I.C.T-5700

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Advanced Drilling and Routing Machine

This Drilling and Routing Machine serves fields including smartphones, smart wearables, automotive electronics, medical devices, and aerospace applications. It manages board dimensions from 340×380mm to 450×600mm, accommodating thicknesses of 0.5 to 5.0mm. The updated CCD vision technology identifies all PCB marks and applies visual correction seamlessly. A spindle operating at 80,000rpm achieves high precision with reduced stress, low inertia, and rapid response. Dual platforms allow processing of varied products concurrently or merge into a single unit for larger tasks. An ion air gun dispels static electricity, preventing dust adhesion on surfaces. Real-time sensors monitor the milling cutter to avoid operational errors. The vacuum dust collector uses a high-efficiency motor for strong suction and quiet performance. Humanized controls make operation straightforward and adaptable.

| Feature

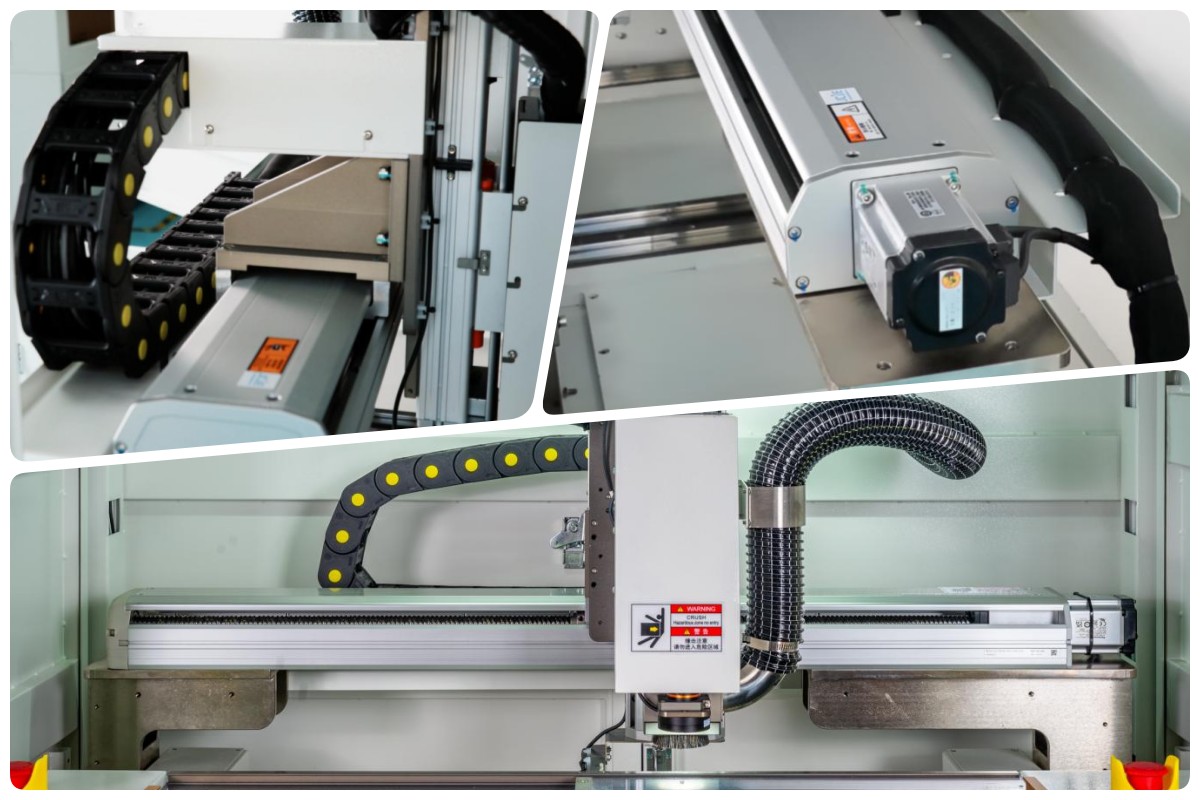

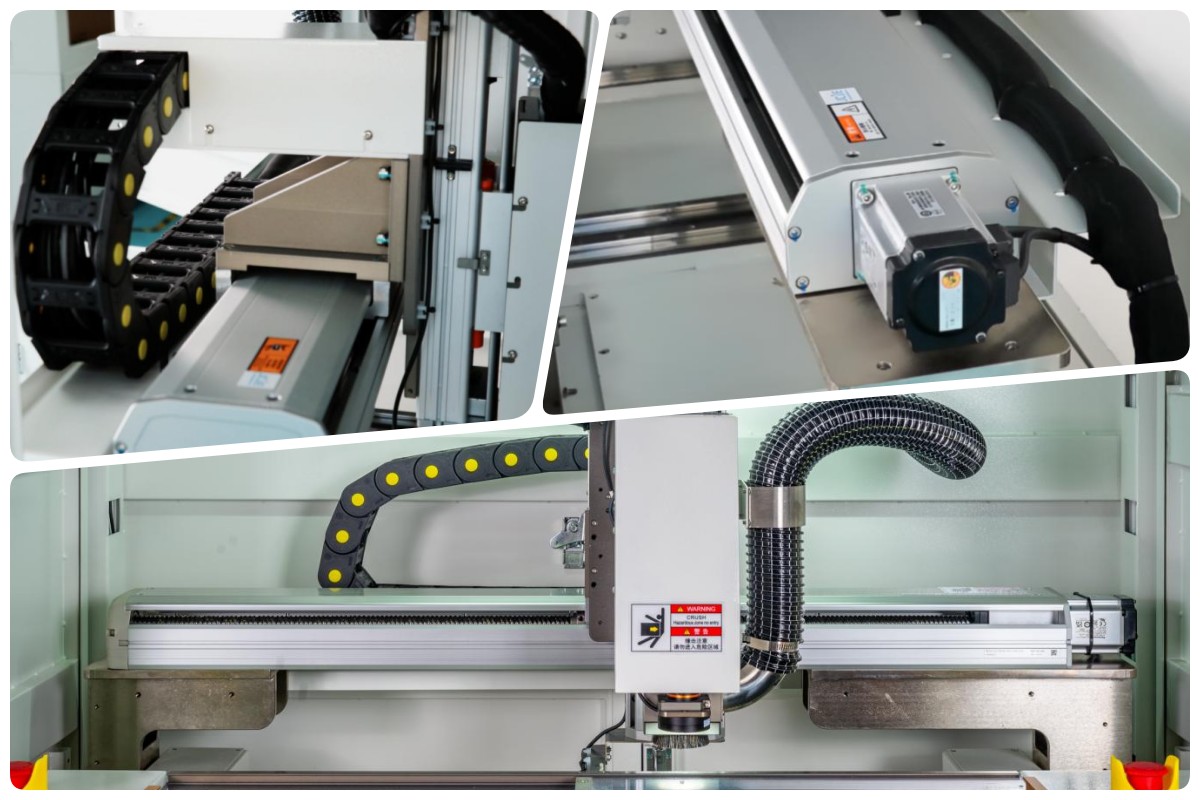

Transmission System

The X-axis module incorporates a unique dust-proof design that significantly lowers maintenance requirements. Flexible tank chains ensure harnesses remain clear of moving elements while preserving an orderly appearance. Imported Panasonic servo motors, combined with high-precision screw rods, deliver exact motion control. A stronger, thicker mechanical structure bolsters overall stability during extended use. These integrated features allow the Drilling and Routing Machine to operate with unwavering reliability in precise manufacturing environments.

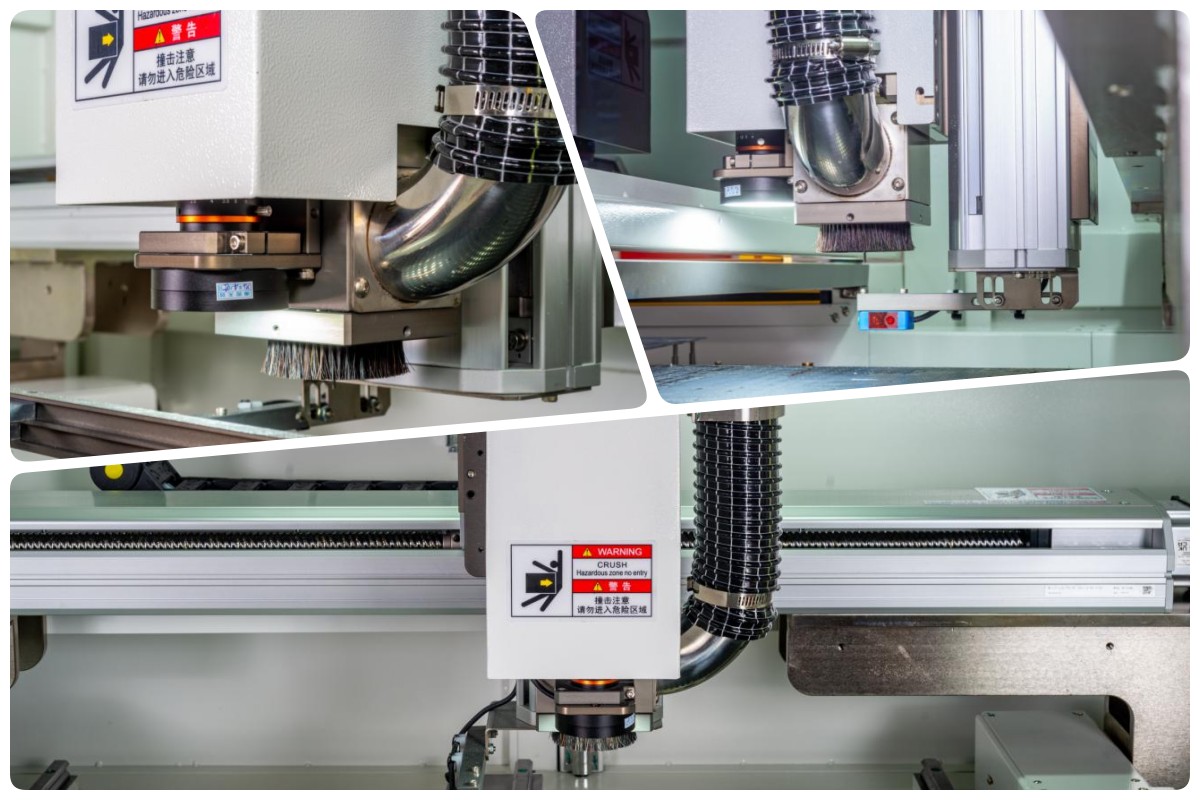

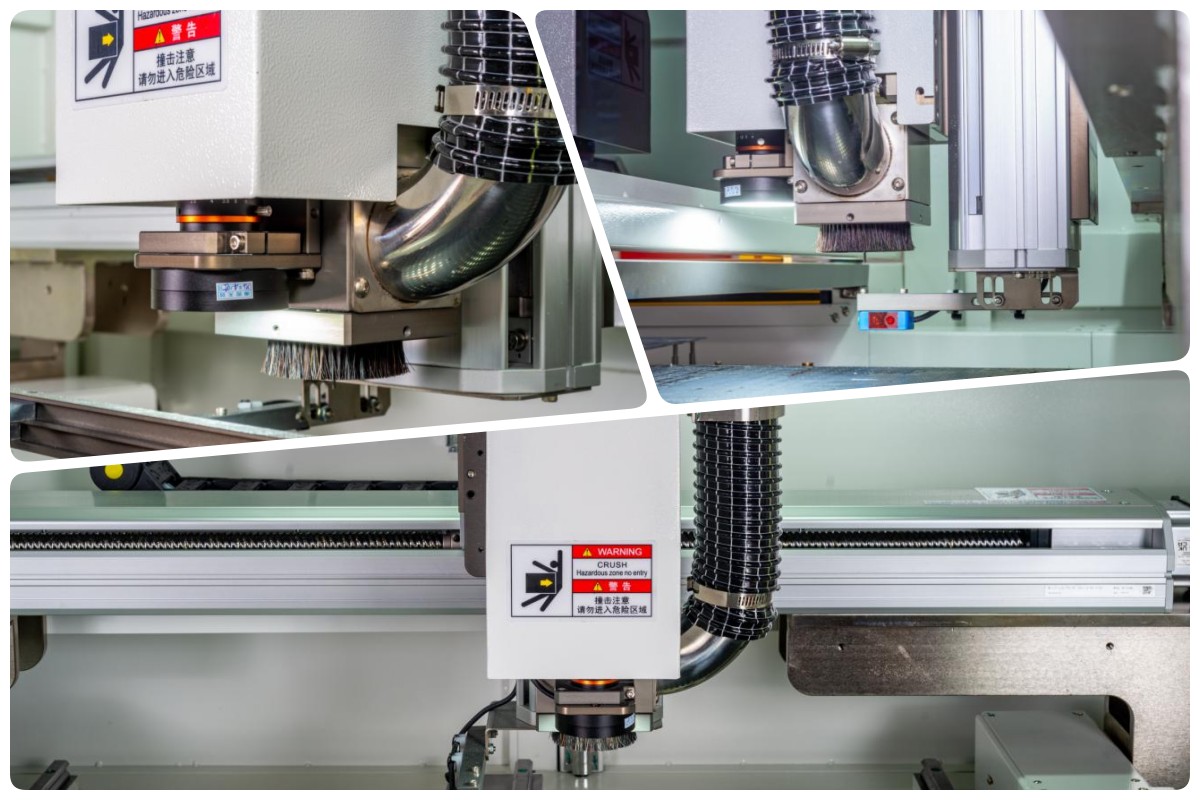

Router System

An imported high-speed spindle greatly reduces cutting stress, offering superior precision, minimal inertia, and swift response times. The ion air gun effectively removes static from PCB surfaces, averting dust adsorption. Optional automatic tool changing enables continuous operation without interruptions, boosting overall efficiency. Standard tool breakage detection provides automatic alarms if the cutter breaks or wears down. A high-definition vision system, coaxial with the milling cutter, facilitates easy calibration. This setup ensures the Drilling and Routing Machine performs consistently and accurately.

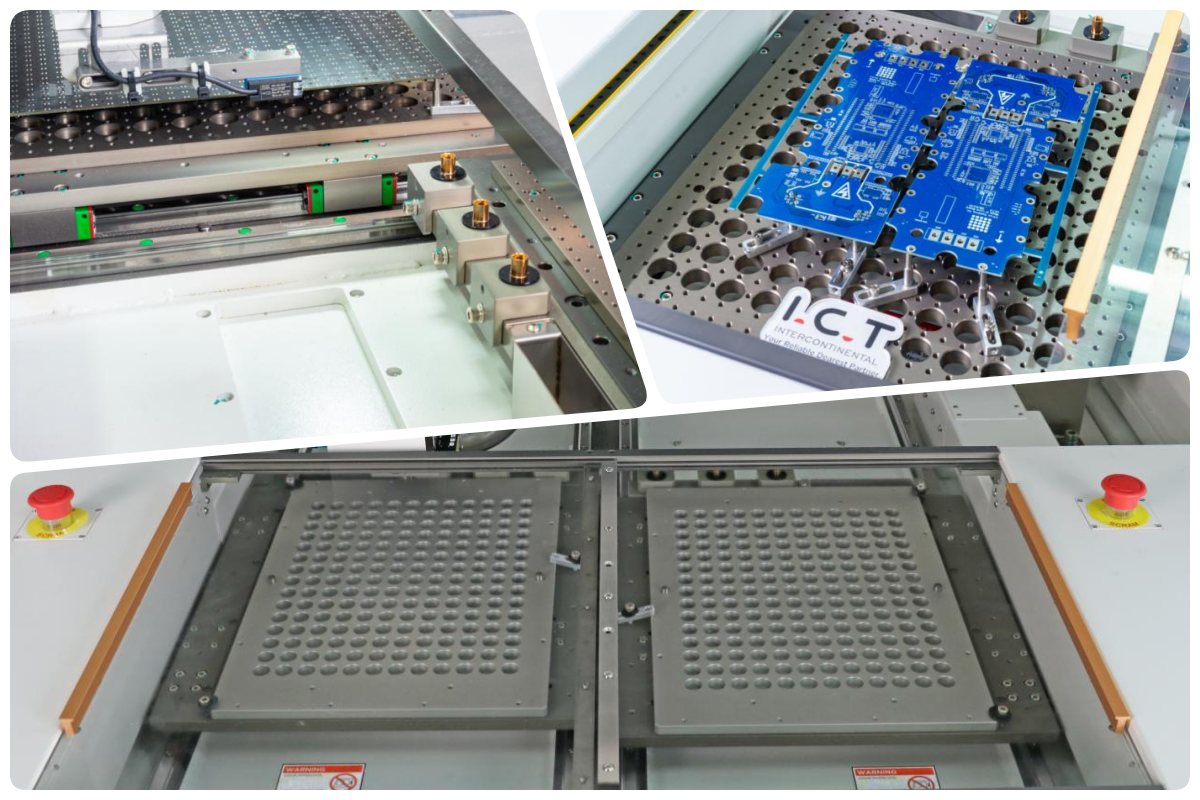

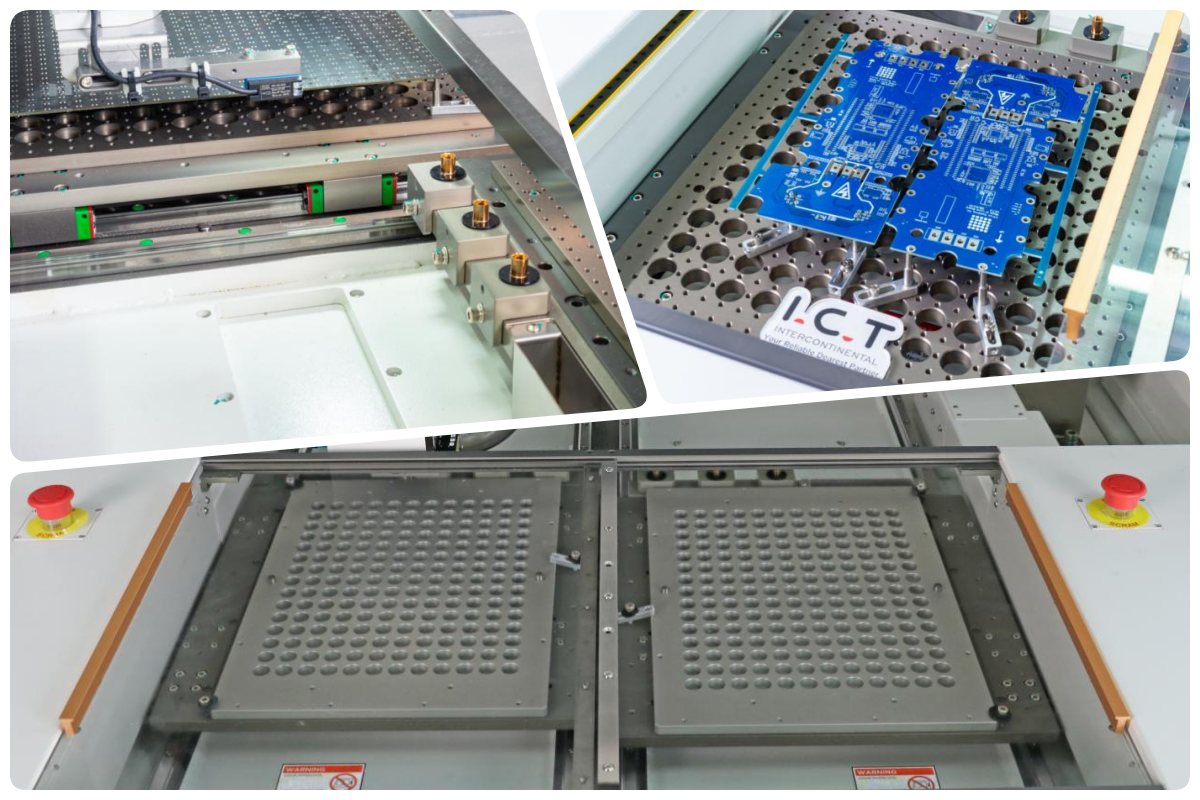

Platform System

Y-axis control relies on slide rails and servo motors for excellent machine stability. Two-way emergency stop buttons offer multiple protective layers. Standard safety covers and light curtains enhance operator security. Start buttons positioned on both sides require simultaneous pressing to initiate safe operations. The honeycomb porous base provides enhanced compatibility and secure holding. Dual platforms support processing different products simultaneously or combining for flexibility in the Drilling and Routing Machine.

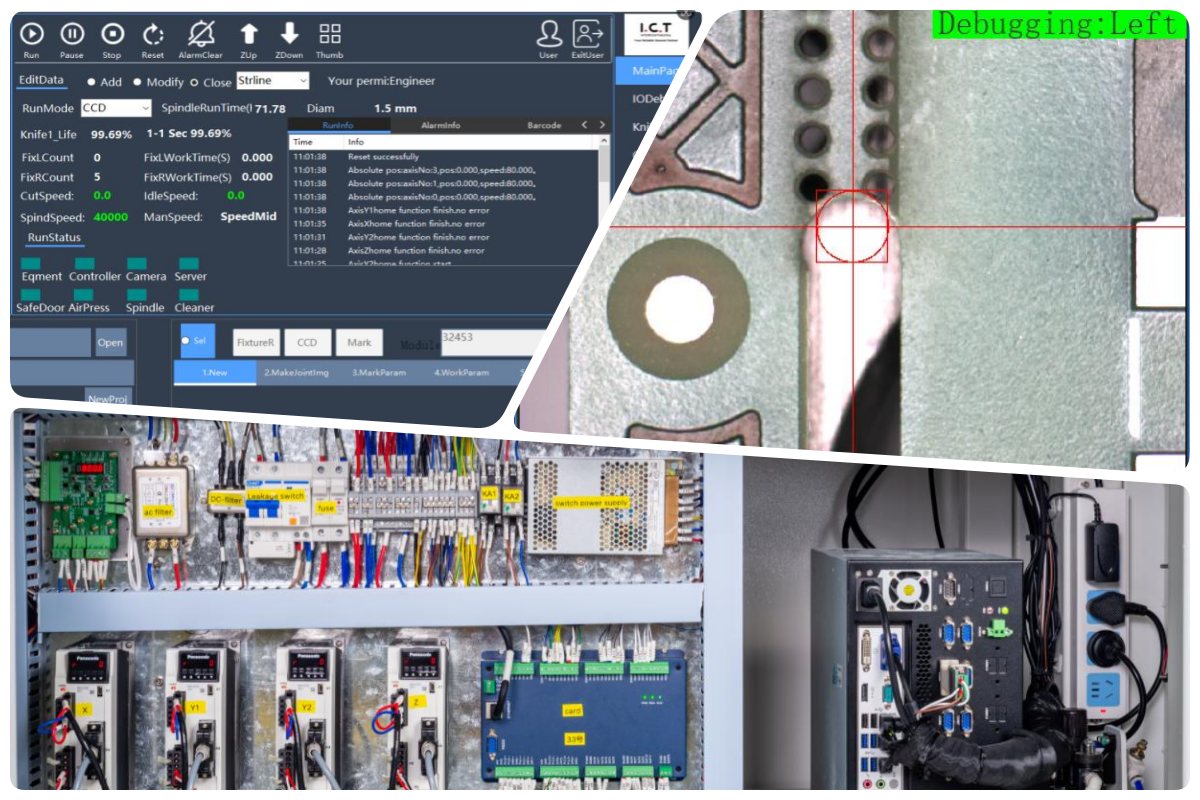

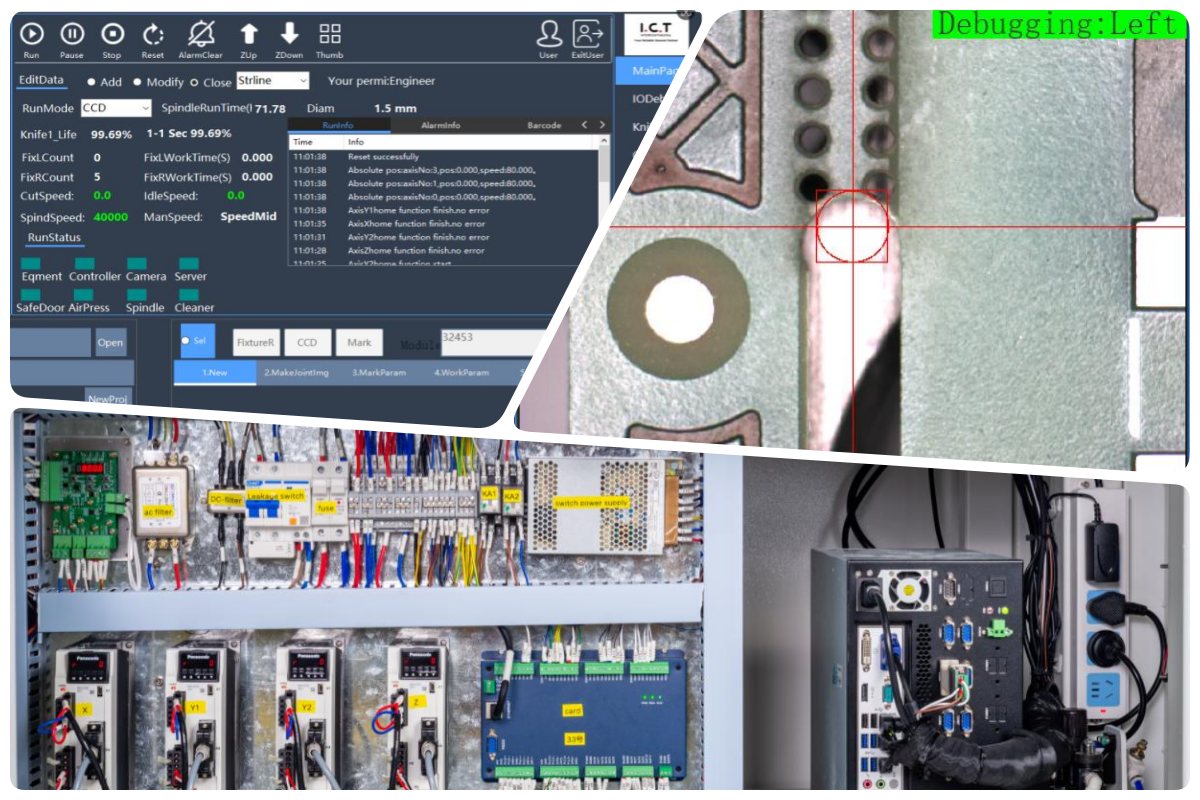

Control System

An industrial computer paired with a CNC controller ensures high control accuracy and strong anti-interference capabilities. Production data traceability generates detailed log reports. The layout adheres to CE and UL standards with a reasonable design. Simple interface allows quick learning and fast program switching. Coaxial CCD camera offers real-time visual feedback. These elements make the Drilling and Routing Machine dependable for sustained, high-quality production tasks.

Detail Display

Convection fan regulates internal temperatures effectively. Side door safety sensors halt operations upon detection of openings. ESD interface safeguards against electrostatic discharge. Automatic tool changer facilitates seamless bit replacements. Broken knife detection sensor continuously assesses cutter condition. Self-locking pneumatic struts support doors securely. Such details contribute to the overall safety and usability of the Drilling and Routing Machine in practical settings.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Conveyor | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

An Algerian client specializing in feature phones visited our facility for on-site acceptance testing. They supplied over ten PCB panels and all required materials. Our team executed a complete SMT production sequence: fully automatic printer applied solder paste, SPI inspected deposits, RX-8 placed small components, RS-1R handled larger parts, tray feeder provided shield covers, reflow oven soldered assemblies, AOI verified quality, and the I.C.T Drilling and Routing Machine performed precise depaneling with minimal stress and clean edges. The demonstration proceeded without issues, highlighting efficiency and reliability. The customer expressed satisfaction with the results and machine capabilities.

| Service and Training Support

I.C.T delivers full installation, operator training, and ongoing maintenance services globally. Engineers instruct on safe handling, programming, tool management, and routine upkeep for the Drilling and Routing Machine. Remote diagnostics and rapid spare parts supply minimize production halts. Service centers ensure prompt issue resolution. This thorough approach equips customers to maximize equipment performance and achieve seamless operations over time.

| Client Testimonials

Clients commend our engineers for their prompt expertise and thorough explanations. They highlight the equipment's consistent precision and durability. Secure packaging and transport receive praise for flawless arrivals. Rapid responses to inquiries strengthen confidence. Overall, customers value I.C.T's reliable products and dedicated assistance.

| Certifications and Standards

I.C.T maintains CE certification for safety compliance, RoHS for environmental standards, ISO9001 for quality management, and various patents for innovative designs. These credentials affirm the high standards and trustworthiness of our Drilling and Routing Machine.

| About I.C.T Company and Factory

I.C.T operates its own R&D and manufacturing facilities with a substantial engineering team. Rapid growth has led to serving over 1600 customers in more than 72 countries. Factories implement rigorous inspection processes and comprehensive quality management systems. This dedication ensures superior products like the Drilling and Routing Machine and fosters enduring global partnerships.

| Advanced Drilling and Routing Machine

This Drilling and Routing Machine serves fields including smartphones, smart wearables, automotive electronics, medical devices, and aerospace applications. It manages board dimensions from 340×380mm to 450×600mm, accommodating thicknesses of 0.5 to 5.0mm. The updated CCD vision technology identifies all PCB marks and applies visual correction seamlessly. A spindle operating at 80,000rpm achieves high precision with reduced stress, low inertia, and rapid response. Dual platforms allow processing of varied products concurrently or merge into a single unit for larger tasks. An ion air gun dispels static electricity, preventing dust adhesion on surfaces. Real-time sensors monitor the milling cutter to avoid operational errors. The vacuum dust collector uses a high-efficiency motor for strong suction and quiet performance. Humanized controls make operation straightforward and adaptable.

| Feature

Transmission System

The X-axis module incorporates a unique dust-proof design that significantly lowers maintenance requirements. Flexible tank chains ensure harnesses remain clear of moving elements while preserving an orderly appearance. Imported Panasonic servo motors, combined with high-precision screw rods, deliver exact motion control. A stronger, thicker mechanical structure bolsters overall stability during extended use. These integrated features allow the Drilling and Routing Machine to operate with unwavering reliability in precise manufacturing environments.

Router System

An imported high-speed spindle greatly reduces cutting stress, offering superior precision, minimal inertia, and swift response times. The ion air gun effectively removes static from PCB surfaces, averting dust adsorption. Optional automatic tool changing enables continuous operation without interruptions, boosting overall efficiency. Standard tool breakage detection provides automatic alarms if the cutter breaks or wears down. A high-definition vision system, coaxial with the milling cutter, facilitates easy calibration. This setup ensures the Drilling and Routing Machine performs consistently and accurately.

Platform System

Y-axis control relies on slide rails and servo motors for excellent machine stability. Two-way emergency stop buttons offer multiple protective layers. Standard safety covers and light curtains enhance operator security. Start buttons positioned on both sides require simultaneous pressing to initiate safe operations. The honeycomb porous base provides enhanced compatibility and secure holding. Dual platforms support processing different products simultaneously or combining for flexibility in the Drilling and Routing Machine.

Control System

An industrial computer paired with a CNC controller ensures high control accuracy and strong anti-interference capabilities. Production data traceability generates detailed log reports. The layout adheres to CE and UL standards with a reasonable design. Simple interface allows quick learning and fast program switching. Coaxial CCD camera offers real-time visual feedback. These elements make the Drilling and Routing Machine dependable for sustained, high-quality production tasks.

Detail Display

Convection fan regulates internal temperatures effectively. Side door safety sensors halt operations upon detection of openings. ESD interface safeguards against electrostatic discharge. Automatic tool changer facilitates seamless bit replacements. Broken knife detection sensor continuously assesses cutter condition. Self-locking pneumatic struts support doors securely. Such details contribute to the overall safety and usability of the Drilling and Routing Machine in practical settings.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Conveyor | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

An Algerian client specializing in feature phones visited our facility for on-site acceptance testing. They supplied over ten PCB panels and all required materials. Our team executed a complete SMT production sequence: fully automatic printer applied solder paste, SPI inspected deposits, RX-8 placed small components, RS-1R handled larger parts, tray feeder provided shield covers, reflow oven soldered assemblies, AOI verified quality, and the I.C.T Drilling and Routing Machine performed precise depaneling with minimal stress and clean edges. The demonstration proceeded without issues, highlighting efficiency and reliability. The customer expressed satisfaction with the results and machine capabilities.

| Service and Training Support

I.C.T delivers full installation, operator training, and ongoing maintenance services globally. Engineers instruct on safe handling, programming, tool management, and routine upkeep for the Drilling and Routing Machine. Remote diagnostics and rapid spare parts supply minimize production halts. Service centers ensure prompt issue resolution. This thorough approach equips customers to maximize equipment performance and achieve seamless operations over time.

| Client Testimonials

Clients commend our engineers for their prompt expertise and thorough explanations. They highlight the equipment's consistent precision and durability. Secure packaging and transport receive praise for flawless arrivals. Rapid responses to inquiries strengthen confidence. Overall, customers value I.C.T's reliable products and dedicated assistance.

| Certifications and Standards

I.C.T maintains CE certification for safety compliance, RoHS for environmental standards, ISO9001 for quality management, and various patents for innovative designs. These credentials affirm the high standards and trustworthiness of our Drilling and Routing Machine.

| About I.C.T Company and Factory

I.C.T operates its own R&D and manufacturing facilities with a substantial engineering team. Rapid growth has led to serving over 1600 customers in more than 72 countries. Factories implement rigorous inspection processes and comprehensive quality management systems. This dedication ensures superior products like the Drilling and Routing Machine and fosters enduring global partnerships.