I.C.T-5700

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Precision Offline PCB Separator

This PCB separator serves industries such as smartphones, smart wearables, automotive electronics, medical devices, and aerospace. It accommodates board sizes ranging from 340×380mm to 450×600mm, with thicknesses of 0.5 to 5.0mm. The updated CCD vision system identifies various marks and performs automatic alignment corrections. A spindle reaching 80,000rpm minimizes cutting stress while maintaining superior accuracy. Dual platforms enable simultaneous handling of diverse products or combination into a single expansive area. An ion air gun clears static to keep dust away. Sensors monitor cutters in real time. The independent dust collector operates with strong suction yet minimal noise. User-friendly design promotes effortless daily performance in assembly heating PCB separator for mobile ipad applications.

| Feature

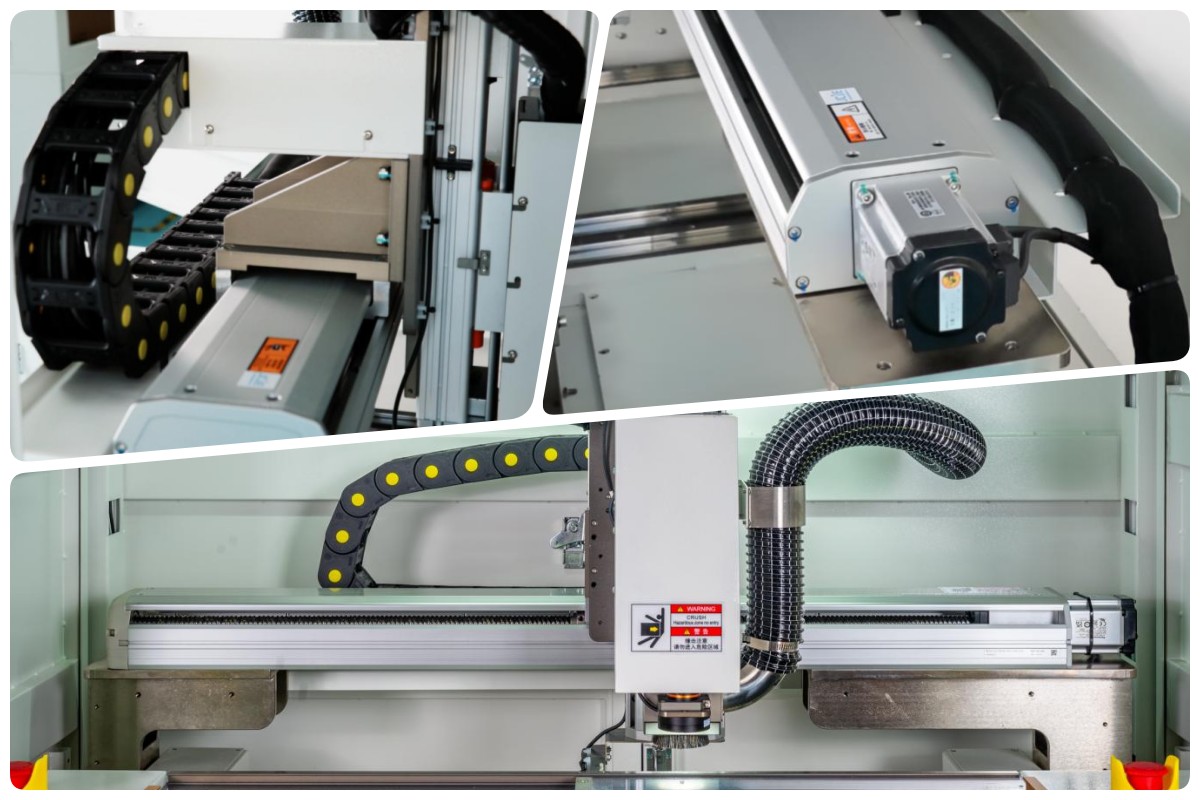

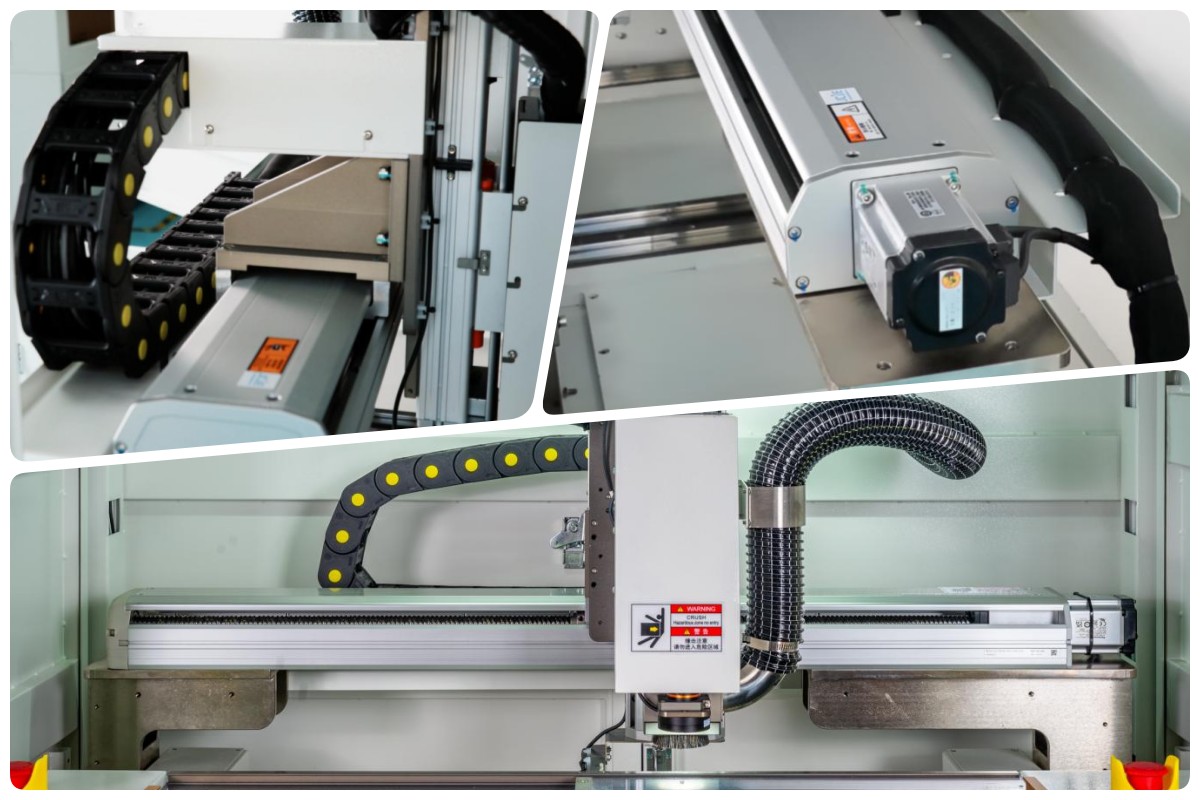

Transmission System

The X-axis features a specialized dust-proof structure that lowers maintenance requirements significantly. Flexible tank chains organize wiring neatly and prevent interference with motion. A robust, reinforced frame enhances overall operational stability. High-precision Taiwan guide rails and screw rods pair with imported Japanese Panasonic servo motors to deliver consistent, smooth movement. These integrated elements ensure the PCB separator maintains exceptional reliability across extended production runs in demanding environments.

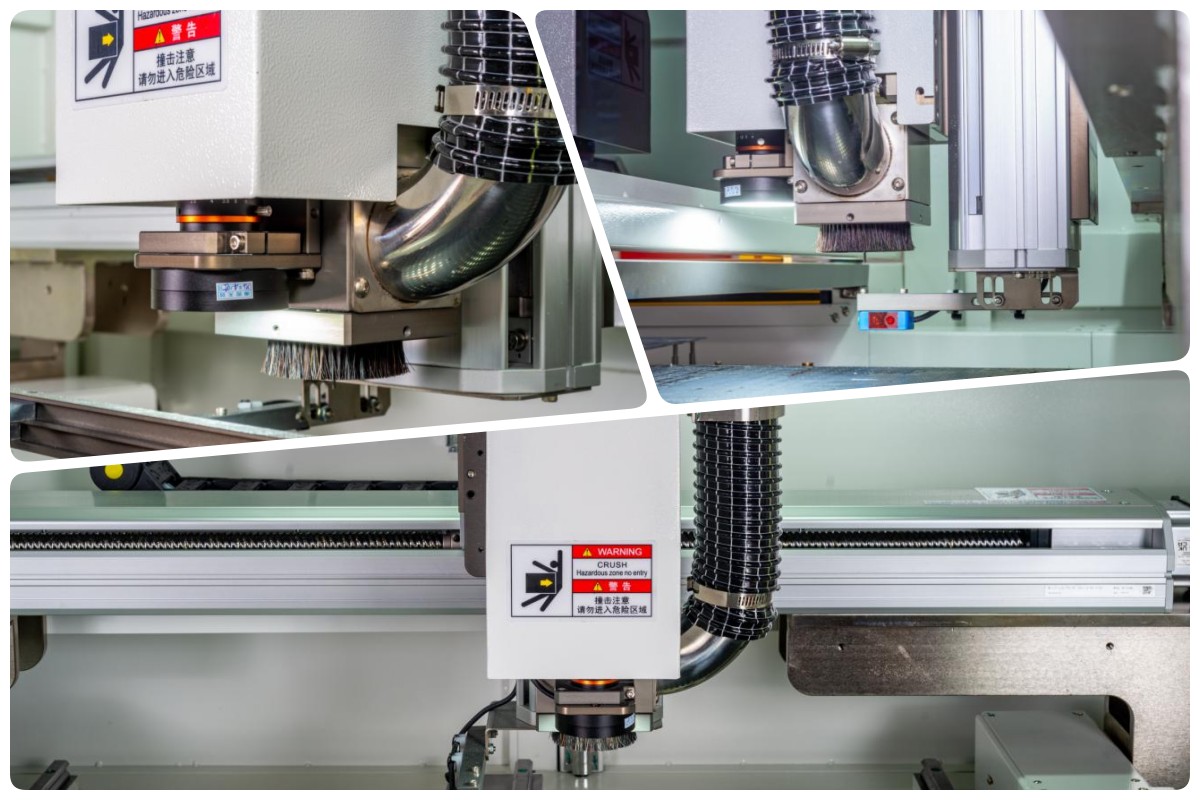

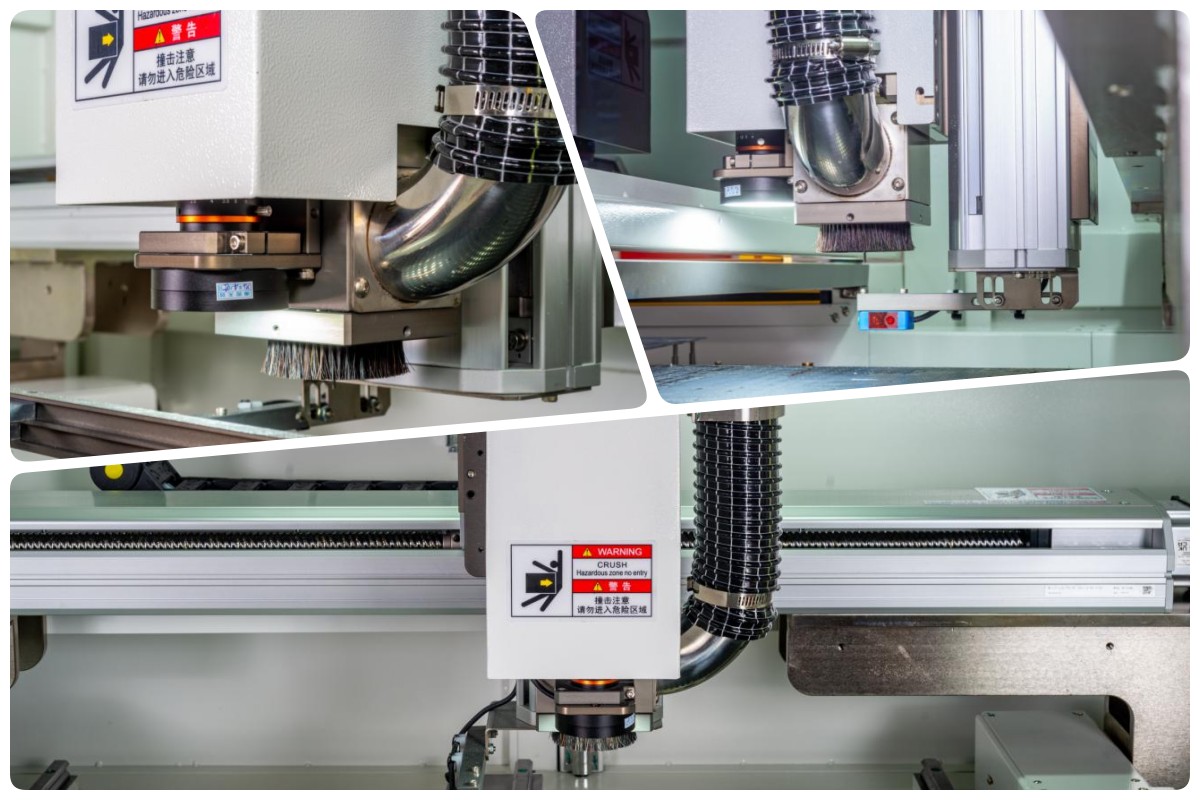

Router System

The high-speed imported spindle provides rapid response, minimal inertia, reduced stress, and outstanding precision during cuts. An ion air gun effectively removes static from board surfaces to avoid dust buildup. Optional automatic tool changing supports uninterrupted workflow for greater output. Immediate alarms activate upon detection of broken or worn tools. A high-definition CCD camera, aligned coaxially with the cutter, simplifies calibration and ensures exact positioning. This sophisticated setup makes the PCB separator a refined tool for flawless results.

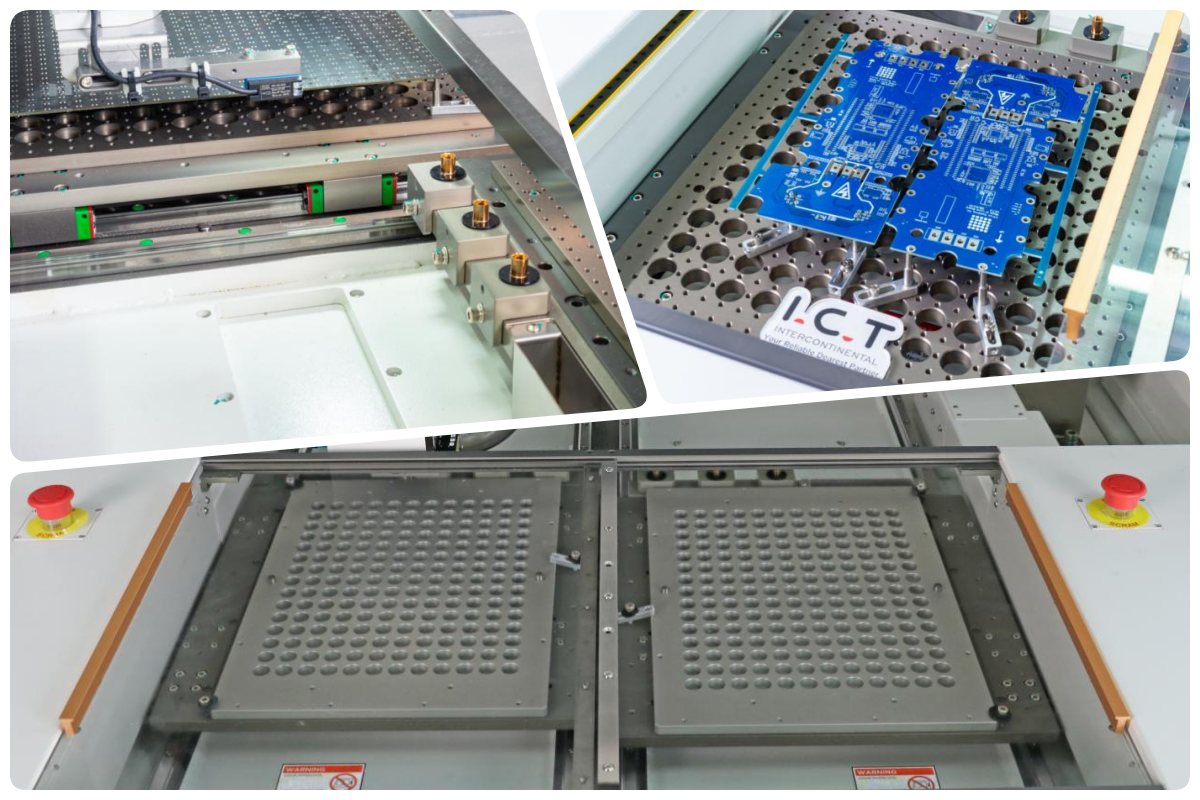

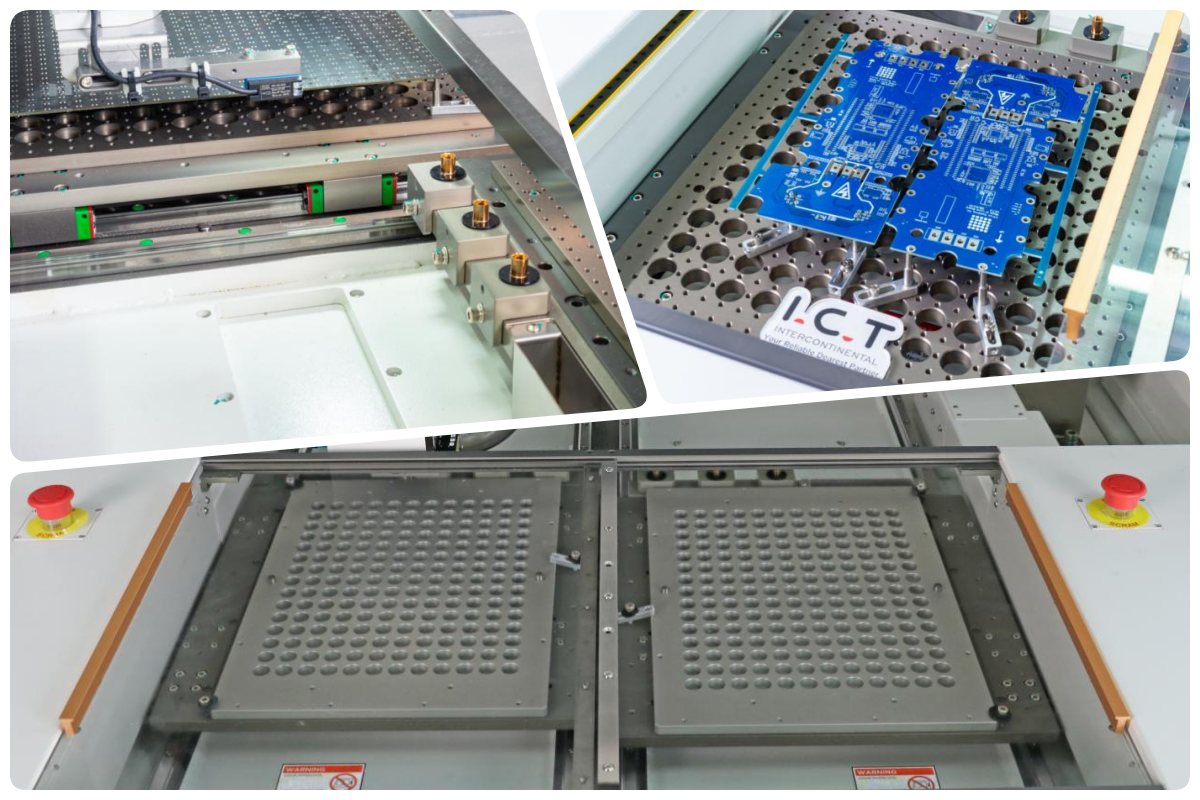

Platform System

The honeycomb base offers superior suction and broad compatibility with different boards. Dual platforms adapt easily to custom or standard fixtures. Simultaneous pressing of dual start buttons guarantees secure initiation. Comprehensive safety covers, light curtains, and bidirectional emergency stops protect operators fully. Servo motors and slide rails manage the Y-axis with unwavering steadiness. Such thoughtful engineering transforms the PCB separator into a safe and versatile asset for modern lines.

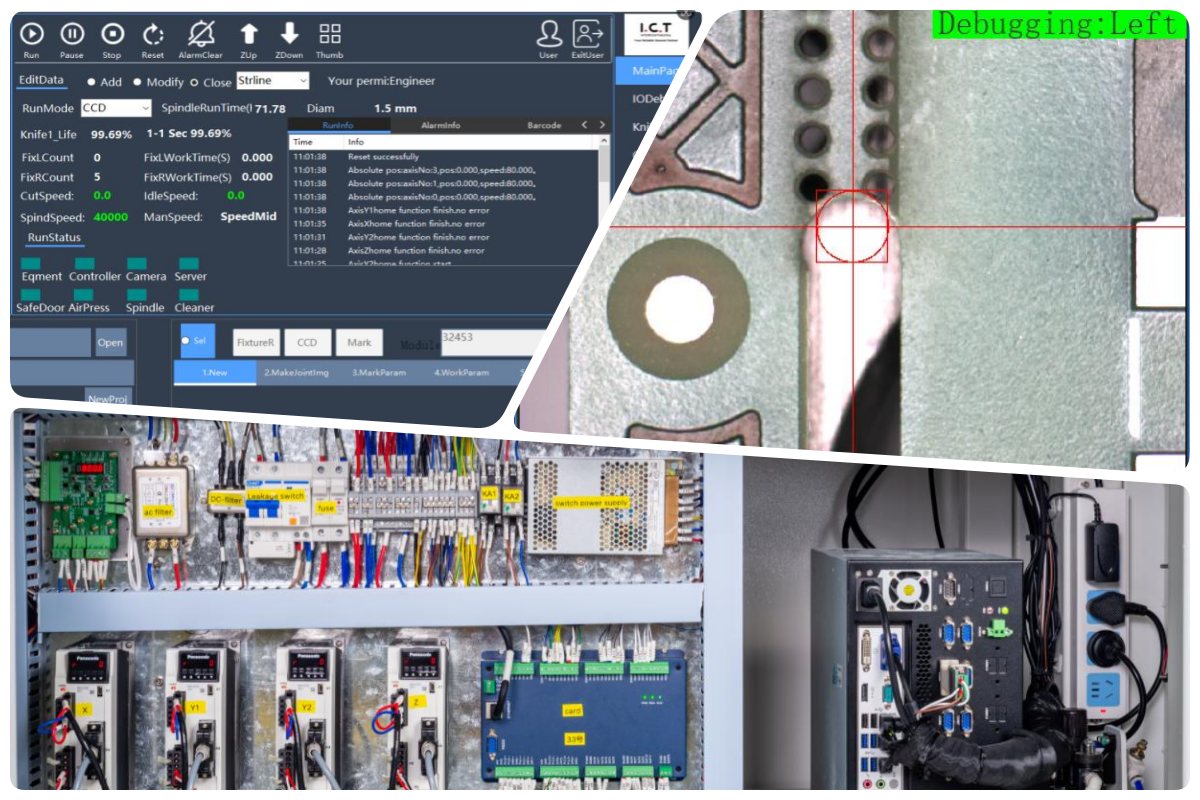

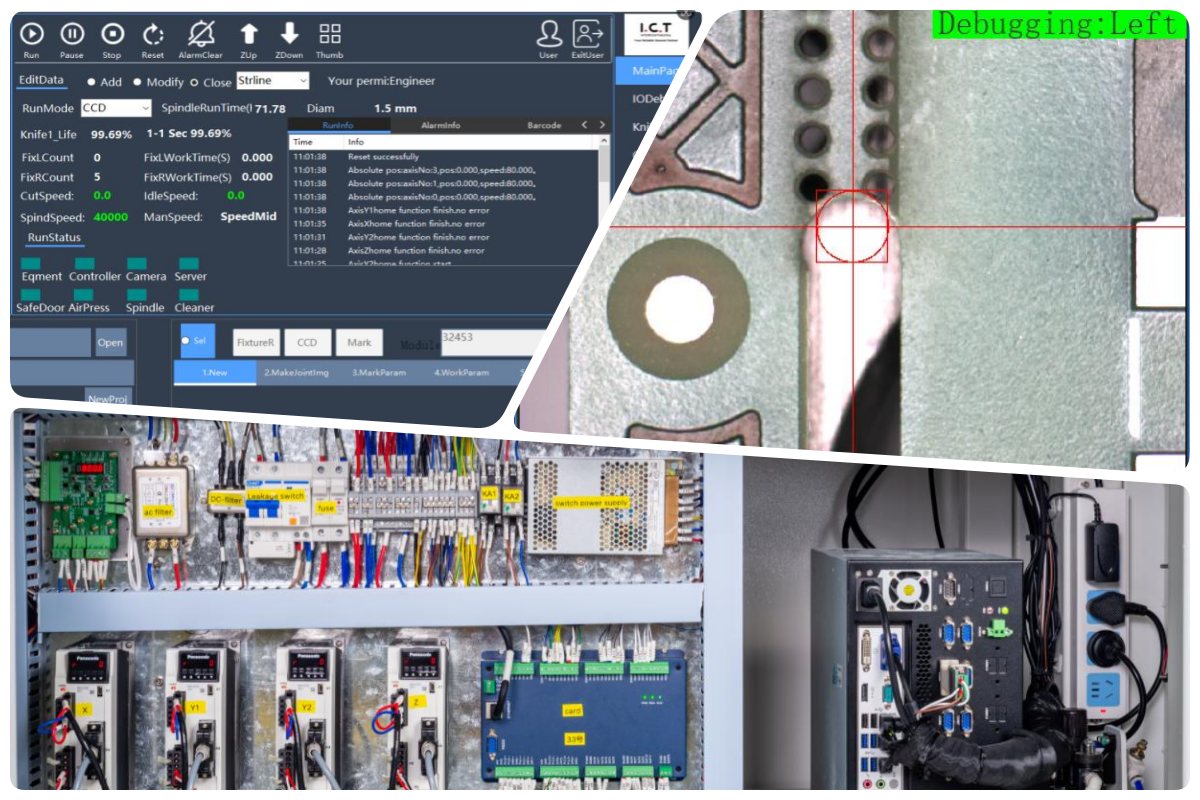

Control System

Coaxial CCD delivers clear real-time visuals for monitoring. The intuitive interface adheres to CE standards and facilitates rapid program switches. Comprehensive logs enable thorough production tracing. A robust CNC controller combined with an industrial computer resists interference effectively. Superior control precision and enduring stability define the system. This elegant control framework allows the PCB separator to perform with grace and consistency in daily operations.

Detail Display

Self-locking pneumatic struts secure doors firmly during access. Continuous monitoring occurs via the broken knife sensor. Optional auto tool changer facilitates seamless replacements. ESD interface safeguards components from static discharge. Side door sensors immediately halt activity if opened. Convection fan maintains balanced internal temperatures. These subtle yet essential details contribute to enhanced safety and user comfort in operating the PCB separator.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Conveyor | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

An Algerian client focused on feature phones traveled to our facility for thorough machine verification. They supplied over ten panels along with necessary components. Our engineers demonstrated a complete SMT process live. It began with automatic printing, followed by SPI inspection, small components placed via RX-8, larger ones by RS-1R, shield covers fed from trays, soldering in reflow, and AOI quality checks. The I.C.T PCB separator concluded with impeccable, clean separations. Smooth execution showcased impressive efficiency and superior outcomes. The visitors departed thoroughly impressed by the assembly heating PCB separator for mobile ipad performance.

| Service and Training Support

Global service networks provide swift responses to inquiries. Rapid spare parts delivery minimizes interruptions. Remote diagnostics resolve many concerns efficiently. On-site sessions cover installation, programming, tool management, and maintenance for the PCB separator. Skilled technicians ensure proper setup from the start. Continuous guidance optimizes long-term line performance. This dedicated approach builds lasting confidence and maximizes investment returns for customers worldwide.

| Client Testimonials

Customers frequently commend our engineers for prompt expertise and clear instructions. They highlight the consistent precision and superior finishes from our machines. Secure packaging and reliable transport deliver equipment undamaged. Immediate responses to concerns foster deep confidence. In summary, clients regard I.C.T as a leader in quality and supportive partnership.

| Certifications and Standards

Multiple patents underscore our innovative advancements. ISO9001 maintains rigorous quality protocols. RoHS verifies environmental responsibility. CE confirms complete safety adherence. These distinguished marks affirm that the PCB separator and all products achieve exceptional international standards reliably.

| About I.C.T Company and Factory

Advanced factories implement stringent testing and comprehensive quality systems. Extensive engineering staff supports in-house research and manufacturing. Rapid expansion has reached over 1600 clients across 72 countries. Each PCB separator undergoes meticulous inspections prior to delivery. Commitment to innovation and worldwide assistance sustains enduring successful collaborations.

| Precision Offline PCB Separator

This PCB separator serves industries such as smartphones, smart wearables, automotive electronics, medical devices, and aerospace. It accommodates board sizes ranging from 340×380mm to 450×600mm, with thicknesses of 0.5 to 5.0mm. The updated CCD vision system identifies various marks and performs automatic alignment corrections. A spindle reaching 80,000rpm minimizes cutting stress while maintaining superior accuracy. Dual platforms enable simultaneous handling of diverse products or combination into a single expansive area. An ion air gun clears static to keep dust away. Sensors monitor cutters in real time. The independent dust collector operates with strong suction yet minimal noise. User-friendly design promotes effortless daily performance in assembly heating PCB separator for mobile ipad applications.

| Feature

Transmission System

The X-axis features a specialized dust-proof structure that lowers maintenance requirements significantly. Flexible tank chains organize wiring neatly and prevent interference with motion. A robust, reinforced frame enhances overall operational stability. High-precision Taiwan guide rails and screw rods pair with imported Japanese Panasonic servo motors to deliver consistent, smooth movement. These integrated elements ensure the PCB separator maintains exceptional reliability across extended production runs in demanding environments.

Router System

The high-speed imported spindle provides rapid response, minimal inertia, reduced stress, and outstanding precision during cuts. An ion air gun effectively removes static from board surfaces to avoid dust buildup. Optional automatic tool changing supports uninterrupted workflow for greater output. Immediate alarms activate upon detection of broken or worn tools. A high-definition CCD camera, aligned coaxially with the cutter, simplifies calibration and ensures exact positioning. This sophisticated setup makes the PCB separator a refined tool for flawless results.

Platform System

The honeycomb base offers superior suction and broad compatibility with different boards. Dual platforms adapt easily to custom or standard fixtures. Simultaneous pressing of dual start buttons guarantees secure initiation. Comprehensive safety covers, light curtains, and bidirectional emergency stops protect operators fully. Servo motors and slide rails manage the Y-axis with unwavering steadiness. Such thoughtful engineering transforms the PCB separator into a safe and versatile asset for modern lines.

Control System

Coaxial CCD delivers clear real-time visuals for monitoring. The intuitive interface adheres to CE standards and facilitates rapid program switches. Comprehensive logs enable thorough production tracing. A robust CNC controller combined with an industrial computer resists interference effectively. Superior control precision and enduring stability define the system. This elegant control framework allows the PCB separator to perform with grace and consistency in daily operations.

Detail Display

Self-locking pneumatic struts secure doors firmly during access. Continuous monitoring occurs via the broken knife sensor. Optional auto tool changer facilitates seamless replacements. ESD interface safeguards components from static discharge. Side door sensors immediately halt activity if opened. Convection fan maintains balanced internal temperatures. These subtle yet essential details contribute to enhanced safety and user comfort in operating the PCB separator.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Conveyor | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

An Algerian client focused on feature phones traveled to our facility for thorough machine verification. They supplied over ten panels along with necessary components. Our engineers demonstrated a complete SMT process live. It began with automatic printing, followed by SPI inspection, small components placed via RX-8, larger ones by RS-1R, shield covers fed from trays, soldering in reflow, and AOI quality checks. The I.C.T PCB separator concluded with impeccable, clean separations. Smooth execution showcased impressive efficiency and superior outcomes. The visitors departed thoroughly impressed by the assembly heating PCB separator for mobile ipad performance.

| Service and Training Support

Global service networks provide swift responses to inquiries. Rapid spare parts delivery minimizes interruptions. Remote diagnostics resolve many concerns efficiently. On-site sessions cover installation, programming, tool management, and maintenance for the PCB separator. Skilled technicians ensure proper setup from the start. Continuous guidance optimizes long-term line performance. This dedicated approach builds lasting confidence and maximizes investment returns for customers worldwide.

| Client Testimonials

Customers frequently commend our engineers for prompt expertise and clear instructions. They highlight the consistent precision and superior finishes from our machines. Secure packaging and reliable transport deliver equipment undamaged. Immediate responses to concerns foster deep confidence. In summary, clients regard I.C.T as a leader in quality and supportive partnership.

| Certifications and Standards

Multiple patents underscore our innovative advancements. ISO9001 maintains rigorous quality protocols. RoHS verifies environmental responsibility. CE confirms complete safety adherence. These distinguished marks affirm that the PCB separator and all products achieve exceptional international standards reliably.

| About I.C.T Company and Factory

Advanced factories implement stringent testing and comprehensive quality systems. Extensive engineering staff supports in-house research and manufacturing. Rapid expansion has reached over 1600 clients across 72 countries. Each PCB separator undergoes meticulous inspections prior to delivery. Commitment to innovation and worldwide assistance sustains enduring successful collaborations.