I.C.T-5700

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Reliable Offline PCB Routing Machine

Workers use this PCB routing machine in fields like smartphones, wearables, smart homes, tablets, automotive electronics, medical tools, and aerospace. It processes boards from 340×380mm up to 450×600mm, thicknesses 0.5 to 5.0mm. The new CCD system spots marks clearly and adjusts alignment on its own. Spindle speeds reach 80,000rpm, easing stress for finer accuracy. Dual platforms run separate jobs or combine for larger ones. Ion air gun clears static so dust stays off. Sensors watch the cutter closely. Quiet dust collector pulls strongly. Simple controls make the PCB router machine circuit board handling straightforward in busy shops.

| Feature

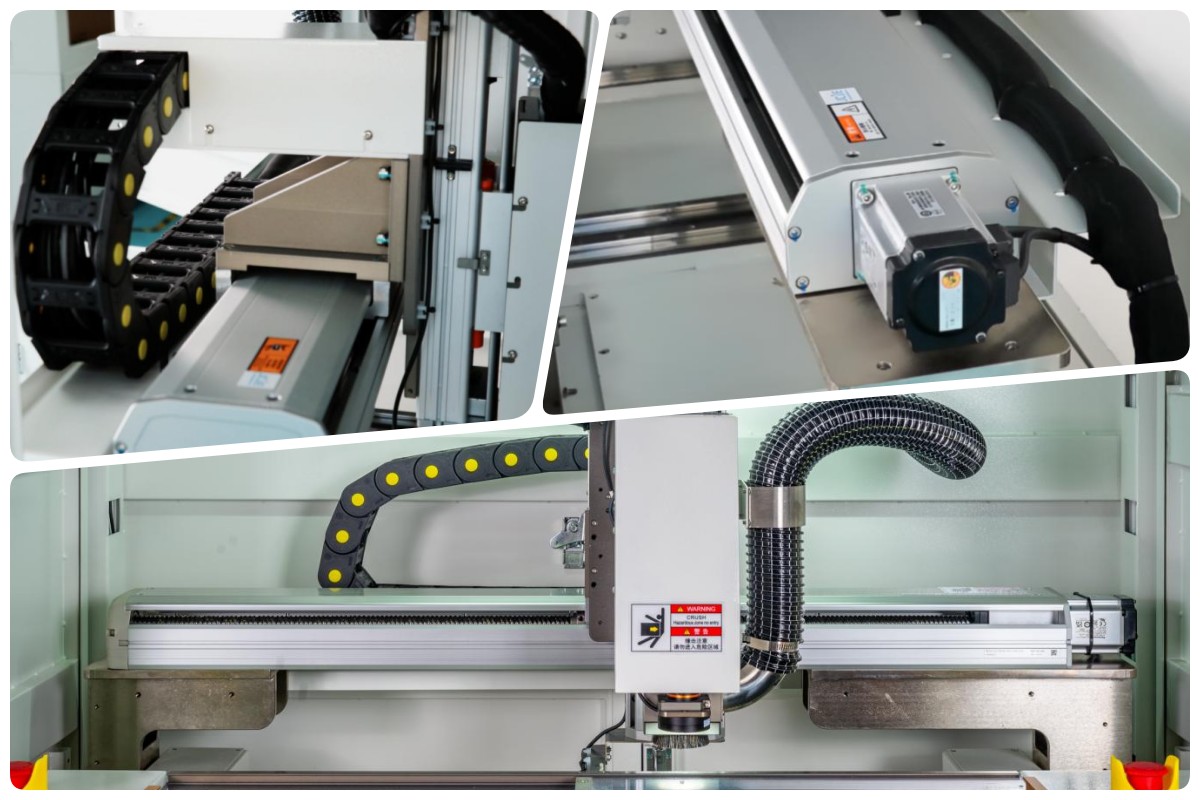

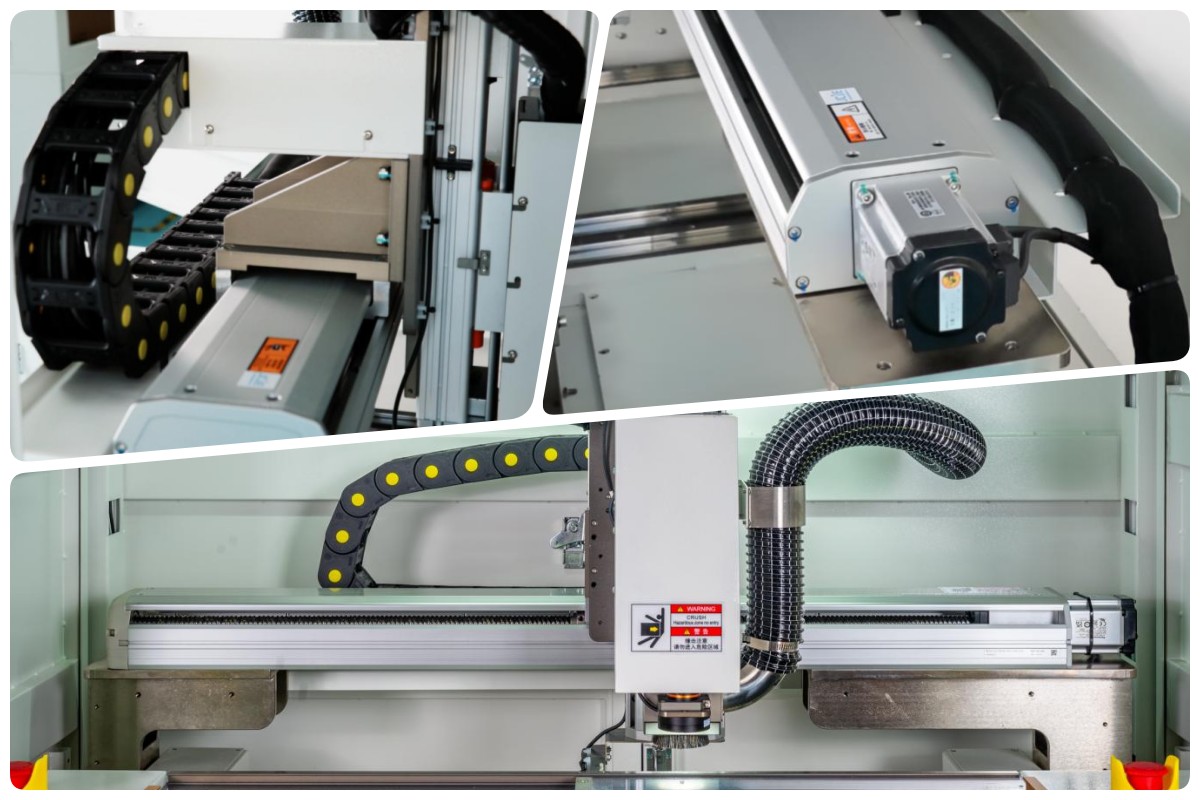

Transmission System

Panasonic servo motors from Japan connect to precise screw rods and Taiwan guide rails for reliable motion day after day. Thicker frame holds everything steady through long shifts. Tank chains keep wires safe and out of the way. Dust-proof X-axis design cuts down on cleaning and fixes. These solid parts let the PCB routing machine run without much trouble, keeping workers focused on production rather than repairs.

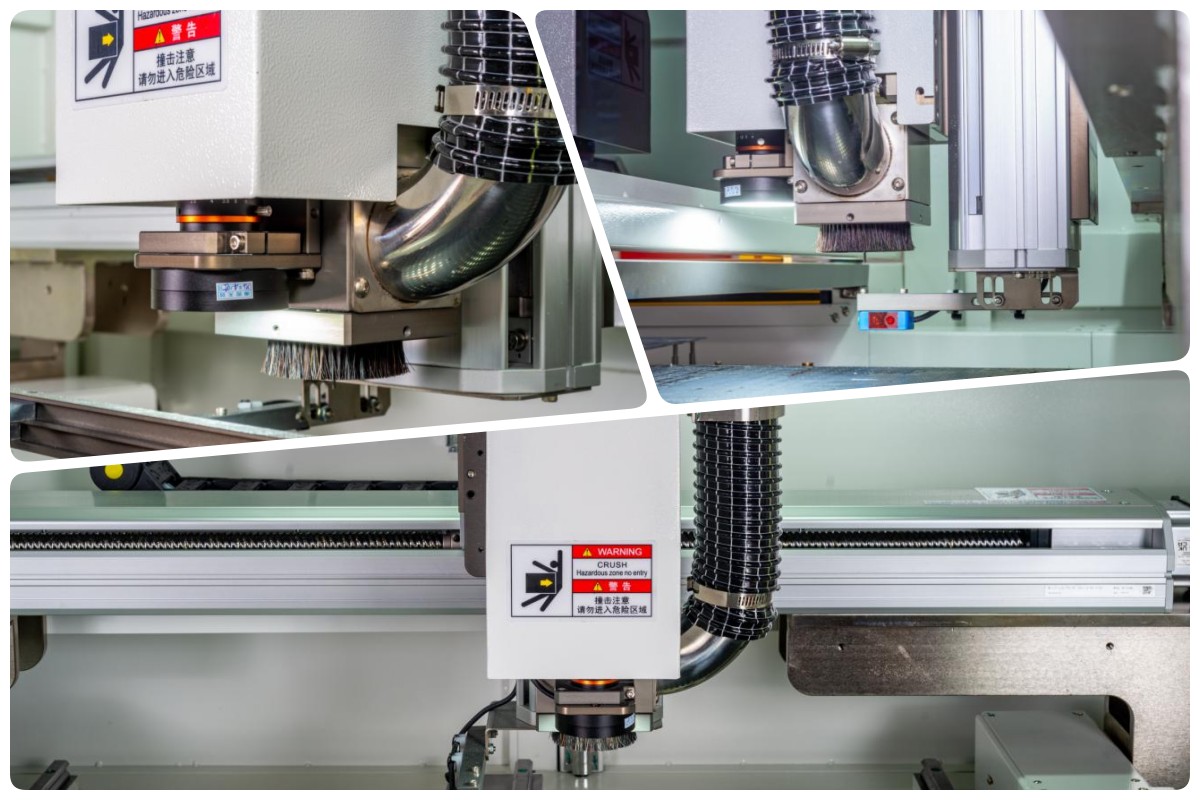

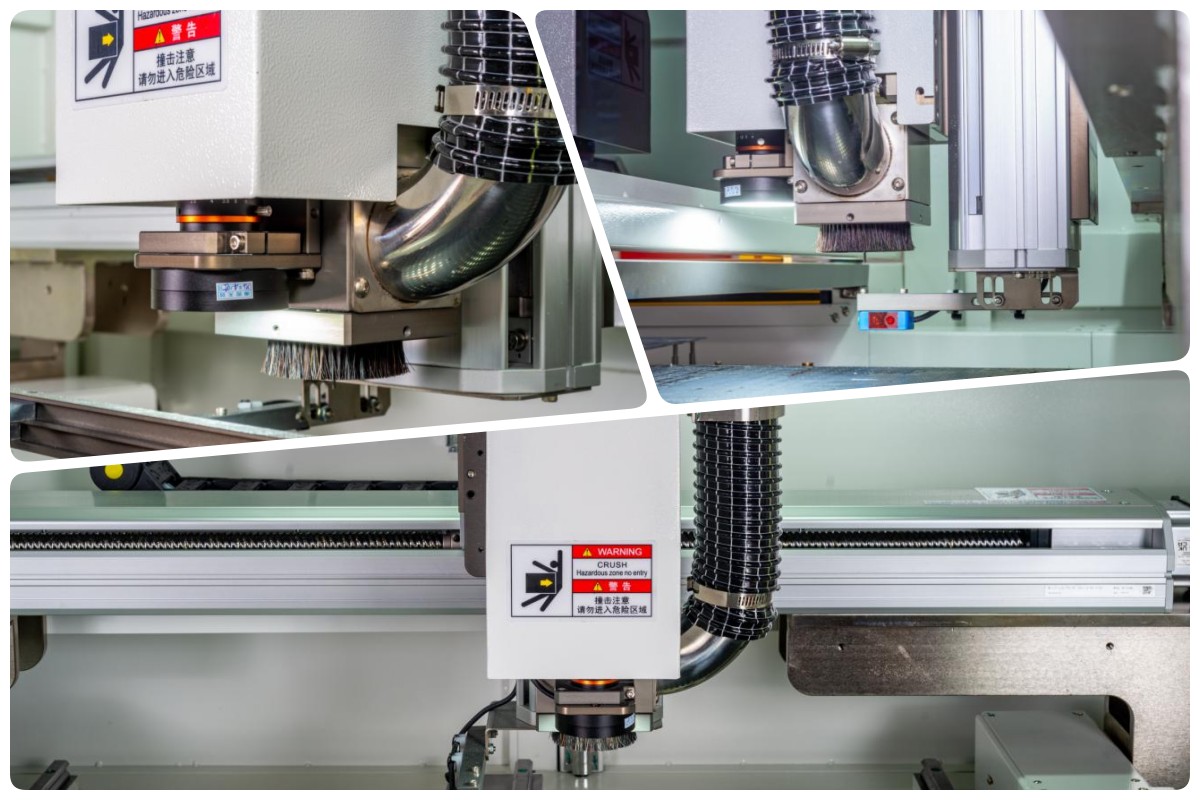

Router System

High-speed spindle responds fast with low inertia, cutting stress small for clean edges. Ion air gun blows static away, keeping surfaces free of dust. Optional auto tool changer allows nonstop work. Broken tool detection alerts right away. Clear CCD camera lines up with the cutter for easy setup. This setup makes the PCB routing machine a dependable tool that operators trust in daily tasks.

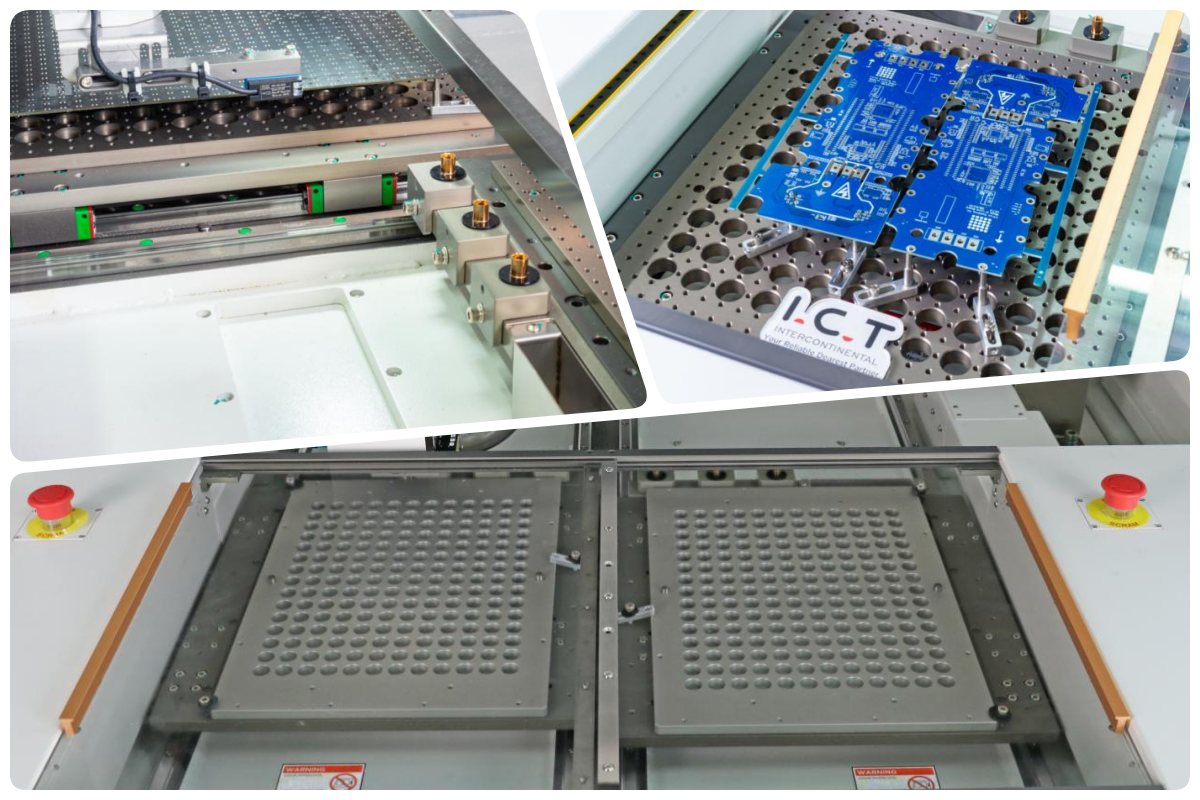

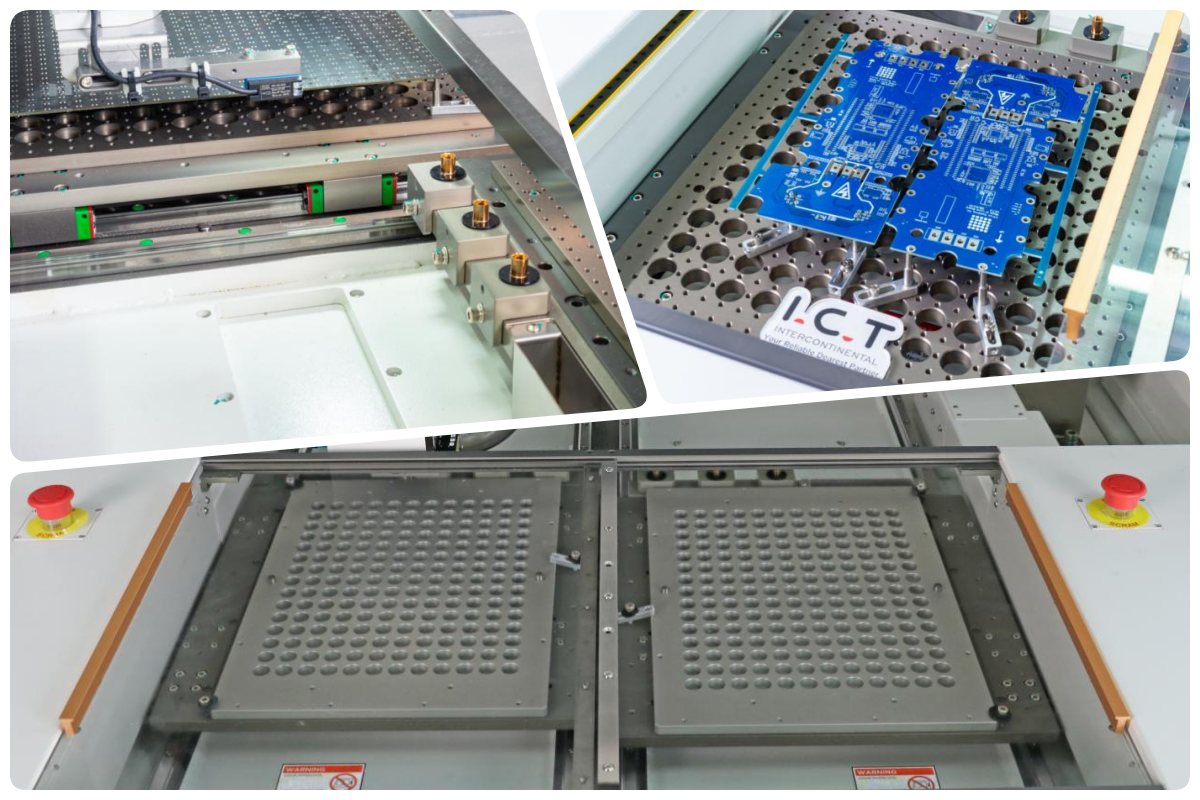

Platform System

Honeycomb base holds boards tight and fits many kinds. Dual platforms take custom fixtures without issue. Two start buttons need pressing together for safety. Light curtains and covers protect fully, with emergency stops ready. Slide rails and servos keep Y-axis firm. The PCB routing machine becomes a safe place where people work with confidence.

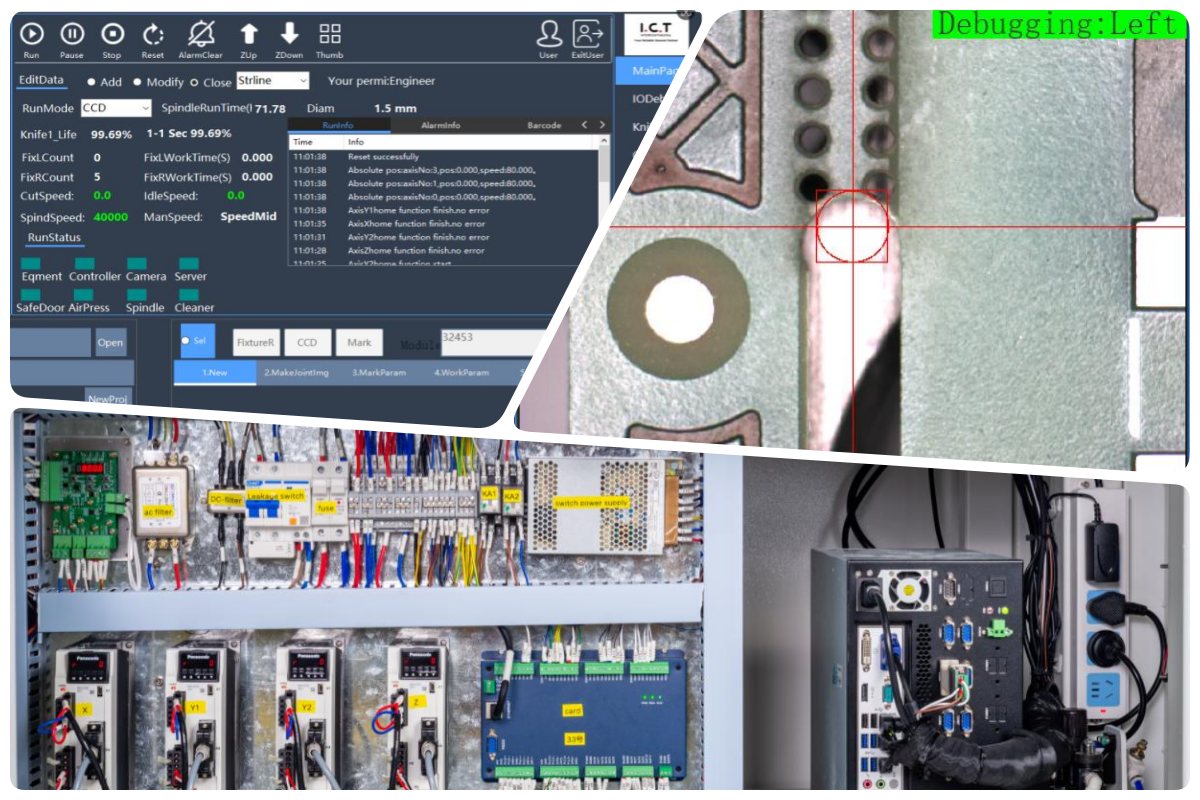

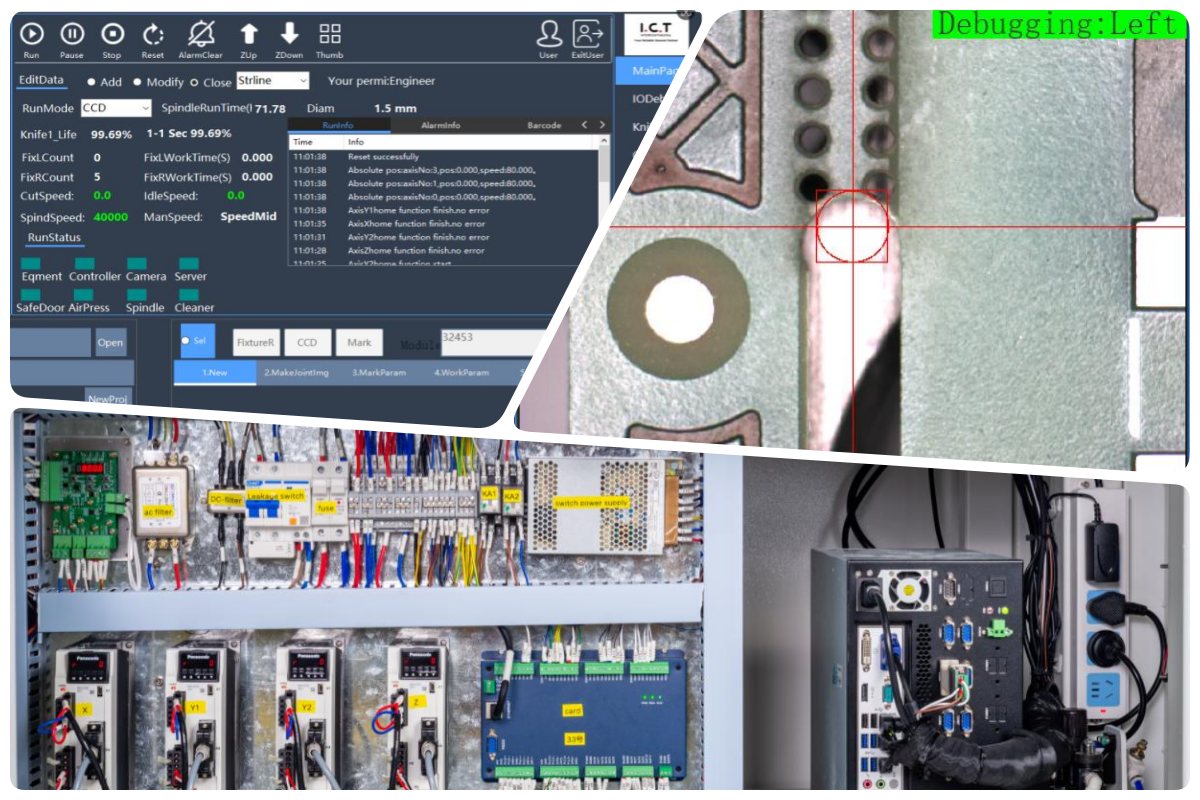

Control System

Real-time CCD shows clear views on screen. Easy interface meets standards and switches jobs quickly. Logs track data for better quality. Strong controller fights interference well. Precision stays high over time. Operators find the PCB routing machine simple to handle, like a familiar tool in their hands.

Detail Display

Convection fan keeps air even inside. Side sensors stop doors from risks. ESD link guards against sparks. Auto changer swaps tools smoothly. Knife sensor watches wear. Pneumatic struts hold doors open steady. These small features make the PCB routing machine feel thoughtful and safe for those who run it every day.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

A team from Algeria making feature phones came to our plant with their panels and parts, over ten boards ready. We showed the full line in action: printer laid solder, SPI checked it, RX-8 placed small pieces, RS-1R handled big ones, tray fed covers, reflow soldered firm, AOI looked close. Then the I.C.T PCB routing machine cut clean separations. Everything moved steady and sure. They saw real efficiency and good results, leaving with trust in the PCB router machine circuit board process.

| Service and Training Support

Service centers worldwide answer fast. Parts arrive quick to keep lines going. Remote help fixes many things. On-site training covers setup, programming, tools, and care for the PCB routing machine. Engineers teach step by step. Ongoing advice improves work over years. This support feels like a steady hand for customers building their shops.

| Client Testimonials

People often say our engineers know their work and help clear. Machines cut steady and true. Packing keeps things safe on the road. Quick answers build good feelings. Customers see I.C.T as strong in gear and care.

| Certifications and Standards

Patents show our own ideas. ISO9001 holds quality tight. RoHS cares for the earth. CE means safe use. These signs tell that the PCB routing machine meets real standards people count on.

| About I.C.T Company and Factory

Factories run strict tests and quality steps. Many engineers drive research and build. Growth brought over 1600 customers in 72 countries. Each PCB routing machine gets careful checks. Focus on new ways and global help keeps ties strong and lasting.

| Reliable Offline PCB Routing Machine

Workers use this PCB routing machine in fields like smartphones, wearables, smart homes, tablets, automotive electronics, medical tools, and aerospace. It processes boards from 340×380mm up to 450×600mm, thicknesses 0.5 to 5.0mm. The new CCD system spots marks clearly and adjusts alignment on its own. Spindle speeds reach 80,000rpm, easing stress for finer accuracy. Dual platforms run separate jobs or combine for larger ones. Ion air gun clears static so dust stays off. Sensors watch the cutter closely. Quiet dust collector pulls strongly. Simple controls make the PCB router machine circuit board handling straightforward in busy shops.

| Feature

Transmission System

Panasonic servo motors from Japan connect to precise screw rods and Taiwan guide rails for reliable motion day after day. Thicker frame holds everything steady through long shifts. Tank chains keep wires safe and out of the way. Dust-proof X-axis design cuts down on cleaning and fixes. These solid parts let the PCB routing machine run without much trouble, keeping workers focused on production rather than repairs.

Router System

High-speed spindle responds fast with low inertia, cutting stress small for clean edges. Ion air gun blows static away, keeping surfaces free of dust. Optional auto tool changer allows nonstop work. Broken tool detection alerts right away. Clear CCD camera lines up with the cutter for easy setup. This setup makes the PCB routing machine a dependable tool that operators trust in daily tasks.

Platform System

Honeycomb base holds boards tight and fits many kinds. Dual platforms take custom fixtures without issue. Two start buttons need pressing together for safety. Light curtains and covers protect fully, with emergency stops ready. Slide rails and servos keep Y-axis firm. The PCB routing machine becomes a safe place where people work with confidence.

Control System

Real-time CCD shows clear views on screen. Easy interface meets standards and switches jobs quickly. Logs track data for better quality. Strong controller fights interference well. Precision stays high over time. Operators find the PCB routing machine simple to handle, like a familiar tool in their hands.

Detail Display

Convection fan keeps air even inside. Side sensors stop doors from risks. ESD link guards against sparks. Auto changer swaps tools smoothly. Knife sensor watches wear. Pneumatic struts hold doors open steady. These small features make the PCB routing machine feel thoughtful and safe for those who run it every day.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

A team from Algeria making feature phones came to our plant with their panels and parts, over ten boards ready. We showed the full line in action: printer laid solder, SPI checked it, RX-8 placed small pieces, RS-1R handled big ones, tray fed covers, reflow soldered firm, AOI looked close. Then the I.C.T PCB routing machine cut clean separations. Everything moved steady and sure. They saw real efficiency and good results, leaving with trust in the PCB router machine circuit board process.

| Service and Training Support

Service centers worldwide answer fast. Parts arrive quick to keep lines going. Remote help fixes many things. On-site training covers setup, programming, tools, and care for the PCB routing machine. Engineers teach step by step. Ongoing advice improves work over years. This support feels like a steady hand for customers building their shops.

| Client Testimonials

People often say our engineers know their work and help clear. Machines cut steady and true. Packing keeps things safe on the road. Quick answers build good feelings. Customers see I.C.T as strong in gear and care.

| Certifications and Standards

Patents show our own ideas. ISO9001 holds quality tight. RoHS cares for the earth. CE means safe use. These signs tell that the PCB routing machine meets real standards people count on.

| About I.C.T Company and Factory

Factories run strict tests and quality steps. Many engineers drive research and build. Growth brought over 1600 customers in 72 countries. Each PCB routing machine gets careful checks. Focus on new ways and global help keeps ties strong and lasting.