I.C.T-5700

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Reliable High-Precision PCB Board CNC Router

This PCB board CNC router works in smartphones, wearables, automotive electronics, medical equipment, and aerospace. It handles boards from 340×380mm up to 450×600mm and thicknesses of 0.5 to 5.0mm. A new CCD vision system reads all marks and corrects position automatically. The spindle reaches 80,000rpm, cutting with minimal stress and high accuracy. Dual platforms process different products at once or join into one large platform. An ion air gun removes static so dust stays away. Tool sensors watch the cutter in real time. The separate dust collector runs quiet and strong. Operation stays simple and stable every day.

| Feature

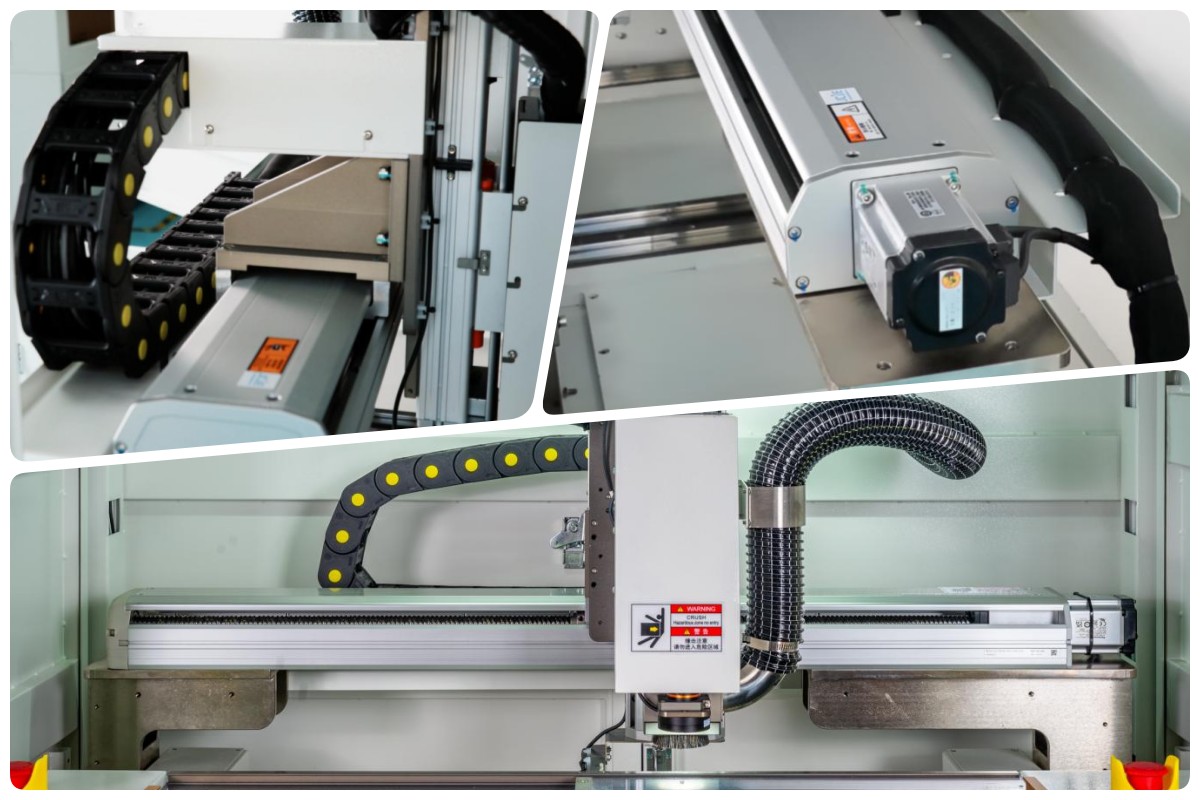

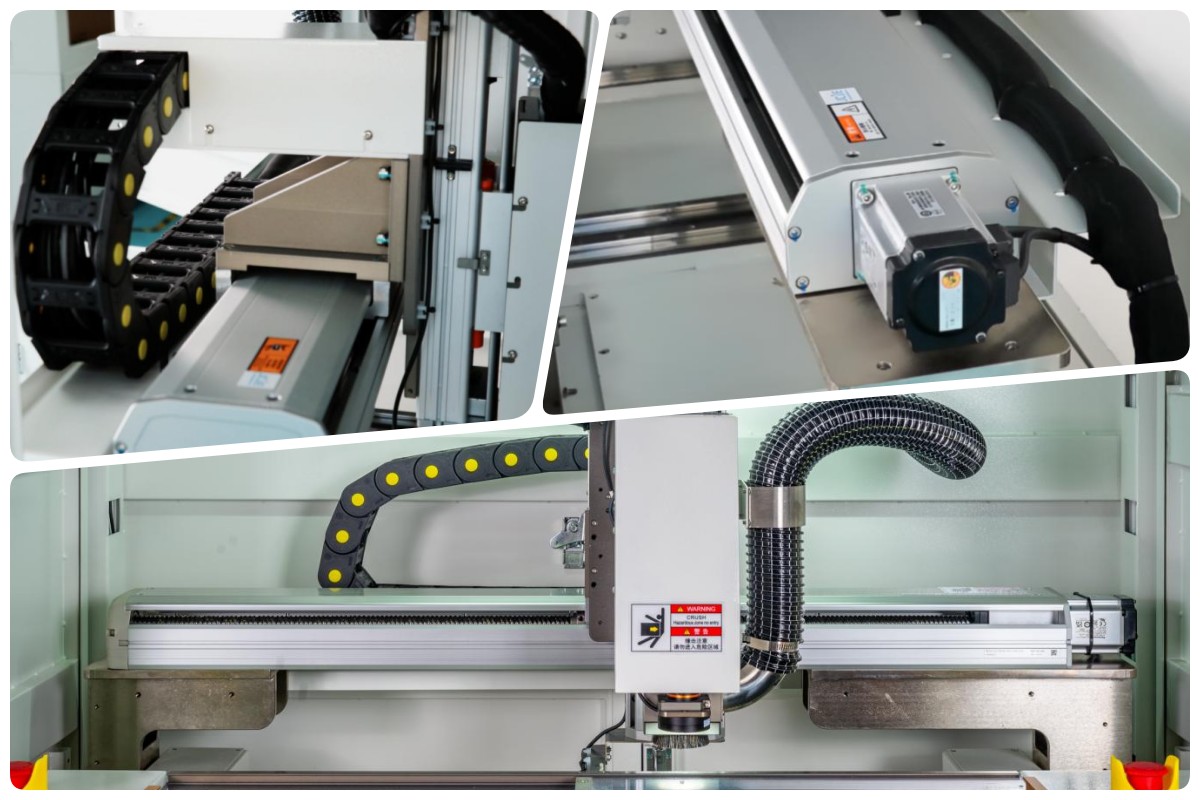

Transmission System

Panasonic servo motors from Japan drive high-precision screws and Taiwan-made guide rails. Movement stays smooth and exact. The thicker frame keeps everything steady during long runs. Flexible tank chains protect wires and look clean. A special dust-proof cover on the X-axis cuts down cleaning time and repair costs. These parts work together so the PCB board CNC router runs day after day without trouble. Maintenance stays low, and accuracy never drops.

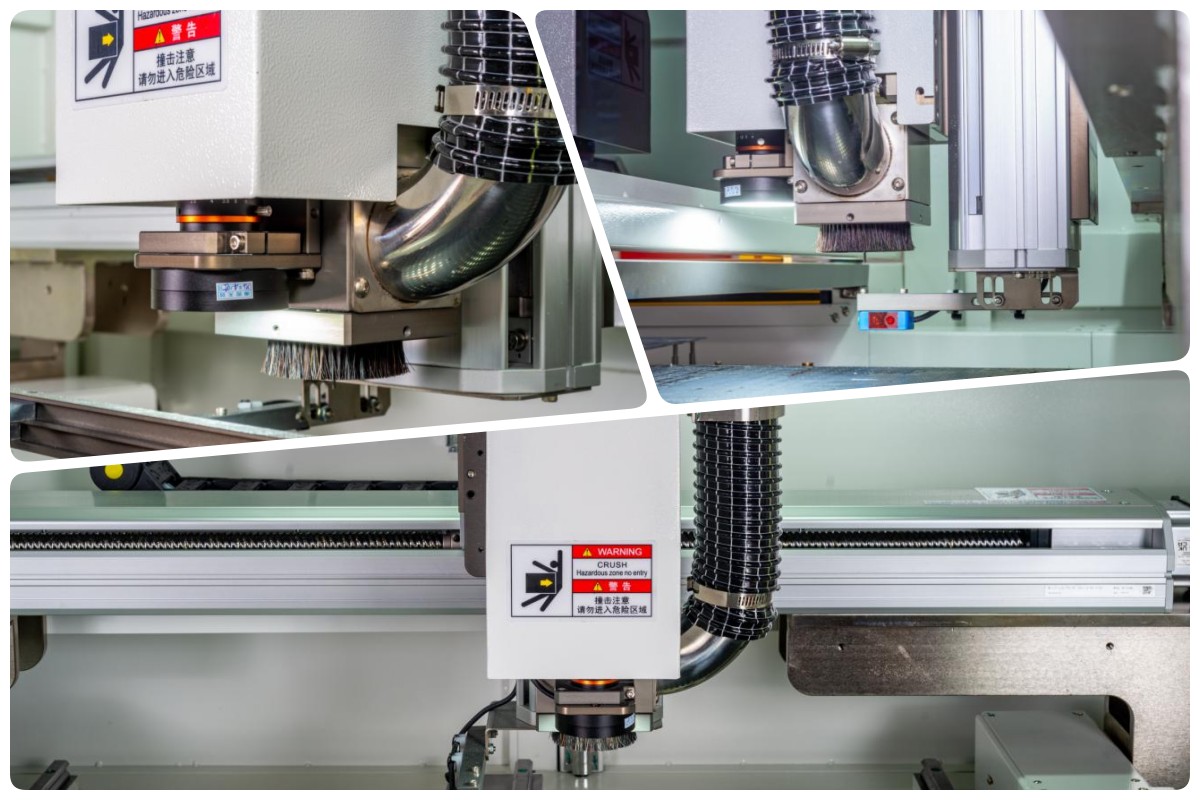

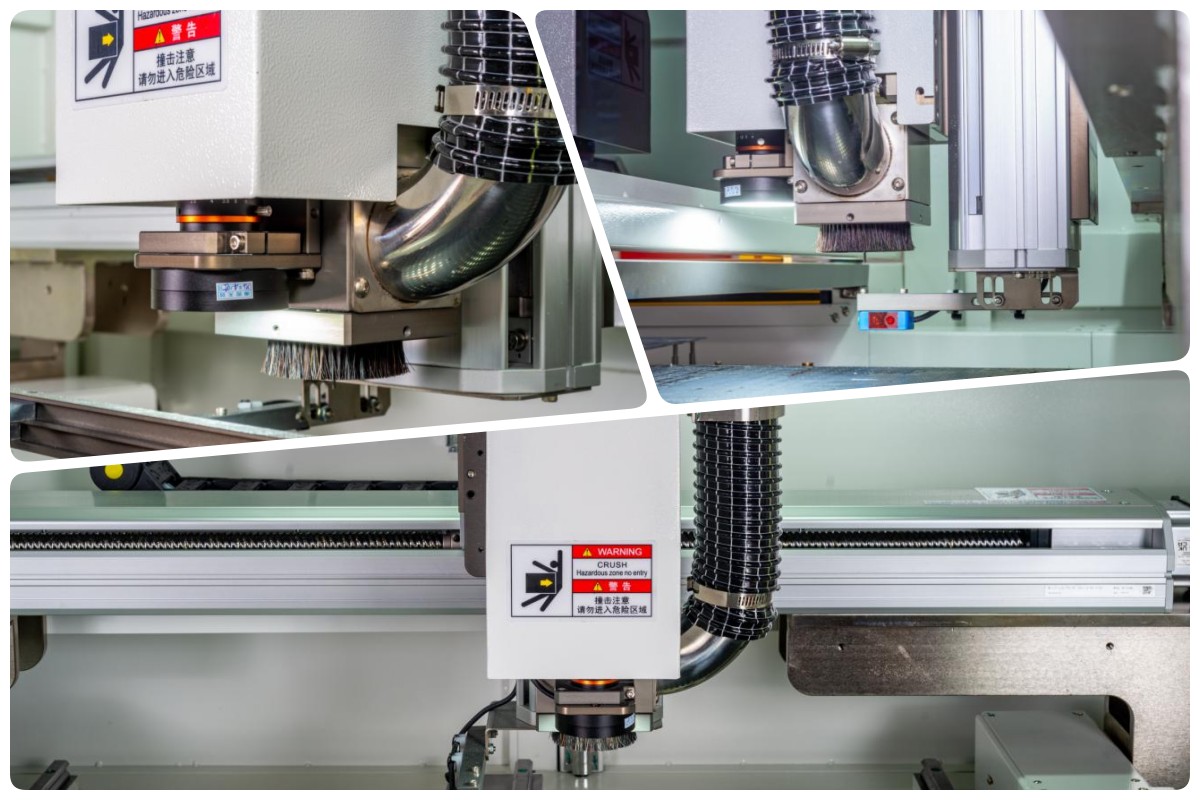

Router System

A clear CCD camera sits right over the cutter for fast, accurate setup. Broken tool detection sounds an alarm the moment something goes wrong. Optional auto tool change keeps production moving without pause. The ion air gun blows away static charge so dust cannot stick to boards. The imported high-speed spindle cuts clean with little force, quick response, and tight precision. Every cut on this PCB board CNC router comes out smooth and exact.

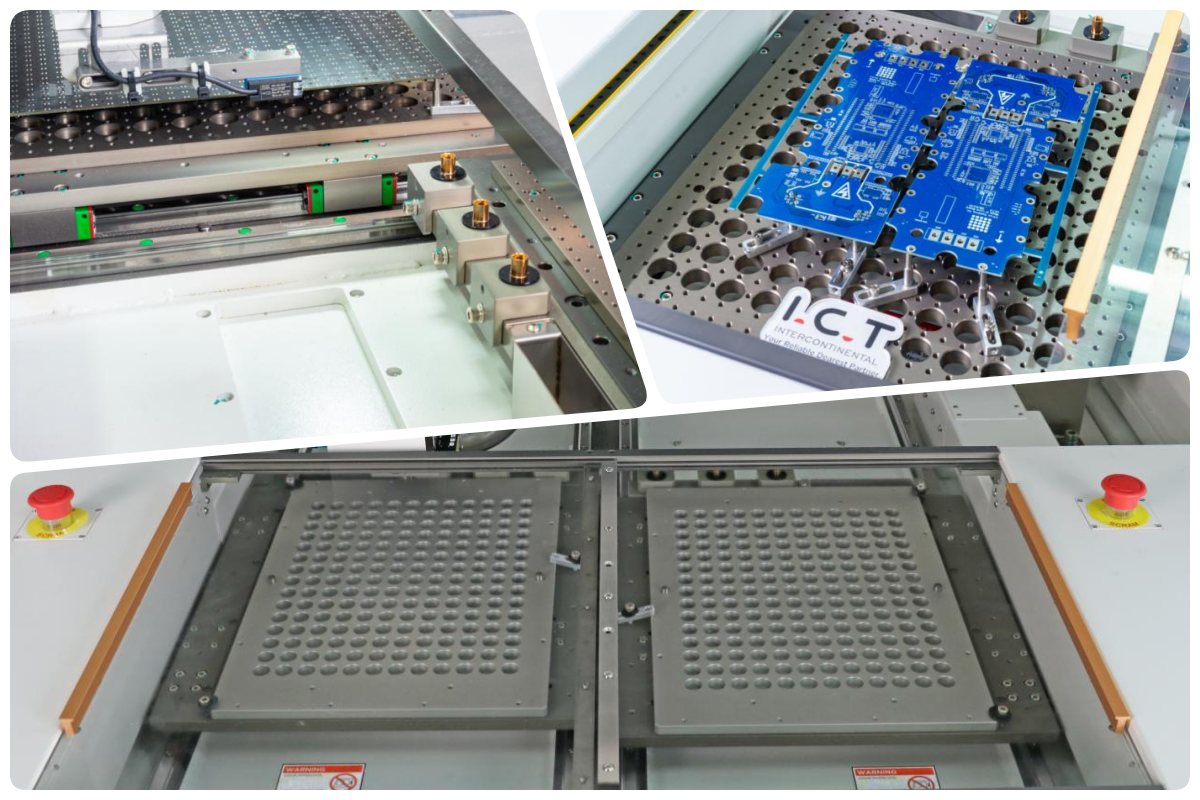

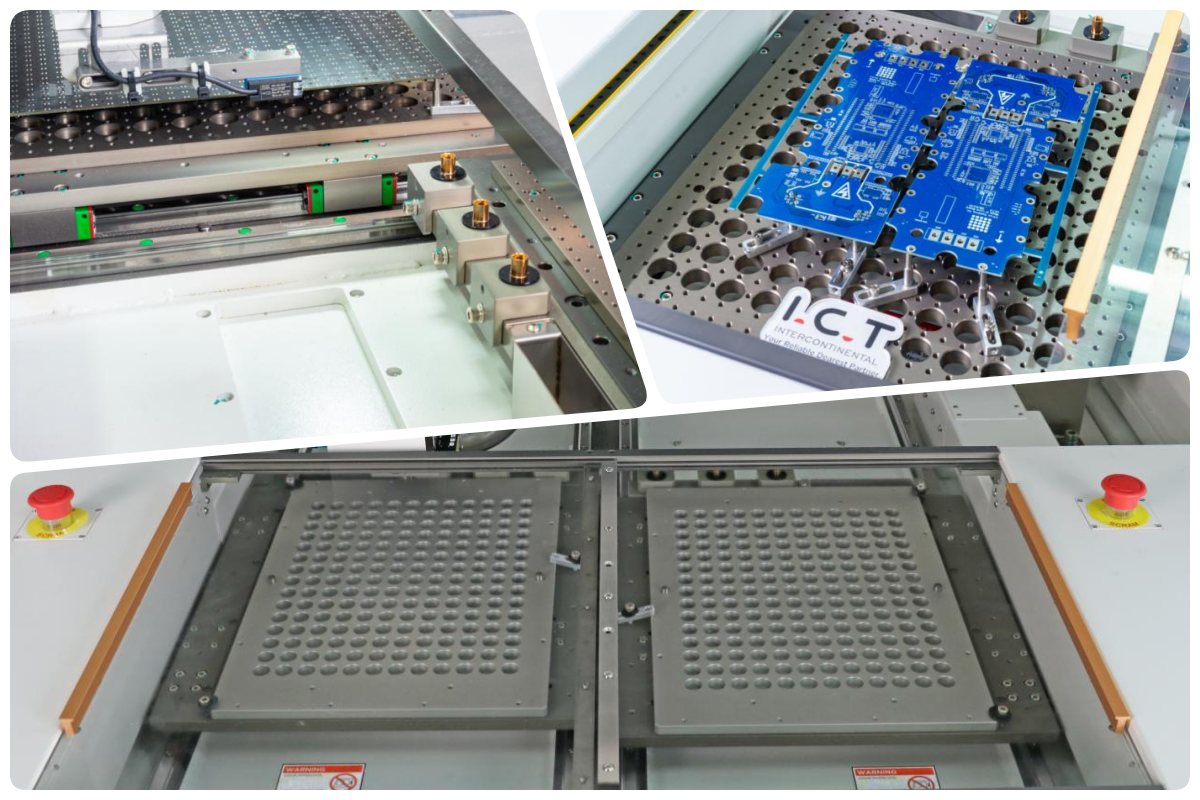

Platform System

Servo motors and slide rails control the Y-axis for rock-solid stability. Emergency stop buttons sit on both sides with full safety covers and light curtains. Operators must press two start buttons together to begin work. The honeycomb base holds boards firmly and fits many types. Dual platforms use special or standard fixtures easily. Safety and flexibility make this PCB board CNC router perfect for busy factories that need steady, secure operation.

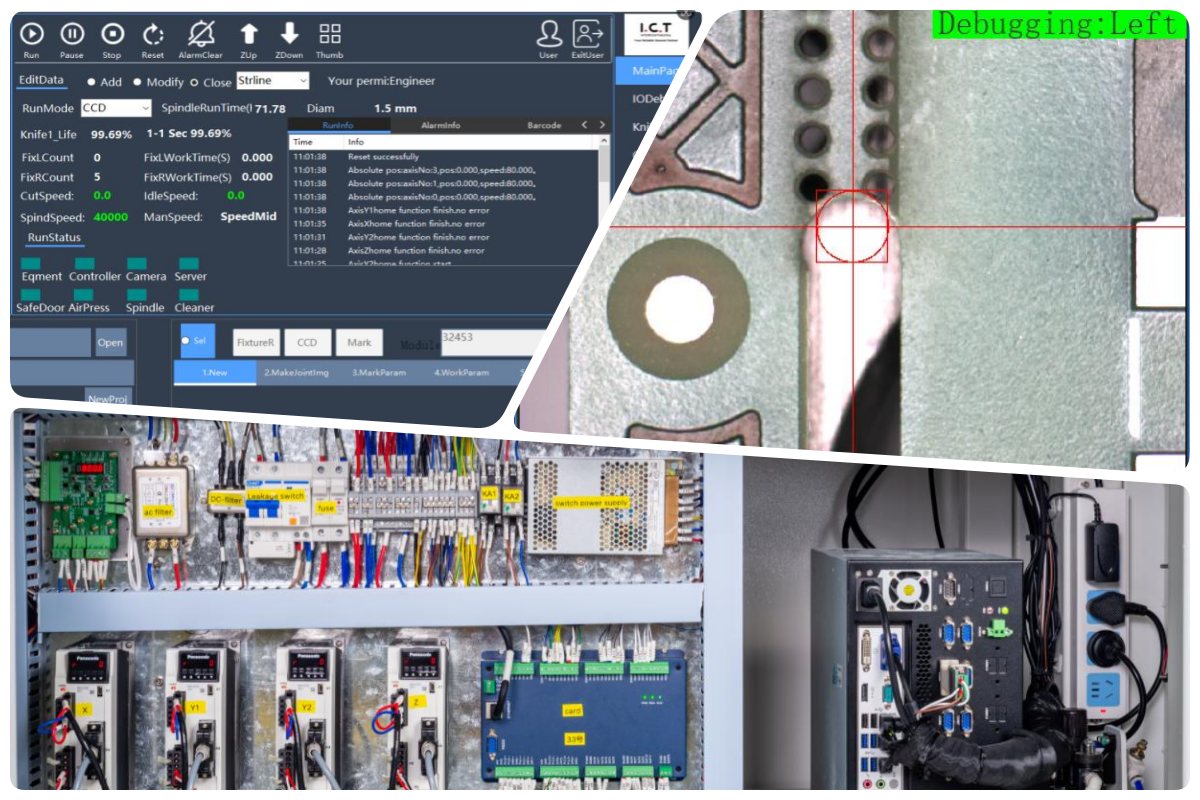

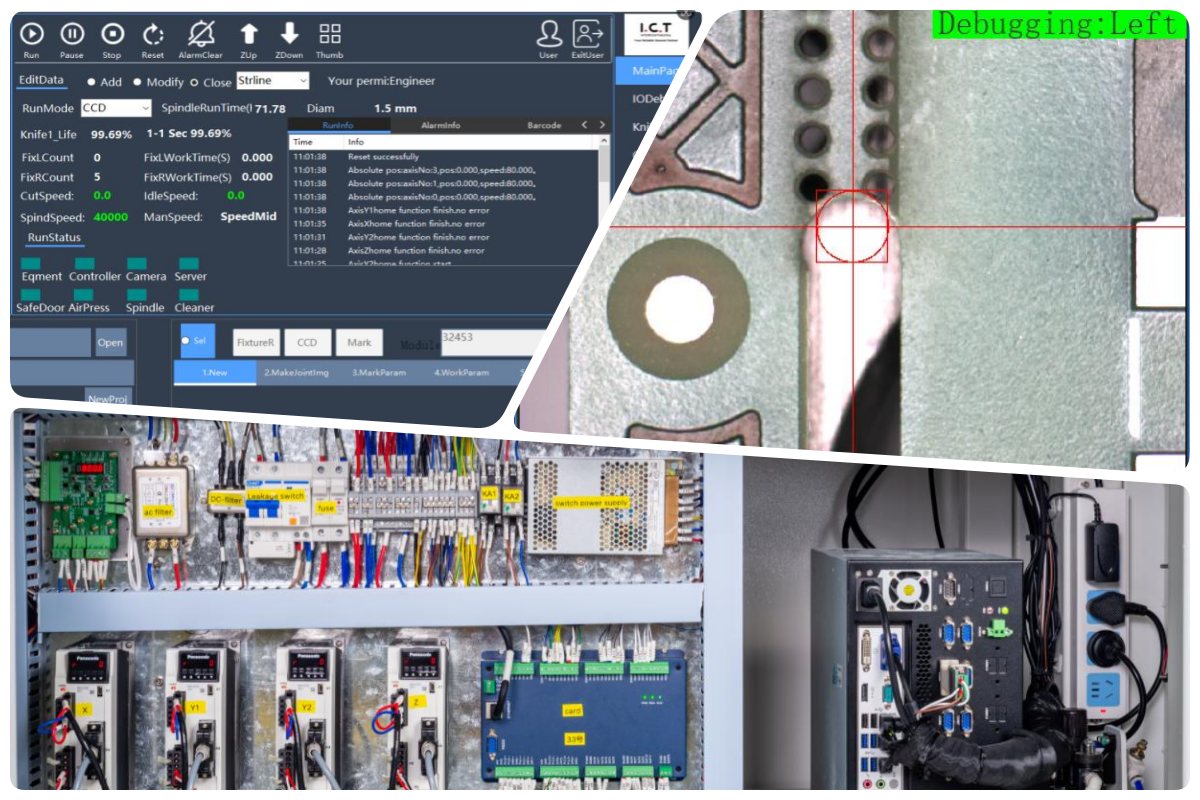

Control System

An industrial computer and dedicated CNC controller run the machine with strong resistance to factory noise. Data logs track every job for quality control. The simple screen follows CE rules and changes programs fast. Real-time CCD view shows exactly what happens. Operators learn quickly and keep consistent results. This control setup makes the PCB board CNC router easy to trust in daily production lines.

Detail Display

Small parts make big differences. A convection fan keeps temperature even. Side door sensors stop motion if opened. ESD connections protect sensitive parts from static. Optional auto tool changer swaps cutters without delay. Broken knife sensor watches wear constantly. Self-locking gas struts hold doors steady. Each detail adds safety and ease to the PCB board CNC router during regular use.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

An Algerian customer making feature phones came to our factory for acceptance testing. They brought more than ten panels and all needed components. We ran a complete SMT line in front of them. First, full automatic printing, then SPI check. Small parts went on the RX-8 placer, larger ones on the RS-1R. Tray feeder supplied shield covers. Reflow oven soldered everything. AOI inspected quality. Finally, the I.C.T PCB board CNC router separated boards with clean, precise cuts. The whole process flowed smoothly. The customer saw high efficiency and perfect results firsthand. They left fully satisfied.

| Service and Training Support

I.C.T sends skilled teams for installation and hands-on training at your site. Engineers teach safe operation, quick programming, tool handling, and daily checks for the PCB board CNC router. Remote help and fast spare parts delivery keep downtime short. Service centers around the world answer calls quickly. Regular updates and process advice help lines run better over time. Customers gain confidence and get the most value from their machine with this complete support system.

| Client Testimonials

Customers often praise our engineers for fast, clear solutions and deep knowledge. They like the steady precision and clean cuts from our machines. Safe packing and careful shipping arrive without damage every time. Quick answers to questions build real trust. Many say I.C.T equipment and support stand above others in the industry.

| Certifications and Standards

I.C.T earns CE for safety compliance, RoHS for environmental care, ISO9001 for strict quality systems, and multiple technology patents. These marks prove every machine meets high global standards. Customers can trust the design, build, and performance of products like the PCB board CNC router without worry.

| About I.C.T Company and Factory

I.C.T runs its own research, development, and production centers with many skilled engineers. The company has grown fast, now serving over 1600 customers across more than 72 countries. Modern factories follow tight testing steps and full quality control. Every machine, including each PCB board CNC router, passes careful checks before shipping. Focus stays on new ideas and strong worldwide service for long-term partner success.

| Reliable High-Precision PCB Board CNC Router

This PCB board CNC router works in smartphones, wearables, automotive electronics, medical equipment, and aerospace. It handles boards from 340×380mm up to 450×600mm and thicknesses of 0.5 to 5.0mm. A new CCD vision system reads all marks and corrects position automatically. The spindle reaches 80,000rpm, cutting with minimal stress and high accuracy. Dual platforms process different products at once or join into one large platform. An ion air gun removes static so dust stays away. Tool sensors watch the cutter in real time. The separate dust collector runs quiet and strong. Operation stays simple and stable every day.

| Feature

Transmission System

Panasonic servo motors from Japan drive high-precision screws and Taiwan-made guide rails. Movement stays smooth and exact. The thicker frame keeps everything steady during long runs. Flexible tank chains protect wires and look clean. A special dust-proof cover on the X-axis cuts down cleaning time and repair costs. These parts work together so the PCB board CNC router runs day after day without trouble. Maintenance stays low, and accuracy never drops.

Router System

A clear CCD camera sits right over the cutter for fast, accurate setup. Broken tool detection sounds an alarm the moment something goes wrong. Optional auto tool change keeps production moving without pause. The ion air gun blows away static charge so dust cannot stick to boards. The imported high-speed spindle cuts clean with little force, quick response, and tight precision. Every cut on this PCB board CNC router comes out smooth and exact.

Platform System

Servo motors and slide rails control the Y-axis for rock-solid stability. Emergency stop buttons sit on both sides with full safety covers and light curtains. Operators must press two start buttons together to begin work. The honeycomb base holds boards firmly and fits many types. Dual platforms use special or standard fixtures easily. Safety and flexibility make this PCB board CNC router perfect for busy factories that need steady, secure operation.

Control System

An industrial computer and dedicated CNC controller run the machine with strong resistance to factory noise. Data logs track every job for quality control. The simple screen follows CE rules and changes programs fast. Real-time CCD view shows exactly what happens. Operators learn quickly and keep consistent results. This control setup makes the PCB board CNC router easy to trust in daily production lines.

Detail Display

Small parts make big differences. A convection fan keeps temperature even. Side door sensors stop motion if opened. ESD connections protect sensitive parts from static. Optional auto tool changer swaps cutters without delay. Broken knife sensor watches wear constantly. Self-locking gas struts hold doors steady. Each detail adds safety and ease to the PCB board CNC router during regular use.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

An Algerian customer making feature phones came to our factory for acceptance testing. They brought more than ten panels and all needed components. We ran a complete SMT line in front of them. First, full automatic printing, then SPI check. Small parts went on the RX-8 placer, larger ones on the RS-1R. Tray feeder supplied shield covers. Reflow oven soldered everything. AOI inspected quality. Finally, the I.C.T PCB board CNC router separated boards with clean, precise cuts. The whole process flowed smoothly. The customer saw high efficiency and perfect results firsthand. They left fully satisfied.

| Service and Training Support

I.C.T sends skilled teams for installation and hands-on training at your site. Engineers teach safe operation, quick programming, tool handling, and daily checks for the PCB board CNC router. Remote help and fast spare parts delivery keep downtime short. Service centers around the world answer calls quickly. Regular updates and process advice help lines run better over time. Customers gain confidence and get the most value from their machine with this complete support system.

| Client Testimonials

Customers often praise our engineers for fast, clear solutions and deep knowledge. They like the steady precision and clean cuts from our machines. Safe packing and careful shipping arrive without damage every time. Quick answers to questions build real trust. Many say I.C.T equipment and support stand above others in the industry.

| Certifications and Standards

I.C.T earns CE for safety compliance, RoHS for environmental care, ISO9001 for strict quality systems, and multiple technology patents. These marks prove every machine meets high global standards. Customers can trust the design, build, and performance of products like the PCB board CNC router without worry.

| About I.C.T Company and Factory

I.C.T runs its own research, development, and production centers with many skilled engineers. The company has grown fast, now serving over 1600 customers across more than 72 countries. Modern factories follow tight testing steps and full quality control. Every machine, including each PCB board CNC router, passes careful checks before shipping. Focus stays on new ideas and strong worldwide service for long-term partner success.