Ceiling LED Light Assembly Line Machine

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| LED Assembly Line Machine Spotlight

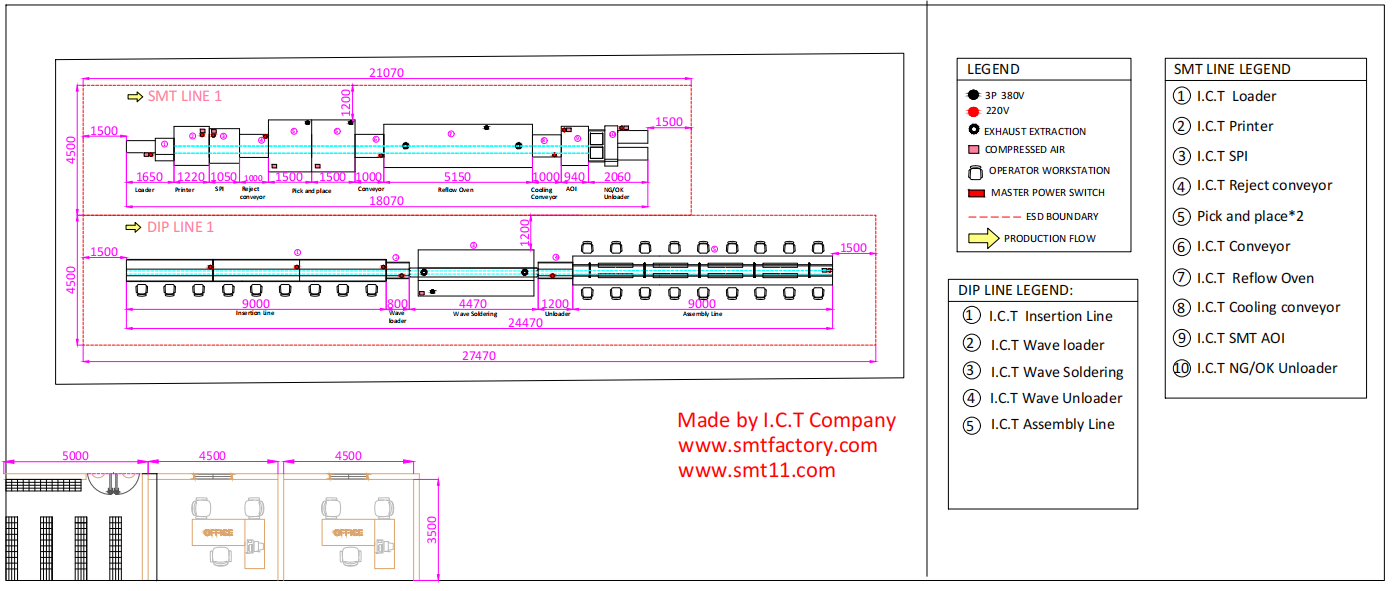

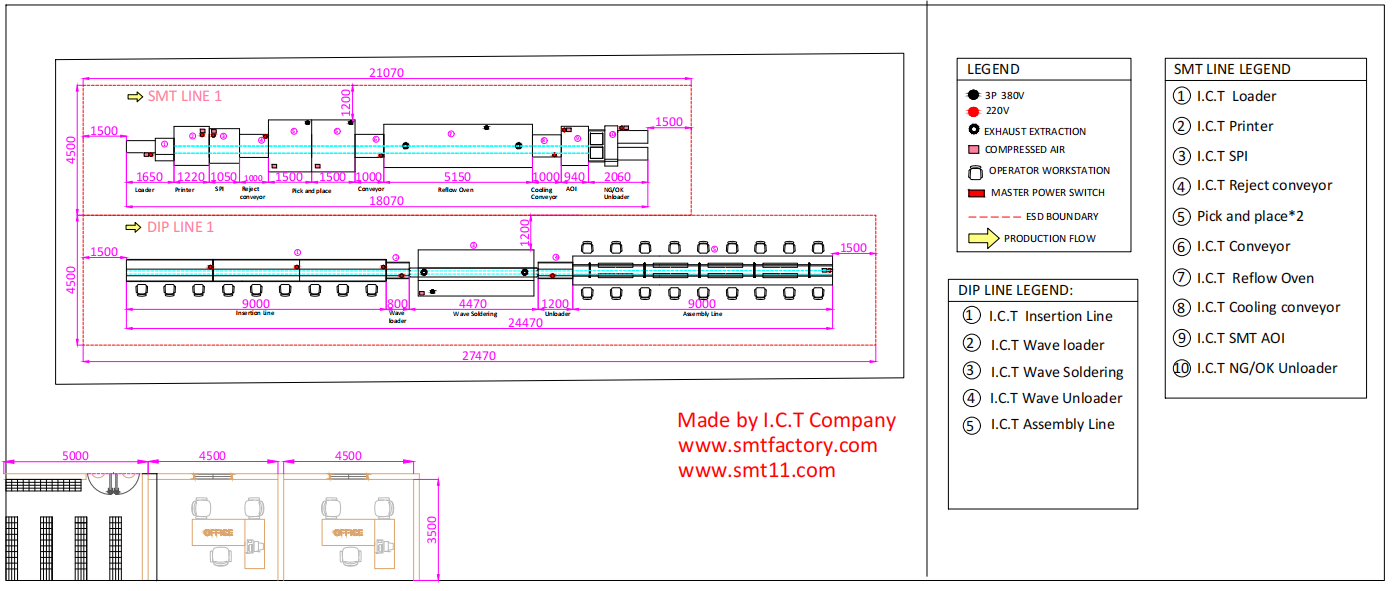

I.C.T delivers LED assembly line machine through three owned factories and 22+ years SMT/DIP expertise, covering factory designs, layouts, manpower forecasts, ROI projections for LED ceiling panels. Semi-auto or full-auto lines feature loaders, printers, placers, reflow ovens, AOI, unloaders. One operator manages shifts. 18Kw/H for eco operations. Clients include LED fixture, panel, ceiling light producers worldwide. 3-day setup includes air, power, exhaust, lighting, 23±1.5°C controls. 7-15 days involve software, upkeep, safety, fixes. 15+ years overseas service. Led Panel Ceiling Light Assembly Line incorporates MES, IoT for intelligent factories. Turnkey accelerates LED ventures, offers flexibility, minimizes risks for startups or leaders in lighting industry with dependable quality, professional guidance, ongoing optimizations, and successful implementations across varied environments.

| Detailed Product Features

Seamless Automation Flow

LED assembly line machine integrates stations with MES for live tracking, yield boosts, refinements in ceiling LED panel assembly. Loaders adjust to panel sizes. Printers apply paste vision-accurate on LED arrays or drivers. Placers handle 01005 LEDs rapidly. Reflow sustains ±1.5°C for solid joints. AOI detects issues AI-smart. Unloaders route forward. Yields improve 25%+ in PCB Assembly Line. Adapts to ceiling fixtures or strips. Buffers maintain balance, remote dashboards oversee, auto recipes switch seamlessly, traceability monitors components for multiple LED designs, simplifying changes, ensuring compliance, enhancing throughput in volume production with provisions for unique patterns, fast modifications, integrated verifications, and scheduled maintenance routines.

Accurate Paste System

Printers in LED assembly line machine align stencils micron-level, support frames for panel dimensions. Quick swaps cut downtime. Auto dispense/clean ensure consistency. 3D SPI checks paste to prevent early defects. Vital for LED controllers or beads. Compatible with pastes, low-melt for delicate LED optics. Squeegee adapts for uniform coverage on irregular surfaces, increasing reliability, reducing rejects, permitting quick adaptations in emerging LED technologies with consistent performance, improved speed, minimal corrections, and greater output per cycle.

Reliable Reflow Process

Ovens include 12+ zones with independent convection for balanced heating in Led Panel Ceiling Light Assembly Line. Nitrogen produces durable joints for LED power or lights. Profiles auto-tune to requirements. Cooling avoids damage in large panels. Recovery supports 18Kw/H. Screens hold extensive recipes. Essential for LED longevity in ceilings. Conveyors sync MES for optimal speeds, variable adjustments, embedded sensors to avoid interruptions in continuous operations, smooth transitions, support high-capacity runs, and feature energy-efficient settings.

Smart Inspection Tools

AOI captures 8K scans at pace, identifying misalignments or solder problems in panels. AI learns from production. Feedback corrects placers instantly. Minimizes escapes in LED assembly line machine. Analytics facilitate improvements. Auto rejects handle without stopping, record data for audits and rapid fixes in diverse lines with reduced halts, enhanced logging, and automated summaries.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| Pick and Place Machine | Mounts components onto PCB precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

Algerian mobile manufacturer arrived for acceptance demonstration. They provided over ten PCBs and components; our team executed on-site assembly. Full-auto printer deposited paste precisely. SPI inspected volumes accurately. RX-8 mounted small elements swiftly. RS-1R placed larger parts correctly. Tray feeder supplied shields uninterrupted. Reflow fused connections solidly. AOI scanned for perfection. 5700 separator divided panels cleanly. Successful execution illustrated efficiency, synchronization for mobile/LED parallels. Aligns with Led Panel Ceiling Light Assembly Line principles. Clients verified specifications, commended seamless operation, intend similar LED assembly line machine locally with PCB Assembly Line for efficient expansion, uniform standards, increased volumes, and adaptability in future projects.

| Service and Training

Project managers oversee LED assembly line machine from planning to upgrades. 3-day installation: validations, test runs, calibrations. 7-15 day curriculum: MES interfaces, panel operations, defect analysis, routine care, safety measures. IoT provides predictive warnings, remote troubleshooting. Spare parts available from 8 global warehouses. 15-year international experience, multilingual support. Annual evaluations, software enhancements ensure sustained performance for reliable LED output, capacity increases, market shifts with proactive measures, specialized knowledge, and personalized advancement strategies.

| Customer Praise

Customers highlight rapid 2-hour remote interventions for LED assembly line machine. Reflow units operate reliably non-stop. Protective packaging withstands shipping. Service exceeds commitments consistently. PCB Assembly Line achieves massive production without issues. Intuitive controls enable quick staff proficiency in LED scenarios with straightforward navigation, rapid comprehension, and practical resources for immediate expertise.

| Accreditation Standards

CE certification meets safety requirements. RoHS guarantees non-toxic materials. ISO9001 maintains quality frameworks. Patents cover innovative conveyor and inspection tech. Reinforces LED assembly line machine suitability internationally. Rigorous factory pre-delivery testing for every unit to confirm reliability, regulations, and excellence.

| I.C.T Company Profile

Three manufacturing sites total 12000m². Team of 89 includes 20 engineers. 25 years experience serving 1600 clients across 72 countries. In-house R&D develops tailored Led Panel Ceiling Light Assembly Line. Multi-level QC from materials to final checks. Network of sales centers, service hubs, warehouses, branches for prompt response. Goal: become leading cross-value platform in electronics, integrating production with smart systems, emphasizing innovation, collaboration, eco-friendliness, and client success.

| LED Assembly Line Machine Spotlight

I.C.T delivers LED assembly line machine through three owned factories and 22+ years SMT/DIP expertise, covering factory designs, layouts, manpower forecasts, ROI projections for LED ceiling panels. Semi-auto or full-auto lines feature loaders, printers, placers, reflow ovens, AOI, unloaders. One operator manages shifts. 18Kw/H for eco operations. Clients include LED fixture, panel, ceiling light producers worldwide. 3-day setup includes air, power, exhaust, lighting, 23±1.5°C controls. 7-15 days involve software, upkeep, safety, fixes. 15+ years overseas service. Led Panel Ceiling Light Assembly Line incorporates MES, IoT for intelligent factories. Turnkey accelerates LED ventures, offers flexibility, minimizes risks for startups or leaders in lighting industry with dependable quality, professional guidance, ongoing optimizations, and successful implementations across varied environments.

| Detailed Product Features

Seamless Automation Flow

LED assembly line machine integrates stations with MES for live tracking, yield boosts, refinements in ceiling LED panel assembly. Loaders adjust to panel sizes. Printers apply paste vision-accurate on LED arrays or drivers. Placers handle 01005 LEDs rapidly. Reflow sustains ±1.5°C for solid joints. AOI detects issues AI-smart. Unloaders route forward. Yields improve 25%+ in PCB Assembly Line. Adapts to ceiling fixtures or strips. Buffers maintain balance, remote dashboards oversee, auto recipes switch seamlessly, traceability monitors components for multiple LED designs, simplifying changes, ensuring compliance, enhancing throughput in volume production with provisions for unique patterns, fast modifications, integrated verifications, and scheduled maintenance routines.

Accurate Paste System

Printers in LED assembly line machine align stencils micron-level, support frames for panel dimensions. Quick swaps cut downtime. Auto dispense/clean ensure consistency. 3D SPI checks paste to prevent early defects. Vital for LED controllers or beads. Compatible with pastes, low-melt for delicate LED optics. Squeegee adapts for uniform coverage on irregular surfaces, increasing reliability, reducing rejects, permitting quick adaptations in emerging LED technologies with consistent performance, improved speed, minimal corrections, and greater output per cycle.

Reliable Reflow Process

Ovens include 12+ zones with independent convection for balanced heating in Led Panel Ceiling Light Assembly Line. Nitrogen produces durable joints for LED power or lights. Profiles auto-tune to requirements. Cooling avoids damage in large panels. Recovery supports 18Kw/H. Screens hold extensive recipes. Essential for LED longevity in ceilings. Conveyors sync MES for optimal speeds, variable adjustments, embedded sensors to avoid interruptions in continuous operations, smooth transitions, support high-capacity runs, and feature energy-efficient settings.

Smart Inspection Tools

AOI captures 8K scans at pace, identifying misalignments or solder problems in panels. AI learns from production. Feedback corrects placers instantly. Minimizes escapes in LED assembly line machine. Analytics facilitate improvements. Auto rejects handle without stopping, record data for audits and rapid fixes in diverse lines with reduced halts, enhanced logging, and automated summaries.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| Pick and Place Machine | Mounts components onto PCB precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

Algerian mobile manufacturer arrived for acceptance demonstration. They provided over ten PCBs and components; our team executed on-site assembly. Full-auto printer deposited paste precisely. SPI inspected volumes accurately. RX-8 mounted small elements swiftly. RS-1R placed larger parts correctly. Tray feeder supplied shields uninterrupted. Reflow fused connections solidly. AOI scanned for perfection. 5700 separator divided panels cleanly. Successful execution illustrated efficiency, synchronization for mobile/LED parallels. Aligns with Led Panel Ceiling Light Assembly Line principles. Clients verified specifications, commended seamless operation, intend similar LED assembly line machine locally with PCB Assembly Line for efficient expansion, uniform standards, increased volumes, and adaptability in future projects.

| Service and Training

Project managers oversee LED assembly line machine from planning to upgrades. 3-day installation: validations, test runs, calibrations. 7-15 day curriculum: MES interfaces, panel operations, defect analysis, routine care, safety measures. IoT provides predictive warnings, remote troubleshooting. Spare parts available from 8 global warehouses. 15-year international experience, multilingual support. Annual evaluations, software enhancements ensure sustained performance for reliable LED output, capacity increases, market shifts with proactive measures, specialized knowledge, and personalized advancement strategies.

| Customer Praise

Customers highlight rapid 2-hour remote interventions for LED assembly line machine. Reflow units operate reliably non-stop. Protective packaging withstands shipping. Service exceeds commitments consistently. PCB Assembly Line achieves massive production without issues. Intuitive controls enable quick staff proficiency in LED scenarios with straightforward navigation, rapid comprehension, and practical resources for immediate expertise.

| Accreditation Standards

CE certification meets safety requirements. RoHS guarantees non-toxic materials. ISO9001 maintains quality frameworks. Patents cover innovative conveyor and inspection tech. Reinforces LED assembly line machine suitability internationally. Rigorous factory pre-delivery testing for every unit to confirm reliability, regulations, and excellence.

| I.C.T Company Profile

Three manufacturing sites total 12000m². Team of 89 includes 20 engineers. 25 years experience serving 1600 clients across 72 countries. In-house R&D develops tailored Led Panel Ceiling Light Assembly Line. Multi-level QC from materials to final checks. Network of sales centers, service hubs, warehouses, branches for prompt response. Goal: become leading cross-value platform in electronics, integrating production with smart systems, emphasizing innovation, collaboration, eco-friendliness, and client success.