SMT Line

I.C.T

LED Panels SMT Production Line

| Availability: | |

|---|---|

| Quantity: | |

| STB Production Line Overview

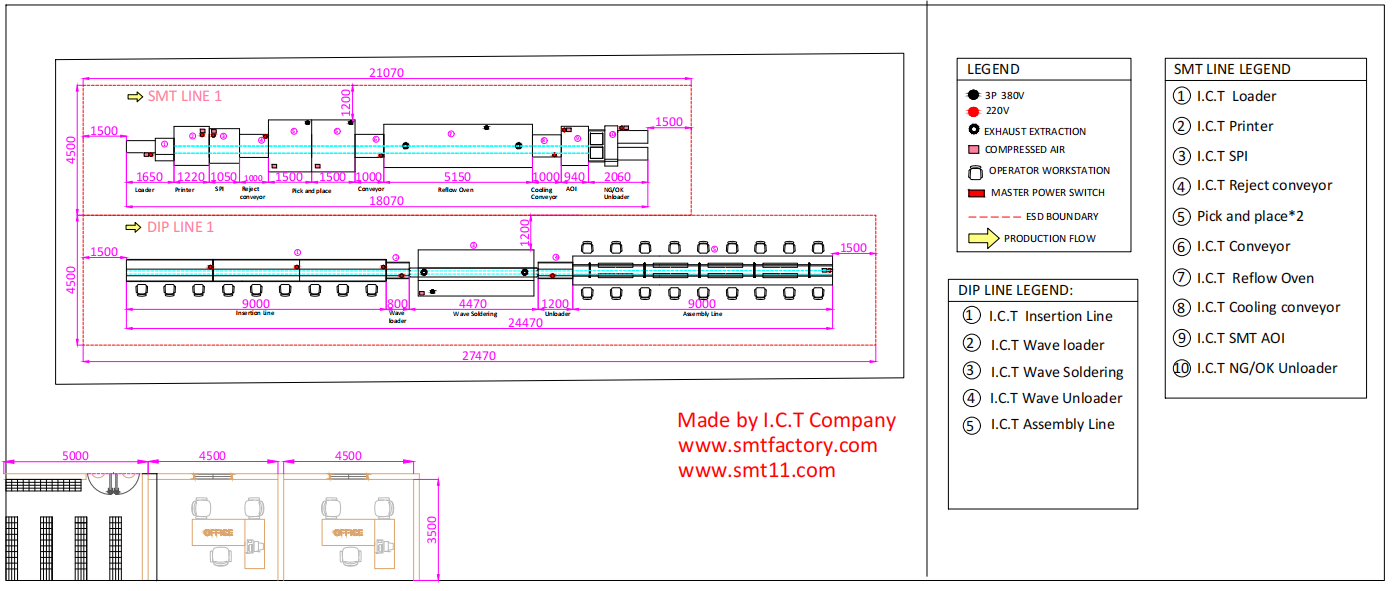

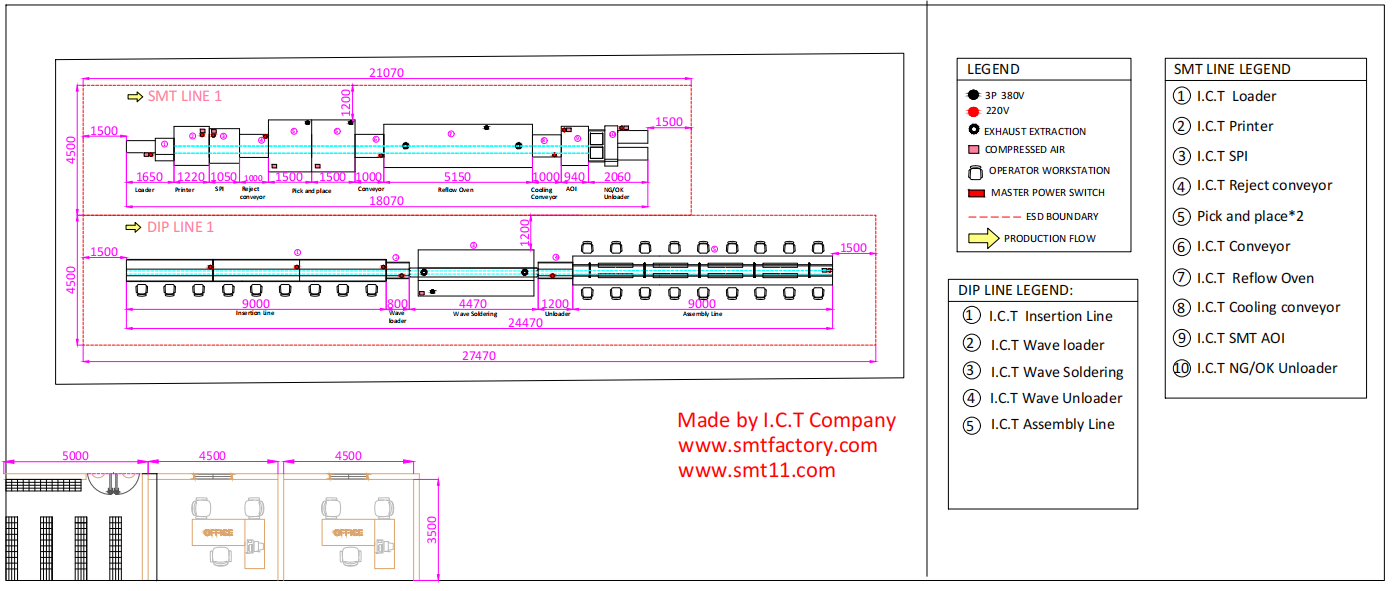

I.C.T deploys comprehensive STB Production Line from three self-manufactured factories and 22+ years in SMT/DIP fields, including factory blueprints, layout plans, manpower estimates, ROI analyses for set-top box makers. Semi-auto or full-auto options feature loaders, printers, placers, reflow ovens, AOI, unloaders. One operator manages shifts. 18Kw/H promotes efficiency. Clients in TV, streaming, telecom worldwide. 3-day setup checks air, power, exhaust, lighting, 23±1.5°C conditions. 7-15 days cover software, maintenance, safety, repairs. 15+ years global support. Full Auto SMT Line for STB Production includes MES, IoT for data-driven, reliable factories. Turnkey system speeds STB launches, offers growth flexibility, low risks for established or emerging players in dynamic entertainment markets with proven scalability and support.

| Detailed Product Features

Automated Process Integration

STB Production Line connects units via MES for instant metrics, yield gains, adjustments in set-top box assembly. Loaders handle compact STB boards precisely. Printers apply paste with vision on tuner chips or ports. Placers mount 01005 parts quickly. Reflow ensures ±1.5°C for strong bonds. AOI identifies issues with AI. Unloaders forward to assembly. Yields boost 25%+ in Full Auto Set Top Box SMT Production Line. Suits various STB models. Buffers steady flows, remote monitors control, auto recipes change swiftly, traceability tracks components for diverse STB variants, minimizing transitions, guaranteeing standards, boosting productivity in mass runs with extra adaptability for custom features and quick model switches.

Paste Application Precision

Printers in STB Production Line lock stencils at micron accuracy, fit frames for STB sizes. Rapid exchanges cut idle time. Auto dispense/wipe keep uniformity. 3D SPI verifies paste to stop early faults. Vital for STB signal processors or interfaces. Supports pastes, low-melt for delicate STB modules. Squeegee fine-tunes for smooth layers on uneven areas, improving consistency, lowering rejects, aiding fast iterations in changing STB tech with dependable outcomes and enhanced throughput every cycle.

Reflow Soldering Reliability

Ovens provide 12+ zones with separate convection for even heat in Full Auto SMT Line for STB Production. Nitrogen creates durable joints for STB HDMI or RF. Profiles self-adapt to specs. Cooling protects small boards. Recovery achieves 18Kw/H. Panels store numerous recipes. Key for STB longevity in homes. Conveyors link MES for coordinated speeds, variable rates, built-in checks to avoid jams in ongoing operations and ensure seamless transitions.

Inspection Automation

AOI takes 8K images fast, detecting offsets or solder problems in STB. AI improves from data. Feedback fixes placers instantly. Reduces flaws in STB Production Line. Reports support enhancements. Auto rejects divert smoothly, record info for reviews and rapid corrections in varied production settings with minimal interruptions.

Modular Upgrade Path

Semi-auto start with full-auto upgrades via modular additions. Layouts reserve for SPI, buffers, IoT. Models show 70% labor efficiency gains. Options include cleanroom, ESD, ERP connectivity.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| Pick and Place Machine | Mounts components onto PCB precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

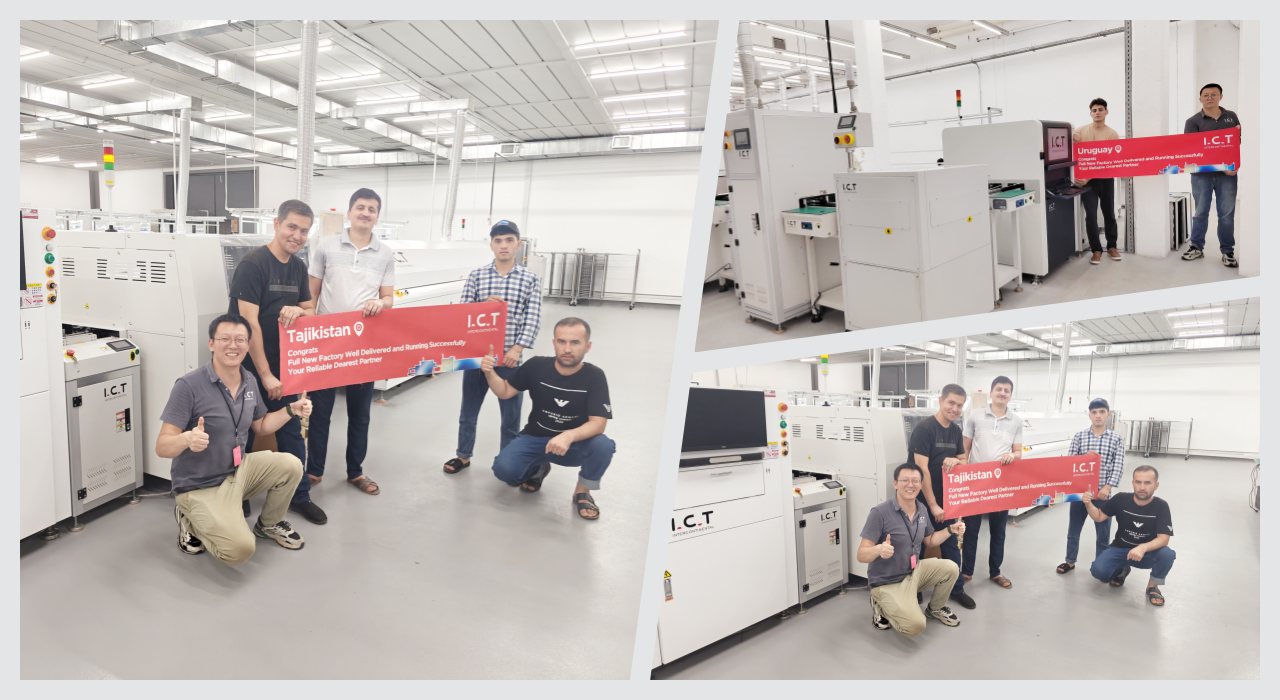

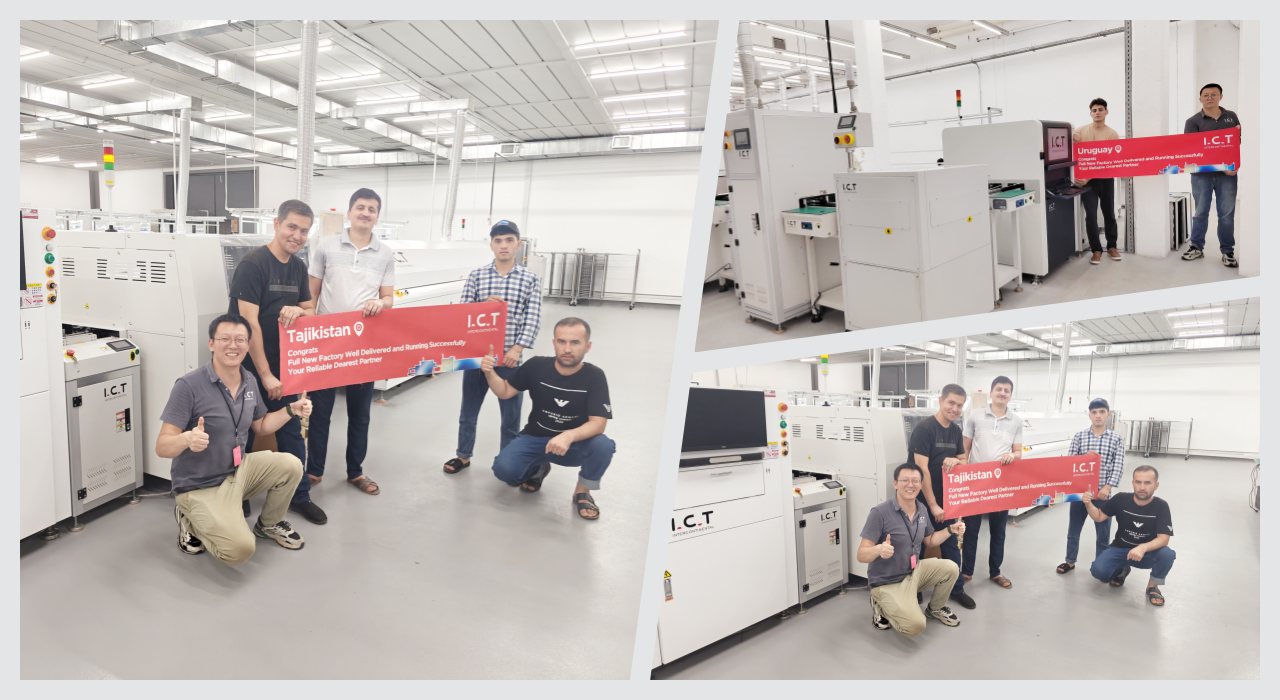

Algerian phone producer came for acceptance testing. They delivered 10+ PCBs and materials; we executed live demo. Auto printer deposited paste flawlessly. SPI examined every spot. RX-8 handled tiny elements efficiently. RS-1R placed bigger ones accurately. Tray feeder inserted shields without breaks. Reflow merged all firmly. AOI ensured perfection. 5700 cut panels exactly. Smooth operation highlighted pace, unity for phone/STB parallels. Reflects Full Auto SMT Line for STB Production versatility. Customers confirmed quality, appreciated integration, intend duplicate STB Production Line at facilities with Full Auto Set Top Box SMT Production Line for effective expansion and consistent results.

| Complete Assistance Framework

Project leaders direct STB Production Line from inception to advancements. 3-day field: verifications, tests, tweaks. 7-15 day sessions: MES, STB operations, analysis, servicing, protocols. IoT anticipates problems, allows distant aid. Parts dispatch from 8 depots swiftly. 15-year knowledge, diverse languages. Periodic evaluations, refreshes sustain superiority for sustained STB dependability, volume increases, and future-proofing in evolving markets.

| Feedback Summary

Acclaim for under-2-hour distant resolutions on STB Production Line. Ovens maintain 24/7 consistency. Crates endure transit. Answers surpass promises. Full Auto SMT Line for STB Production reaches peak capacities perfectly. User-friendly screens accelerate onboarding in STB scenarios with quick mastery and operational ease.

| Compliance Assurance

CE verifies protection. RoHS confirms safe components. ISO9001 oversees procedures. Patents safeguard innovations. Confirms STB Production Line credibility internationally. In-depth outgoing inspections standard for all systems to guarantee performance.

| About I.C.T Company and Factory

Three plants total 12000m² area. 89 employees, 20 specialists. 25 years aiding 1600 users in 72 nations. R&D develops specialized Full Auto Set Top Box SMT Production Line. QC spans every phase strictly. International outlets, support, stocks, subsidiaries provide immediate help. Objective: premier cross-value electronics production base emphasizing progress and partnerships.

| STB Production Line Overview

I.C.T deploys comprehensive STB Production Line from three self-manufactured factories and 22+ years in SMT/DIP fields, including factory blueprints, layout plans, manpower estimates, ROI analyses for set-top box makers. Semi-auto or full-auto options feature loaders, printers, placers, reflow ovens, AOI, unloaders. One operator manages shifts. 18Kw/H promotes efficiency. Clients in TV, streaming, telecom worldwide. 3-day setup checks air, power, exhaust, lighting, 23±1.5°C conditions. 7-15 days cover software, maintenance, safety, repairs. 15+ years global support. Full Auto SMT Line for STB Production includes MES, IoT for data-driven, reliable factories. Turnkey system speeds STB launches, offers growth flexibility, low risks for established or emerging players in dynamic entertainment markets with proven scalability and support.

| Detailed Product Features

Automated Process Integration

STB Production Line connects units via MES for instant metrics, yield gains, adjustments in set-top box assembly. Loaders handle compact STB boards precisely. Printers apply paste with vision on tuner chips or ports. Placers mount 01005 parts quickly. Reflow ensures ±1.5°C for strong bonds. AOI identifies issues with AI. Unloaders forward to assembly. Yields boost 25%+ in Full Auto Set Top Box SMT Production Line. Suits various STB models. Buffers steady flows, remote monitors control, auto recipes change swiftly, traceability tracks components for diverse STB variants, minimizing transitions, guaranteeing standards, boosting productivity in mass runs with extra adaptability for custom features and quick model switches.

Paste Application Precision

Printers in STB Production Line lock stencils at micron accuracy, fit frames for STB sizes. Rapid exchanges cut idle time. Auto dispense/wipe keep uniformity. 3D SPI verifies paste to stop early faults. Vital for STB signal processors or interfaces. Supports pastes, low-melt for delicate STB modules. Squeegee fine-tunes for smooth layers on uneven areas, improving consistency, lowering rejects, aiding fast iterations in changing STB tech with dependable outcomes and enhanced throughput every cycle.

Reflow Soldering Reliability

Ovens provide 12+ zones with separate convection for even heat in Full Auto SMT Line for STB Production. Nitrogen creates durable joints for STB HDMI or RF. Profiles self-adapt to specs. Cooling protects small boards. Recovery achieves 18Kw/H. Panels store numerous recipes. Key for STB longevity in homes. Conveyors link MES for coordinated speeds, variable rates, built-in checks to avoid jams in ongoing operations and ensure seamless transitions.

Inspection Automation

AOI takes 8K images fast, detecting offsets or solder problems in STB. AI improves from data. Feedback fixes placers instantly. Reduces flaws in STB Production Line. Reports support enhancements. Auto rejects divert smoothly, record info for reviews and rapid corrections in varied production settings with minimal interruptions.

Modular Upgrade Path

Semi-auto start with full-auto upgrades via modular additions. Layouts reserve for SPI, buffers, IoT. Models show 70% labor efficiency gains. Options include cleanroom, ESD, ERP connectivity.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| Pick and Place Machine | Mounts components onto PCB precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

Algerian phone producer came for acceptance testing. They delivered 10+ PCBs and materials; we executed live demo. Auto printer deposited paste flawlessly. SPI examined every spot. RX-8 handled tiny elements efficiently. RS-1R placed bigger ones accurately. Tray feeder inserted shields without breaks. Reflow merged all firmly. AOI ensured perfection. 5700 cut panels exactly. Smooth operation highlighted pace, unity for phone/STB parallels. Reflects Full Auto SMT Line for STB Production versatility. Customers confirmed quality, appreciated integration, intend duplicate STB Production Line at facilities with Full Auto Set Top Box SMT Production Line for effective expansion and consistent results.

| Complete Assistance Framework

Project leaders direct STB Production Line from inception to advancements. 3-day field: verifications, tests, tweaks. 7-15 day sessions: MES, STB operations, analysis, servicing, protocols. IoT anticipates problems, allows distant aid. Parts dispatch from 8 depots swiftly. 15-year knowledge, diverse languages. Periodic evaluations, refreshes sustain superiority for sustained STB dependability, volume increases, and future-proofing in evolving markets.

| Feedback Summary

Acclaim for under-2-hour distant resolutions on STB Production Line. Ovens maintain 24/7 consistency. Crates endure transit. Answers surpass promises. Full Auto SMT Line for STB Production reaches peak capacities perfectly. User-friendly screens accelerate onboarding in STB scenarios with quick mastery and operational ease.

| Compliance Assurance

CE verifies protection. RoHS confirms safe components. ISO9001 oversees procedures. Patents safeguard innovations. Confirms STB Production Line credibility internationally. In-depth outgoing inspections standard for all systems to guarantee performance.

| About I.C.T Company and Factory

Three plants total 12000m² area. 89 employees, 20 specialists. 25 years aiding 1600 users in 72 nations. R&D develops specialized Full Auto Set Top Box SMT Production Line. QC spans every phase strictly. International outlets, support, stocks, subsidiaries provide immediate help. Objective: premier cross-value electronics production base emphasizing progress and partnerships.

FAQ

Q: What is the assembly line of a PCB?

A: In SMT Line, the primary machine used is the SMT (Surface Mount Technology) machine. It's essential for precise component placement on PCBs.

Q:What is the SMT assembly line of a PCB?

A: The PCB assembly line, often referred to as the SMT (Surface Mount Technology) Line, is a sequence of automated processes for PCB manufacturing. It includes stencil printing machine, pick and place machine, reflow soldering oven, inspection machine, testing machine. This line ensures precise and efficient assembly of electronic components onto PCBs, integral in modern electronics manufacturing.

Q: What is the name of the SMT machine used in PCB assembly line?

A: The machine used in PCB assembly is commonly known as the "SMT (Surface Mount Technology) machine." This vital equipment precisely places electronic components onto printed circuit boards (PCBs), ensuring accurate and efficient assembly in the SMT Line.

Q: What is PCB machine?

A: A PCB machine, often referred to as an "SMT (Surface Mount Technology) machine," is a critical component of the SMT Line in electronics manufacturing. This specialized machine is responsible for precisely placing electronic components, such as resistors, capacitors, and integrated circuits, onto printed circuit boards (PCBs). The SMT machine ensures accurate alignment and soldering of these components, contributing to the overall quality and efficiency of PCB assembly. It plays a pivotal role in modern electronics production, allowing for high-speed and precision assembly of components, making it a cornerstone of PCB manufacturing processes.

FAQ

Q: What is the assembly line of a PCB?

A: In SMT Line, the primary machine used is the SMT (Surface Mount Technology) machine. It's essential for precise component placement on PCBs.

Q:What is the SMT assembly line of a PCB?

A: The PCB assembly line, often referred to as the SMT (Surface Mount Technology) Line, is a sequence of automated processes for PCB manufacturing. It includes stencil printing machine, pick and place machine, reflow soldering oven, inspection machine, testing machine. This line ensures precise and efficient assembly of electronic components onto PCBs, integral in modern electronics manufacturing.

Q: What is the name of the SMT machine used in PCB assembly line?

A: The machine used in PCB assembly is commonly known as the "SMT (Surface Mount Technology) machine." This vital equipment precisely places electronic components onto printed circuit boards (PCBs), ensuring accurate and efficient assembly in the SMT Line.

Q: What is PCB machine?

A: A PCB machine, often referred to as an "SMT (Surface Mount Technology) machine," is a critical component of the SMT Line in electronics manufacturing. This specialized machine is responsible for precisely placing electronic components, such as resistors, capacitors, and integrated circuits, onto printed circuit boards (PCBs). The SMT machine ensures accurate alignment and soldering of these components, contributing to the overall quality and efficiency of PCB assembly. It plays a pivotal role in modern electronics production, allowing for high-speed and precision assembly of components, making it a cornerstone of PCB manufacturing processes.