D600 (LENS)

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

The I.C.T dispensing system has significant strength in cost performance. Being reliable, durable, and concisely designed, it can be applied to PCB and base materials of different specifications. The UFD operating software ensures the stability and reliability of the system. The system is designed for chip sealing, PCB assembly, SMT red glue dispensing,led lens,and medical products. With adjustable track width, it can be applied to more products.

• High cost performance;

• Non-contact jet valve to realize smaller dispensing diameter and wider application area

• Jet valve can improve the reliability and uniformity of dispensing, and improve the output and material utilization rate;

• Minimum width of excessive glue can be controlled in 0.2mm(related to the configuration and glue);

• Chip edge identification is much more accurate than mark-point identification.

• ID identification, automatic program calling, fool-proofing and data statistics function helps to realize smart manufacturing.

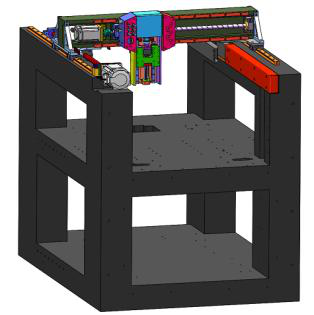

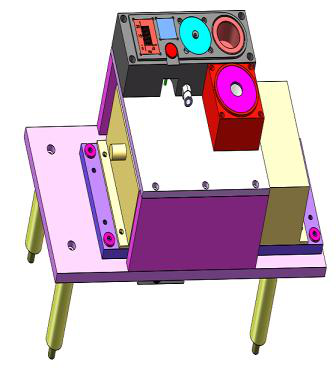

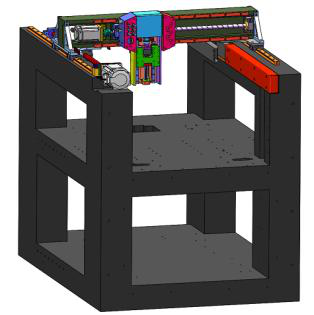

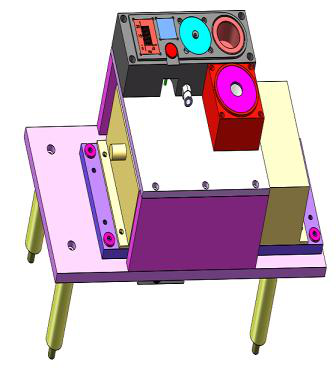

Platform System

Integral frame, marble platform supporting moving parts, moving parts using imported accessories, to ensure high accuracy and stability of equipment operation.

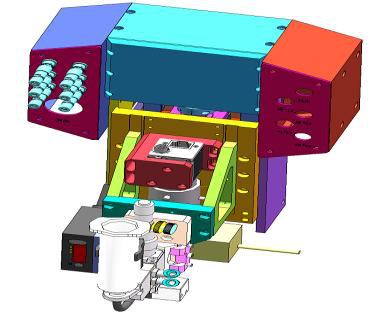

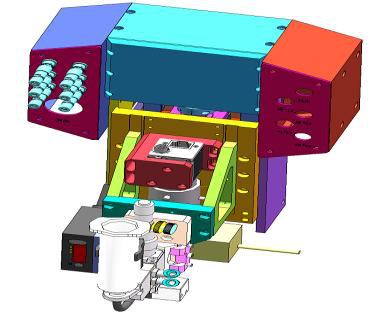

Dispensing System

Needle dispensing and spray valve dispensing can be selected. Spray valve dispensing can be fixed and rotary. CCD camera, laser altimeter and glue sensor can be selected.

Calibration System

Calibration Platform Standards: 0.1mg Electronic Scale, Scale, Ceramic Plate, Mechanical Height Detection, Vacuum Cleaning, Gluing Cup

Industry:

• Underfill

• Led lens

• Pin encapsulation

• Conformal coating

• Edge/corner bonding

• Surface mounted package

• Package on package (POP)

• Dam & fill

• Red glue dispensing

• FPC reinforcement

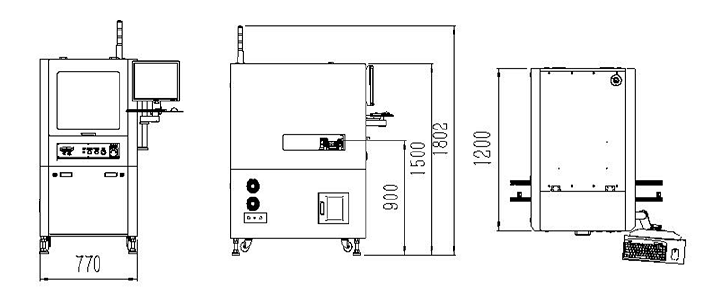

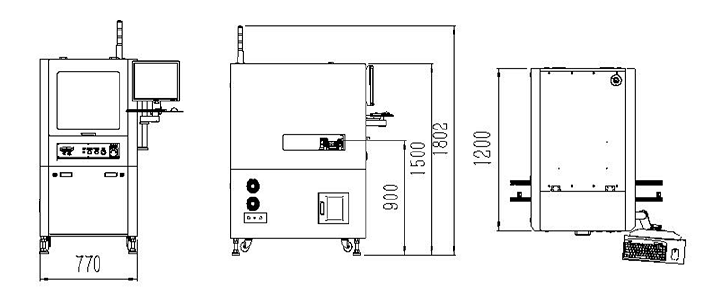

Specification: Desk Automatic SMT Dispensing Machine

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

FAQ

1: What is a desk SMT dispensing machine, and how does it differ from other dispensing equipment?

Answer: A desk SMT dispensing machine is a compact and versatile device used in surface mount technology (SMT) assembly to dispense adhesive, solder paste, or other materials onto printed circuit boards (PCBs). Unlike larger, floor-standing dispensing machines, a desk SMT dispensing machine is designed to be placed on a workbench or desk, offering space-saving benefits for smaller production environments. Despite its compact size, it retains the functionality and precision required for accurate dispensing tasks, making it suitable for a wide range of applications in electronics manufacturing.

2: What are the key features to consider when choosing a desk SMT dispensing machine?

Answer: When selecting a desk SMT dispensing machine, several key features should be considered to ensure it meets your specific production requirements. These features may include dispensing accuracy, speed, dispensing volume range, compatibility with various dispensing materials, ease of programming and operation, as well as the availability of optional accessories such as needle tips, syringes, and dispensing valves. Additionally, factors like machine footprint, maintenance requirements, and technical support from the manufacturer should also be taken into account to make an informed purchasing decision.

3: How can a desk SMT dispensing machine improve the efficiency of PCB assembly?

Answer: A desk SMT dispensing machine can significantly enhance the efficiency of PCB assembly by automating the dispensing process and ensuring precise application of adhesive, solder paste, or other materials onto PCBs. By eliminating the need for manual dispensing, it reduces labor costs, minimizes material waste, and improves production consistency. Moreover, its compact size allows it to be easily integrated into existing assembly lines or workstations, enabling seamless workflow optimization. Overall, investing in a desk SMT dispensing machine can lead to increased throughput, higher quality assemblies, and improved overall productivity in electronics manufacturing.

The I.C.T dispensing system has significant strength in cost performance. Being reliable, durable, and concisely designed, it can be applied to PCB and base materials of different specifications. The UFD operating software ensures the stability and reliability of the system. The system is designed for chip sealing, PCB assembly, SMT red glue dispensing,led lens,and medical products. With adjustable track width, it can be applied to more products.

• High cost performance;

• Non-contact jet valve to realize smaller dispensing diameter and wider application area

• Jet valve can improve the reliability and uniformity of dispensing, and improve the output and material utilization rate;

• Minimum width of excessive glue can be controlled in 0.2mm(related to the configuration and glue);

• Chip edge identification is much more accurate than mark-point identification.

• ID identification, automatic program calling, fool-proofing and data statistics function helps to realize smart manufacturing.

Platform System

Integral frame, marble platform supporting moving parts, moving parts using imported accessories, to ensure high accuracy and stability of equipment operation.

Dispensing System

Needle dispensing and spray valve dispensing can be selected. Spray valve dispensing can be fixed and rotary. CCD camera, laser altimeter and glue sensor can be selected.

Calibration System

Calibration Platform Standards: 0.1mg Electronic Scale, Scale, Ceramic Plate, Mechanical Height Detection, Vacuum Cleaning, Gluing Cup

Industry:

• Underfill

• Led lens

• Pin encapsulation

• Conformal coating

• Edge/corner bonding

• Surface mounted package

• Package on package (POP)

• Dam & fill

• Red glue dispensing

• FPC reinforcement

Specification: Desk Automatic SMT Dispensing Machine

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

FAQ

1: What is a desk SMT dispensing machine, and how does it differ from other dispensing equipment?

Answer: A desk SMT dispensing machine is a compact and versatile device used in surface mount technology (SMT) assembly to dispense adhesive, solder paste, or other materials onto printed circuit boards (PCBs). Unlike larger, floor-standing dispensing machines, a desk SMT dispensing machine is designed to be placed on a workbench or desk, offering space-saving benefits for smaller production environments. Despite its compact size, it retains the functionality and precision required for accurate dispensing tasks, making it suitable for a wide range of applications in electronics manufacturing.

2: What are the key features to consider when choosing a desk SMT dispensing machine?

Answer: When selecting a desk SMT dispensing machine, several key features should be considered to ensure it meets your specific production requirements. These features may include dispensing accuracy, speed, dispensing volume range, compatibility with various dispensing materials, ease of programming and operation, as well as the availability of optional accessories such as needle tips, syringes, and dispensing valves. Additionally, factors like machine footprint, maintenance requirements, and technical support from the manufacturer should also be taken into account to make an informed purchasing decision.

3: How can a desk SMT dispensing machine improve the efficiency of PCB assembly?

Answer: A desk SMT dispensing machine can significantly enhance the efficiency of PCB assembly by automating the dispensing process and ensuring precise application of adhesive, solder paste, or other materials onto PCBs. By eliminating the need for manual dispensing, it reduces labor costs, minimizes material waste, and improves production consistency. Moreover, its compact size allows it to be easily integrated into existing assembly lines or workstations, enabling seamless workflow optimization. Overall, investing in a desk SMT dispensing machine can lead to increased throughput, higher quality assemblies, and improved overall productivity in electronics manufacturing.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

Successful Experience:

I.C.T's customer in 35 countries around the world

1. We have been helping customers to build a lot of new factories around the world.

2. Training more than 500 experts and technician for customers.

3. Became the most reliable Chinese partner for you.

For SMT factory setup,we can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

Successful Experience:

I.C.T's customer in 35 countries around the world

1. We have been helping customers to build a lot of new factories around the world.

2. Training more than 500 experts and technician for customers.

3. Became the most reliable Chinese partner for you.

For SMT factory setup,we can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT