I.C.T-GV330

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| High-Strength Guillotine PCB Depaneling Solution

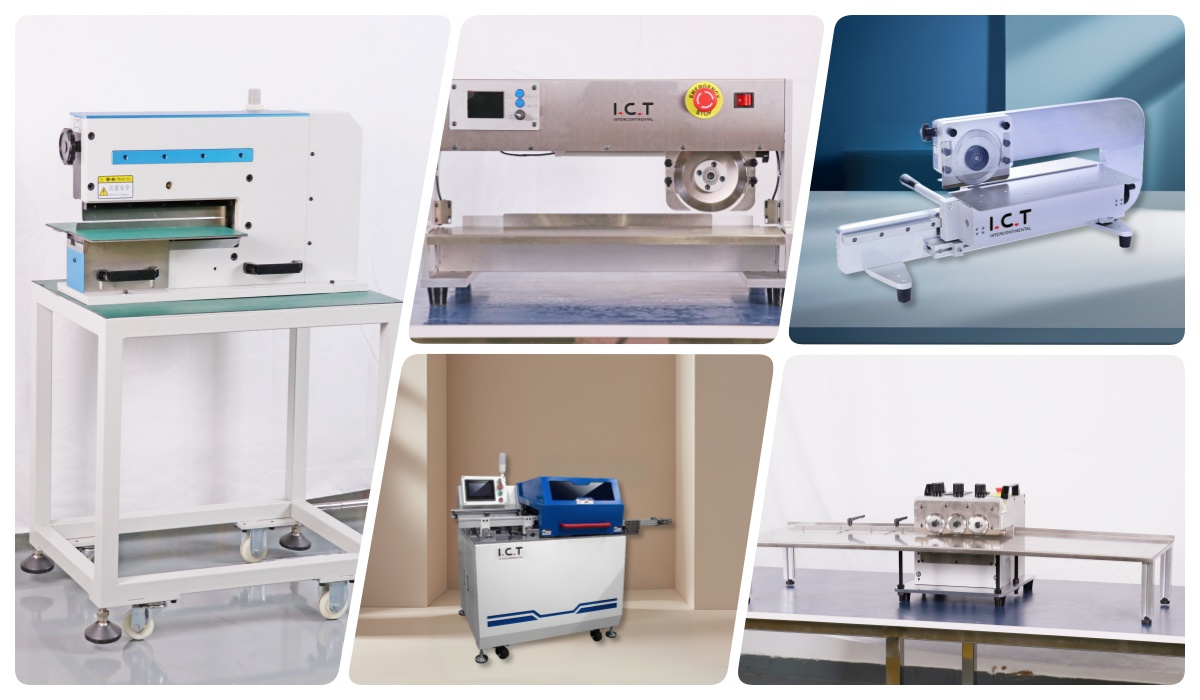

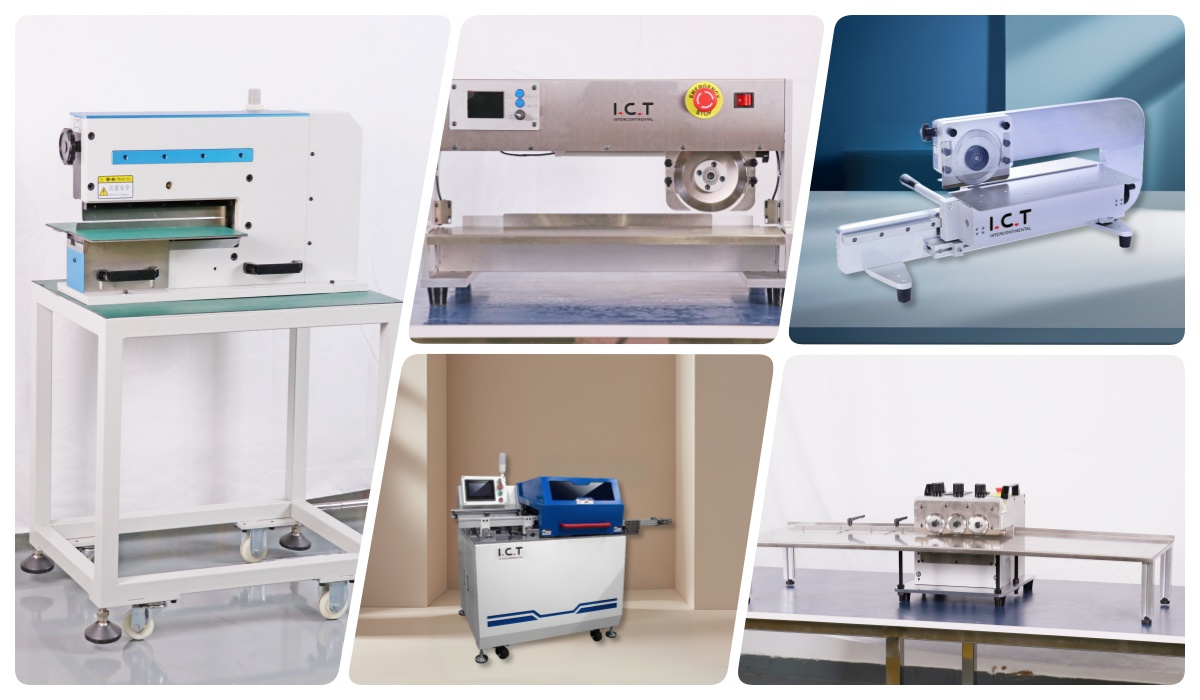

The Guillotine Type PCB V-cut Machine is designed for precise separation of PCB panels using a vertical cutting method along pre-scored V-grooves. This structure applies uniform downward force, helping boards split cleanly without bending or twisting. It is commonly used after SMT or assembly processes where board strength and edge quality are critical. With a rigid frame and controlled blade movement, the machine supports various PCB thicknesses and materials. The Guillotine Type PCB V-cut Machine is suitable for factories that require stable, repeatable depaneling results in medium- to high-volume production environments.

Function and application overview:

PCB depaneling converts large panels into individual boards before testing and final assembly;

The machine is widely applied in LED lighting, power electronics, and industrial control products;

It supports V-cut separation where high strength and clean edges are required.

| Feature

Multi-Blades LED Separator

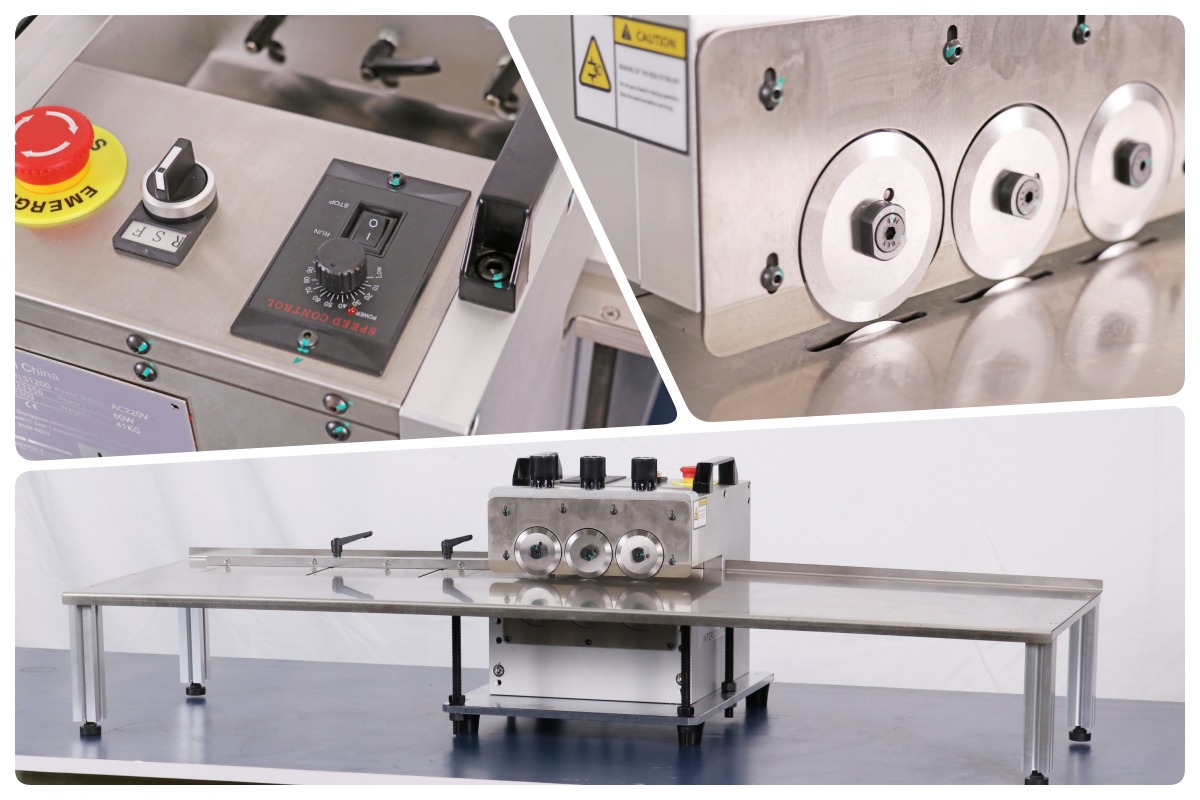

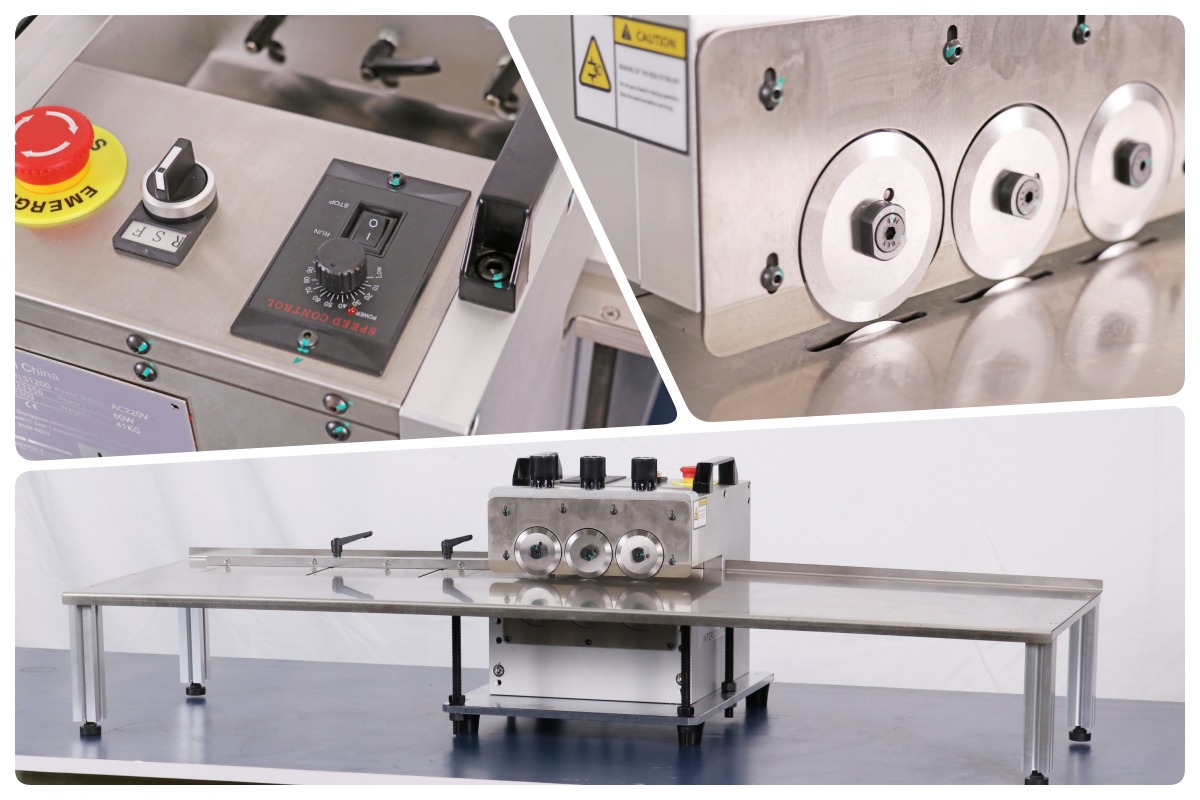

The Multi-Blades LED Separator is designed for straight-line depaneling of long and narrow PCB panels. By using multiple circular blades positioned above and below the board, cutting force is evenly distributed, reducing mechanical stress during separation. This structure is especially effective for LED applications where components are placed close to the edge. It is often used as a Pcb Cutter Led Cutting Machine for light bar and strip products. The adjustable blade spacing allows the machine to handle different panel widths, while its simple mechanical design ensures stable performance and easy maintenance in continuous LED production.

Guillotine Type V-Cut Machine

The Guillotine Type V-Cut Machine uses a vertical blade that presses directly down along the V-groove, making it ideal for thick PCBs and deep scoring lines. This design prevents lateral movement and keeps the board firmly supported during cutting. As a core part of the Guillotine Type PCB V-cut Machine family, it delivers strong cutting power with clean, straight edges. The machine is commonly selected as a cutting machine PCB solution for power boards and industrial electronics where high mechanical strength is required. Adjustable parameters allow it to adapt to different materials while maintaining consistent quality.

Move-Blade (Sliding) V-Cut Machine

The Move-Blade V-Cut Machine separates PCBs by sliding the blade smoothly along the V-cut line instead of cutting in a single press. This method reduces sudden impact and helps protect delicate solder joints. It is suitable for mixed-product lines and boards with longer cutting paths. Many factories use it as a Pcb Automatic V-Cut Machine when flexibility and low-stress cutting are important. The sliding motion also improves blade life and provides more stable results for diversified PCB designs that change frequently in daily production.

| Specification

| Parameter | Manual Single-Blade V-cut Machine | Multi-Blades LED Separator | Guillotine Type V-cut Machine | Move-Blade (Sliding) V-cut Machine | Multi Group Blades PCB V-cut Machine |

|---|---|---|---|---|---|

| Operation Type | Manual (hand sliding) | Manual (hand push) | Manual (pneumatic foot switch) | Manual (adjustable sliding) | Manual (multi-group push) |

| Blade Setup | 1 circular + 1 straight blade | 6 circular blades (3 groups top/bottom) | Single straight guillotine blade | 1 circular + 1 straight (adjustable gap) | Multiple groups of circular blades (custom multi-knife) |

| PCB Length | 0–350 mm | Unlimited (with 1.2m / 2.4m platforms) | 0–330 mm | 0–350 mm (typical) | Unlimited or very long (platform-dependent) |

| PCB Thickness | 0.8–5 mm | 0.2–5 mm | 0.3–5 mm | 0.8–5 mm | 0.2–5 mm (typical for multi-group) |

| Cutting Method | Single pass sliding | 3-phase (40% + 40% + 20%) | One-shot downward cut | Single pass with adjustable depth | Multi-group sequential cutting |

| Best Application | General PCBs, prototypes, medium volume | Long LED strips, aluminum PCBs, high-volume LED | FR4 boards, clean/dust-free edges | Mixed components, flexible V-depth | Extra-long or wide PCBs, high-efficiency separation |

| SMT Line Equipment List

I.C.T puts together full SMT lines that link loaders, printers, mounters, reflow ovens, AOI units, conveyors, and aluminum PCB cutting machine sections into one working system. Everything matches up right. When space runs tight, U-shaped layouts use the floor well without losing flow. The whole setup raises output, cuts mistakes, and delivers steady quality for automotive parts, LED products, and everyday electronics. Customers get help from start to finish—planning the line, setting it up, and tuning it so production runs smooth and strong from the first day onward.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

In 2025, an I.C.T engineer supported an automotive electronics manufacturer in Uzbekistan that purchased a complete SMT production line. Due to limited floor space, I.C.T designed a compact U-shaped layout that ensured smooth material flow. The project included printing, placement, reflow soldering, inspection, depaneling, and auxiliary equipment. On site, the engineer guided installation and trained operators in real production conditions. After the support period, the customer independently operated the full line, maintaining stable output while producing motor control boards with consistent quality.

| Service and Training Support

I.C.T provides complete service and training support for every Guillotine Type PCB V-cut Machine delivered. Before shipment, application requirements are reviewed to ensure proper configuration. After installation, operators receive hands-on training covering operation steps, safety guidelines, blade adjustment, and routine maintenance. Clear documentation and remote guidance help solve daily questions efficiently. When deeper technical support is needed, I.C.T responds quickly to reduce downtime. This service system helps customers fully understand their equipment and keep production running smoothly over the long term.

| Customer Feedback

Customers often speak highly of I.C.T engineers for their practical experience and clear training methods. The machines are praised for strong cutting performance, stable operation, and reliable results during long working hours. Many customers also note the careful packaging, which protects equipment well during international transport. When issues or questions arise, fast response and effective solutions from I.C.T create strong trust. These positive experiences encourage customers to continue cooperation and confidently expand their depaneling capacity, including applications such as Led Strip Light Bar Pcb Depaneling.

| Certifications and Standards

All I.C.T depaneling equipment is manufactured under strict quality control standards. Machines comply with CE and RoHS requirements to meet international safety and environmental regulations. Production management follows the ISO9001 quality system to ensure consistency and reliability. In addition, I.C.T holds multiple patents related to mechanical structure and cutting technology, including designs used in Cutting Saw Machinery For Pcb applications. These certifications reflect I.C.T’s long-term commitment to safe operation, stable quality, and continuous technical innovation.

| About I.C.T Company and Factory

I.C.T is an experienced manufacturer providing complete electronics manufacturing solutions, including SMT, DIP, assembly, inspection, and PCB depaneling systems. With a skilled engineering team and modern production facilities, I.C.T focuses on practical machine design and real production needs. Every Guillotine Type PCB V-cut Machine is assembled, tested, and inspected before delivery. Serving customers worldwide, I.C.T helps manufacturers improve efficiency, ensure product quality, and build stable, long-term production systems.

| High-Strength Guillotine PCB Depaneling Solution

The Guillotine Type PCB V-cut Machine is designed for precise separation of PCB panels using a vertical cutting method along pre-scored V-grooves. This structure applies uniform downward force, helping boards split cleanly without bending or twisting. It is commonly used after SMT or assembly processes where board strength and edge quality are critical. With a rigid frame and controlled blade movement, the machine supports various PCB thicknesses and materials. The Guillotine Type PCB V-cut Machine is suitable for factories that require stable, repeatable depaneling results in medium- to high-volume production environments.

Function and application overview:

PCB depaneling converts large panels into individual boards before testing and final assembly;

The machine is widely applied in LED lighting, power electronics, and industrial control products;

It supports V-cut separation where high strength and clean edges are required.

| Feature

Multi-Blades LED Separator

The Multi-Blades LED Separator is designed for straight-line depaneling of long and narrow PCB panels. By using multiple circular blades positioned above and below the board, cutting force is evenly distributed, reducing mechanical stress during separation. This structure is especially effective for LED applications where components are placed close to the edge. It is often used as a Pcb Cutter Led Cutting Machine for light bar and strip products. The adjustable blade spacing allows the machine to handle different panel widths, while its simple mechanical design ensures stable performance and easy maintenance in continuous LED production.

Guillotine Type V-Cut Machine

The Guillotine Type V-Cut Machine uses a vertical blade that presses directly down along the V-groove, making it ideal for thick PCBs and deep scoring lines. This design prevents lateral movement and keeps the board firmly supported during cutting. As a core part of the Guillotine Type PCB V-cut Machine family, it delivers strong cutting power with clean, straight edges. The machine is commonly selected as a cutting machine PCB solution for power boards and industrial electronics where high mechanical strength is required. Adjustable parameters allow it to adapt to different materials while maintaining consistent quality.

Move-Blade (Sliding) V-Cut Machine

The Move-Blade V-Cut Machine separates PCBs by sliding the blade smoothly along the V-cut line instead of cutting in a single press. This method reduces sudden impact and helps protect delicate solder joints. It is suitable for mixed-product lines and boards with longer cutting paths. Many factories use it as a Pcb Automatic V-Cut Machine when flexibility and low-stress cutting are important. The sliding motion also improves blade life and provides more stable results for diversified PCB designs that change frequently in daily production.

| Specification

| Parameter | Manual Single-Blade V-cut Machine | Multi-Blades LED Separator | Guillotine Type V-cut Machine | Move-Blade (Sliding) V-cut Machine | Multi Group Blades PCB V-cut Machine |

|---|---|---|---|---|---|

| Operation Type | Manual (hand sliding) | Manual (hand push) | Manual (pneumatic foot switch) | Manual (adjustable sliding) | Manual (multi-group push) |

| Blade Setup | 1 circular + 1 straight blade | 6 circular blades (3 groups top/bottom) | Single straight guillotine blade | 1 circular + 1 straight (adjustable gap) | Multiple groups of circular blades (custom multi-knife) |

| PCB Length | 0–350 mm | Unlimited (with 1.2m / 2.4m platforms) | 0–330 mm | 0–350 mm (typical) | Unlimited or very long (platform-dependent) |

| PCB Thickness | 0.8–5 mm | 0.2–5 mm | 0.3–5 mm | 0.8–5 mm | 0.2–5 mm (typical for multi-group) |

| Cutting Method | Single pass sliding | 3-phase (40% + 40% + 20%) | One-shot downward cut | Single pass with adjustable depth | Multi-group sequential cutting |

| Best Application | General PCBs, prototypes, medium volume | Long LED strips, aluminum PCBs, high-volume LED | FR4 boards, clean/dust-free edges | Mixed components, flexible V-depth | Extra-long or wide PCBs, high-efficiency separation |

| SMT Line Equipment List

I.C.T puts together full SMT lines that link loaders, printers, mounters, reflow ovens, AOI units, conveyors, and aluminum PCB cutting machine sections into one working system. Everything matches up right. When space runs tight, U-shaped layouts use the floor well without losing flow. The whole setup raises output, cuts mistakes, and delivers steady quality for automotive parts, LED products, and everyday electronics. Customers get help from start to finish—planning the line, setting it up, and tuning it so production runs smooth and strong from the first day onward.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

In 2025, an I.C.T engineer supported an automotive electronics manufacturer in Uzbekistan that purchased a complete SMT production line. Due to limited floor space, I.C.T designed a compact U-shaped layout that ensured smooth material flow. The project included printing, placement, reflow soldering, inspection, depaneling, and auxiliary equipment. On site, the engineer guided installation and trained operators in real production conditions. After the support period, the customer independently operated the full line, maintaining stable output while producing motor control boards with consistent quality.

| Service and Training Support

I.C.T provides complete service and training support for every Guillotine Type PCB V-cut Machine delivered. Before shipment, application requirements are reviewed to ensure proper configuration. After installation, operators receive hands-on training covering operation steps, safety guidelines, blade adjustment, and routine maintenance. Clear documentation and remote guidance help solve daily questions efficiently. When deeper technical support is needed, I.C.T responds quickly to reduce downtime. This service system helps customers fully understand their equipment and keep production running smoothly over the long term.

| Customer Feedback

Customers often speak highly of I.C.T engineers for their practical experience and clear training methods. The machines are praised for strong cutting performance, stable operation, and reliable results during long working hours. Many customers also note the careful packaging, which protects equipment well during international transport. When issues or questions arise, fast response and effective solutions from I.C.T create strong trust. These positive experiences encourage customers to continue cooperation and confidently expand their depaneling capacity, including applications such as Led Strip Light Bar Pcb Depaneling.

| Certifications and Standards

All I.C.T depaneling equipment is manufactured under strict quality control standards. Machines comply with CE and RoHS requirements to meet international safety and environmental regulations. Production management follows the ISO9001 quality system to ensure consistency and reliability. In addition, I.C.T holds multiple patents related to mechanical structure and cutting technology, including designs used in Cutting Saw Machinery For Pcb applications. These certifications reflect I.C.T’s long-term commitment to safe operation, stable quality, and continuous technical innovation.

| About I.C.T Company and Factory

I.C.T is an experienced manufacturer providing complete electronics manufacturing solutions, including SMT, DIP, assembly, inspection, and PCB depaneling systems. With a skilled engineering team and modern production facilities, I.C.T focuses on practical machine design and real production needs. Every Guillotine Type PCB V-cut Machine is assembled, tested, and inspected before delivery. Serving customers worldwide, I.C.T helps manufacturers improve efficiency, ensure product quality, and build stable, long-term production systems.