Launch Assembled Line Smt Machine for budget-friendly PCBA output.

a. Pre-configured station links.

b. Value-engineered components.

c. Plug-and-play 3-day start.

d. 18Kw/H thrift operation.

e. Localized spare inventory.

f. 7-15 day skill transfer.

g. Tailored PCBA Assembly Line.

PCB Assembly Line

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Assembled Line Smt Machine Essentials

I.C.T supplies ready-to-run Assembled Line Smt Machine backed by three owned plants. With 22+ years in SMT/DIP, we bundle factory planning, layout drawings, labor estimates, and ROI models. Semi-auto or full-auto PCBA Assembly Line options use proven printers, placers, ovens, and AOI. One operator per shift suffices. 18Kw/H keeps bills low. We serve LED, TV, phone, EMS worldwide. 3-day install covers air, power, exhaust setup. 7-15 days train on programming and upkeep. Global service spans 15+ years. Cost-effective SMD Production Line fits tight budgets without quality loss.

| Feature

Turnkey Station Flow

Assembled Line Smt Machine arrives pre-linked for instant production. Loader feeds boards to auto-cleaner. Printer deposits paste via vision-guided squeegees. Placer mounts SMDs at optimized speed. Reflow bonds with multi-zone precision. AOI verifies joints. Unloader sorts OK/NG. This Cost-effective SMD Production Line cuts setup time 70%. Handles 100-1200mm boards.

SMD Placement Technology

Compact printer in Assembled Line Smt Machine aligns stencil automatically. Dual rails support quick changeover. 2D inspection flags paste issues early. Supports low-cost lead-free materials. Ideal for PCBA Assembly Line startups.

Reflow Oven Efficiency

Reflow oven uses chain conveyor with ±0.3°C stability. Independent top/bottom heaters. Fast cooldown prevents warpage. Stores 50 recipes. 18Kw/H via smart insulation. Suits high-mix Assembled Line Smt Machine.

Inspection and Testing

AOI scans at line pace with color cameras. Detects shifts, excess solder. Links to placer for auto offset. Data dashboard tracks DPMO. Core to Cost-effective SMD Production Line reliability.

Flexible Line Options

Begin semi-auto PCBA Assembly Line, add modules later. Drawings reserve space for SPI or buffer. Labor models show 50% headcount reduction.

| Specification

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

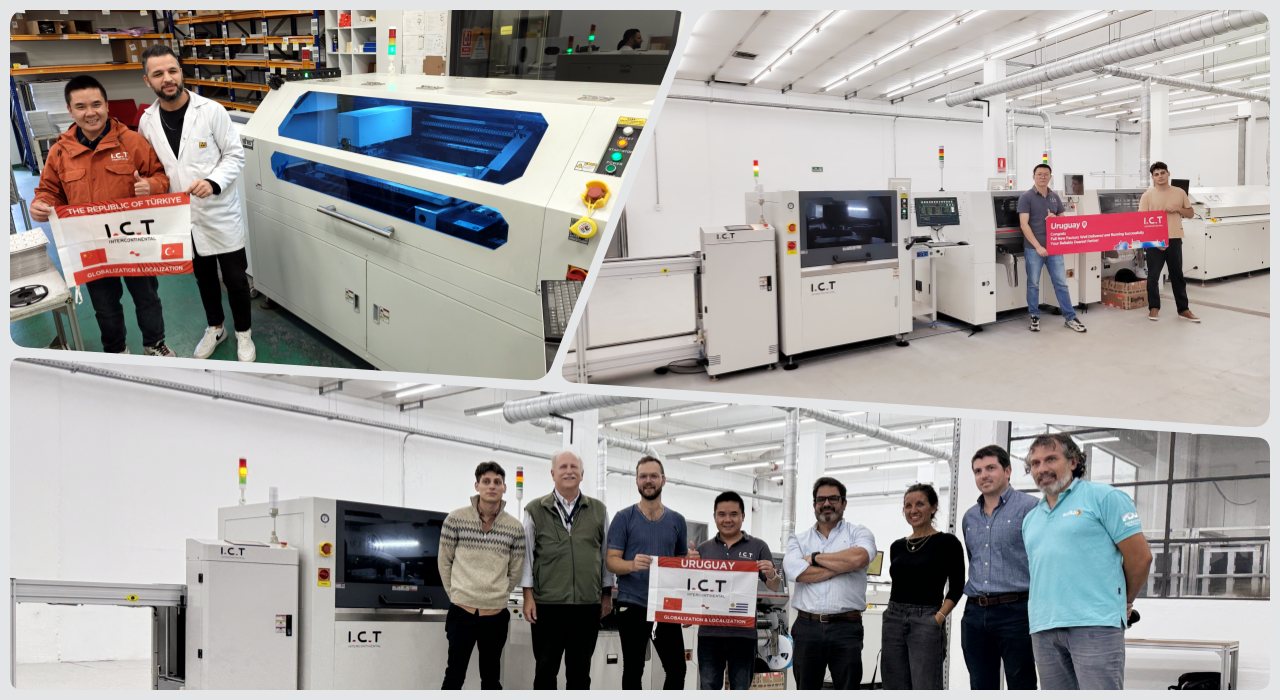

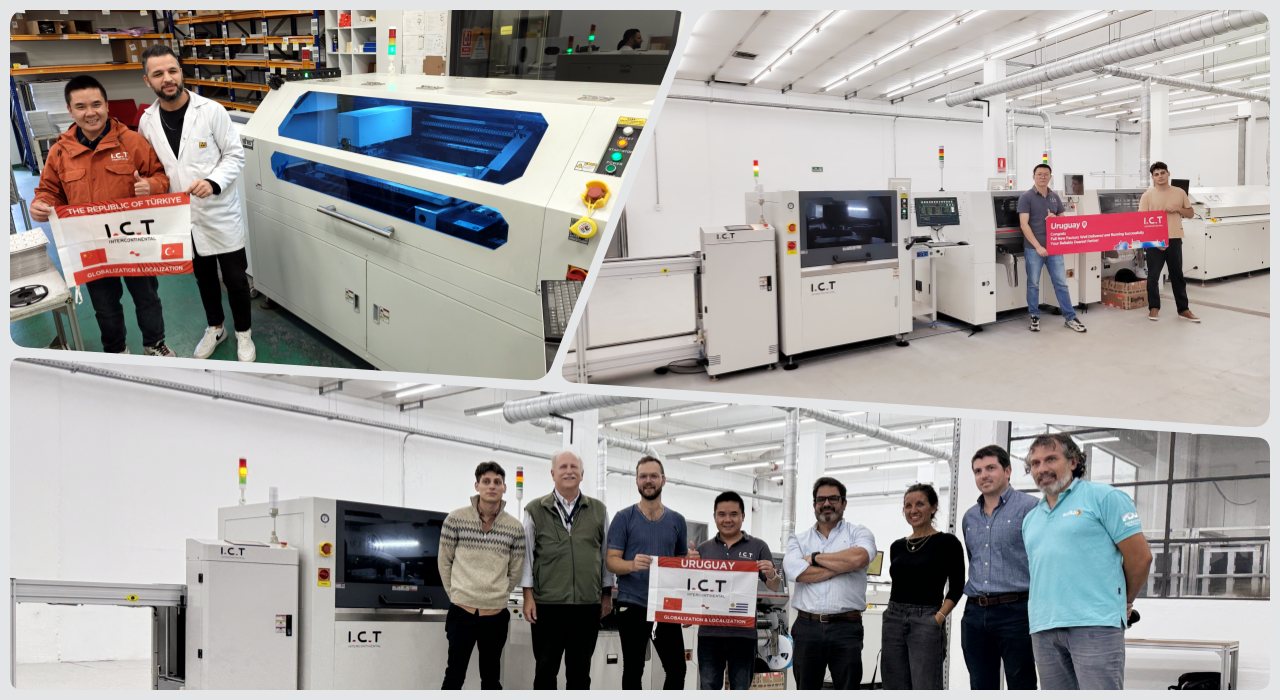

| Customer Success Video

EMS client deployed our Assembled Line Smt Machine for phone boards. Video captures loader-to-unloader cycle under 5 minutes. They highlight 3-day launch and single-operator run. Yield hit 99.5% first month. PCBA Assembly Line paid back in 8 months. Cost-effective SMD Production Line exceeded volume targets.

| Service and Training Support

I.C.T manages Assembled Line Smt Machine from quote to years ahead. 3-day on-site alignment and trial run. 7-15 day curriculum: software, daily checks, minor fixes. Parts ship from 8 global warehouses. 15-year service record. Free remote diagnostics.

| Client Testimonials

Users note zero-damage shipping for Assembled Line Smt Machine. Engineers solve issues in <6 hours overseas. PCBA Assembly Line runs 22-hour shifts. Cost-effective SMD Production Line saves 30% vs competitors.

| Certifications and Standards

CE for safety. RoHS material check. ISO9001 process audit. Patents on linkage tech. Underpins trustworthy Assembled Line Smt Machine.

| About I.C.T Company and Factory

Three factories total 12000m². 89 staff, 20 engineers. 25 years serving 1600 clients in 72 countries. In-house R&D crafts custom PCBA Assembly Line. Multi-point QC from incoming to packing. Global centers, warehouses, branches. Goal: cross-value electronics hub.

| Assembled Line Smt Machine Essentials

I.C.T supplies ready-to-run Assembled Line Smt Machine backed by three owned plants. With 22+ years in SMT/DIP, we bundle factory planning, layout drawings, labor estimates, and ROI models. Semi-auto or full-auto PCBA Assembly Line options use proven printers, placers, ovens, and AOI. One operator per shift suffices. 18Kw/H keeps bills low. We serve LED, TV, phone, EMS worldwide. 3-day install covers air, power, exhaust setup. 7-15 days train on programming and upkeep. Global service spans 15+ years. Cost-effective SMD Production Line fits tight budgets without quality loss.

| Feature

Turnkey Station Flow

Assembled Line Smt Machine arrives pre-linked for instant production. Loader feeds boards to auto-cleaner. Printer deposits paste via vision-guided squeegees. Placer mounts SMDs at optimized speed. Reflow bonds with multi-zone precision. AOI verifies joints. Unloader sorts OK/NG. This Cost-effective SMD Production Line cuts setup time 70%. Handles 100-1200mm boards.

SMD Placement Technology

Compact printer in Assembled Line Smt Machine aligns stencil automatically. Dual rails support quick changeover. 2D inspection flags paste issues early. Supports low-cost lead-free materials. Ideal for PCBA Assembly Line startups.

Reflow Oven Efficiency

Reflow oven uses chain conveyor with ±0.3°C stability. Independent top/bottom heaters. Fast cooldown prevents warpage. Stores 50 recipes. 18Kw/H via smart insulation. Suits high-mix Assembled Line Smt Machine.

Inspection and Testing

AOI scans at line pace with color cameras. Detects shifts, excess solder. Links to placer for auto offset. Data dashboard tracks DPMO. Core to Cost-effective SMD Production Line reliability.

Flexible Line Options

Begin semi-auto PCBA Assembly Line, add modules later. Drawings reserve space for SPI or buffer. Labor models show 50% headcount reduction.

| Specification

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

EMS client deployed our Assembled Line Smt Machine for phone boards. Video captures loader-to-unloader cycle under 5 minutes. They highlight 3-day launch and single-operator run. Yield hit 99.5% first month. PCBA Assembly Line paid back in 8 months. Cost-effective SMD Production Line exceeded volume targets.

| Service and Training Support

I.C.T manages Assembled Line Smt Machine from quote to years ahead. 3-day on-site alignment and trial run. 7-15 day curriculum: software, daily checks, minor fixes. Parts ship from 8 global warehouses. 15-year service record. Free remote diagnostics.

| Client Testimonials

Users note zero-damage shipping for Assembled Line Smt Machine. Engineers solve issues in <6 hours overseas. PCBA Assembly Line runs 22-hour shifts. Cost-effective SMD Production Line saves 30% vs competitors.

| Certifications and Standards

CE for safety. RoHS material check. ISO9001 process audit. Patents on linkage tech. Underpins trustworthy Assembled Line Smt Machine.

| About I.C.T Company and Factory

Three factories total 12000m². 89 staff, 20 engineers. 25 years serving 1600 clients in 72 countries. In-house R&D crafts custom PCBA Assembly Line. Multi-point QC from incoming to packing. Global centers, warehouses, branches. Goal: cross-value electronics hub.