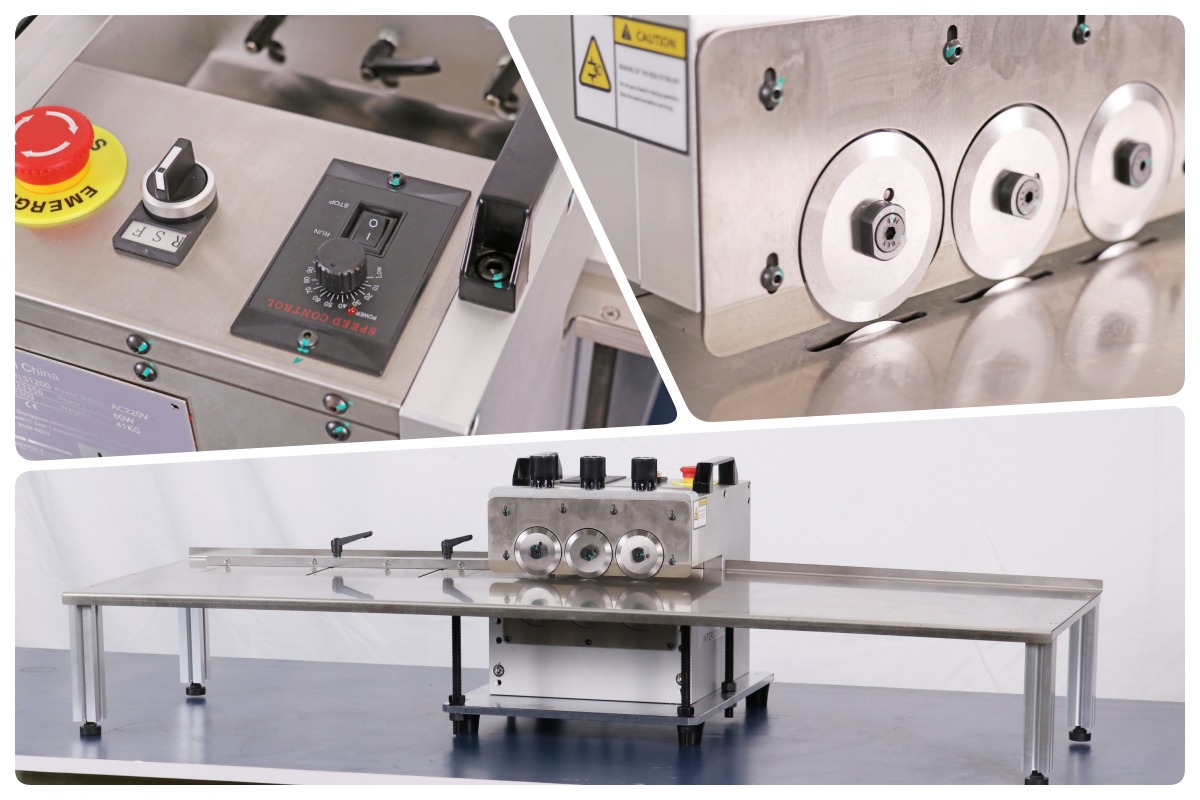

The Multi-Blades LED Separator uses multiple circular blades positioned both above and below the PCB to achieve efficient straight-line separation. This design ensures that the cutting force is evenly distributed, minimizing the risk of board deformation. It is especially suitable for LED strip and light bar PCBs, where components are placed close to the edges. With adjustable blade spacing, this machine can accommodate various PCB widths, ensuring flexible and reliable operation in high-volume production environments. The multi-blade system also ensures long-lasting performance, making it ideal for continuous LED production.

Guillotine Type V-Cut Machine

The Guillotine Type V-Cut Machine is designed to apply vertical force directly along the V-groove, providing precise and clean cuts for thicker PCBs or those with deep V-grooves. This machine is ideal for separating PCBs with high component density or thicker materials. The uniform cutting force helps prevent component damage and ensures that the board remains stable during the separation process. It’s especially effective for power control boards and other industrial PCBs, where strong, reliable cutting is required. The adjustable settings make this machine adaptable to various PCB thicknesses and types, providing consistent performance.

Move-Blade (Sliding) V-Cut Machine

The Move-Blade V-Cut Machine offers a sliding blade mechanism that follows the V-groove for smooth and controlled separation. This method reduces sudden impacts on the PCB, ensuring minimal stress on sensitive components. With adjustable blade height, this machine can handle PCBs with varying thicknesses and V-slot depths. It is ideal for mixed production lines, where different types of PCBs are being processed. The smooth motion of the blade also improves cutting consistency and extends blade life, making it a highly versatile tool for PCB depaneling in a variety of applications.

| Specification

| Parameter | Manual Single-Blade V-cut Machine | Multi-Blades LED Separator | Guillotine Type V-cut Machine | Move-Blade (Sliding) V-cut Machine | Multi Group Blades PCB V-cut Machine |

|---|---|---|---|---|---|

| Operation Type | Manual (hand sliding) | Manual (hand push) | Manual (pneumatic foot switch) | Manual (adjustable sliding) | Manual (multi-group push) |

| Blade Setup | 1 circular + 1 straight blade | 6 circular blades (3 groups top/bottom) | Single straight guillotine blade | 1 circular + 1 straight (adjustable gap) | Multiple groups of circular blades (custom multi-knife) |

| PCB Length | 0–350 mm | Unlimited (with 1.2m / 2.4m platforms) | 0–330 mm | 0–350 mm (typical) | Unlimited or very long (platform-dependent) |

| PCB Thickness | 0.8–5 mm | 0.2–5 mm | 0.3–5 mm | 0.8–5 mm | 0.2–5 mm (typical for multi-group) |

| Cutting Method | Single pass sliding | 3-phase (40% + 40% + 20%) | One-shot downward cut | Single pass with adjustable depth | Multi-group sequential cutting |

| Best Application | General PCBs, prototypes, medium volume | Long LED strips, aluminum PCBs, high-volume LED | FR4 boards, clean/dust-free edges | Mixed components, flexible V-depth | Extra-long or wide PCBs, high-efficiency separation |

| SMT Line Equipment List

I.C.T puts together full SMT lines that link loaders, printers, mounters, reflow ovens, AOI units, conveyors, and aluminum PCB cutting machine sections into one working system. Everything matches up right. When space runs tight, U-shaped layouts use the floor well without losing flow. The whole setup raises output, cuts mistakes, and delivers steady quality for automotive parts, LED products, and everyday electronics. Customers get help from start to finish—planning the line, setting it up, and tuning it so production runs smooth and strong from the first day onward.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

In 2025, I.C.T engineer Peter traveled to Uzbekistan to support a customer who had purchased a full SMT production line for automotive motor parts. The factory had limited space, so I.C.T designed a compact production layout to maximize efficiency. The solution included various machines such as the 5151 full-automatic printer, high-speed mounter, and L8 reflow oven. After installation, Peter provided hands-on training to ensure the customer could operate all the machines independently. The customer was able to run the entire production line without issues, achieving consistent output and high-quality components.

| Service and Training Support

I.C.T provides full installation and training services for the LED Strip PCB Depaneling Machine. Our engineers assist with the setup process, ensuring the machine is configured correctly for your production needs. During the training session, operators learn how to safely operate the machine, adjust the cutting settings, and maintain the equipment for optimal performance. I.C.T also offers remote support and troubleshooting services to address any issues that arise during production. Our goal is to ensure that you can operate the machine with confidence and maximize its performance throughout its lifespan.

| Customer Feedback

"We are extremely satisfied with the performance of I.C.T's LED Strip PCB Depaneling Machine. The machine provides precise and clean cuts without damaging our components, even for delicate boards. The engineers who came for installation were knowledgeable and provided us with clear training. We also appreciated the efficient packaging, which ensured the equipment arrived in perfect condition. Whenever we have technical questions, I.C.T’s support team is always quick to respond and offer solutions. Their commitment to customer satisfaction has made us loyal customers, and we look forward to working with them on future projects."

| Certifications and Standards

I.C.T’s LED Strip PCB Depaneling Machine meets international standards for quality and safety, including CE, RoHS, and ISO 9001 certifications. These certifications ensure that the machine is built to provide safe and reliable operation while meeting environmental standards. In addition, I.C.T holds patents for several cutting technologies used in our machines, ensuring we stay at the forefront of the industry. These certifications reflect I.C.T’s commitment to continuous innovation and customer satisfaction, ensuring high-quality equipment that performs consistently over time.

| About I.C.T Company and Factory

I.C.T is a trusted provider of electronics manufacturing solutions, specializing in high-quality equipment for PCB separation, SMT, DIP, and assembly processes. With more than 25 years of experience, we serve industries worldwide, including LED lighting, automotive, and consumer electronics. Our factory is equipped with state-of-the-art production technologies, and we employ a skilled team of engineers who ensure that each machine meets the highest standards. I.C.T’s focus on quality, efficiency, and customer support has made us a leader in the field of electronics manufacturing equipment.

| Precision Cutting for LED Strip PCBs

The LED Strip PCB Depaneling Machine is designed to handle the precise and efficient separation of PCB panels after assembly, especially in LED lighting applications. This machine applies controlled cutting force to separate PCBs along V-grooves or straight cuts, ensuring minimal stress on components during the process. It is ideal for mass production environments where high cutting precision is required. The adjustable cutting speed and blade height provide flexibility for various PCB types, making it suitable for both standard and complex PCB designs. This machine offers reliable and consistent results, ensuring that LED strip and light bar PCBs are separated safely and effectively.

Function and application overview:

The machine is used for depaneling PCBs post-SMT to prepare them for further assembly or testing;

It is especially suitable for LED strip PCBs and light bar applications, where precise cutting is crucial;

The machine ensures clean separation with minimal impact on sensitive components, making it ideal for high-quality LED production

| Feature

Multi-Blades LED Separator

The Multi-Blades LED Separator uses multiple circular blades positioned both above and below the PCB to achieve efficient straight-line separation. This design ensures that the cutting force is evenly distributed, minimizing the risk of board deformation. It is especially suitable for LED strip and light bar PCBs, where components are placed close to the edges. With adjustable blade spacing, this machine can accommodate various PCB widths, ensuring flexible and reliable operation in high-volume production environments. The multi-blade system also ensures long-lasting performance, making it ideal for continuous LED production.

Guillotine Type V-Cut Machine

The Guillotine Type V-Cut Machine is designed to apply vertical force directly along the V-groove, providing precise and clean cuts for thicker PCBs or those with deep V-grooves. This machine is ideal for separating PCBs with high component density or thicker materials. The uniform cutting force helps prevent component damage and ensures that the board remains stable during the separation process. It’s especially effective for power control boards and other industrial PCBs, where strong, reliable cutting is required. The adjustable settings make this machine adaptable to various PCB thicknesses and types, providing consistent performance.

Move-Blade (Sliding) V-Cut Machine

The Move-Blade V-Cut Machine offers a sliding blade mechanism that follows the V-groove for smooth and controlled separation. This method reduces sudden impacts on the PCB, ensuring minimal stress on sensitive components. With adjustable blade height, this machine can handle PCBs with varying thicknesses and V-slot depths. It is ideal for mixed production lines, where different types of PCBs are being processed. The smooth motion of the blade also improves cutting consistency and extends blade life, making it a highly versatile tool for PCB depaneling in a variety of applications.

| Specification

| Parameter | Manual Single-Blade V-cut Machine | Multi-Blades LED Separator | Guillotine Type V-cut Machine | Move-Blade (Sliding) V-cut Machine | Multi Group Blades PCB V-cut Machine |

|---|---|---|---|---|---|

| Operation Type | Manual (hand sliding) | Manual (hand push) | Manual (pneumatic foot switch) | Manual (adjustable sliding) | Manual (multi-group push) |

| Blade Setup | 1 circular + 1 straight blade | 6 circular blades (3 groups top/bottom) | Single straight guillotine blade | 1 circular + 1 straight (adjustable gap) | Multiple groups of circular blades (custom multi-knife) |

| PCB Length | 0–350 mm | Unlimited (with 1.2m / 2.4m platforms) | 0–330 mm | 0–350 mm (typical) | Unlimited or very long (platform-dependent) |

| PCB Thickness | 0.8–5 mm | 0.2–5 mm | 0.3–5 mm | 0.8–5 mm | 0.2–5 mm (typical for multi-group) |

| Cutting Method | Single pass sliding | 3-phase (40% + 40% + 20%) | One-shot downward cut | Single pass with adjustable depth | Multi-group sequential cutting |

| Best Application | General PCBs, prototypes, medium volume | Long LED strips, aluminum PCBs, high-volume LED | FR4 boards, clean/dust-free edges | Mixed components, flexible V-depth | Extra-long or wide PCBs, high-efficiency separation |

| SMT Line Equipment List

I.C.T puts together full SMT lines that link loaders, printers, mounters, reflow ovens, AOI units, conveyors, and aluminum PCB cutting machine sections into one working system. Everything matches up right. When space runs tight, U-shaped layouts use the floor well without losing flow. The whole setup raises output, cuts mistakes, and delivers steady quality for automotive parts, LED products, and everyday electronics. Customers get help from start to finish—planning the line, setting it up, and tuning it so production runs smooth and strong from the first day onward.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

In 2025, I.C.T engineer Peter traveled to Uzbekistan to support a customer who had purchased a full SMT production line for automotive motor parts. The factory had limited space, so I.C.T designed a compact production layout to maximize efficiency. The solution included various machines such as the 5151 full-automatic printer, high-speed mounter, and L8 reflow oven. After installation, Peter provided hands-on training to ensure the customer could operate all the machines independently. The customer was able to run the entire production line without issues, achieving consistent output and high-quality components.

| Service and Training Support

I.C.T provides full installation and training services for the LED Strip PCB Depaneling Machine. Our engineers assist with the setup process, ensuring the machine is configured correctly for your production needs. During the training session, operators learn how to safely operate the machine, adjust the cutting settings, and maintain the equipment for optimal performance. I.C.T also offers remote support and troubleshooting services to address any issues that arise during production. Our goal is to ensure that you can operate the machine with confidence and maximize its performance throughout its lifespan.

| Customer Feedback

"We are extremely satisfied with the performance of I.C.T's LED Strip PCB Depaneling Machine. The machine provides precise and clean cuts without damaging our components, even for delicate boards. The engineers who came for installation were knowledgeable and provided us with clear training. We also appreciated the efficient packaging, which ensured the equipment arrived in perfect condition. Whenever we have technical questions, I.C.T’s support team is always quick to respond and offer solutions. Their commitment to customer satisfaction has made us loyal customers, and we look forward to working with them on future projects."

| Certifications and Standards

I.C.T’s LED Strip PCB Depaneling Machine meets international standards for quality and safety, including CE, RoHS, and ISO 9001 certifications. These certifications ensure that the machine is built to provide safe and reliable operation while meeting environmental standards. In addition, I.C.T holds patents for several cutting technologies used in our machines, ensuring we stay at the forefront of the industry. These certifications reflect I.C.T’s commitment to continuous innovation and customer satisfaction, ensuring high-quality equipment that performs consistently over time.

| About I.C.T Company and Factory

I.C.T is a trusted provider of electronics manufacturing solutions, specializing in high-quality equipment for PCB separation, SMT, DIP, and assembly processes. With more than 25 years of experience, we serve industries worldwide, including LED lighting, automotive, and consumer electronics. Our factory is equipped with state-of-the-art production technologies, and we employ a skilled team of engineers who ensure that each machine meets the highest standards. I.C.T’s focus on quality, efficiency, and customer support has made us a leader in the field of electronics manufacturing equipment.