I.C.T-5700

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T-5700 High-Precision PCB Separator Machine

Engineers choose the I.C.T-5700 PCB Separator Machine when they need clean, accurate separation of assembled boards. This machine handles PCBs up to 450×600 mm and thicknesses from 0.5 to 5.0 mm. It works well in smartphones, wearables, automotive electronics, medical devices, and military products. The dual-platform setup lets operators process two different jobs at once or combine them for larger panels. A high-speed spindle spins up to 60,000 rpm and cuts with very little stress. Advanced CCD vision finds marks quickly and corrects position in real time. Ion air guns keep surfaces free of static and dust. The separate vacuum system pulls dust away quietly and powerfully. Built-in safety features and easy controls make daily work straightforward and reliable. Many factories rely on this Automatic PCB Separator Machine to improve quality and speed in final PCBA steps.

| Feature

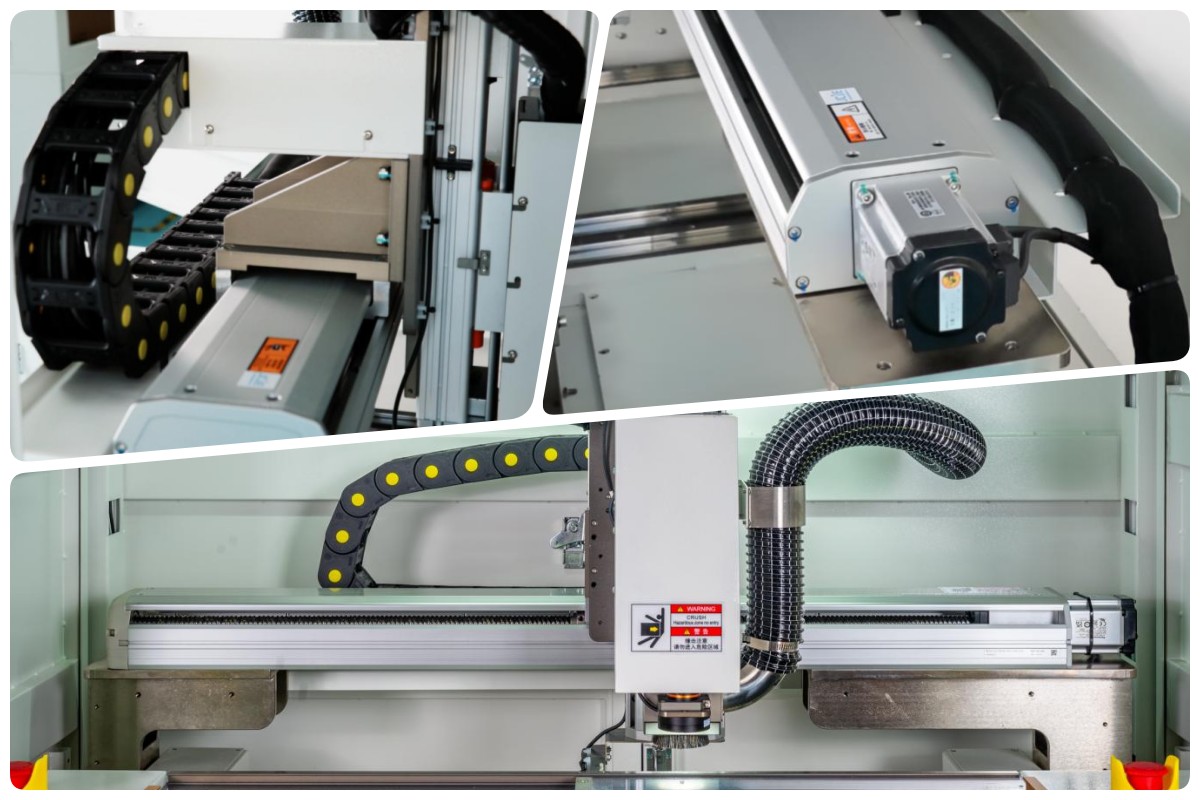

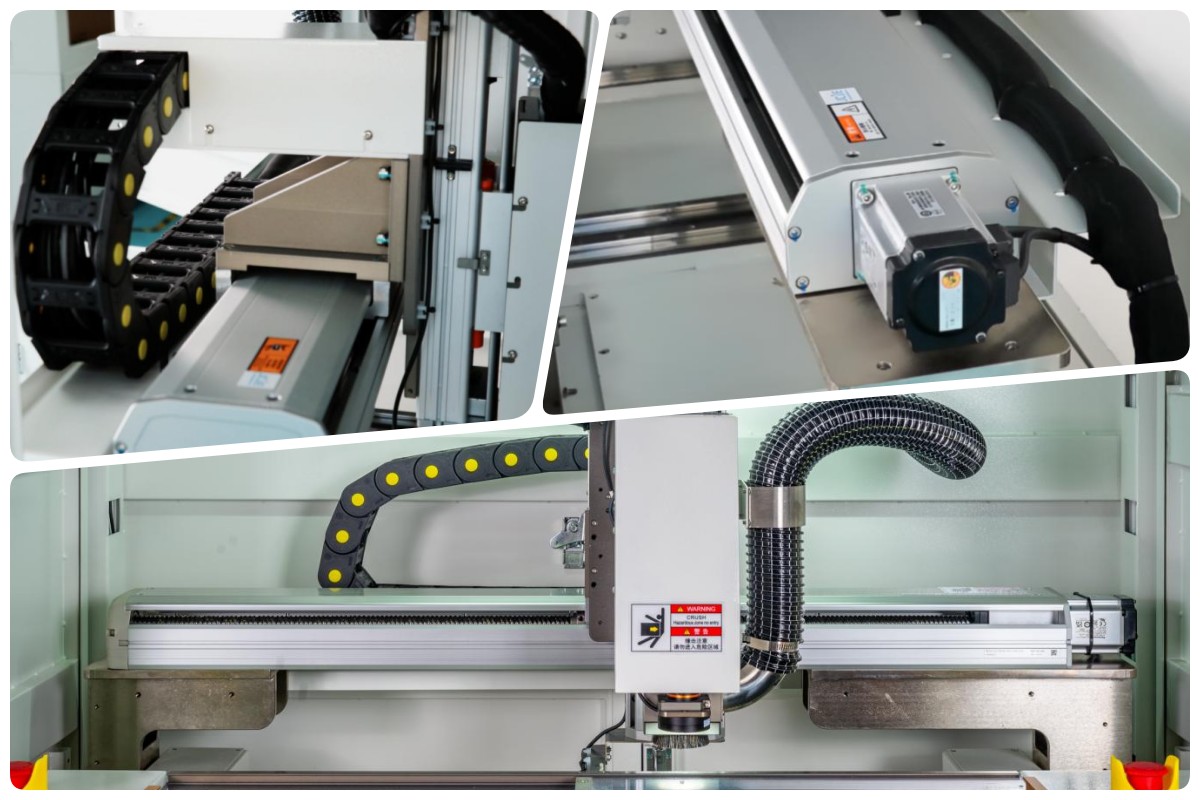

Transmission System

The transmission uses Panasonic servo motors from Japan and high-precision ball screws. Every movement stays exact. The frame is thicker and stronger than most designs. It runs steady even during long hours. Flexible tank chains keep cables neat and safe from moving parts. The X-axis has a special dust-proof cover. Dust stays out, so cleaning happens less often. Maintenance costs drop. Repeat accuracy reaches ±0.01 mm. Cutting speed goes up to 100 mm per second. Operators get smooth, fast motion on every job. This setup supports heavy use in busy lines. Factories see fewer errors and longer machine life. The whole system works quietly and reliably for years.

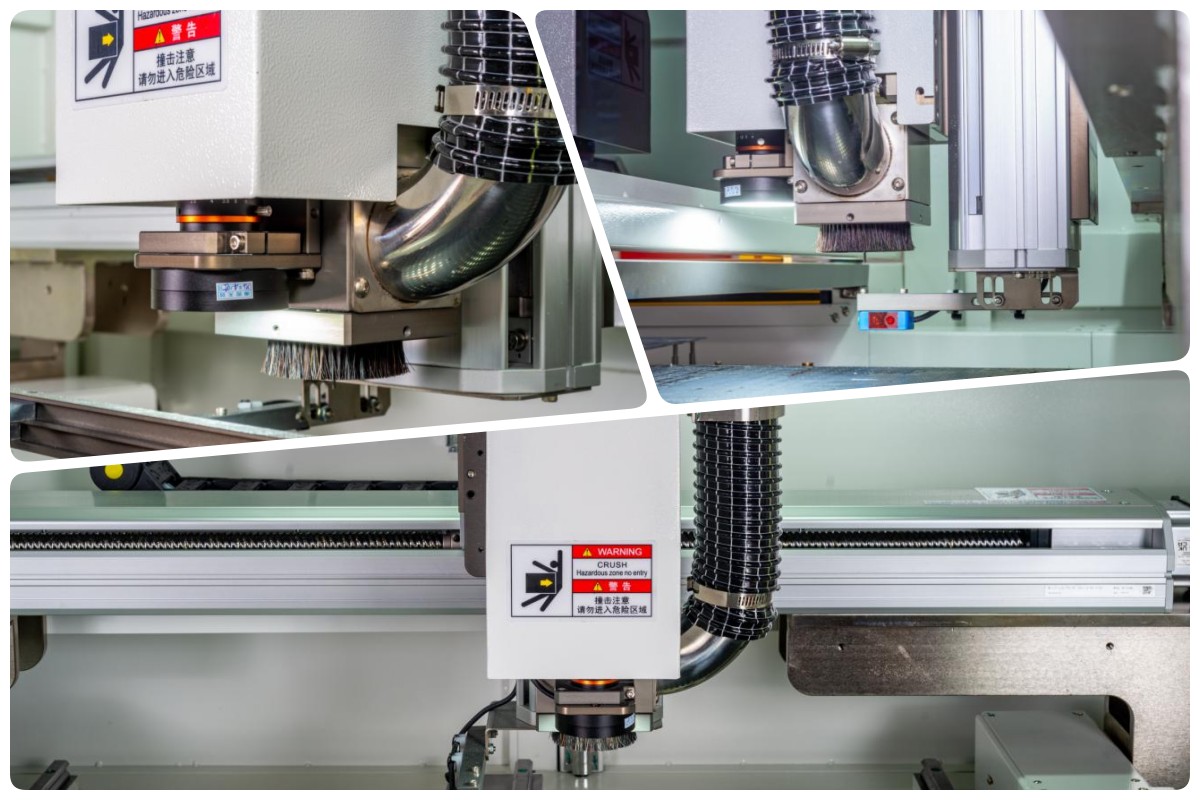

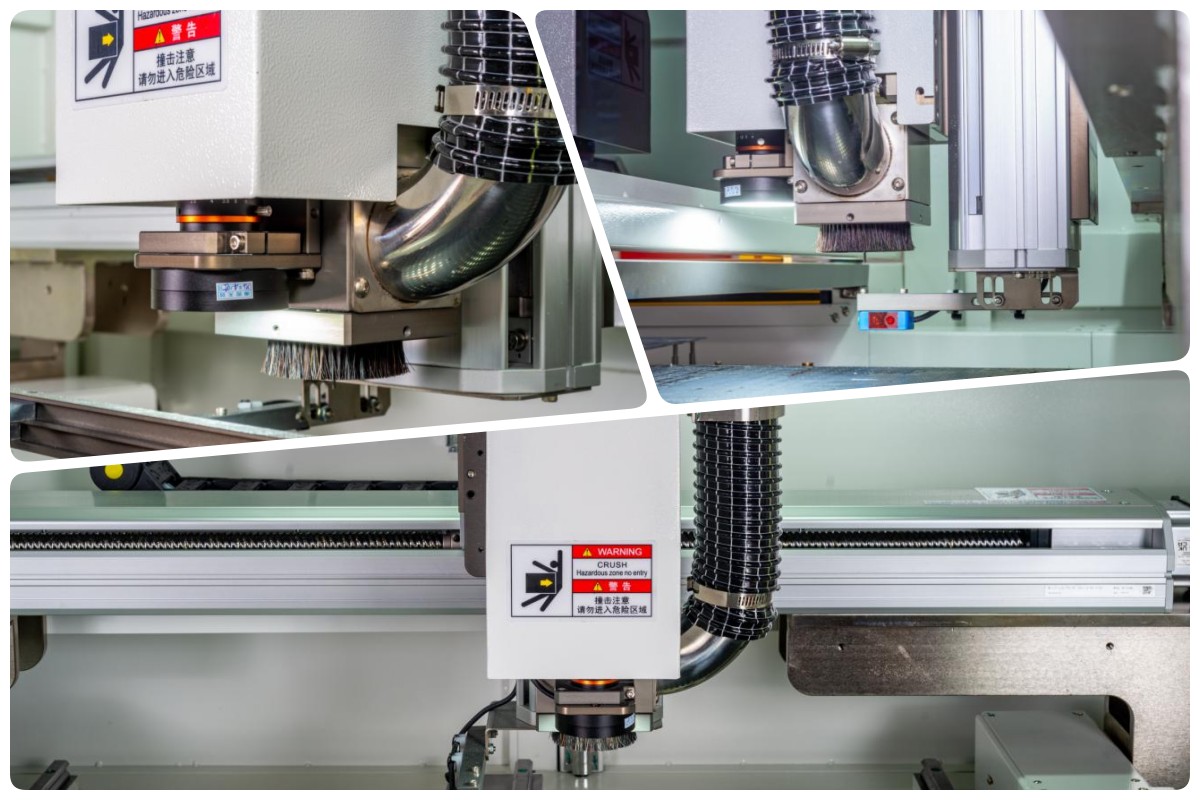

Router System

A high-definition CCD camera sits right next to the milling cutter. Calibration takes little time. The system spots tool breakage instantly and sounds an alarm. Operators stop before damage spreads. An optional automatic tool changer keeps production going without pauses. Efficiency rises. The ion air gun blows static away from every board. Dust does not stick. Imported high-speed spindles cut with low force. Precision stays high. Inertia stays small. Response comes fast. Milling cutters range from 0.8 to 3 mm. The PCBA Router Machine handles fine and complex shapes well. Dust collection works strong and steady. Clean boards leave the machine every time.

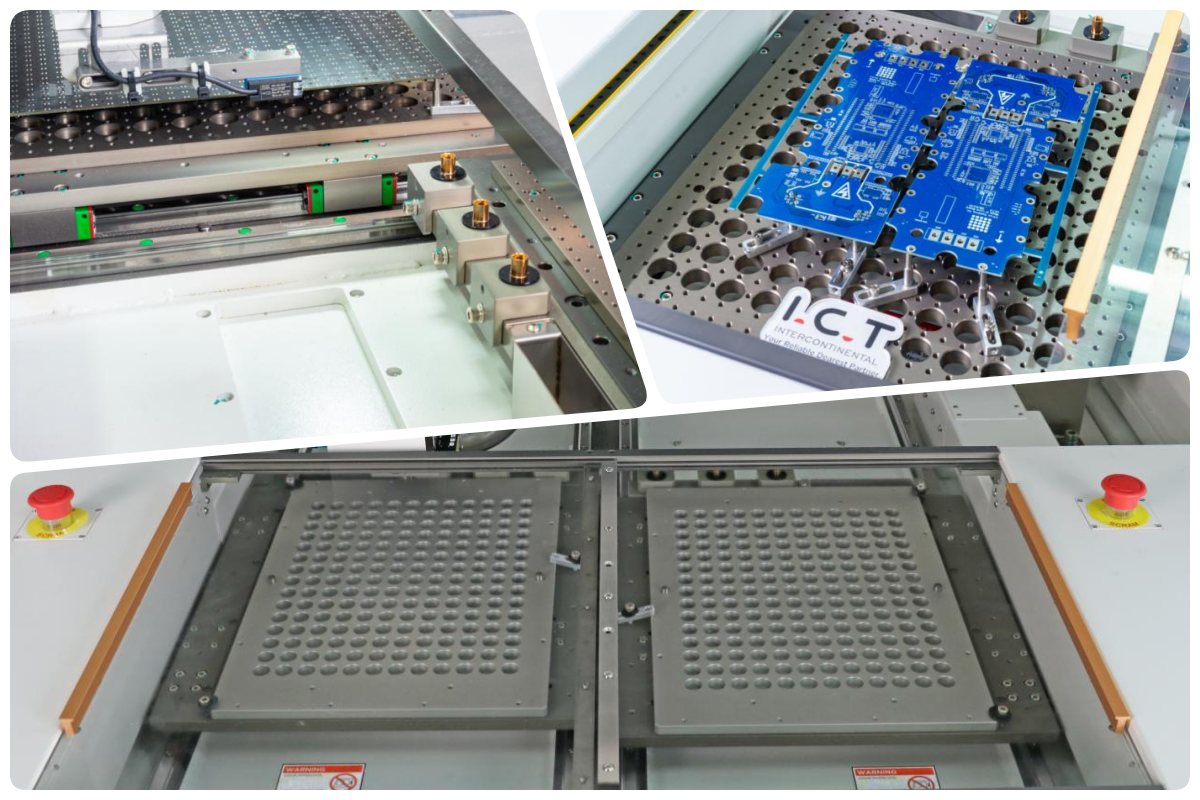

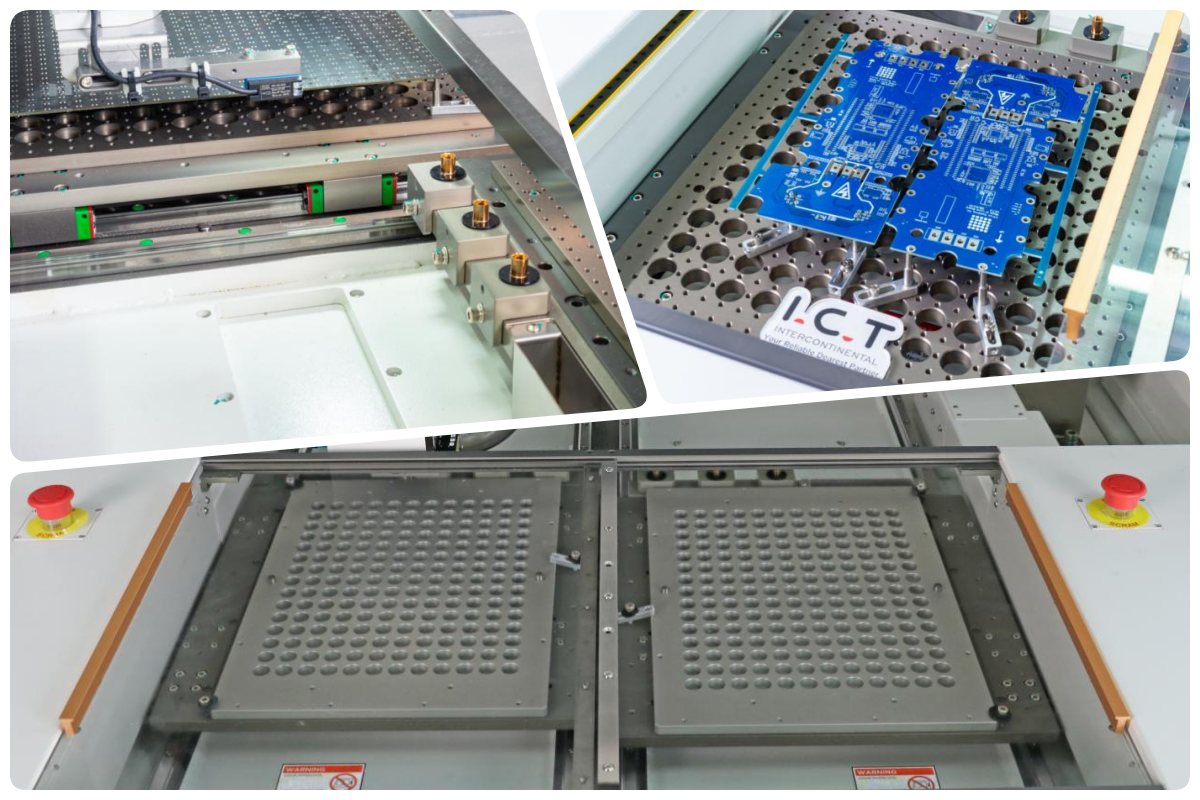

Platform System

Y-axis movement runs on slide rails and servo motors. Stability never wavers. Emergency stop buttons sit on both sides. Safety comes first. Light curtains and covers protect operators. Start buttons require two hands to press. Accidents stay low. The honeycomb base accepts many fixture types. Compatibility covers most boards. Dual platforms run separate jobs or join for big panels. Flexibility fits changing production needs. Safety meets CE and UL rules. The design supports precise cuts at ±0.05 mm. Operators work confidently in high-tech fields like automotive and medical lines.

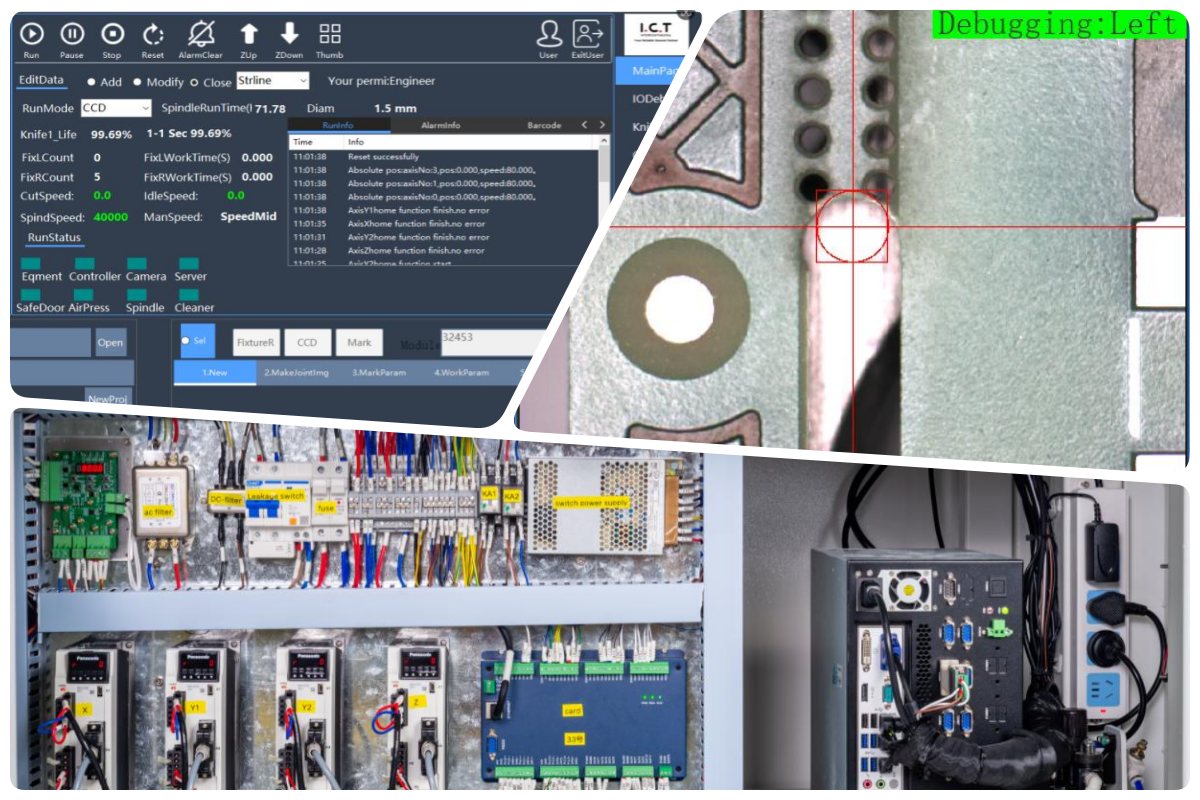

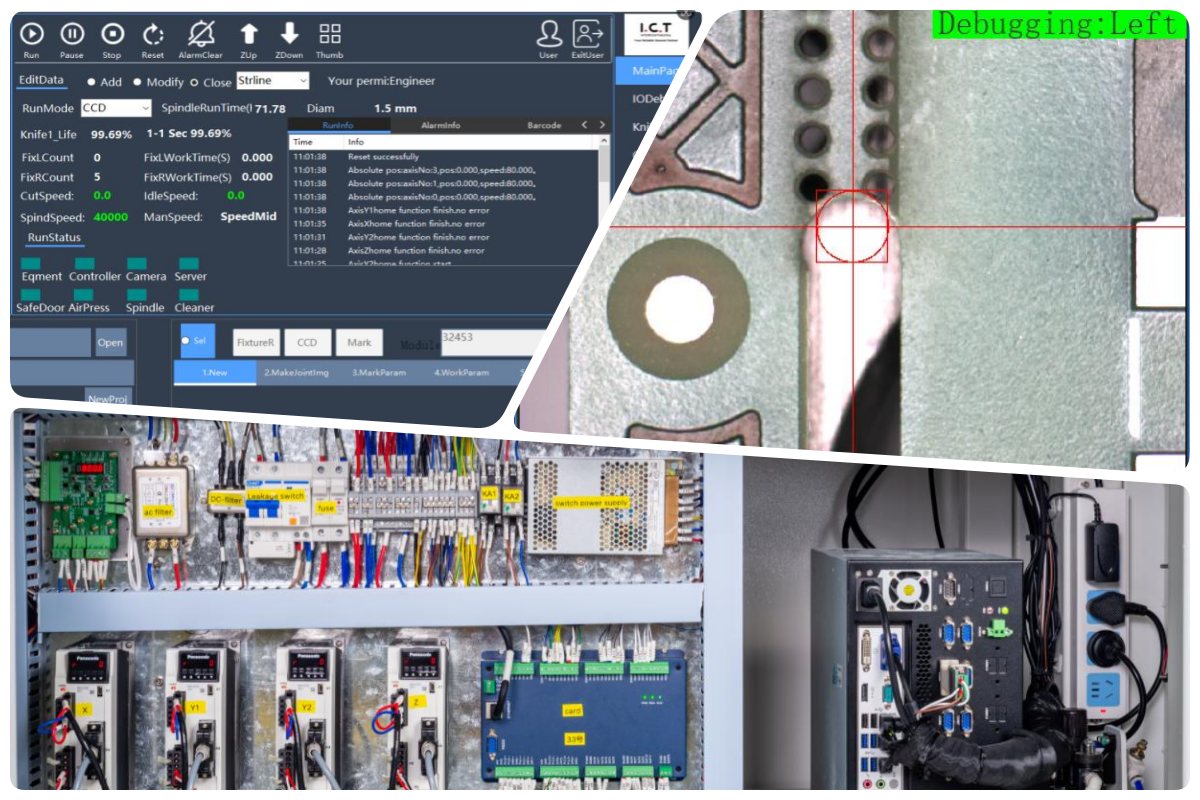

Control System

An industrial computer plus control card runs the show. Accuracy stays high. Stability holds strong. All production data gets recorded. Log reports come out easily. The layout follows CE and UL standards. Safety checks out. The interface stays simple. New operators learn fast. Program changes happen quickly. The coaxial CCD camera shows real-time views. Alignment stays perfect. CNC controllers resist interference. Breakage and slip detection run as standard features. The whole system uses 1.5 kW at 220 V. It fits well in modern SMT floors. Data tracking helps improve processes over time.

Detail Display

Look at the key parts. Convection fans keep temperature even. Side door sensors add safety. ESD interfaces protect sensitive boards. The automatic tool changer saves time. Broken knife sensors catch problems early. Self-locking pneumatic struts open smoothly. Top brands supply components. Panasonic servos come from Japan. Spindles are RSK or NSK. CCD uses HIKVISION. Guide rails are PMI or HIWIN from Taiwan. Ball screws are TBI. Delta powers the system. Omron sensors and NSK bearings last long. These choices mean fewer repairs. The machine runs steady for years. Options like upper vacuuming give extra dust control.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

An Algerian factory making feature phones sent a team to verify the machine. They arrived with more than ten different boards and full materials. Our engineers set up a complete SMT line on the spot. The process started with full automatic printing, then SPI checked paste. RX-8 placed small parts. RS-1R handled bigger components. A tray feeder supplied shielding covers. Reflow soldered everything. AOI inspected quality. Finally, the PCBA routing Machine separated boards cleanly. The client watched every step. Cuts came out perfect. Defects stayed near zero. They saw how stable and fast the whole line runs. The team left confident about adding this equipment to their factory. Real production proved the value.

| Service and Training Support

I.C.T delivers complete service from day one. Engineers install the PCB Separator Machine on-site and test it fully. Training covers operation, programming, and daily maintenance. Sessions fit beginners and experienced staff. Remote support answers questions fast. Spare parts ship quickly to keep downtime short. With more than 25 years in the industry, the team understands real factory needs. Customers in 72 countries receive the same professional help. Process optimization and upgrades come when production changes. The goal stays simple: zero worries and maximum output. Long-term partnership keeps lines running strong year after year.

| Client Testimonials

Customers frequently praise our engineers for clear explanations and fast fixes during setup. They call the Pcb Router Separator reliable and precise in daily runs. Many mention excellent packaging and safe shipping that protects the machine perfectly. Quick email and phone responses solve issues right away. Trust grows with every interaction. Overall, factories value the consistent quality and support that help them meet tight deadlines without stress.

| Certifications and Standards

I.C.T products carry CE, RoHS, and ISO9001 certifications. Multiple patents protect the design and technology. These approvals confirm the Automatic PCB Separator Machine meets international safety, environmental, and quality rules. Strict factory testing backs every certificate. Customers buy with confidence knowing standards stay high.

| About I.C.T Company and Factory

I.C.T started in 2012. The factory covers 12,000 square meters. Eighty-nine staff members work here, including twenty experienced engineers. R&D and production happen in-house. Growth continues fast. More than 1,600 customers in 72 countries use our equipment. The factory follows strict inspection steps at every stage. A complete quality management system keeps standards high. This approach delivers reliable SMT solutions worldwide. Customers trust the consistent performance and long-term support.

| I.C.T-5700 High-Precision PCB Separator Machine

Engineers choose the I.C.T-5700 PCB Separator Machine when they need clean, accurate separation of assembled boards. This machine handles PCBs up to 450×600 mm and thicknesses from 0.5 to 5.0 mm. It works well in smartphones, wearables, automotive electronics, medical devices, and military products. The dual-platform setup lets operators process two different jobs at once or combine them for larger panels. A high-speed spindle spins up to 60,000 rpm and cuts with very little stress. Advanced CCD vision finds marks quickly and corrects position in real time. Ion air guns keep surfaces free of static and dust. The separate vacuum system pulls dust away quietly and powerfully. Built-in safety features and easy controls make daily work straightforward and reliable. Many factories rely on this Automatic PCB Separator Machine to improve quality and speed in final PCBA steps.

| Feature

Transmission System

The transmission uses Panasonic servo motors from Japan and high-precision ball screws. Every movement stays exact. The frame is thicker and stronger than most designs. It runs steady even during long hours. Flexible tank chains keep cables neat and safe from moving parts. The X-axis has a special dust-proof cover. Dust stays out, so cleaning happens less often. Maintenance costs drop. Repeat accuracy reaches ±0.01 mm. Cutting speed goes up to 100 mm per second. Operators get smooth, fast motion on every job. This setup supports heavy use in busy lines. Factories see fewer errors and longer machine life. The whole system works quietly and reliably for years.

Router System

A high-definition CCD camera sits right next to the milling cutter. Calibration takes little time. The system spots tool breakage instantly and sounds an alarm. Operators stop before damage spreads. An optional automatic tool changer keeps production going without pauses. Efficiency rises. The ion air gun blows static away from every board. Dust does not stick. Imported high-speed spindles cut with low force. Precision stays high. Inertia stays small. Response comes fast. Milling cutters range from 0.8 to 3 mm. The PCBA Router Machine handles fine and complex shapes well. Dust collection works strong and steady. Clean boards leave the machine every time.

Platform System

Y-axis movement runs on slide rails and servo motors. Stability never wavers. Emergency stop buttons sit on both sides. Safety comes first. Light curtains and covers protect operators. Start buttons require two hands to press. Accidents stay low. The honeycomb base accepts many fixture types. Compatibility covers most boards. Dual platforms run separate jobs or join for big panels. Flexibility fits changing production needs. Safety meets CE and UL rules. The design supports precise cuts at ±0.05 mm. Operators work confidently in high-tech fields like automotive and medical lines.

Control System

An industrial computer plus control card runs the show. Accuracy stays high. Stability holds strong. All production data gets recorded. Log reports come out easily. The layout follows CE and UL standards. Safety checks out. The interface stays simple. New operators learn fast. Program changes happen quickly. The coaxial CCD camera shows real-time views. Alignment stays perfect. CNC controllers resist interference. Breakage and slip detection run as standard features. The whole system uses 1.5 kW at 220 V. It fits well in modern SMT floors. Data tracking helps improve processes over time.

Detail Display

Look at the key parts. Convection fans keep temperature even. Side door sensors add safety. ESD interfaces protect sensitive boards. The automatic tool changer saves time. Broken knife sensors catch problems early. Self-locking pneumatic struts open smoothly. Top brands supply components. Panasonic servos come from Japan. Spindles are RSK or NSK. CCD uses HIKVISION. Guide rails are PMI or HIWIN from Taiwan. Ball screws are TBI. Delta powers the system. Omron sensors and NSK bearings last long. These choices mean fewer repairs. The machine runs steady for years. Options like upper vacuuming give extra dust control.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

An Algerian factory making feature phones sent a team to verify the machine. They arrived with more than ten different boards and full materials. Our engineers set up a complete SMT line on the spot. The process started with full automatic printing, then SPI checked paste. RX-8 placed small parts. RS-1R handled bigger components. A tray feeder supplied shielding covers. Reflow soldered everything. AOI inspected quality. Finally, the PCBA routing Machine separated boards cleanly. The client watched every step. Cuts came out perfect. Defects stayed near zero. They saw how stable and fast the whole line runs. The team left confident about adding this equipment to their factory. Real production proved the value.

| Service and Training Support

I.C.T delivers complete service from day one. Engineers install the PCB Separator Machine on-site and test it fully. Training covers operation, programming, and daily maintenance. Sessions fit beginners and experienced staff. Remote support answers questions fast. Spare parts ship quickly to keep downtime short. With more than 25 years in the industry, the team understands real factory needs. Customers in 72 countries receive the same professional help. Process optimization and upgrades come when production changes. The goal stays simple: zero worries and maximum output. Long-term partnership keeps lines running strong year after year.

| Client Testimonials

Customers frequently praise our engineers for clear explanations and fast fixes during setup. They call the Pcb Router Separator reliable and precise in daily runs. Many mention excellent packaging and safe shipping that protects the machine perfectly. Quick email and phone responses solve issues right away. Trust grows with every interaction. Overall, factories value the consistent quality and support that help them meet tight deadlines without stress.

| Certifications and Standards

I.C.T products carry CE, RoHS, and ISO9001 certifications. Multiple patents protect the design and technology. These approvals confirm the Automatic PCB Separator Machine meets international safety, environmental, and quality rules. Strict factory testing backs every certificate. Customers buy with confidence knowing standards stay high.

| About I.C.T Company and Factory

I.C.T started in 2012. The factory covers 12,000 square meters. Eighty-nine staff members work here, including twenty experienced engineers. R&D and production happen in-house. Growth continues fast. More than 1,600 customers in 72 countries use our equipment. The factory follows strict inspection steps at every stage. A complete quality management system keeps standards high. This approach delivers reliable SMT solutions worldwide. Customers trust the consistent performance and long-term support.