I.C.T-MLS1200

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Guillotine PCB Cutting Machine – Clean Separation Without Waste

The Guillotine PCB Cutting Machine does one job well: it cuts PCBs along V-grooves with the least possible harm. The board stays fixed in place while the blade drops straight down under air pressure. This keeps internal stress below 180 microstrain, which means solder joints do not crack and nearby components remain undamaged. The cut happens right at the edge of the groove, with only 0.3mm clearance to parts, and it handles components up to 60mm tall. No motor spins, no friction grinds, so dust stays low, carbon does not form, and almost no metal residue appears. One cut takes one second, controlled by a foot switch, and the blade pulls back safely after each use. Blade life goes beyond six million cycles, and simple sanding brings sharpness back when needed. Compared to a V-cut PCB depaneling Machine that slides or routes, this method avoids extra heat, cuts cleaner, and requires less maintenance. It suits factories that need reliable, dust-free results on FR4 boards without complications.

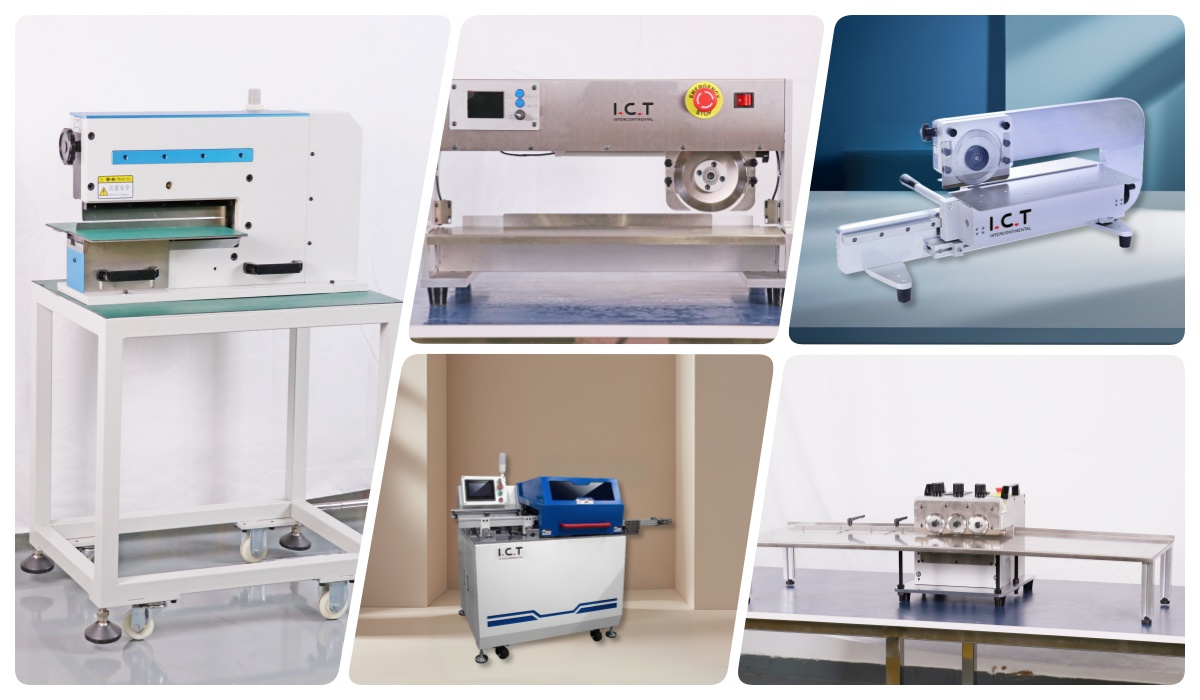

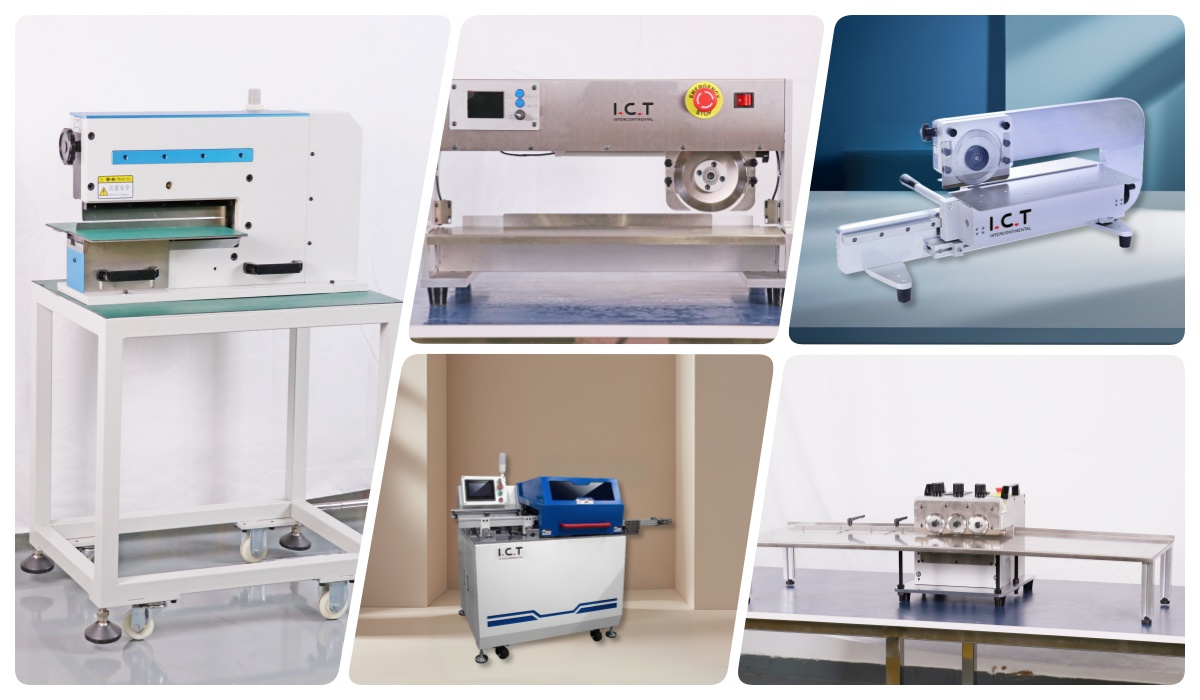

I.C.T offers five main types of V-cut machines, each built for a clear purpose:

Standard manual type: Simple and low-cost for small batches.

Multi-blades LED separator: Gentle phased cuts for long LED boards.

Guillotine type: Fast air-powered drop for thicker materials.

Move-blade sliding type: Flexible adjustment for various grooves.

Multi-knife group type: Handles unlimited lengths with steady results.

| Feature

Multi-Blades LED Separator

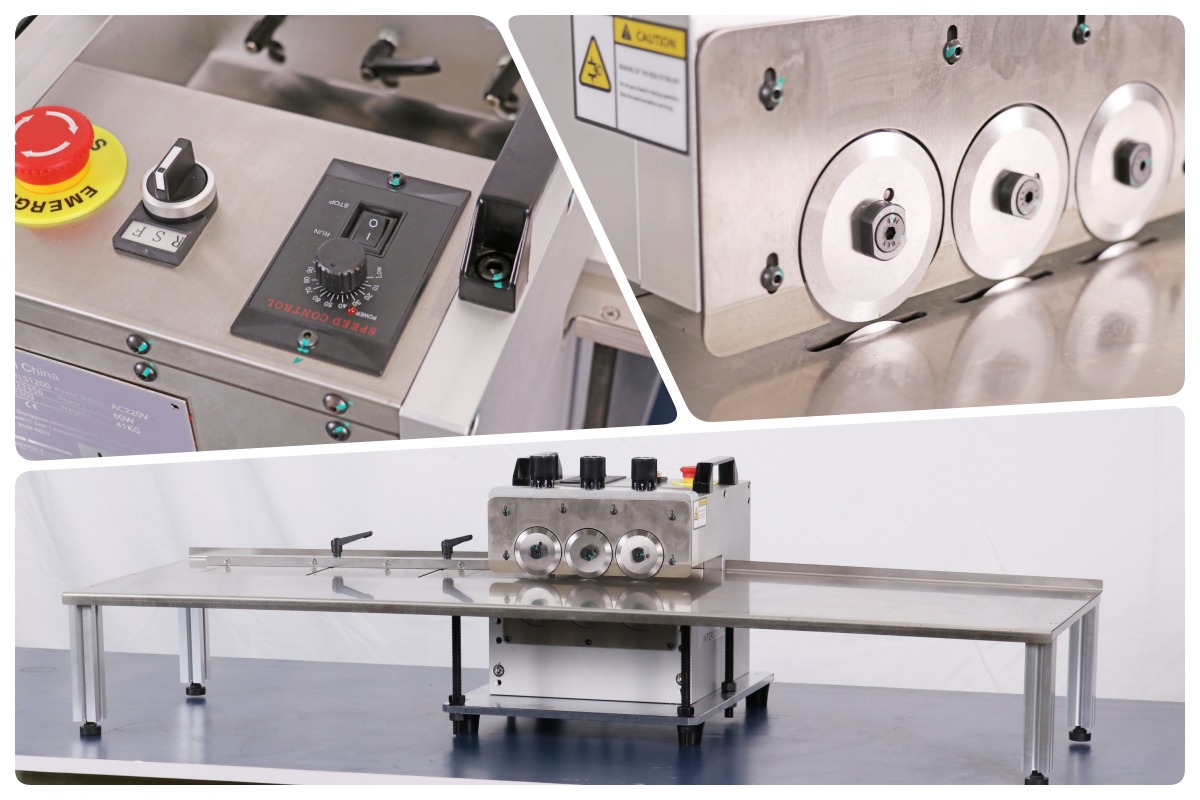

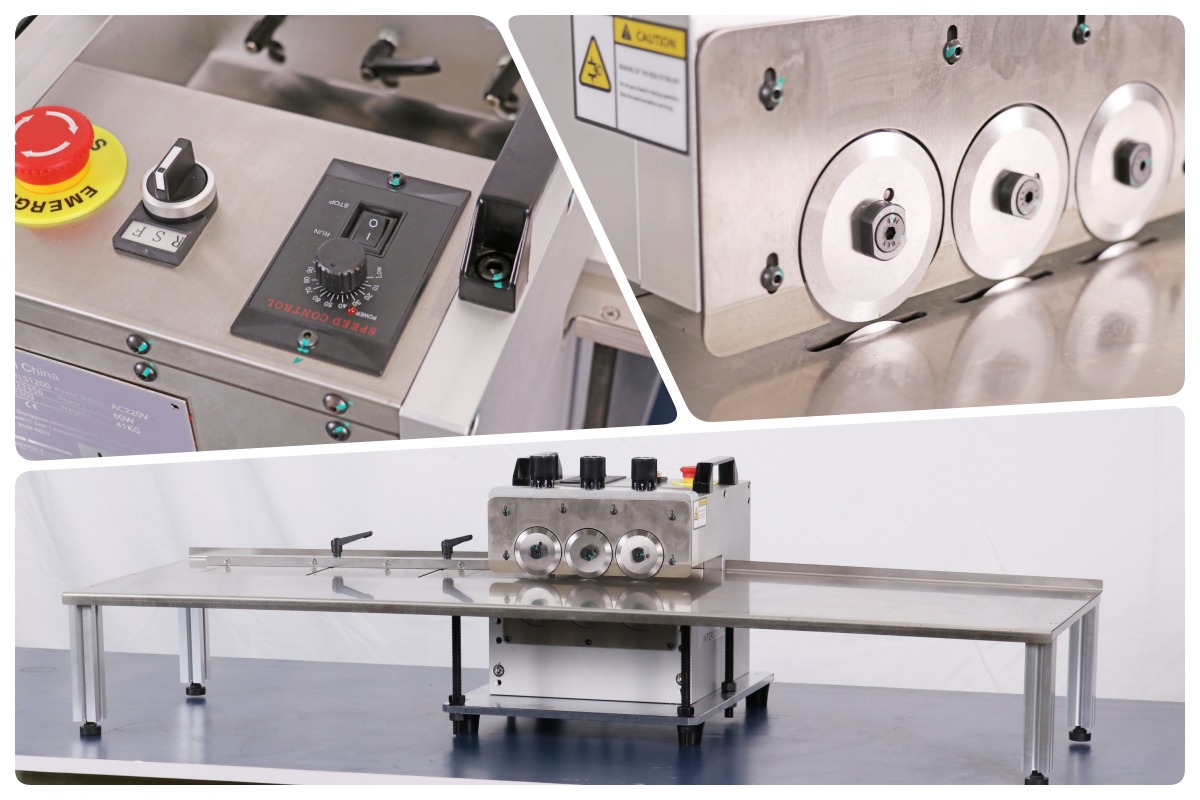

The multi-blades Guillotine PCB Cutting Machine uses six circular blades in three groups that cut in stages. First group takes 40% along the V-groove, second group follows for the next 40%, and third group finishes the last 20%. Each short cut lowers internal stress by up to 80% compared with single long cuts, so aluminum boards and LED strips stay flat and do not warp. Blades come from Taiwan, last over one year, and sharpen many times. Dual-frequency laser calibration keeps blade tip jump under 0.02mm for consistent quality. Extra stainless platforms reach 1.2m or 2.4m for longer boards. Top and bottom blades adjust precisely, and custom blocks fit different widths. Free X and Y adjustments improve accuracy. This design fits high-volume LED production where board flatness and clean edges matter most. It avoids deformation that ruins expensive panels.

Guillotine Type V-Cut Machine

The guillotine Guillotine PCB Cutting Machine drops straight down with clean air power. Stress stays under 180 microstrain to protect solder and components. It cuts at the V-groove edge with 0.3mm clearance to parts and handles heights up to 60mm. No rotation means no dust or carbon pollution. No friction leaves almost no metal residue. One cut per second comes from a foot switch, and negative blade activation keeps position safe. Blade life exceeds six million cuts. Simple sanding restores the edge. This machine suits FR4 boards and factories that need fast, clean separation without particles in the air. It gives sharp edges and reliable results day after day. Professionals choose it when cleanliness and speed count more than complex setup.

Move-Blade (Sliding) V-Cut Machine

The move-blade Guillotine PCB Cutting Machine lets the operator control sliding speed and blade distance to match any V-groove depth. The PCB stays fixed, so components up to 34mm tall crossing the cut line stay safe. Low pressure avoids cracks in solder or board material. The strong frame provides stability. Blade customization meets special needs. It works well for medium production, prototypes, or shops wanting simple, affordable separation without automation. Operators like the hands-on control that lets them adjust to each board quickly. Results stay clean and consistent in everyday use. This type balances flexibility with low cost for practical factories.

| Specification

| Parameter | Manual Single-Blade V-cut Machine | Multi-Blades LED Separator | Guillotine Type V-cut Machine | Move-Blade (Sliding) V-cut Machine | Multi Group Blades PCB V-cut Machine |

|---|---|---|---|---|---|

| Operation Type | Manual (hand sliding) | Manual (hand push) | Manual (pneumatic foot switch) | Manual (adjustable sliding) | Manual (multi-group push) |

| Blade Setup | 1 circular + 1 straight blade | 6 circular blades (3 groups top/bottom) | Single straight guillotine blade | 1 circular + 1 straight (adjustable gap) | Multiple groups of circular blades (custom multi-knife) |

| PCB Length | 0–350 mm | Unlimited (with 1.2m / 2.4m platforms) | 0–330 mm | 0–350 mm (typical) | Unlimited or very long (platform-dependent) |

| PCB Thickness | 0.8–5 mm | 0.2–5 mm | 0.3–5 mm | 0.8–5 mm | 0.2–5 mm (typical for multi-group) |

| Cutting Method | Single pass sliding | 3-phase (40% + 40% + 20%) | One-shot downward cut | Single pass with adjustable depth | Multi-group sequential cutting |

| Best Application | General PCBs, prototypes, medium volume | Long LED strips, aluminum PCBs, high-volume LED | FR4 boards, clean/dust-free edges | Mixed components, flexible V-depth | Extra-long or wide PCBs, high-efficiency separation |

| SMT Line Equipment List

I.C.T builds full SMT lines that connect loaders, printers, mounters, reflow ovens, AOI, conveyors, and Guillotine PCB Cutting Machine units into one working system. Layouts like U-shape fit tight spaces. The complete line raises efficiency, cuts defects, and keeps quality steady for automotive, LED, and consumer products. Customers get planning help, installation, and ongoing support. Everything matches so production starts fast and runs without major stops.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

In early 2025, I.C.T engineer Peter went to Uzbekistan for sixteen days of installation and training. The customer bought a full SMT line for automotive motors and parts, including 5151 automatic printer, mounter, L8 reflow oven, AOI, NG/OK unloader, BGA rework station, walk-knife depaneler, solder paste mixer, translation conveyor, and more. Factory space was limited, so I.C.T designed a U-shaped line to use the area well. Peter taught the team step by step. When he left, the customer ran the line independently and produced smoothly without issues.

| Service and Training Support

I.C.T provides complete service and training for every Guillotine PCB Cutting Machine and SMT line. Engineers go on-site worldwide to install equipment, run demonstrations, and train operators on use, maintenance, troubleshooting, and process improvement. Training builds skill so teams work confidently from day one. After setup, support continues through phone, email, or remote help for quick fixes and low downtime. This approach helps customers start production fast, maintain high output, and solve problems without delay.

| Client Testimonials

Customers praise I.C.T engineers for their clear knowledge, patient teaching, and hard work on-site. They value the Guillotine PCB Cutting Machine for reliable cuts, low board stress, and long blade life. Many mention careful packing and safe shipping that deliver machines in perfect condition. Fast answers to questions build strong trust. Users often say the equipment performs well and support remains excellent long after purchase.

| Certifications and Standards

The Guillotine PCB Cutting Machine holds CE for safety, RoHS for environmental standards, and ISO9001 for quality control. Multiple patents cover our depaneling designs. These certifications confirm the machine meets global rules for performance, safety, and responsible production. Factories trust them for consistent results.

| About I.C.T Company and Factory

I.C.T runs its own R&D and factory in Dongguan, China, with 89 staff including 20 engineers. Founded in 2012, the company has grown quickly and now serves over 1600 customers in 72 countries. The 12000m² facility uses strict testing and a full quality system to deliver reliable machines. We offer one-stop SMT solutions from planning to after-sales support, helping clients build and improve production lines worldwide.

| Guillotine PCB Cutting Machine – Clean Separation Without Waste

The Guillotine PCB Cutting Machine does one job well: it cuts PCBs along V-grooves with the least possible harm. The board stays fixed in place while the blade drops straight down under air pressure. This keeps internal stress below 180 microstrain, which means solder joints do not crack and nearby components remain undamaged. The cut happens right at the edge of the groove, with only 0.3mm clearance to parts, and it handles components up to 60mm tall. No motor spins, no friction grinds, so dust stays low, carbon does not form, and almost no metal residue appears. One cut takes one second, controlled by a foot switch, and the blade pulls back safely after each use. Blade life goes beyond six million cycles, and simple sanding brings sharpness back when needed. Compared to a V-cut PCB depaneling Machine that slides or routes, this method avoids extra heat, cuts cleaner, and requires less maintenance. It suits factories that need reliable, dust-free results on FR4 boards without complications.

I.C.T offers five main types of V-cut machines, each built for a clear purpose:

Standard manual type: Simple and low-cost for small batches.

Multi-blades LED separator: Gentle phased cuts for long LED boards.

Guillotine type: Fast air-powered drop for thicker materials.

Move-blade sliding type: Flexible adjustment for various grooves.

Multi-knife group type: Handles unlimited lengths with steady results.

| Feature

Multi-Blades LED Separator

The multi-blades Guillotine PCB Cutting Machine uses six circular blades in three groups that cut in stages. First group takes 40% along the V-groove, second group follows for the next 40%, and third group finishes the last 20%. Each short cut lowers internal stress by up to 80% compared with single long cuts, so aluminum boards and LED strips stay flat and do not warp. Blades come from Taiwan, last over one year, and sharpen many times. Dual-frequency laser calibration keeps blade tip jump under 0.02mm for consistent quality. Extra stainless platforms reach 1.2m or 2.4m for longer boards. Top and bottom blades adjust precisely, and custom blocks fit different widths. Free X and Y adjustments improve accuracy. This design fits high-volume LED production where board flatness and clean edges matter most. It avoids deformation that ruins expensive panels.

Guillotine Type V-Cut Machine

The guillotine Guillotine PCB Cutting Machine drops straight down with clean air power. Stress stays under 180 microstrain to protect solder and components. It cuts at the V-groove edge with 0.3mm clearance to parts and handles heights up to 60mm. No rotation means no dust or carbon pollution. No friction leaves almost no metal residue. One cut per second comes from a foot switch, and negative blade activation keeps position safe. Blade life exceeds six million cuts. Simple sanding restores the edge. This machine suits FR4 boards and factories that need fast, clean separation without particles in the air. It gives sharp edges and reliable results day after day. Professionals choose it when cleanliness and speed count more than complex setup.

Move-Blade (Sliding) V-Cut Machine

The move-blade Guillotine PCB Cutting Machine lets the operator control sliding speed and blade distance to match any V-groove depth. The PCB stays fixed, so components up to 34mm tall crossing the cut line stay safe. Low pressure avoids cracks in solder or board material. The strong frame provides stability. Blade customization meets special needs. It works well for medium production, prototypes, or shops wanting simple, affordable separation without automation. Operators like the hands-on control that lets them adjust to each board quickly. Results stay clean and consistent in everyday use. This type balances flexibility with low cost for practical factories.

| Specification

| Parameter | Manual Single-Blade V-cut Machine | Multi-Blades LED Separator | Guillotine Type V-cut Machine | Move-Blade (Sliding) V-cut Machine | Multi Group Blades PCB V-cut Machine |

|---|---|---|---|---|---|

| Operation Type | Manual (hand sliding) | Manual (hand push) | Manual (pneumatic foot switch) | Manual (adjustable sliding) | Manual (multi-group push) |

| Blade Setup | 1 circular + 1 straight blade | 6 circular blades (3 groups top/bottom) | Single straight guillotine blade | 1 circular + 1 straight (adjustable gap) | Multiple groups of circular blades (custom multi-knife) |

| PCB Length | 0–350 mm | Unlimited (with 1.2m / 2.4m platforms) | 0–330 mm | 0–350 mm (typical) | Unlimited or very long (platform-dependent) |

| PCB Thickness | 0.8–5 mm | 0.2–5 mm | 0.3–5 mm | 0.8–5 mm | 0.2–5 mm (typical for multi-group) |

| Cutting Method | Single pass sliding | 3-phase (40% + 40% + 20%) | One-shot downward cut | Single pass with adjustable depth | Multi-group sequential cutting |

| Best Application | General PCBs, prototypes, medium volume | Long LED strips, aluminum PCBs, high-volume LED | FR4 boards, clean/dust-free edges | Mixed components, flexible V-depth | Extra-long or wide PCBs, high-efficiency separation |

| SMT Line Equipment List

I.C.T builds full SMT lines that connect loaders, printers, mounters, reflow ovens, AOI, conveyors, and Guillotine PCB Cutting Machine units into one working system. Layouts like U-shape fit tight spaces. The complete line raises efficiency, cuts defects, and keeps quality steady for automotive, LED, and consumer products. Customers get planning help, installation, and ongoing support. Everything matches so production starts fast and runs without major stops.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

In early 2025, I.C.T engineer Peter went to Uzbekistan for sixteen days of installation and training. The customer bought a full SMT line for automotive motors and parts, including 5151 automatic printer, mounter, L8 reflow oven, AOI, NG/OK unloader, BGA rework station, walk-knife depaneler, solder paste mixer, translation conveyor, and more. Factory space was limited, so I.C.T designed a U-shaped line to use the area well. Peter taught the team step by step. When he left, the customer ran the line independently and produced smoothly without issues.

| Service and Training Support

I.C.T provides complete service and training for every Guillotine PCB Cutting Machine and SMT line. Engineers go on-site worldwide to install equipment, run demonstrations, and train operators on use, maintenance, troubleshooting, and process improvement. Training builds skill so teams work confidently from day one. After setup, support continues through phone, email, or remote help for quick fixes and low downtime. This approach helps customers start production fast, maintain high output, and solve problems without delay.

| Client Testimonials

Customers praise I.C.T engineers for their clear knowledge, patient teaching, and hard work on-site. They value the Guillotine PCB Cutting Machine for reliable cuts, low board stress, and long blade life. Many mention careful packing and safe shipping that deliver machines in perfect condition. Fast answers to questions build strong trust. Users often say the equipment performs well and support remains excellent long after purchase.

| Certifications and Standards

The Guillotine PCB Cutting Machine holds CE for safety, RoHS for environmental standards, and ISO9001 for quality control. Multiple patents cover our depaneling designs. These certifications confirm the machine meets global rules for performance, safety, and responsible production. Factories trust them for consistent results.

| About I.C.T Company and Factory

I.C.T runs its own R&D and factory in Dongguan, China, with 89 staff including 20 engineers. Founded in 2012, the company has grown quickly and now serves over 1600 customers in 72 countries. The 12000m² facility uses strict testing and a full quality system to deliver reliable machines. We offer one-stop SMT solutions from planning to after-sales support, helping clients build and improve production lines worldwide.