LED Lamp Line Assemble Strip SMT Line

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Assembly Line for LED Lamps Essentials

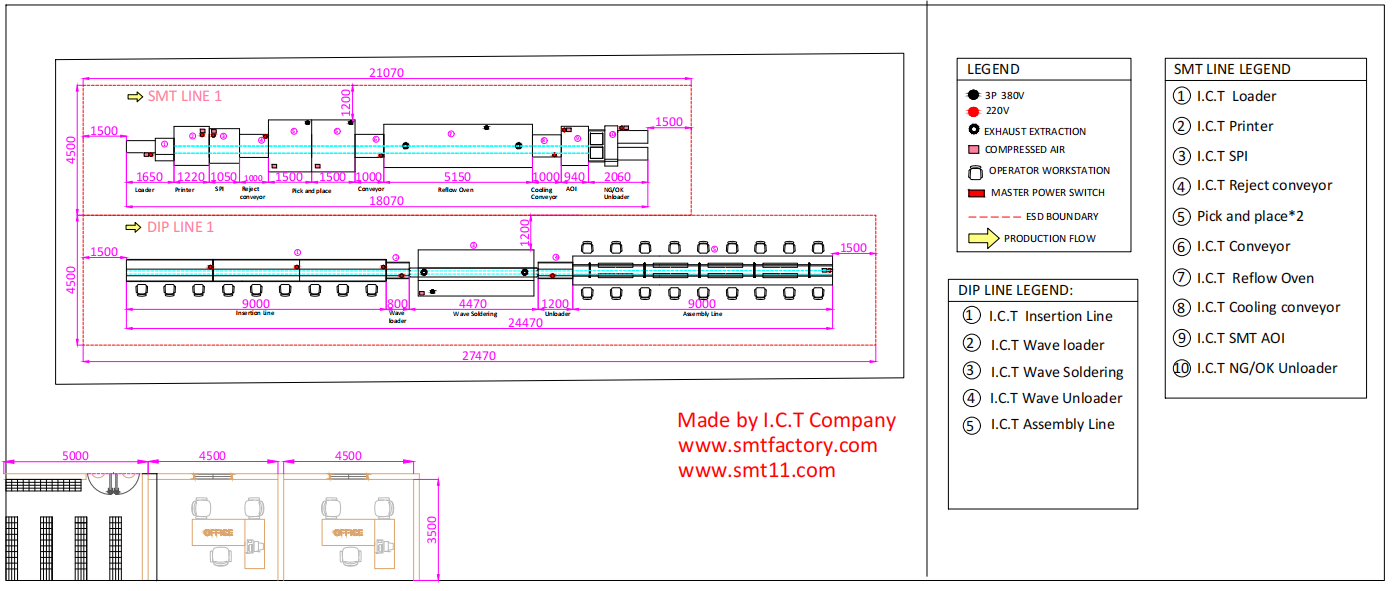

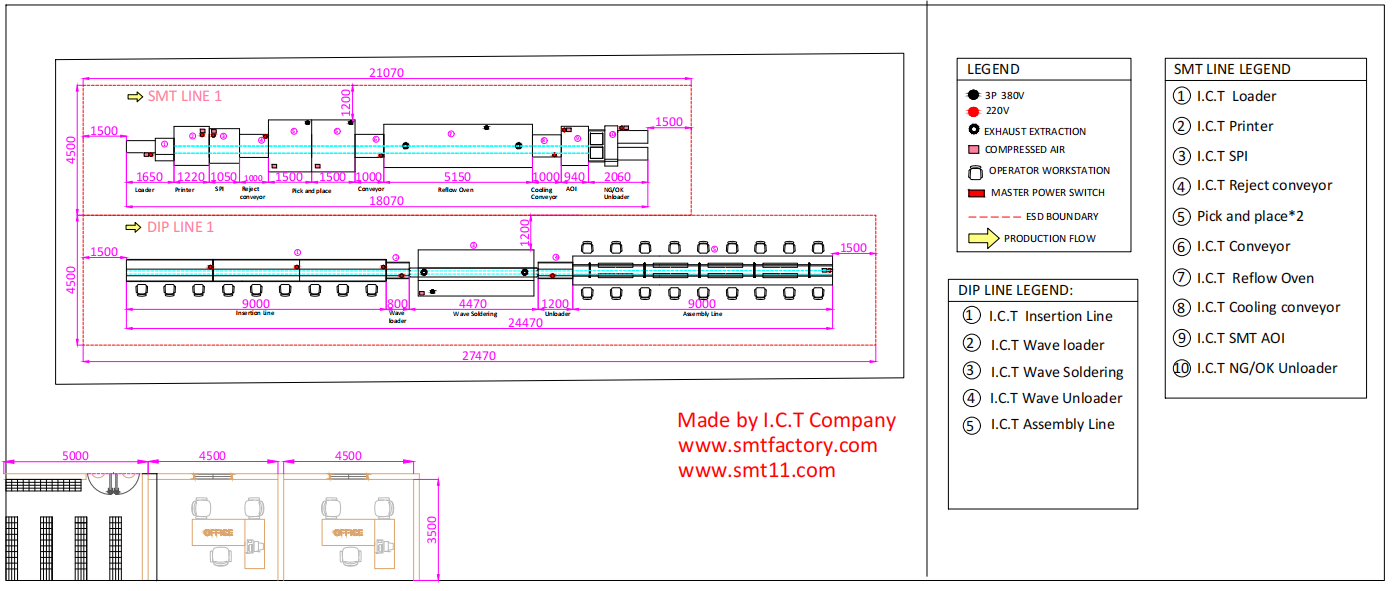

I.C.T supplies LED lamp line assemble from three factories and 22+ years SMT/DIP expertise, offering factory plans, layouts, labor data, ROI for LED strips. Semi-auto or full-auto includes loaders, printers, placers, reflow ovens, AOI, unloaders. One operator handles shifts. 18Kw/H reduces costs. Serves strip makers, flexible lights, signage globally. 3-day install checks air, power, exhaust, lighting. 7-15 days teach software, maintenance, safety, fixes. 15+ years global support. LED strip SMT line features MES, IoT for advanced factories. Complete package speeds strip production, supports scaling, lowers risks for beginners or experts in lighting markets with proven quality, expert advice, updates, and successes in multiple applications.

| Detailed Product Features

Integrated Strip Assembly

LED lamp line assemble connects equipment via MES for real-time data, yield gains, adjustments in LED strip boards. Loaders manage strip lengths. Printers deposit paste vision-controlled on LED chains or drivers. Placers position 01005 LEDs accurately. Reflow maintains ±0.3°C for reliable bonds. AOI identifies defects AI-assisted. Unloaders forward products. Yields increase 25%+ in LED strip SMT line. Fits flexible or rigid strips. Buffers balance flow, remote access controls, auto recipes adjust quickly, traceability logs materials for various strip types, easing transitions, ensuring standards, boosting efficiency in volume runs with space for custom lengths, rapid changes, joint inspections, and preventive maintenance approaches.

Accurate Paste System

Printers in LED lamp line assemble secure stencils micron-precise, accommodate frames for strip widths. Quick swaps minimize pauses. Auto dispense/clean cycles keep uniformity. 3D SPI verifies paste to prevent initial errors. Essential for LED sequences or controls. Supports multiple pastes, low-melt for sensitive LED elements. Squeegee fine-tunes for even spreads on flexible surfaces, enhancing consistency, reducing defects, enabling fast iterations in evolving strip designs with dependable results, superior throughput, fewer repairs, and expanded capacity per operation.

Placement Accuracy Unit

Placers in LED lamp line assemble employ JUKI systems for rapid, exact LED placement on strip substrates. Manages 01005 to larger components seamlessly. Vision systems ensure alignment. Multi-heads achieve high speeds. Feeders auto-switch for continuous runs. Software adapts to strip variations. Lowers placement faults in long LED chains, raises line velocity, allows mixed strip formats in batches with simple reconfiguration, precise calibration, and consistent accuracy for everyday large-scale strip manufacturing.

Reliable Reflow Process

Ovens provide 12+ zones with independent convection for uniform heating in LED strip SMT line. Nitrogen ensures strong joints for LED connections or drivers. Profiles adapt to specifications. Cooling prevents warping in strips. Recovery achieves 18Kw/H. Interfaces store numerous recipes. Critical for strip durability in use. Conveyors integrate MES for synchronized pacing, adjustable rates, built-in checks to eliminate stops in ongoing processes, secure handling, promote sustained high-output, and incorporate low-energy options.

Smart Inspection Tools

AOI performs 8K scans swiftly, detecting misplacements or solder issues in strips. AI refines from datasets. Feedback corrects placers immediately. Decreases faults in LED lamp line assemble. Analytics support enhancements. Auto rejects route without halting, document details for evaluations and quick corrections in varied productions with minimal interruptions, detailed tracking, and generated reports.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| Pick and Place Machine | Mounts components onto PCB precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

Algerian electronics team arrived for practical demo. Supplied 10+ PCBs and parts; we ran full process. Auto printer applied paste evenly. SPI confirmed coverage. RX-8 placed tiny items quickly. RS-1R handled bigger precisely. Tray feeder added components steadily. Reflow fused solidly. AOI verified excellence. 5700 separated accurately. Effective demo highlighted pace, integration for electronics/strip applications. Demonstrates LED strip SMT line capability. Clients approved results, praised coordination, plan implement LED lamp line assemble onsite with LED strip SMT line for smooth expansion, consistent performance, higher yields, and adaptability in ongoing operations.

| Comprehensive Support

Coordinators manage LED lamp line assemble from design to ongoing use. 3-day onsite: verifications, trials, optimizations. 7-15 day sessions: MES usage, strip handling, diagnostics, preventive maintenance, safety protocols. IoT detects potential failures early, enables remote interventions. Parts delivered from 8 warehouses worldwide. 15-year expertise, multilingual teams. Regular audits, upgrades maintain efficiency for durable LED strip reliability, production growth, market adaptations with strategic planning, dedicated specialists, and customized enhancement paths tailored to specific client needs and evolving industry demands.

| User Feedback Highlights

Users commend sub-2-hour remote fixes keeping LED lamp line assemble operational without delays. Ovens deliver constant 24/7 performance across shifts. Secure crates protect during international transport. Responses consistently surpass service level agreements. LED strip SMT line handles massive volumes flawlessly with minimal defects. Intuitive software interfaces allow new operators to master controls rapidly in LED environments through clear guidance, practical exercises, and accessible resources that accelerate proficiency and reduce training time significantly for teams of varying experience levels.

| Quality Standards Met

CE validates electrical safety standards compliance. RoHS confirms absence of hazardous substances in materials. ISO9001 enforces rigorous quality management systems. Patents safeguard unique conveyor designs and AI inspection algorithms. Establishes LED lamp line assemble credibility for worldwide markets. Exhaustive pre-shipment testing protocols on every system verify operational integrity, regulatory adherence, superior build quality, and long-term performance reliability under diverse conditions to ensure customer satisfaction from day one.

| About I.C.T Company and Factory

Three production facilities span 12000m² combined area. 89 employees include 20 dedicated engineers. 25 years experience supporting 1600 clients in 72 countries. Internal R&D creates specialized LED strip SMT line solutions. Quality control spans incoming materials to final assembly checks. Extensive network of sales offices, service centers, warehouses, and branches ensures rapid global response. Vision: establish premier cross-value electronics manufacturing ecosystem integrating advanced production, intelligent systems, sustainability initiatives, collaborative partnerships, and customer-focused innovations for continuous industry leadership and mutual growth opportunities.

| Assembly Line for LED Lamps Essentials

I.C.T supplies LED lamp line assemble from three factories and 22+ years SMT/DIP expertise, offering factory plans, layouts, labor data, ROI for LED strips. Semi-auto or full-auto includes loaders, printers, placers, reflow ovens, AOI, unloaders. One operator handles shifts. 18Kw/H reduces costs. Serves strip makers, flexible lights, signage globally. 3-day install checks air, power, exhaust, lighting. 7-15 days teach software, maintenance, safety, fixes. 15+ years global support. LED strip SMT line features MES, IoT for advanced factories. Complete package speeds strip production, supports scaling, lowers risks for beginners or experts in lighting markets with proven quality, expert advice, updates, and successes in multiple applications.

| Detailed Product Features

Integrated Strip Assembly

LED lamp line assemble connects equipment via MES for real-time data, yield gains, adjustments in LED strip boards. Loaders manage strip lengths. Printers deposit paste vision-controlled on LED chains or drivers. Placers position 01005 LEDs accurately. Reflow maintains ±0.3°C for reliable bonds. AOI identifies defects AI-assisted. Unloaders forward products. Yields increase 25%+ in LED strip SMT line. Fits flexible or rigid strips. Buffers balance flow, remote access controls, auto recipes adjust quickly, traceability logs materials for various strip types, easing transitions, ensuring standards, boosting efficiency in volume runs with space for custom lengths, rapid changes, joint inspections, and preventive maintenance approaches.

Accurate Paste System

Printers in LED lamp line assemble secure stencils micron-precise, accommodate frames for strip widths. Quick swaps minimize pauses. Auto dispense/clean cycles keep uniformity. 3D SPI verifies paste to prevent initial errors. Essential for LED sequences or controls. Supports multiple pastes, low-melt for sensitive LED elements. Squeegee fine-tunes for even spreads on flexible surfaces, enhancing consistency, reducing defects, enabling fast iterations in evolving strip designs with dependable results, superior throughput, fewer repairs, and expanded capacity per operation.

Placement Accuracy Unit

Placers in LED lamp line assemble employ JUKI systems for rapid, exact LED placement on strip substrates. Manages 01005 to larger components seamlessly. Vision systems ensure alignment. Multi-heads achieve high speeds. Feeders auto-switch for continuous runs. Software adapts to strip variations. Lowers placement faults in long LED chains, raises line velocity, allows mixed strip formats in batches with simple reconfiguration, precise calibration, and consistent accuracy for everyday large-scale strip manufacturing.

Reliable Reflow Process

Ovens provide 12+ zones with independent convection for uniform heating in LED strip SMT line. Nitrogen ensures strong joints for LED connections or drivers. Profiles adapt to specifications. Cooling prevents warping in strips. Recovery achieves 18Kw/H. Interfaces store numerous recipes. Critical for strip durability in use. Conveyors integrate MES for synchronized pacing, adjustable rates, built-in checks to eliminate stops in ongoing processes, secure handling, promote sustained high-output, and incorporate low-energy options.

Smart Inspection Tools

AOI performs 8K scans swiftly, detecting misplacements or solder issues in strips. AI refines from datasets. Feedback corrects placers immediately. Decreases faults in LED lamp line assemble. Analytics support enhancements. Auto rejects route without halting, document details for evaluations and quick corrections in varied productions with minimal interruptions, detailed tracking, and generated reports.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| Pick and Place Machine | Mounts components onto PCB precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

Algerian electronics team arrived for practical demo. Supplied 10+ PCBs and parts; we ran full process. Auto printer applied paste evenly. SPI confirmed coverage. RX-8 placed tiny items quickly. RS-1R handled bigger precisely. Tray feeder added components steadily. Reflow fused solidly. AOI verified excellence. 5700 separated accurately. Effective demo highlighted pace, integration for electronics/strip applications. Demonstrates LED strip SMT line capability. Clients approved results, praised coordination, plan implement LED lamp line assemble onsite with LED strip SMT line for smooth expansion, consistent performance, higher yields, and adaptability in ongoing operations.

| Comprehensive Support

Coordinators manage LED lamp line assemble from design to ongoing use. 3-day onsite: verifications, trials, optimizations. 7-15 day sessions: MES usage, strip handling, diagnostics, preventive maintenance, safety protocols. IoT detects potential failures early, enables remote interventions. Parts delivered from 8 warehouses worldwide. 15-year expertise, multilingual teams. Regular audits, upgrades maintain efficiency for durable LED strip reliability, production growth, market adaptations with strategic planning, dedicated specialists, and customized enhancement paths tailored to specific client needs and evolving industry demands.

| User Feedback Highlights

Users commend sub-2-hour remote fixes keeping LED lamp line assemble operational without delays. Ovens deliver constant 24/7 performance across shifts. Secure crates protect during international transport. Responses consistently surpass service level agreements. LED strip SMT line handles massive volumes flawlessly with minimal defects. Intuitive software interfaces allow new operators to master controls rapidly in LED environments through clear guidance, practical exercises, and accessible resources that accelerate proficiency and reduce training time significantly for teams of varying experience levels.

| Quality Standards Met

CE validates electrical safety standards compliance. RoHS confirms absence of hazardous substances in materials. ISO9001 enforces rigorous quality management systems. Patents safeguard unique conveyor designs and AI inspection algorithms. Establishes LED lamp line assemble credibility for worldwide markets. Exhaustive pre-shipment testing protocols on every system verify operational integrity, regulatory adherence, superior build quality, and long-term performance reliability under diverse conditions to ensure customer satisfaction from day one.

| About I.C.T Company and Factory

Three production facilities span 12000m² combined area. 89 employees include 20 dedicated engineers. 25 years experience supporting 1600 clients in 72 countries. Internal R&D creates specialized LED strip SMT line solutions. Quality control spans incoming materials to final assembly checks. Extensive network of sales offices, service centers, warehouses, and branches ensures rapid global response. Vision: establish premier cross-value electronics manufacturing ecosystem integrating advanced production, intelligent systems, sustainability initiatives, collaborative partnerships, and customer-focused innovations for continuous industry leadership and mutual growth opportunities.