D600 (LENS)

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Glue Dispenser for PCB – Raw Power on the Line

Speed 800 mm/s. Accuracy 0.015 mm screw, 0.01 mm motor. Panasonic servos roar quiet. Screws grind true. Vision camera grabs Mark points cold. Valve pumps exact glue. Preheats on its own. Syringes click in 30 seconds. The glue dispenser PCB conformal coating machine runs nonstop. LED lenses sealed. Medical boards clean. Red glue perfect. Yield 99.5 plus locked in. Downtime zero. Factories scream for more. We ship.

| Detailed Product Features

Valve snaps open. Glue drops dead same weight. Servo drives hard. Screw repeats forever. Preheats 0.1 C tight. Red glue. UV. Hot melt. All obey. Syringe change 60 seconds. Purge blasts clean 8 seconds. No strings. No waste. The glue dispenser for PCB bonds lenses solid every run.

Belts roll anti-static. Motors split drive. Board enters. Stop bar crashes down. Board pins center. Rails shift width. Parallel 0.02 mm locked. 50 to 600 mm square. 5 kg. 300 mm/s any way. The glue dispenser PCB conformal coating machine feeds the line perfect. No slip.

One button smash. 8 seconds valve clean. Temp holds viscosity iron. No clogs ever. The glue dispenser for PCB ready again fast.

PLC PC scream together. Panasonic Omron Schneider muscle. CE stamped hard. 4.0 wired. MES open. Add 3D UV tomorrow – software hungry. Screen huge. Buttons simple. New operator full throttle hour one. The glue dispenser for PCB runs 24/7 brutal.

| Specification

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

| SMT Line Equipment List

Loader slams. Glue dispenser for PCB blasts perfect dots 800 mm/s. Pick place drops lenses on wet glue. IR UV oven slams cure seconds. AOI scans optional. SMEMA chain tight. 1-2 operators chill. Yield 99.5 locked. Uptime savage. Auto medical LED. Standards crushed. Costs gutted. Profits explode. One complete glue dispenser PCB conformal coating machine line. You hit start. Money rains.

| Product Name | Purpose in Glue Dispensing Line |

|---|---|

| Glue Dispensing Machine | Delivers high-speed, ultra-precise glue dispensing |

| Conformal Coating Machine | Applies final protective coating for reliability |

| Pick and Place Machine | Accurately places components onto fresh glue |

| Curing Oven | Rapidly cures glue with IR or UV technology |

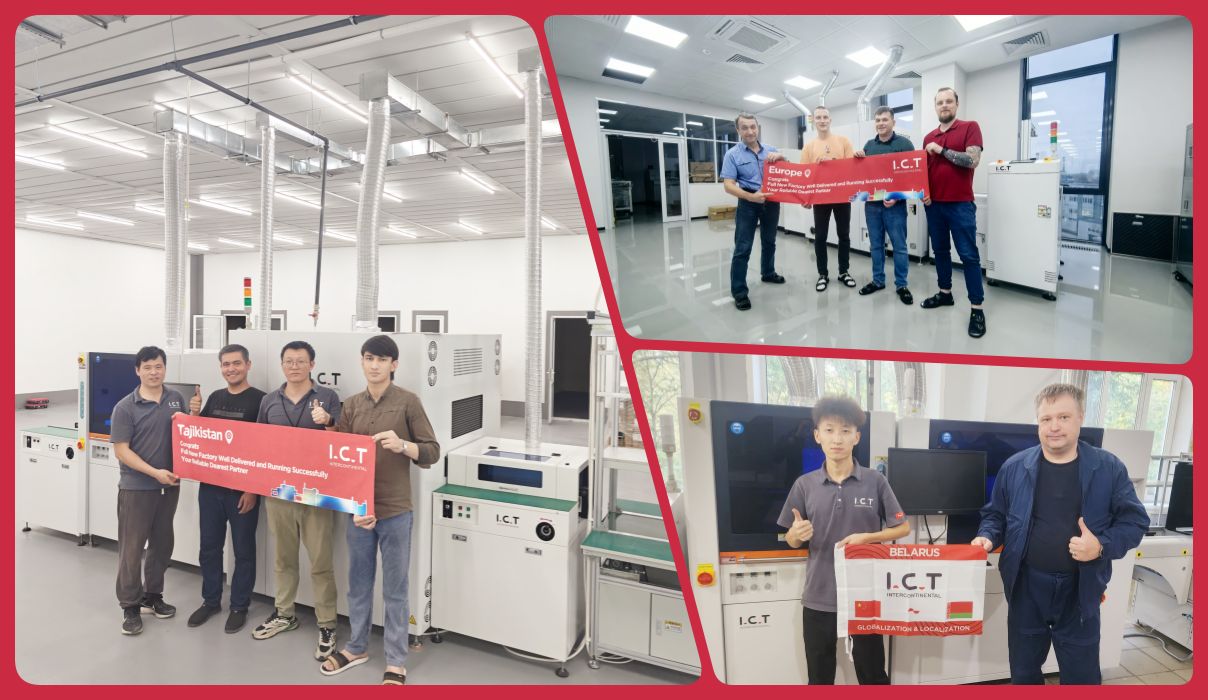

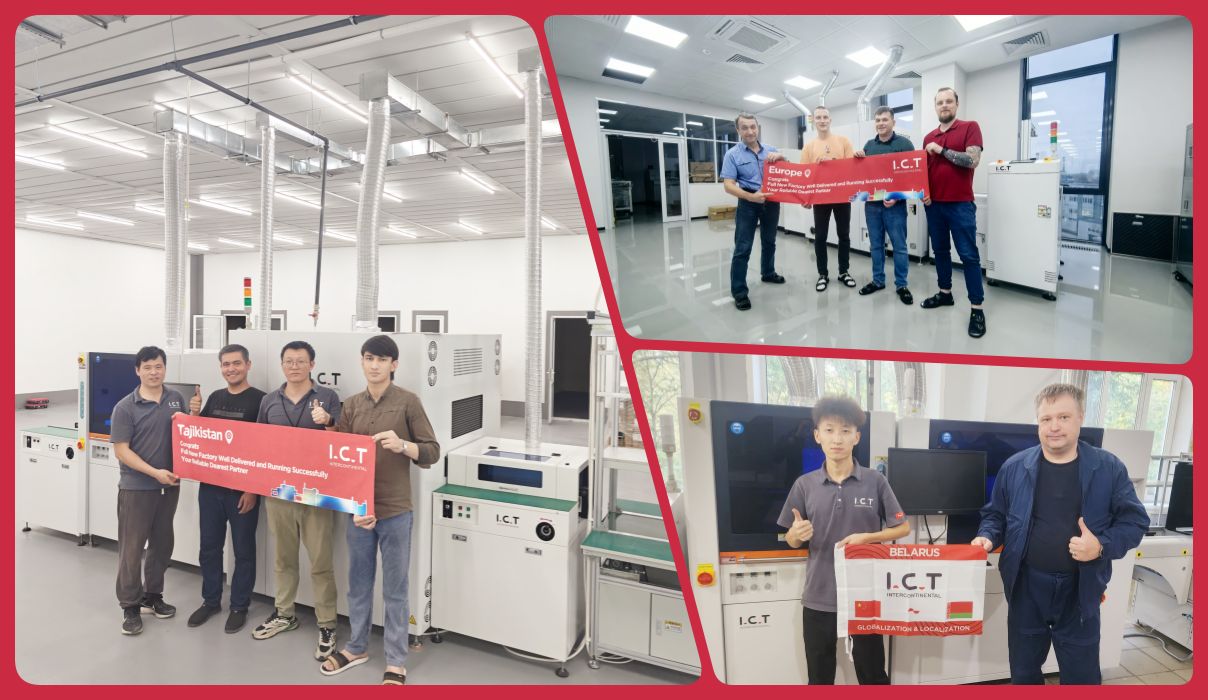

| Customer Success Story

Two I.C.T engineers hit Dushanbe dirt. Customer bought two SMT lines, one DIP, one coating, one glue line, one full LED bulb line. Crates ripped open. Machines bolted. Glue dispenser for PCB fired first dots – dead on. Lenses placed. Ovens cured. AOI passed. Ten days local crew owned it. Customer on camera: “I.C.T talked big and delivered bigger.” Output doubled. Defects dead.

| Professional Training & Support

We roll in with the glue dispenser for PCB. Stay till your crew kicks us out. Remote team nails 80 % before you blink. Parts fly same day. Tech boots on ground 48 hours anywhere. Updates free forever. Tuning free. The glue dispenser PCB conformal coating machine makes cash from day one.

| Customer Praise

“Engineers owned every inch.”“Lenses glued eternal.”“Crate survived 10 000 km clean.”“Fixed at 2 a.m. China clock.”“Line pounding seventeen months straight.”

| Our Certification

CE. RoHS. ISO9001. Patents ironclad. Every glue dispenser for PCB ships full test sheet and serial burn. Customs waves through.

| About Us and Factory

Dongguan. 12 000 m². 89 bodies. 20 engineers. 30 million capital. 2012 kickoff. 1 600 customers. 72 countries. Every glue dispenser for PCB tortured full load before release. Quality never sleeps.

| Glue Dispenser for PCB – Raw Power on the Line

Speed 800 mm/s. Accuracy 0.015 mm screw, 0.01 mm motor. Panasonic servos roar quiet. Screws grind true. Vision camera grabs Mark points cold. Valve pumps exact glue. Preheats on its own. Syringes click in 30 seconds. The glue dispenser PCB conformal coating machine runs nonstop. LED lenses sealed. Medical boards clean. Red glue perfect. Yield 99.5 plus locked in. Downtime zero. Factories scream for more. We ship.

| Detailed Product Features

Valve snaps open. Glue drops dead same weight. Servo drives hard. Screw repeats forever. Preheats 0.1 C tight. Red glue. UV. Hot melt. All obey. Syringe change 60 seconds. Purge blasts clean 8 seconds. No strings. No waste. The glue dispenser for PCB bonds lenses solid every run.

Belts roll anti-static. Motors split drive. Board enters. Stop bar crashes down. Board pins center. Rails shift width. Parallel 0.02 mm locked. 50 to 600 mm square. 5 kg. 300 mm/s any way. The glue dispenser PCB conformal coating machine feeds the line perfect. No slip.

One button smash. 8 seconds valve clean. Temp holds viscosity iron. No clogs ever. The glue dispenser for PCB ready again fast.

PLC PC scream together. Panasonic Omron Schneider muscle. CE stamped hard. 4.0 wired. MES open. Add 3D UV tomorrow – software hungry. Screen huge. Buttons simple. New operator full throttle hour one. The glue dispenser for PCB runs 24/7 brutal.

| Specification

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

| SMT Line Equipment List

Loader slams. Glue dispenser for PCB blasts perfect dots 800 mm/s. Pick place drops lenses on wet glue. IR UV oven slams cure seconds. AOI scans optional. SMEMA chain tight. 1-2 operators chill. Yield 99.5 locked. Uptime savage. Auto medical LED. Standards crushed. Costs gutted. Profits explode. One complete glue dispenser PCB conformal coating machine line. You hit start. Money rains.

| Product Name | Purpose in Glue Dispensing Line |

|---|---|

| Glue Dispensing Machine | Delivers high-speed, ultra-precise glue dispensing |

| Conformal Coating Machine | Applies final protective coating for reliability |

| Pick and Place Machine | Accurately places components onto fresh glue |

| Curing Oven | Rapidly cures glue with IR or UV technology |

| Customer Success Story

Two I.C.T engineers hit Dushanbe dirt. Customer bought two SMT lines, one DIP, one coating, one glue line, one full LED bulb line. Crates ripped open. Machines bolted. Glue dispenser for PCB fired first dots – dead on. Lenses placed. Ovens cured. AOI passed. Ten days local crew owned it. Customer on camera: “I.C.T talked big and delivered bigger.” Output doubled. Defects dead.

| Professional Training & Support

We roll in with the glue dispenser for PCB. Stay till your crew kicks us out. Remote team nails 80 % before you blink. Parts fly same day. Tech boots on ground 48 hours anywhere. Updates free forever. Tuning free. The glue dispenser PCB conformal coating machine makes cash from day one.

| Customer Praise

“Engineers owned every inch.”“Lenses glued eternal.”“Crate survived 10 000 km clean.”“Fixed at 2 a.m. China clock.”“Line pounding seventeen months straight.”

| Our Certification

CE. RoHS. ISO9001. Patents ironclad. Every glue dispenser for PCB ships full test sheet and serial burn. Customs waves through.

| About Us and Factory

Dongguan. 12 000 m². 89 bodies. 20 engineers. 30 million capital. 2012 kickoff. 1 600 customers. 72 countries. Every glue dispenser for PCB tortured full load before release. Quality never sleeps.