SMT Line

I.C.T

Full Auto SMT Line for STB Production

| Availability: | |

|---|---|

| Quantity: | |

| Full Auto SMT Line Essentials

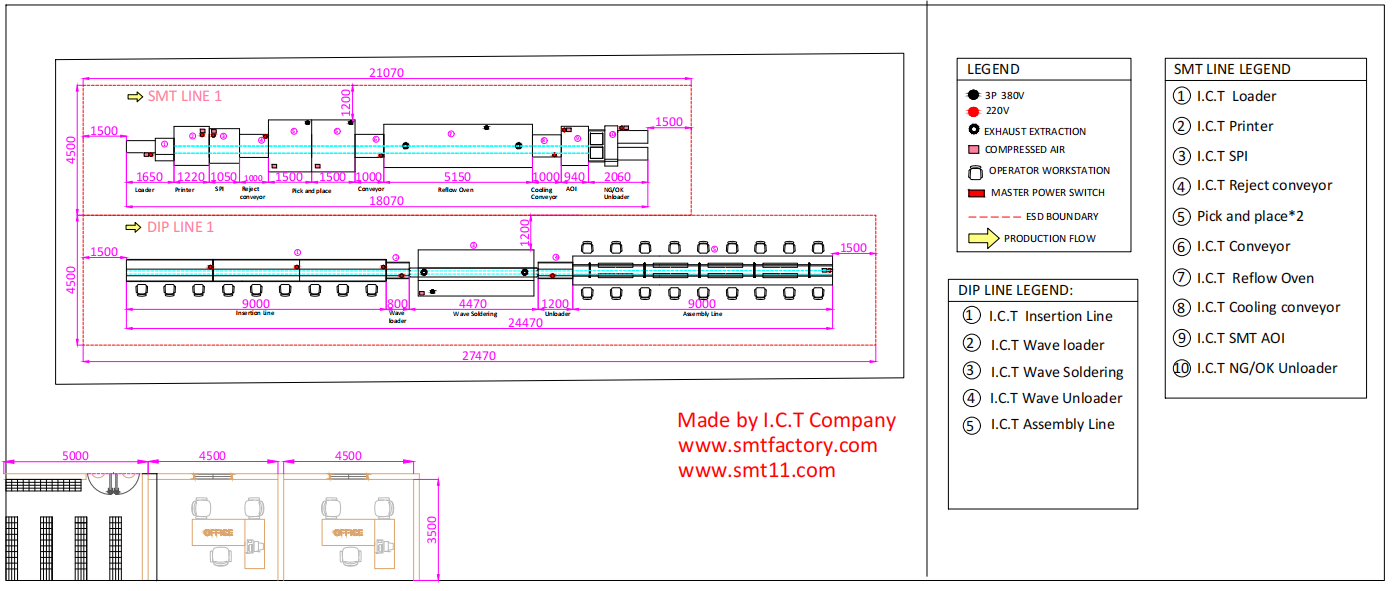

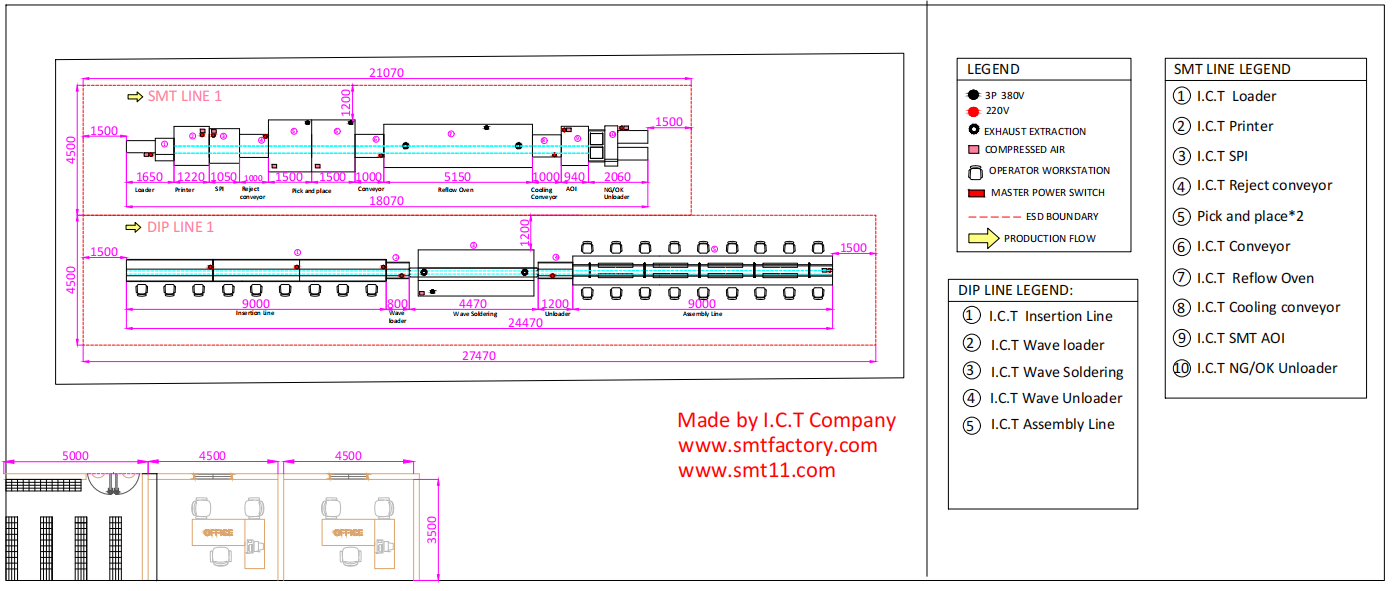

I.C.T introduces cutting-edge Full Auto SMT Line from three dedicated factories and 22+ years SMT/DIP excellence, featuring factory designs, layouts, labor calculations, ROI insights for set-top boxes. Semi-auto or full-auto models incorporate loaders, printers, placers, reflow ovens, AOI, unloaders. One operator oversees operations. 18Kw/H supports sustainability. Targets TV services, content providers, device makers internationally. 3-day installation confirms air, power, exhaust, lighting, 23±1.5°C settings. 7-15 days educate on software, upkeep, safety, troubleshooting. 15+ years worldwide assistance. Full Auto SMT Line for STB Production integrates MES, IoT for optimized, dependable factories. Complete solution fast-tracks STB initiatives, provides scalability, reduces uncertainties for novices or experts in fast-paced media landscapes with strong reliability, expert advice, and ongoing enhancements.

| Feature

Integrated Automation Workflow

Full Auto SMT Line unites equipment through MES for immediate data, yield improvements, refinements in STB PCBA processes. Loaders accommodate STB receiver boards accurately. Printers apply paste camera-guided on RF modules or outputs. Placers install 01005 components rapidly. Reflow maintains ±1.5°C for secure attachments. AOI uncovers anomalies AI-powered. Unloaders direct to casing. Yields increase 25%+ in Full Auto SMT Line for STB Production. Handles multiple STB types. Buffers stabilize rhythms, remote systems supervise, auto profiles transition quickly, traceability monitors elements for assorted STB productions, easing shifts, maintaining norms, raising efficiency in bulk scenarios with added versatility for unique attributes, swift revisions, unified checks, and proactive maintenance protocols.

Paste Management Precision

Printers in Full Auto SMT Line fasten stencils sub-micron exact, match frames for STB scales. Speedy replacements minimize halts. Auto feed/wipe sequences uphold excellence. 3D SPI evaluates paste to block premature problems. Essential for STB decoders or connectors. Accepts varied pastes, low-melt for sensitive STB chips. Squeegee modifies for balanced spreads on diverse textures, enhancing reliability, minimizing scrap, enabling quick evolutions in developing STB technologies with uniform superiority, greater velocity, decreased corrections, and boosted capacity each round.

Reliable Reflow Process

Ovens supply 12+ zones with individual convection for consistent warmth in Full Auto SMT Line for STB Production. Nitrogen forms robust joints for STB Ethernet or tuners. Profiles customize to details. Cooling preserves fragile layouts. Recycling attains 18Kw/H. Screens save abundant recipes. Crucial for STB resilience in consumer settings. Conveyors connect MES for matched tempos, adaptable rates, inbuilt validations to prevent interruptions in perpetual activities, ensure smooth transfers, facilitate non-stop high-yield environments, and incorporate energy-saving modes.

Smart Inspection Tools

AOI seizes 8K pictures swiftly, locating displacements or solder issues in STB. AI evolves from records. Feedback adjusts placers promptly. Diminishes errors in Full Auto SMT Line. Visualizations promote advancements. Auto rejects guide effortlessly, capture specifics for assessments and speedy resolutions in combined workflows with nominal pauses, improved logging, and automated reporting tools.

Flexible Scaling Options

Semi-auto start with full-auto upgrades via modular additions. Layouts reserve for SPI, buffers, IoT. Models show 70% labor efficiency gains. Options include cleanroom, ESD, ERP connectivity.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| Pick and Place Machine | Mounts components onto PCB precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

Algerian handset builder visited for proof-of-concept trial. Furnished 10+ PCBs and items; we conducted onsite execution. Auto printer distributed paste perfectly. SPI inspected thoroughly. RX-8 mounted small parts nimbly. RS-1R positioned larger accurately. Tray feeder supplied shields continuously. Reflow consolidated firmly. AOI validated impeccably. 5700 separated panels precisely. Flawless presentation stressed rhythm, harmony for handset/STB similarities. Represents Full Auto SMT Line for STB Production flexibility. Purchasers endorsed outcomes, commended coordination, schedule similar Full Auto SMT Line domestically with Full Auto SMT Line for STB Production for streamlined enlargement, steady excellence, elevated throughput, and future adaptability in their facilities.

| End-to-End Support System

Managers navigate Full Auto SMT Line from beginning to progressions. 3-day venue: examinations, executions, fine-tunings. 7-15 day courses: MES, STB functions, reviews, preservation, standards. IoT predicts glitches, offers virtual support. Parts hurry from 8 repositories. 15-year skill, multiple dialects. Regular inspections, refreshes retain dominance for lasting STB trustworthiness, output expansions, modifications in changing sectors with forward-thinking approaches, committed knowledge, and customized improvement plans.

| User Feedback Highlights

Applause for less-than-2-hour virtual repairs on Full Auto SMT Line. Ovens sustain 24/7 steadiness. Containers withstand voyages. Responses eclipse pledges. Full Auto SMT Line for STB Production accomplishes top volumes impeccably. Straightforward displays quicken instruction in STB situations with instinctive controls, effective assimilation, and supportive resources for rapid proficiency.

| Quality Standards Met

CE proves safeguarding. RoHS authenticates harmless ingredients. ISO9001 manages practices. Patents secure developments. Affirms Full Auto SMT Line validity globally. Comprehensive departure evaluations customary for every setup to confirm operation, adherence, and superior standards.

| About I.C.T Company and Factory

Three locations combine 12000m² expanse. 89 members, 20 professionals. 25 years helping 1600 clients in 72 countries. R&D formulates bespoke Full Auto SMT Line for STB Production. QC covers every step meticulously. Global divisions, assistance, stocks, affiliates deliver instant help. Goal: foremost cross-value electronics creation foundation highlighting innovation, collaborations, sustainability, and client-centric growth strategies.

| Full Auto SMT Line Essentials

I.C.T introduces cutting-edge Full Auto SMT Line from three dedicated factories and 22+ years SMT/DIP excellence, featuring factory designs, layouts, labor calculations, ROI insights for set-top boxes. Semi-auto or full-auto models incorporate loaders, printers, placers, reflow ovens, AOI, unloaders. One operator oversees operations. 18Kw/H supports sustainability. Targets TV services, content providers, device makers internationally. 3-day installation confirms air, power, exhaust, lighting, 23±1.5°C settings. 7-15 days educate on software, upkeep, safety, troubleshooting. 15+ years worldwide assistance. Full Auto SMT Line for STB Production integrates MES, IoT for optimized, dependable factories. Complete solution fast-tracks STB initiatives, provides scalability, reduces uncertainties for novices or experts in fast-paced media landscapes with strong reliability, expert advice, and ongoing enhancements.

| Feature

Integrated Automation Workflow

Full Auto SMT Line unites equipment through MES for immediate data, yield improvements, refinements in STB PCBA processes. Loaders accommodate STB receiver boards accurately. Printers apply paste camera-guided on RF modules or outputs. Placers install 01005 components rapidly. Reflow maintains ±1.5°C for secure attachments. AOI uncovers anomalies AI-powered. Unloaders direct to casing. Yields increase 25%+ in Full Auto SMT Line for STB Production. Handles multiple STB types. Buffers stabilize rhythms, remote systems supervise, auto profiles transition quickly, traceability monitors elements for assorted STB productions, easing shifts, maintaining norms, raising efficiency in bulk scenarios with added versatility for unique attributes, swift revisions, unified checks, and proactive maintenance protocols.

Paste Management Precision

Printers in Full Auto SMT Line fasten stencils sub-micron exact, match frames for STB scales. Speedy replacements minimize halts. Auto feed/wipe sequences uphold excellence. 3D SPI evaluates paste to block premature problems. Essential for STB decoders or connectors. Accepts varied pastes, low-melt for sensitive STB chips. Squeegee modifies for balanced spreads on diverse textures, enhancing reliability, minimizing scrap, enabling quick evolutions in developing STB technologies with uniform superiority, greater velocity, decreased corrections, and boosted capacity each round.

Reliable Reflow Process

Ovens supply 12+ zones with individual convection for consistent warmth in Full Auto SMT Line for STB Production. Nitrogen forms robust joints for STB Ethernet or tuners. Profiles customize to details. Cooling preserves fragile layouts. Recycling attains 18Kw/H. Screens save abundant recipes. Crucial for STB resilience in consumer settings. Conveyors connect MES for matched tempos, adaptable rates, inbuilt validations to prevent interruptions in perpetual activities, ensure smooth transfers, facilitate non-stop high-yield environments, and incorporate energy-saving modes.

Smart Inspection Tools

AOI seizes 8K pictures swiftly, locating displacements or solder issues in STB. AI evolves from records. Feedback adjusts placers promptly. Diminishes errors in Full Auto SMT Line. Visualizations promote advancements. Auto rejects guide effortlessly, capture specifics for assessments and speedy resolutions in combined workflows with nominal pauses, improved logging, and automated reporting tools.

Flexible Scaling Options

Semi-auto start with full-auto upgrades via modular additions. Layouts reserve for SPI, buffers, IoT. Models show 70% labor efficiency gains. Options include cleanroom, ESD, ERP connectivity.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| Pick and Place Machine | Mounts components onto PCB precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

Algerian handset builder visited for proof-of-concept trial. Furnished 10+ PCBs and items; we conducted onsite execution. Auto printer distributed paste perfectly. SPI inspected thoroughly. RX-8 mounted small parts nimbly. RS-1R positioned larger accurately. Tray feeder supplied shields continuously. Reflow consolidated firmly. AOI validated impeccably. 5700 separated panels precisely. Flawless presentation stressed rhythm, harmony for handset/STB similarities. Represents Full Auto SMT Line for STB Production flexibility. Purchasers endorsed outcomes, commended coordination, schedule similar Full Auto SMT Line domestically with Full Auto SMT Line for STB Production for streamlined enlargement, steady excellence, elevated throughput, and future adaptability in their facilities.

| End-to-End Support System

Managers navigate Full Auto SMT Line from beginning to progressions. 3-day venue: examinations, executions, fine-tunings. 7-15 day courses: MES, STB functions, reviews, preservation, standards. IoT predicts glitches, offers virtual support. Parts hurry from 8 repositories. 15-year skill, multiple dialects. Regular inspections, refreshes retain dominance for lasting STB trustworthiness, output expansions, modifications in changing sectors with forward-thinking approaches, committed knowledge, and customized improvement plans.

| User Feedback Highlights

Applause for less-than-2-hour virtual repairs on Full Auto SMT Line. Ovens sustain 24/7 steadiness. Containers withstand voyages. Responses eclipse pledges. Full Auto SMT Line for STB Production accomplishes top volumes impeccably. Straightforward displays quicken instruction in STB situations with instinctive controls, effective assimilation, and supportive resources for rapid proficiency.

| Quality Standards Met

CE proves safeguarding. RoHS authenticates harmless ingredients. ISO9001 manages practices. Patents secure developments. Affirms Full Auto SMT Line validity globally. Comprehensive departure evaluations customary for every setup to confirm operation, adherence, and superior standards.

| About I.C.T Company and Factory

Three locations combine 12000m² expanse. 89 members, 20 professionals. 25 years helping 1600 clients in 72 countries. R&D formulates bespoke Full Auto SMT Line for STB Production. QC covers every step meticulously. Global divisions, assistance, stocks, affiliates deliver instant help. Goal: foremost cross-value electronics creation foundation highlighting innovation, collaborations, sustainability, and client-centric growth strategies.