I.C.T-5700

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Advanced PCB Separation Solution

Factories producing smartphones, smart wearables, automotive electronics, medical instruments, and aerospace components rely on this PCB separation machine for clean results. It manages board sizes ranging from 340×380mm to 450×600mm, with thicknesses between 0.5 and 5.0mm. The updated CCD vision system recognizes all marks and automatically corrects alignment. A high-speed spindle reaching 80,000rpm cuts with very little stress, maintaining high accuracy and quick response. Dual platforms handle different products at once or combine into a single larger area when needed. The ion air gun removes static electricity so dust cannot settle on boards. Real-time sensors watch the milling cutter closely. Quiet, powerful dust collection keeps the workspace clean. Simple controls make daily operation straightforward and consistent.

| Feature

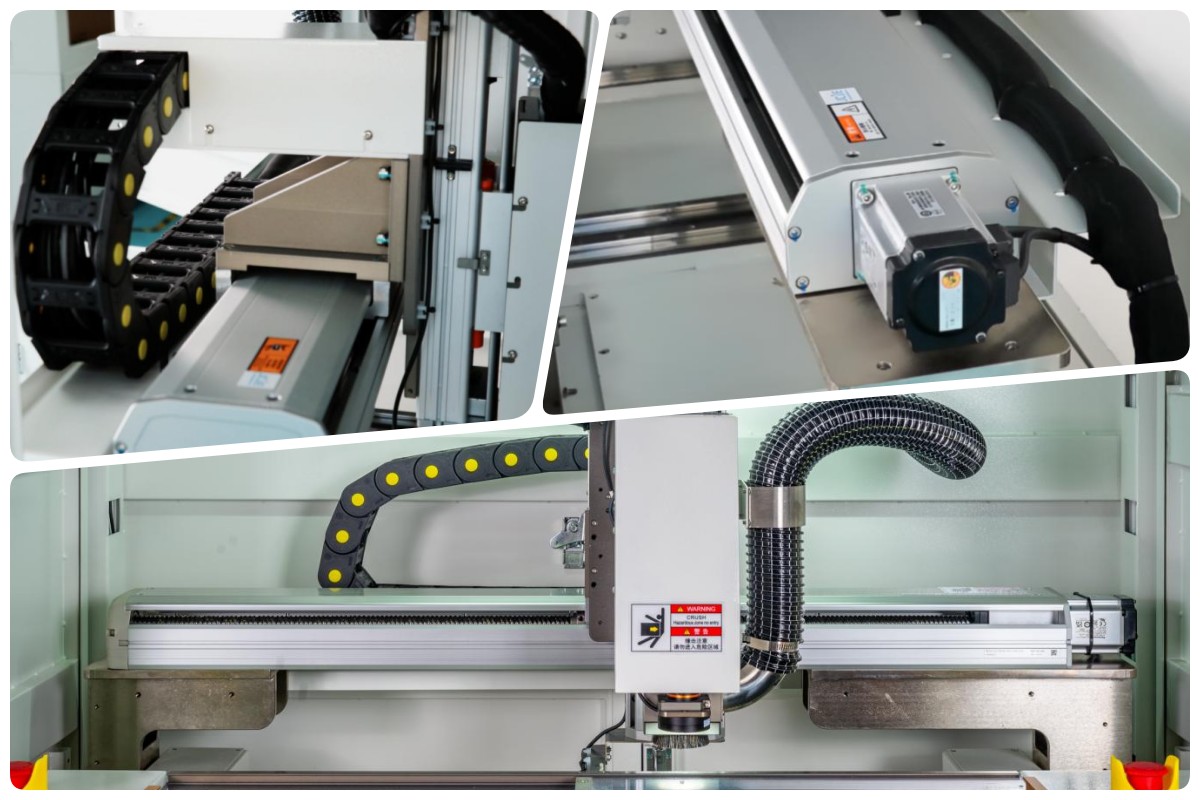

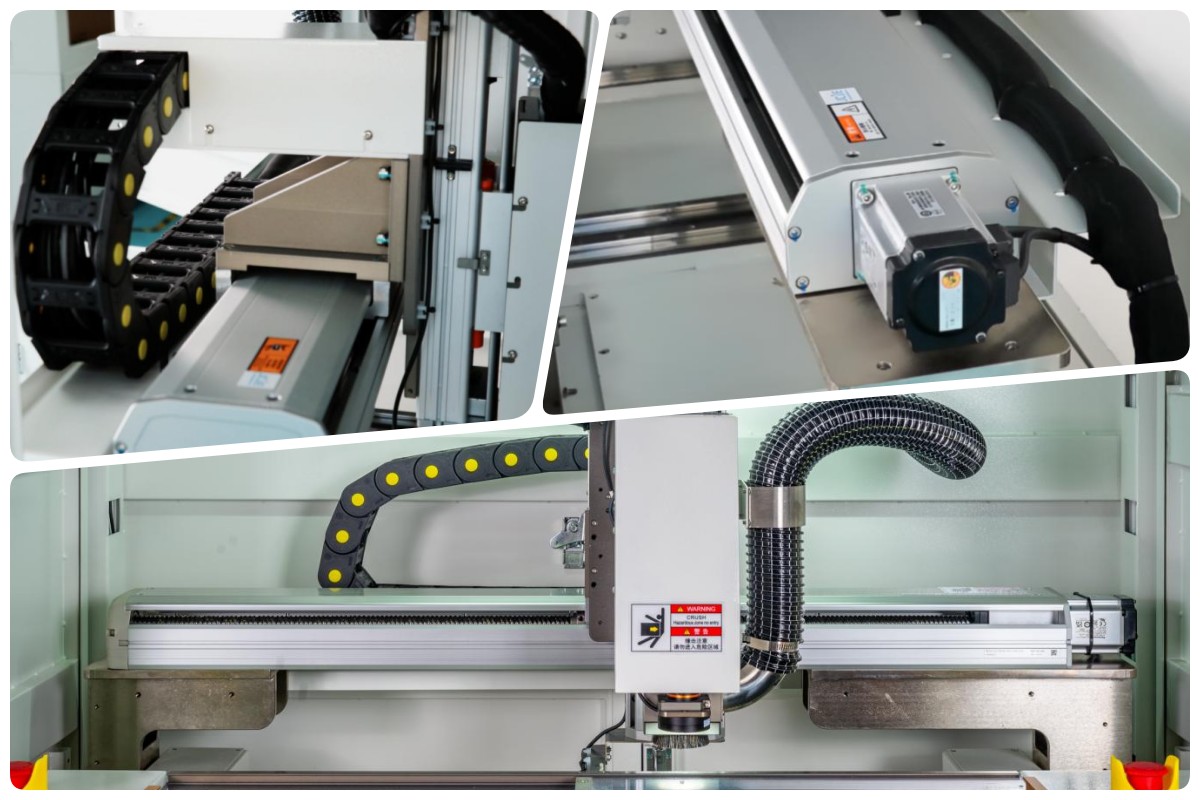

Transmission System

Thicker mechanical framing holds everything steady through long hours of use. Flexible tank chains guide cables neatly without interfering with moving parts. The X-axis carries a special dust-proof cover that greatly reduces cleaning and repair needs. Imported Panasonic servo motors work together with high-precision screw rods and reliable Taiwan guide rails. Movement remains accurate and fluid shift after shift. These carefully chosen components give the PCB separation machine lasting stability and keep maintenance low while supporting tight tolerances required in modern electronics assembly.

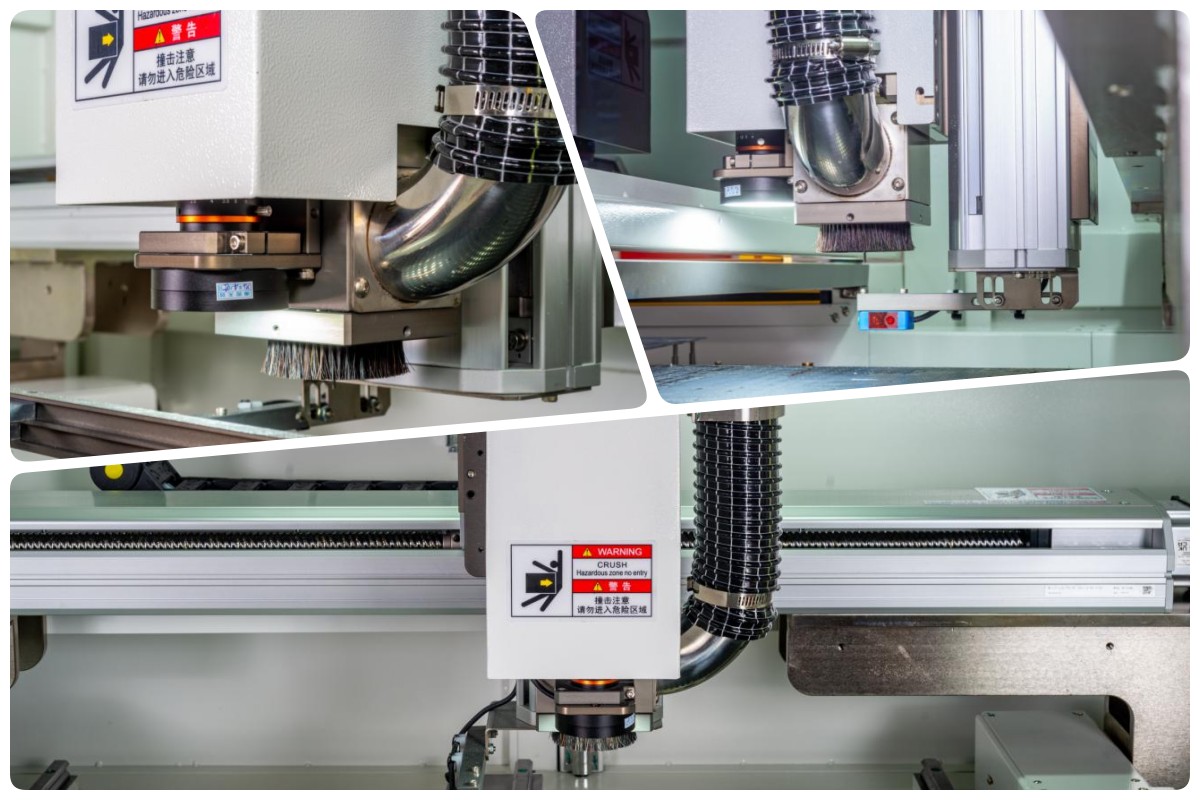

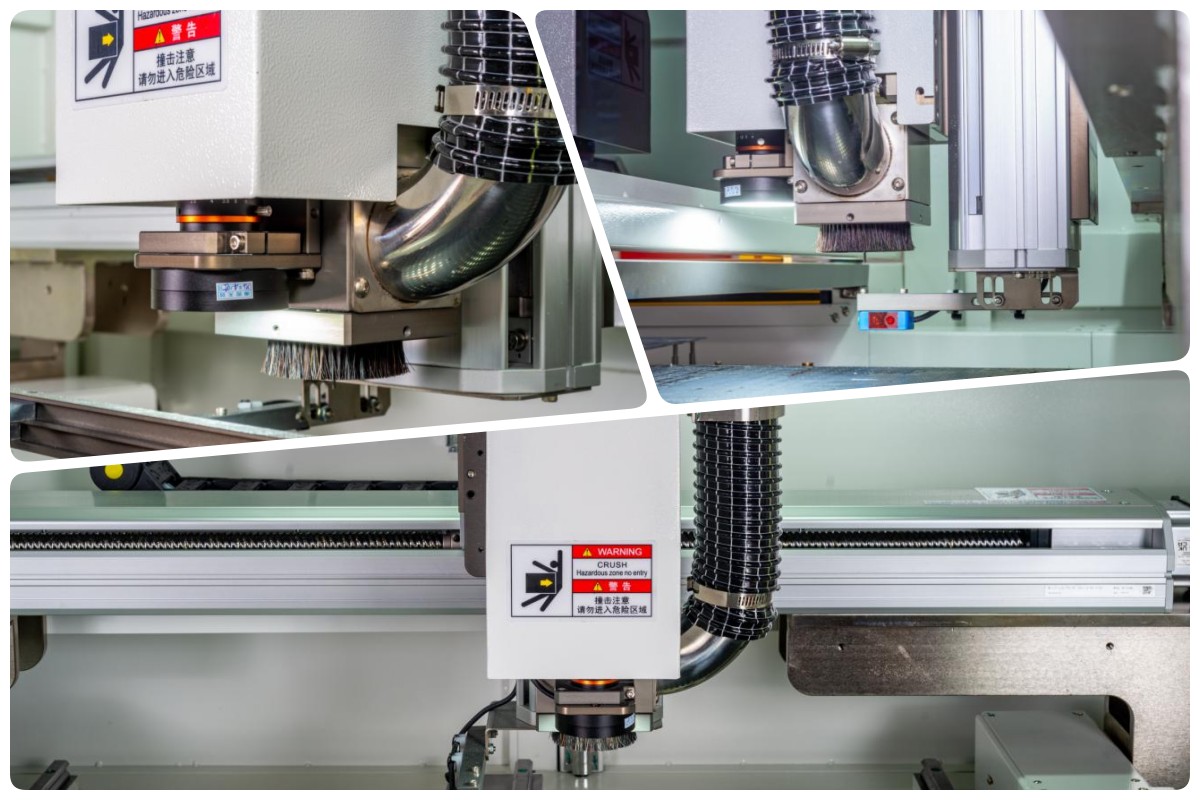

Router System

A high-definition CCD camera aligns perfectly with the milling cutter for easy and exact calibration. Standard breakage detection immediately alerts operators when a cutter wears down or snaps. Optional automatic tool changing allows continuous running without interruption, improving overall output. The ion air gun clears static charge from PCB surfaces and stops dust from collecting. An imported high-speed spindle reduces cutting force, delivers high precision, low inertia, and fast reaction. Together these features ensure every board cut by the PCB separator manual or PCBA Router Machine comes out clean and undamaged.

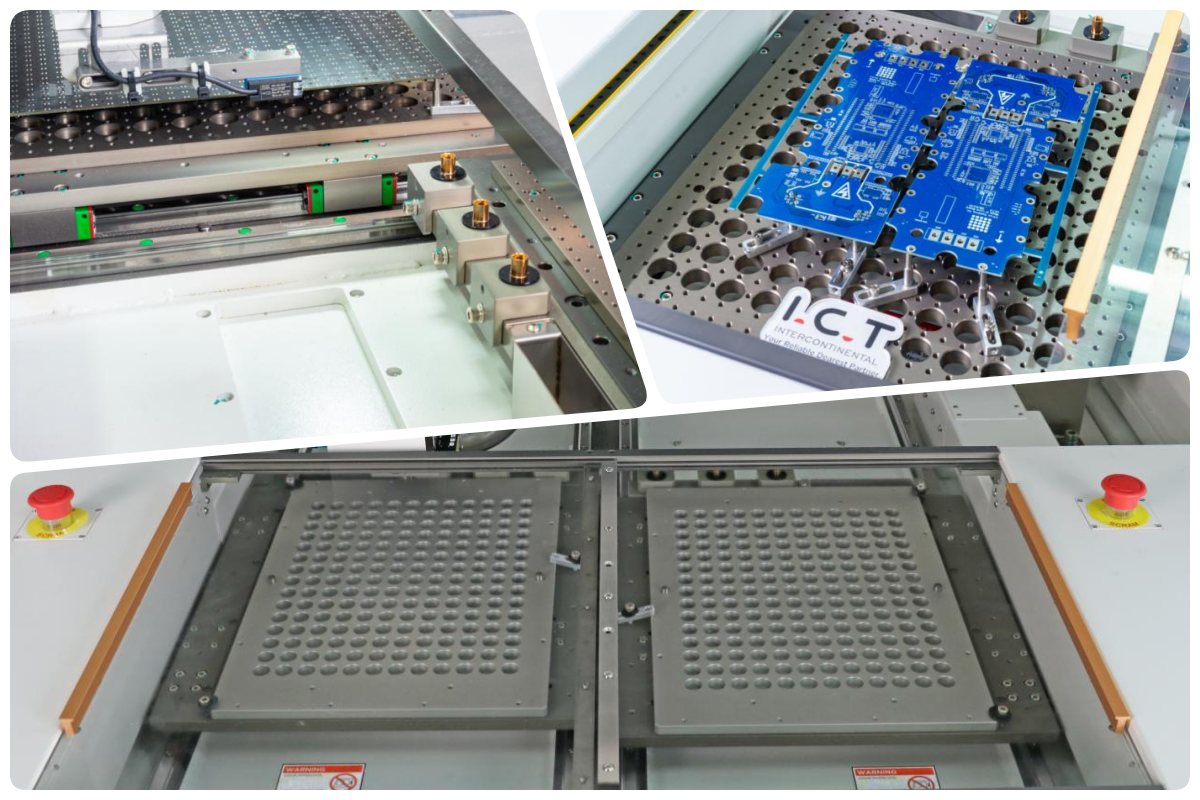

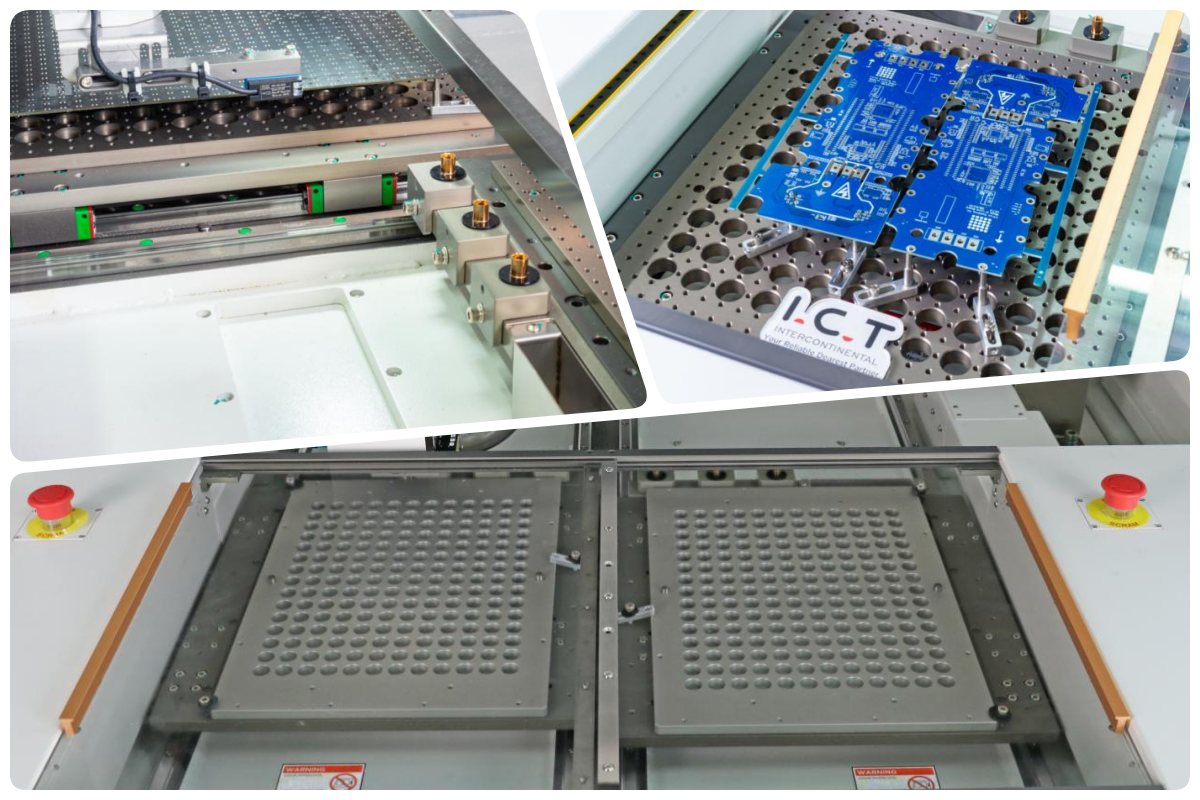

Platform System

Y-axis movement relies on sturdy slide rails and servo motors for dependable stability. Two-way emergency stops, full safety covers, and light curtains protect operators at every moment. Start buttons on both sides require simultaneous pressing to begin operation safely. The standard honeycomb porous base provides strong hold and works well with many board types. Dual platforms accept special or standard fixtures without difficulty. This practical design makes the in line PCBA router or LED aluminum PCB depaneling process secure and adaptable for busy production lines.

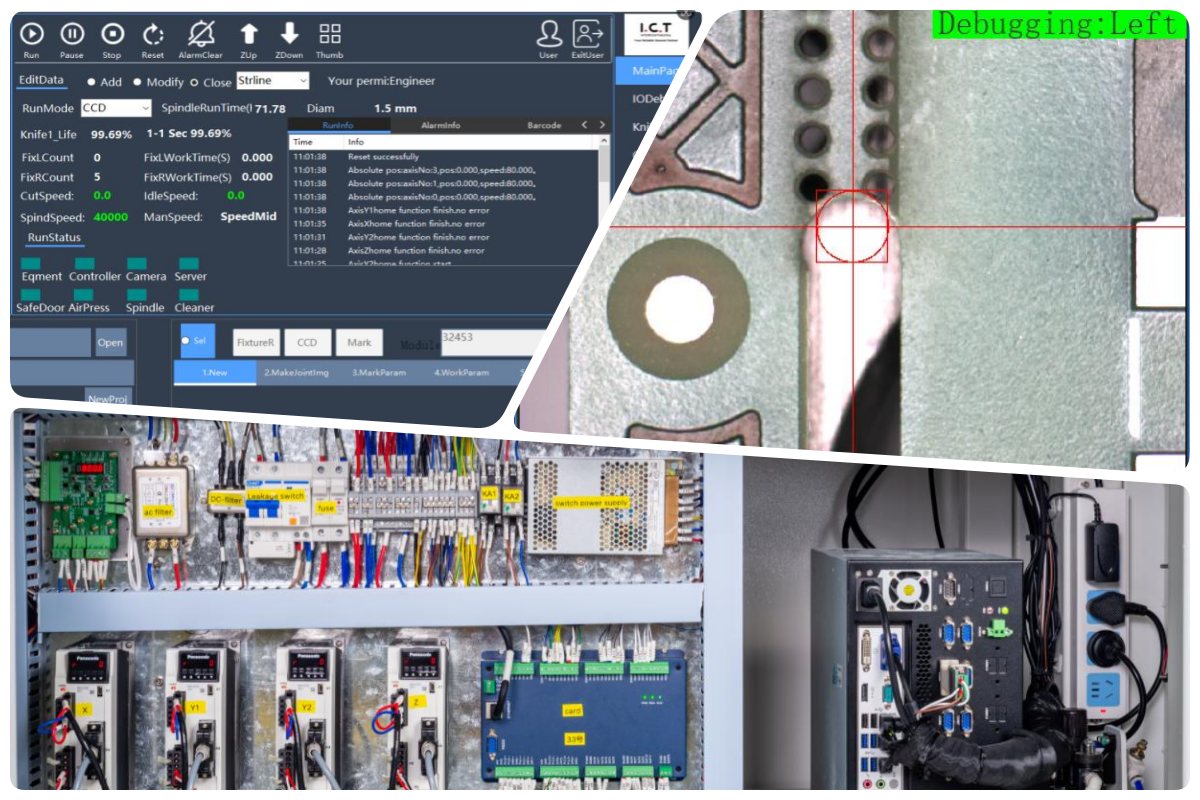

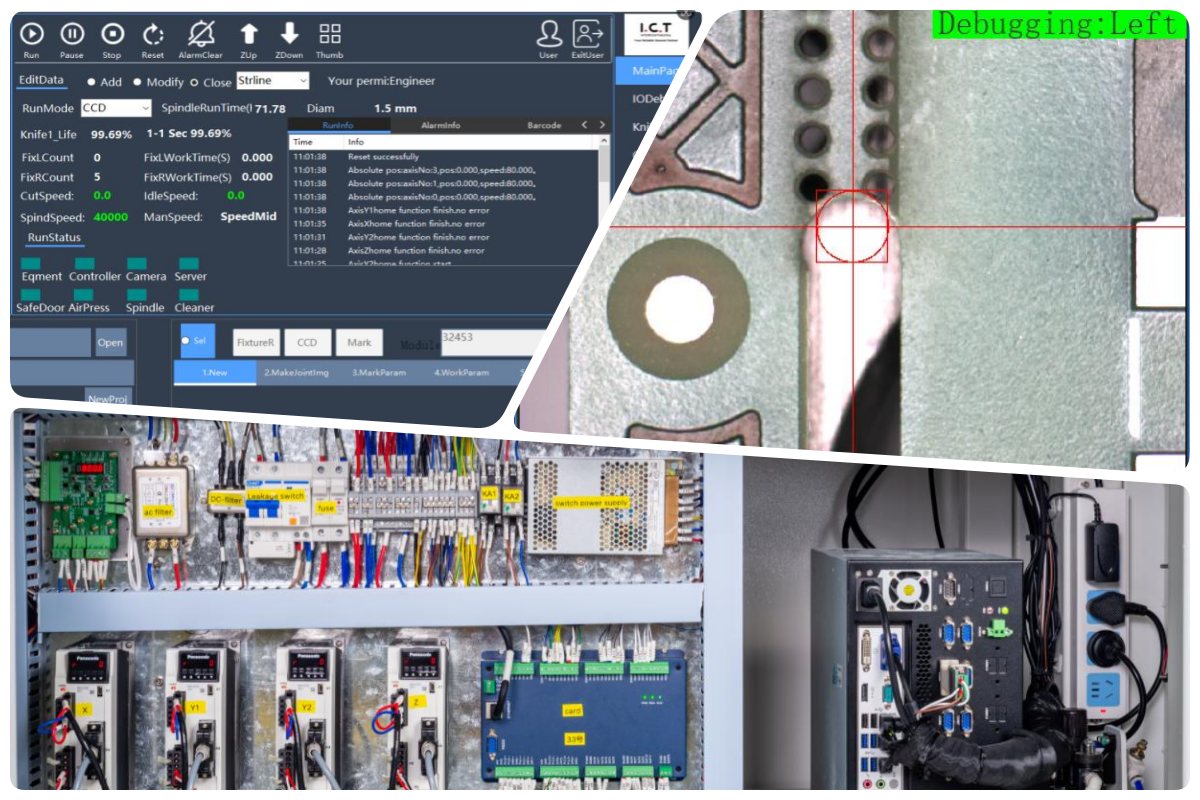

Control System

A dedicated CNC controller paired with an industrial computer offers strong resistance to electrical interference common in factories. Detailed production logs track each job for quality records. The clear interface follows CE requirements and allows fast program changes when products switch. Real-time coaxial CCD display shows exactly what occurs during cutting. Operators quickly learn the system and maintain consistent performance day after day. These elements make the PCB separation machine reliable and easy to manage in real production settings.

Detail Display

Self-locking pneumatic struts keep doors firmly in place during work. Broken knife detection sensor constantly checks cutter condition. Optional automatic tool changer swaps bits without stopping the process. ESD interface protects sensitive components from static harm. Side door safety sensors immediately halt motion if doors open unexpectedly. Convection fan maintains even temperatures inside. Every small feature contributes practical safety and convenience to regular use of this PCB separation machine.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

A customer from Algeria, focused on feature phone production, traveled to our facility for full machine acceptance. They arrived with more than ten PCB panels and complete sets of components. Our team demonstrated the entire SMT line step by step: automatic solder paste printing, SPI inspection, RX-8 placement for small parts, RS-1R for larger components, tray feeding of shield covers, reflow soldering, AOI quality check, and finally precise board separation using the I.C.T PCB separation machine. The process flowed without issues, delivering clean cuts and high efficiency. The customer observed everything closely, expressed satisfaction with the results, and approved the equipment before departure.

| Service and Training Support

I.C.T provides complete on-site installation and thorough operator training tailored to your needs. Experienced engineers explain safe handling, programming, tool maintenance, and daily routines for the PCB separation machine. Remote assistance and rapid spare parts delivery minimize any production delays. Service centers located around the world respond quickly to questions or concerns. Ongoing process guidance helps adjust operations as your requirements evolve. This comprehensive approach gives customers confidence, reduces worries, and maximizes the long-term value of their investment in our equipment.

| Customer Feedback

Customers frequently highlight the knowledge and quick response of our engineers during installation and troubleshooting. They praise the consistent precision and gentle handling of boards by our machines. Secure, professional packaging ensures safe arrival with no damage. Fast replies to technical questions build strong confidence. Many note that I.C.T support and equipment quality stand out clearly in the industry.

| Certifications and Standards

CE certification confirms full safety compliance. RoHS verifies environmentally responsible materials. ISO9001 demonstrates a rigorous quality management system throughout production. Multiple patents protect our technical innovations. These recognized approvals assure customers that every PCB separation machine meets strict international standards for safety, quality, and reliability.

| About I.C.T Company and Factory

I.C.T maintains its own research, development, and manufacturing facilities with a large team of dedicated engineers. Steady growth has allowed us to serve more than 1600 customers across over 72 countries worldwide. Modern factories follow strict inspection procedures and comprehensive quality control systems. Each machine, including the PCB separation machine, undergoes careful testing before shipment. Our focus remains on continuous improvement, innovative solutions, and reliable global service to support long-term success for every partner.

| Advanced PCB Separation Solution

Factories producing smartphones, smart wearables, automotive electronics, medical instruments, and aerospace components rely on this PCB separation machine for clean results. It manages board sizes ranging from 340×380mm to 450×600mm, with thicknesses between 0.5 and 5.0mm. The updated CCD vision system recognizes all marks and automatically corrects alignment. A high-speed spindle reaching 80,000rpm cuts with very little stress, maintaining high accuracy and quick response. Dual platforms handle different products at once or combine into a single larger area when needed. The ion air gun removes static electricity so dust cannot settle on boards. Real-time sensors watch the milling cutter closely. Quiet, powerful dust collection keeps the workspace clean. Simple controls make daily operation straightforward and consistent.

| Feature

Transmission System

Thicker mechanical framing holds everything steady through long hours of use. Flexible tank chains guide cables neatly without interfering with moving parts. The X-axis carries a special dust-proof cover that greatly reduces cleaning and repair needs. Imported Panasonic servo motors work together with high-precision screw rods and reliable Taiwan guide rails. Movement remains accurate and fluid shift after shift. These carefully chosen components give the PCB separation machine lasting stability and keep maintenance low while supporting tight tolerances required in modern electronics assembly.

Router System

A high-definition CCD camera aligns perfectly with the milling cutter for easy and exact calibration. Standard breakage detection immediately alerts operators when a cutter wears down or snaps. Optional automatic tool changing allows continuous running without interruption, improving overall output. The ion air gun clears static charge from PCB surfaces and stops dust from collecting. An imported high-speed spindle reduces cutting force, delivers high precision, low inertia, and fast reaction. Together these features ensure every board cut by the PCB separator manual or PCBA Router Machine comes out clean and undamaged.

Platform System

Y-axis movement relies on sturdy slide rails and servo motors for dependable stability. Two-way emergency stops, full safety covers, and light curtains protect operators at every moment. Start buttons on both sides require simultaneous pressing to begin operation safely. The standard honeycomb porous base provides strong hold and works well with many board types. Dual platforms accept special or standard fixtures without difficulty. This practical design makes the in line PCBA router or LED aluminum PCB depaneling process secure and adaptable for busy production lines.

Control System

A dedicated CNC controller paired with an industrial computer offers strong resistance to electrical interference common in factories. Detailed production logs track each job for quality records. The clear interface follows CE requirements and allows fast program changes when products switch. Real-time coaxial CCD display shows exactly what occurs during cutting. Operators quickly learn the system and maintain consistent performance day after day. These elements make the PCB separation machine reliable and easy to manage in real production settings.

Detail Display

Self-locking pneumatic struts keep doors firmly in place during work. Broken knife detection sensor constantly checks cutter condition. Optional automatic tool changer swaps bits without stopping the process. ESD interface protects sensitive components from static harm. Side door safety sensors immediately halt motion if doors open unexpectedly. Convection fan maintains even temperatures inside. Every small feature contributes practical safety and convenience to regular use of this PCB separation machine.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

A customer from Algeria, focused on feature phone production, traveled to our facility for full machine acceptance. They arrived with more than ten PCB panels and complete sets of components. Our team demonstrated the entire SMT line step by step: automatic solder paste printing, SPI inspection, RX-8 placement for small parts, RS-1R for larger components, tray feeding of shield covers, reflow soldering, AOI quality check, and finally precise board separation using the I.C.T PCB separation machine. The process flowed without issues, delivering clean cuts and high efficiency. The customer observed everything closely, expressed satisfaction with the results, and approved the equipment before departure.

| Service and Training Support

I.C.T provides complete on-site installation and thorough operator training tailored to your needs. Experienced engineers explain safe handling, programming, tool maintenance, and daily routines for the PCB separation machine. Remote assistance and rapid spare parts delivery minimize any production delays. Service centers located around the world respond quickly to questions or concerns. Ongoing process guidance helps adjust operations as your requirements evolve. This comprehensive approach gives customers confidence, reduces worries, and maximizes the long-term value of their investment in our equipment.

| Customer Feedback

Customers frequently highlight the knowledge and quick response of our engineers during installation and troubleshooting. They praise the consistent precision and gentle handling of boards by our machines. Secure, professional packaging ensures safe arrival with no damage. Fast replies to technical questions build strong confidence. Many note that I.C.T support and equipment quality stand out clearly in the industry.

| Certifications and Standards

CE certification confirms full safety compliance. RoHS verifies environmentally responsible materials. ISO9001 demonstrates a rigorous quality management system throughout production. Multiple patents protect our technical innovations. These recognized approvals assure customers that every PCB separation machine meets strict international standards for safety, quality, and reliability.

| About I.C.T Company and Factory

I.C.T maintains its own research, development, and manufacturing facilities with a large team of dedicated engineers. Steady growth has allowed us to serve more than 1600 customers across over 72 countries worldwide. Modern factories follow strict inspection procedures and comprehensive quality control systems. Each machine, including the PCB separation machine, undergoes careful testing before shipment. Our focus remains on continuous improvement, innovative solutions, and reliable global service to support long-term success for every partner.