SMT Machines for LED

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| PCB Assembly Line Overview

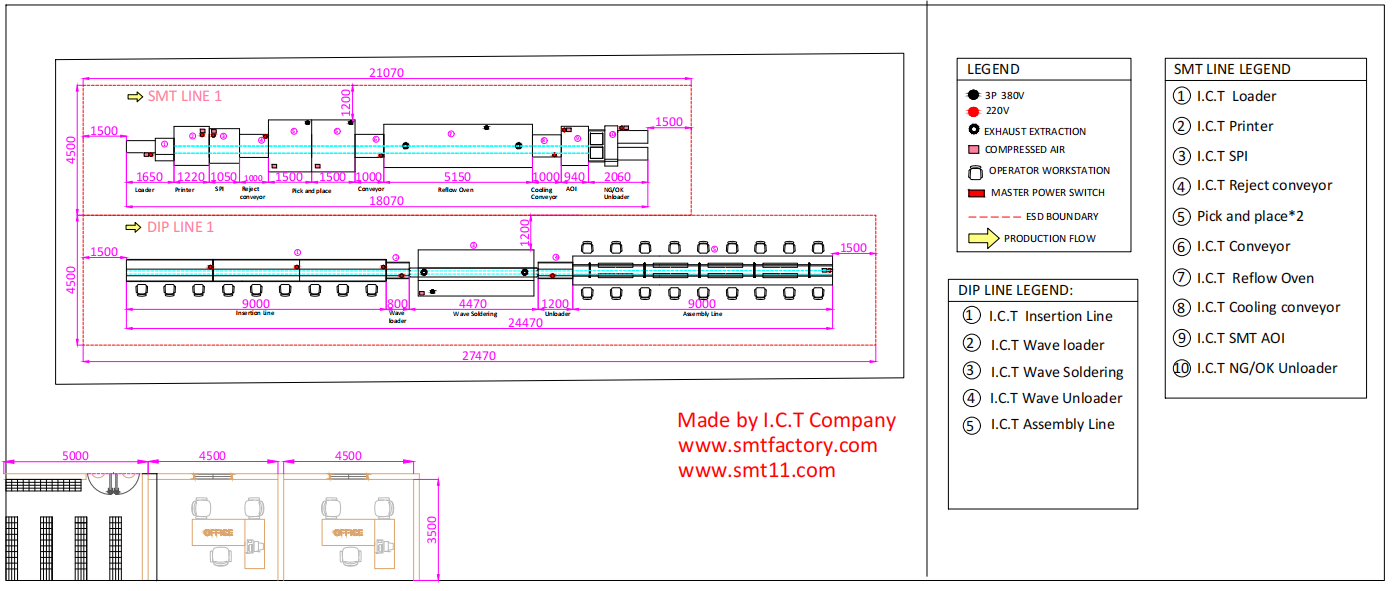

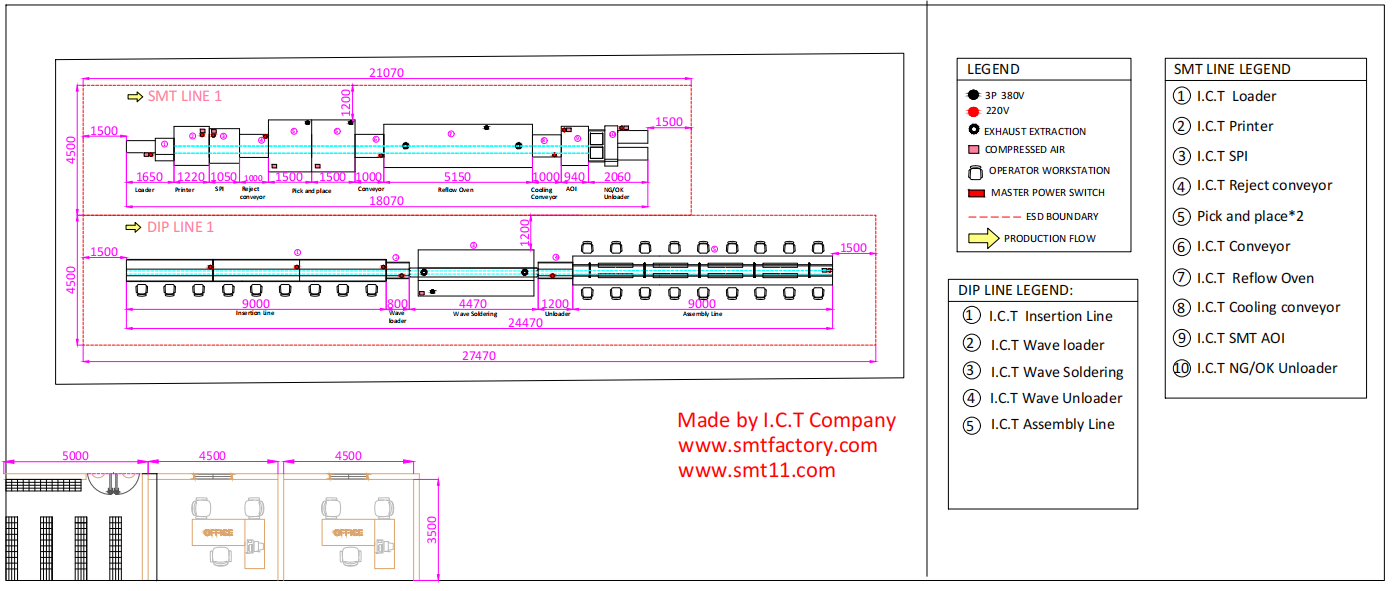

I.C.T provides PCB Assembly Line using three owned factories and 22+ years SMT/DIP experience, including factory planning, layouts, labor estimates, ROI calculations for LED lighting. Semi-auto or full-auto options have loaders, printers, placers, reflow ovens, AOI, unloaders. One operator per shift. 18Kw/H for low costs. Serves LED bulb, panel, ceiling light makers globally. 3-day setup verifies air, power, exhaust, lighting. 7-15 days cover software, maintenance, safety, troubleshooting. 15+ years service worldwide. SMT Machines for LED include MES, IoT for smart operations. Turnkey system speeds LED launches, supports expansion, lowers risks for new or established firms in growing lighting markets with consistent quality, expert help, regular updates, and field-proven efficiency in various setups.

| Detailed Product Features

Seamless Automation Flow

PCB Assembly Line connects machines with MES for current data, yield increases, adjustments in LED ceiling light boards. Loaders handle LED driver sizes. Printers put paste vision-guided on LED beads or controls. Placers place 01005 parts quickly. Reflow holds ±1.5°C for good joints. AOI checks defects AI-based. Unloaders move to next. Yields rise 25%+ in ceiling LED light assembly line. Suits ceiling panels or strips. Buffers keep steady, remote tools watch, auto recipes change fast, traceability tracks items for different LED models, easing switches, following standards, improving rate in large runs with options for custom shapes, quick changes, combined tests, and planned upkeep methods.

Accurate Paste System

Printers in PCB Assembly Line fix stencils micron-accurate, match frames for LED boards. Quick swaps reduce stops. Auto dispense/wipe keep steady. 3D SPI measures paste to avoid early faults. Important for LED power supplies or arrays. Handles various pastes, low-melt for sensitive LED lenses. Squeegee sets for flat layers on bumpy areas, boosting firmness, cutting waste, allowing rapid updates in new LED styles with even results, faster output, less rework, and higher totals per shift.

Reliable Reflow Process

Ovens feature 12+ zones with separate convection for even heat in SMT Machines for LED. Nitrogen builds strong joints for LED drivers or outputs. Profiles adjust to specs. Cooling protects thin PCBs. Recovery reaches 18Kw/H. Interfaces store many recipes. Key for LED durability in ceilings. Conveyors link MES for correct paces, flexible speeds, inner checks to prevent halts in constant work, safe moves, enable ongoing high-volume, and include eco modes.

Smart Inspection Tools

AOI takes 8K images at speed, finds offsets or solder issues in LED. AI improves from data. Feedback sets placers right away. Reduces faults in PCB Assembly Line. Reports aid upgrades. Auto rejects shift without pause, log info for reviews and quick repairs in multi lines with low downtime, strong tracking, and report generation.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| Pick and Place Machine | Mounts components onto PCB precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

Algerian phone company visited for machine test. Supplied 10+ PCBs and materials; we ran live production. Auto printer applied paste correctly. SPI verified deposits. RX-8 placed small components fast. RS-1R handled large ones precisely. Tray feeder provided shields steadily. Reflow soldered well. AOI confirmed quality. 5700 divided panels accurately. Clean run showed speed, connection for phone/LED uses. Matches SMT Machines for LED versatility. Clients accepted boards, noted smooth process, plan similar PCB Assembly Line at home with ceiling LED light assembly line for easy growth, stable levels, greater volumes, and future options in operations.

| End-to-End Support System

Managers lead PCB Assembly Line from start to improvements. 3-day onsite: checks, trials, tuning. 7-15 day training: MES, LED handling, analysis, upkeep, protocols. IoT warns of issues, allows remote aid. Parts from 8 warehouses quick. 15-year experience, various languages. Yearly checks, updates maintain best for lasting LED reliability, volume growth, changes in markets with smart plans, expert input, and tailored progress steps.

| User Feedback Highlights

Praise for 2-hour remote solutions on PCB Assembly Line. Ovens stable 24/7. Packaging handles travel. Responses better than promised. ceiling LED light assembly line produces high amounts well. Clear interfaces speed learning in LED work with simple steps, fast grasp, and useful aids for quick ability.

| Quality Standards Met

CE confirms safety. RoHS ensures clean materials. ISO9001 guides processes. Patents protect features. Supports PCB Assembly Line acceptance everywhere. Full pre-ship tests standard for all to verify function, rules, and top quality.

| About I.C.T Company and Factory

Three factories cover 12000m². 89 staff, 20 engineers. 25 years serving 1600 customers in 72 countries. R&D builds custom SMT Machines for LED. QC checks every stage carefully. Global centers, warehouses, branches give fast support. Mission: lead cross-value electronics platform with focus on innovation, partnerships, sustainability, and customer-driven development.

| PCB Assembly Line Overview

I.C.T provides PCB Assembly Line using three owned factories and 22+ years SMT/DIP experience, including factory planning, layouts, labor estimates, ROI calculations for LED lighting. Semi-auto or full-auto options have loaders, printers, placers, reflow ovens, AOI, unloaders. One operator per shift. 18Kw/H for low costs. Serves LED bulb, panel, ceiling light makers globally. 3-day setup verifies air, power, exhaust, lighting. 7-15 days cover software, maintenance, safety, troubleshooting. 15+ years service worldwide. SMT Machines for LED include MES, IoT for smart operations. Turnkey system speeds LED launches, supports expansion, lowers risks for new or established firms in growing lighting markets with consistent quality, expert help, regular updates, and field-proven efficiency in various setups.

| Detailed Product Features

Seamless Automation Flow

PCB Assembly Line connects machines with MES for current data, yield increases, adjustments in LED ceiling light boards. Loaders handle LED driver sizes. Printers put paste vision-guided on LED beads or controls. Placers place 01005 parts quickly. Reflow holds ±1.5°C for good joints. AOI checks defects AI-based. Unloaders move to next. Yields rise 25%+ in ceiling LED light assembly line. Suits ceiling panels or strips. Buffers keep steady, remote tools watch, auto recipes change fast, traceability tracks items for different LED models, easing switches, following standards, improving rate in large runs with options for custom shapes, quick changes, combined tests, and planned upkeep methods.

Accurate Paste System

Printers in PCB Assembly Line fix stencils micron-accurate, match frames for LED boards. Quick swaps reduce stops. Auto dispense/wipe keep steady. 3D SPI measures paste to avoid early faults. Important for LED power supplies or arrays. Handles various pastes, low-melt for sensitive LED lenses. Squeegee sets for flat layers on bumpy areas, boosting firmness, cutting waste, allowing rapid updates in new LED styles with even results, faster output, less rework, and higher totals per shift.

Reliable Reflow Process

Ovens feature 12+ zones with separate convection for even heat in SMT Machines for LED. Nitrogen builds strong joints for LED drivers or outputs. Profiles adjust to specs. Cooling protects thin PCBs. Recovery reaches 18Kw/H. Interfaces store many recipes. Key for LED durability in ceilings. Conveyors link MES for correct paces, flexible speeds, inner checks to prevent halts in constant work, safe moves, enable ongoing high-volume, and include eco modes.

Smart Inspection Tools

AOI takes 8K images at speed, finds offsets or solder issues in LED. AI improves from data. Feedback sets placers right away. Reduces faults in PCB Assembly Line. Reports aid upgrades. Auto rejects shift without pause, log info for reviews and quick repairs in multi lines with low downtime, strong tracking, and report generation.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| Pick and Place Machine | Mounts components onto PCB precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

Algerian phone company visited for machine test. Supplied 10+ PCBs and materials; we ran live production. Auto printer applied paste correctly. SPI verified deposits. RX-8 placed small components fast. RS-1R handled large ones precisely. Tray feeder provided shields steadily. Reflow soldered well. AOI confirmed quality. 5700 divided panels accurately. Clean run showed speed, connection for phone/LED uses. Matches SMT Machines for LED versatility. Clients accepted boards, noted smooth process, plan similar PCB Assembly Line at home with ceiling LED light assembly line for easy growth, stable levels, greater volumes, and future options in operations.

| End-to-End Support System

Managers lead PCB Assembly Line from start to improvements. 3-day onsite: checks, trials, tuning. 7-15 day training: MES, LED handling, analysis, upkeep, protocols. IoT warns of issues, allows remote aid. Parts from 8 warehouses quick. 15-year experience, various languages. Yearly checks, updates maintain best for lasting LED reliability, volume growth, changes in markets with smart plans, expert input, and tailored progress steps.

| User Feedback Highlights

Praise for 2-hour remote solutions on PCB Assembly Line. Ovens stable 24/7. Packaging handles travel. Responses better than promised. ceiling LED light assembly line produces high amounts well. Clear interfaces speed learning in LED work with simple steps, fast grasp, and useful aids for quick ability.

| Quality Standards Met

CE confirms safety. RoHS ensures clean materials. ISO9001 guides processes. Patents protect features. Supports PCB Assembly Line acceptance everywhere. Full pre-ship tests standard for all to verify function, rules, and top quality.

| About I.C.T Company and Factory

Three factories cover 12000m². 89 staff, 20 engineers. 25 years serving 1600 customers in 72 countries. R&D builds custom SMT Machines for LED. QC checks every stage carefully. Global centers, warehouses, branches give fast support. Mission: lead cross-value electronics platform with focus on innovation, partnerships, sustainability, and customer-driven development.