I.C.T-MBV360C

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T LED PCB Separator

The I.C.T LED PCB Separator is designed to efficiently and accurately separate PCBs without damaging sensitive components. Featuring a guillotine cutting mechanism, it minimizes internal pressure, preventing solder cracks and component deformation. It is compatible with various PCB types, including aluminum-based boards, and offers customizable blade adjustments for different thicknesses and V-slot depths. This machine is ideal for manufacturers requiring high-quality, precise PCB separation.

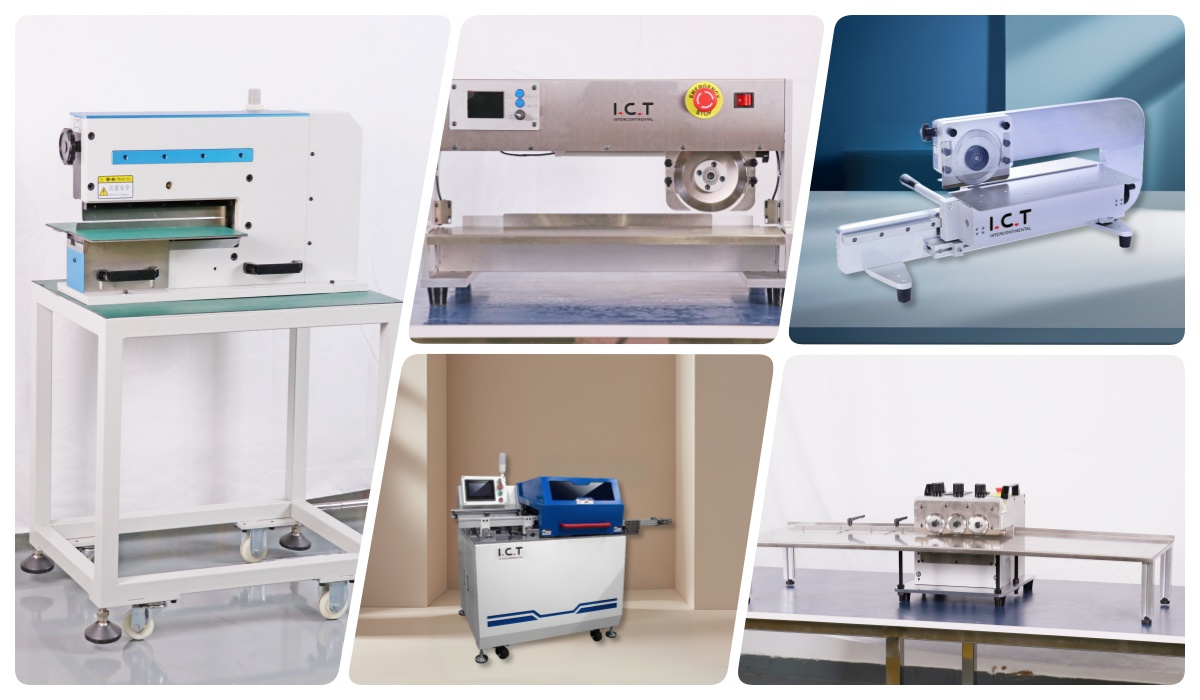

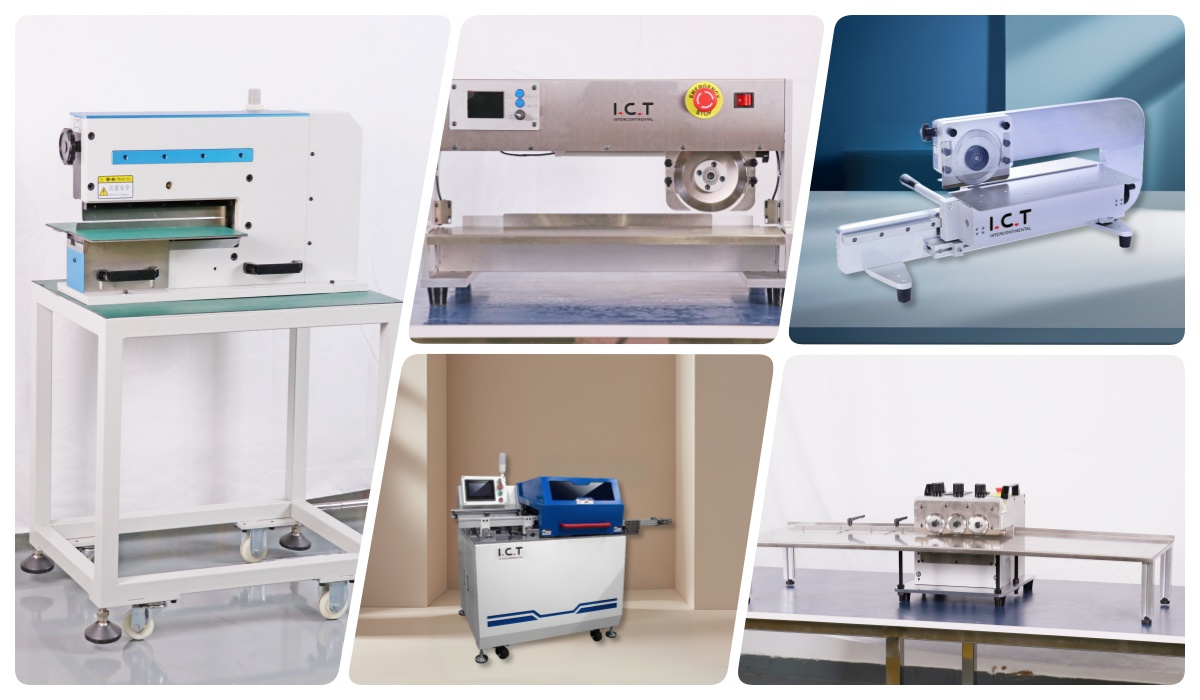

I.C.T builds five kinds of V-cut machines so each shop finds the right fit:

Standard manual type keeps things simple and low-cost for smaller jobs.

Multi-blades model cuts long LED strips in careful stages with minimal stress.

Guillotine version drops straight down with air power for thicker FR4 work.

Move-blade style slides smoothly and adjusts to many groove shapes.

Multi-knife group handles very long boards without length limits.

| Feature

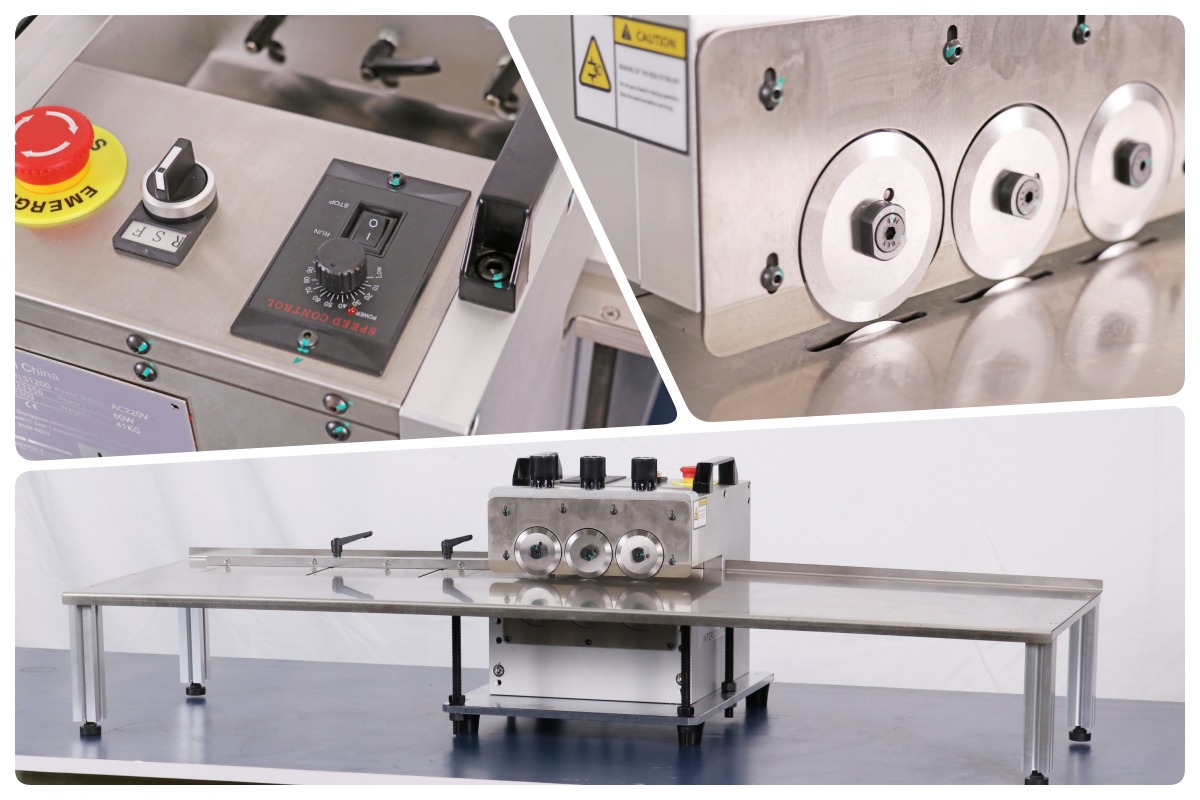

Multi-Blades LED Separator

This advanced design uses six circular blades grouped for separation, significantly reducing PCB deformation, especially for aluminum boards. The process is divided into multiple phases, with each group handling a portion of the separation, ensuring stability and minimal internal stress. This feature guarantees long-lasting performance, with blades that can be calibrated to maintain high precision.

Guillotine Type V-Cut Machine

The guillotine mechanism is designed to ensure precise and clean cuts while minimizing the risk of solder cracks and component damage. It supports V-slot separation with minimal distance to components, making it perfect for PCBs with components up to 60mm high. The machine’s design avoids rotational cuts, ensuring smooth, non-friction separation with no metal residue left behind.

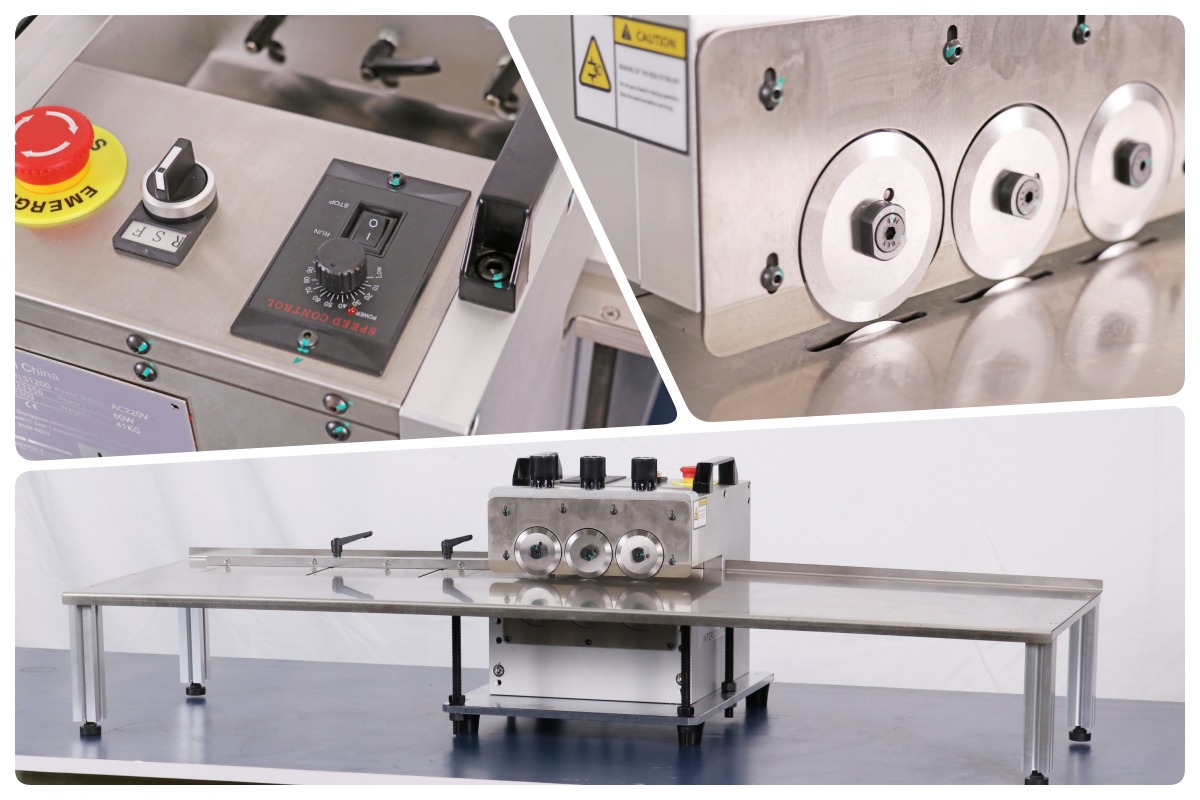

Move-Blade (Sliding) V-Cut Machine

This machine offers enhanced precision through a sliding blade mechanism, which can be adjusted to accommodate different PCB thicknesses and V-slot depths. It provides stable and reliable results, ensuring smooth, burr-free cutting and reducing potential damage to components.

| Specification

| Parameter | Manual Single-Blade V-cut Machine | Multi-Blades LED Separator | Guillotine Type V-cut Machine | Move-Blade (Sliding) V-cut Machine | Multi Group Blades PCB V-cut Machine |

|---|---|---|---|---|---|

| Operation Type | Manual (hand sliding) | Manual (hand push) | Manual (pneumatic foot switch) | Manual (adjustable sliding) | Manual (multi-group push) |

| Blade Setup | 1 circular + 1 straight blade | 6 circular blades (3 groups top/bottom) | Single straight guillotine blade | 1 circular + 1 straight (adjustable gap) | Multiple groups of circular blades (custom multi-knife) |

| PCB Length | 0–350 mm | Unlimited (with 1.2m / 2.4m platforms) | 0–330 mm | 0–350 mm (typical) | Unlimited or very long (platform-dependent) |

| PCB Thickness | 0.8–5 mm | 0.2–5 mm | 0.3–5 mm | 0.8–5 mm | 0.2–5 mm (typical for multi-group) |

| Cutting Method | Single pass sliding | 3-phase (40% + 40% + 20%) | One-shot downward cut | Single pass with adjustable depth | Multi-group sequential cutting |

| Best Application | General PCBs, prototypes, medium volume | Long LED strips, aluminum PCBs, high-volume LED | FR4 boards, clean/dust-free edges | Mixed components, flexible V-depth | Extra-long or wide PCBs, high-efficiency separation |

| SMT Line Equipment List

I.C.T puts together full SMT lines that link loaders, printers, mounters, reflow ovens, AOI units, conveyors, and aluminum PCB cutting machine sections into one working system. Everything matches up right. When space runs tight, U-shaped layouts use the floor well without losing flow. The whole setup raises output, cuts mistakes, and delivers steady quality for automotive parts, LED products, and everyday electronics. Customers get help from start to finish—planning the line, setting it up, and tuning it so production runs smooth and strong from the first day onward.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

In early 2025, I.C.T engineer Peter traveled to Uzbekistan for a 16-day on-site project to assist with the installation of a new SMT production line dedicated to automotive motor parts. The complete package included a high-speed mounter, reflow oven, and various other equipment. Despite limited space in the factory, I.C.T’s solution featured a U-shaped layout that maximized the available area. Peter provided step-by-step guidance during the installation and training process, ensuring the customer could operate the machines independently. After the setup, the production line ran smoothly, with the customer handling operations without any interruptions.

| Service and Training Support

I.C.T offers a comprehensive service package, including installation, technical support, and training. Our engineers ensure that your team is fully equipped to operate the LED PCB Separator with confidence. The training covers setup, operation, and troubleshooting, empowering your staff to handle the equipment independently. Additionally, we offer remote support for any inquiries or issues that may arise, ensuring continuous production flow and optimal machine performance.

| Client Testimonials

The customer praised I.C.T for its prompt and efficient service, noting the professionalism of our engineers during the installation and training process. They were particularly impressed with the precision of our LED PCB Separator, which minimized component damage and ensured high-quality separation. The customer also highlighted the careful packaging and timely delivery of the equipment, along with I.C.T’s quick response to technical queries. Overall, they expressed complete satisfaction with both the machine's performance and the after-sales support provided.

| Certifications and Standards

I.C.T is committed to maintaining high standards of quality and safety. Our LED PCB Separator meets international certifications, including CE, RoHS, and ISO 9001. Additionally, we hold several patents for innovative technology in PCB separation. These certifications and patents demonstrate our commitment to delivering cutting-edge, reliable solutions that comply with global industry standards.

| About I.C.T Company and Factory

I.C.T is a global leader in providing comprehensive solutions for electronics manufacturing. With over 25 years of experience, we specialize in high-quality equipment and services for the SMT, DIP, and assembly sectors. Our commitment to innovation and customer satisfaction has earned us trust from over 1600 customers in 72 countries. From factory setup to production optimization, I.C.T provides one-stop solutions tailored to meet the needs of electronics manufacturers worldwide.

| I.C.T LED PCB Separator

The I.C.T LED PCB Separator is designed to efficiently and accurately separate PCBs without damaging sensitive components. Featuring a guillotine cutting mechanism, it minimizes internal pressure, preventing solder cracks and component deformation. It is compatible with various PCB types, including aluminum-based boards, and offers customizable blade adjustments for different thicknesses and V-slot depths. This machine is ideal for manufacturers requiring high-quality, precise PCB separation.

I.C.T builds five kinds of V-cut machines so each shop finds the right fit:

Standard manual type keeps things simple and low-cost for smaller jobs.

Multi-blades model cuts long LED strips in careful stages with minimal stress.

Guillotine version drops straight down with air power for thicker FR4 work.

Move-blade style slides smoothly and adjusts to many groove shapes.

Multi-knife group handles very long boards without length limits.

| Feature

Multi-Blades LED Separator

This advanced design uses six circular blades grouped for separation, significantly reducing PCB deformation, especially for aluminum boards. The process is divided into multiple phases, with each group handling a portion of the separation, ensuring stability and minimal internal stress. This feature guarantees long-lasting performance, with blades that can be calibrated to maintain high precision.

Guillotine Type V-Cut Machine

The guillotine mechanism is designed to ensure precise and clean cuts while minimizing the risk of solder cracks and component damage. It supports V-slot separation with minimal distance to components, making it perfect for PCBs with components up to 60mm high. The machine’s design avoids rotational cuts, ensuring smooth, non-friction separation with no metal residue left behind.

Move-Blade (Sliding) V-Cut Machine

This machine offers enhanced precision through a sliding blade mechanism, which can be adjusted to accommodate different PCB thicknesses and V-slot depths. It provides stable and reliable results, ensuring smooth, burr-free cutting and reducing potential damage to components.

| Specification

| Parameter | Manual Single-Blade V-cut Machine | Multi-Blades LED Separator | Guillotine Type V-cut Machine | Move-Blade (Sliding) V-cut Machine | Multi Group Blades PCB V-cut Machine |

|---|---|---|---|---|---|

| Operation Type | Manual (hand sliding) | Manual (hand push) | Manual (pneumatic foot switch) | Manual (adjustable sliding) | Manual (multi-group push) |

| Blade Setup | 1 circular + 1 straight blade | 6 circular blades (3 groups top/bottom) | Single straight guillotine blade | 1 circular + 1 straight (adjustable gap) | Multiple groups of circular blades (custom multi-knife) |

| PCB Length | 0–350 mm | Unlimited (with 1.2m / 2.4m platforms) | 0–330 mm | 0–350 mm (typical) | Unlimited or very long (platform-dependent) |

| PCB Thickness | 0.8–5 mm | 0.2–5 mm | 0.3–5 mm | 0.8–5 mm | 0.2–5 mm (typical for multi-group) |

| Cutting Method | Single pass sliding | 3-phase (40% + 40% + 20%) | One-shot downward cut | Single pass with adjustable depth | Multi-group sequential cutting |

| Best Application | General PCBs, prototypes, medium volume | Long LED strips, aluminum PCBs, high-volume LED | FR4 boards, clean/dust-free edges | Mixed components, flexible V-depth | Extra-long or wide PCBs, high-efficiency separation |

| SMT Line Equipment List

I.C.T puts together full SMT lines that link loaders, printers, mounters, reflow ovens, AOI units, conveyors, and aluminum PCB cutting machine sections into one working system. Everything matches up right. When space runs tight, U-shaped layouts use the floor well without losing flow. The whole setup raises output, cuts mistakes, and delivers steady quality for automotive parts, LED products, and everyday electronics. Customers get help from start to finish—planning the line, setting it up, and tuning it so production runs smooth and strong from the first day onward.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

In early 2025, I.C.T engineer Peter traveled to Uzbekistan for a 16-day on-site project to assist with the installation of a new SMT production line dedicated to automotive motor parts. The complete package included a high-speed mounter, reflow oven, and various other equipment. Despite limited space in the factory, I.C.T’s solution featured a U-shaped layout that maximized the available area. Peter provided step-by-step guidance during the installation and training process, ensuring the customer could operate the machines independently. After the setup, the production line ran smoothly, with the customer handling operations without any interruptions.

| Service and Training Support

I.C.T offers a comprehensive service package, including installation, technical support, and training. Our engineers ensure that your team is fully equipped to operate the LED PCB Separator with confidence. The training covers setup, operation, and troubleshooting, empowering your staff to handle the equipment independently. Additionally, we offer remote support for any inquiries or issues that may arise, ensuring continuous production flow and optimal machine performance.

| Client Testimonials

The customer praised I.C.T for its prompt and efficient service, noting the professionalism of our engineers during the installation and training process. They were particularly impressed with the precision of our LED PCB Separator, which minimized component damage and ensured high-quality separation. The customer also highlighted the careful packaging and timely delivery of the equipment, along with I.C.T’s quick response to technical queries. Overall, they expressed complete satisfaction with both the machine's performance and the after-sales support provided.

| Certifications and Standards

I.C.T is committed to maintaining high standards of quality and safety. Our LED PCB Separator meets international certifications, including CE, RoHS, and ISO 9001. Additionally, we hold several patents for innovative technology in PCB separation. These certifications and patents demonstrate our commitment to delivering cutting-edge, reliable solutions that comply with global industry standards.

| About I.C.T Company and Factory

I.C.T is a global leader in providing comprehensive solutions for electronics manufacturing. With over 25 years of experience, we specialize in high-quality equipment and services for the SMT, DIP, and assembly sectors. Our commitment to innovation and customer satisfaction has earned us trust from over 1600 customers in 72 countries. From factory setup to production optimization, I.C.T provides one-stop solutions tailored to meet the needs of electronics manufacturers worldwide.