Smart Factory Solution for IFPD

I.C.T

Smart Factory Solution for IFPD

| Availability: | |

|---|---|

| Quantity: | |

| SMT Line Solutions for IFPD Details

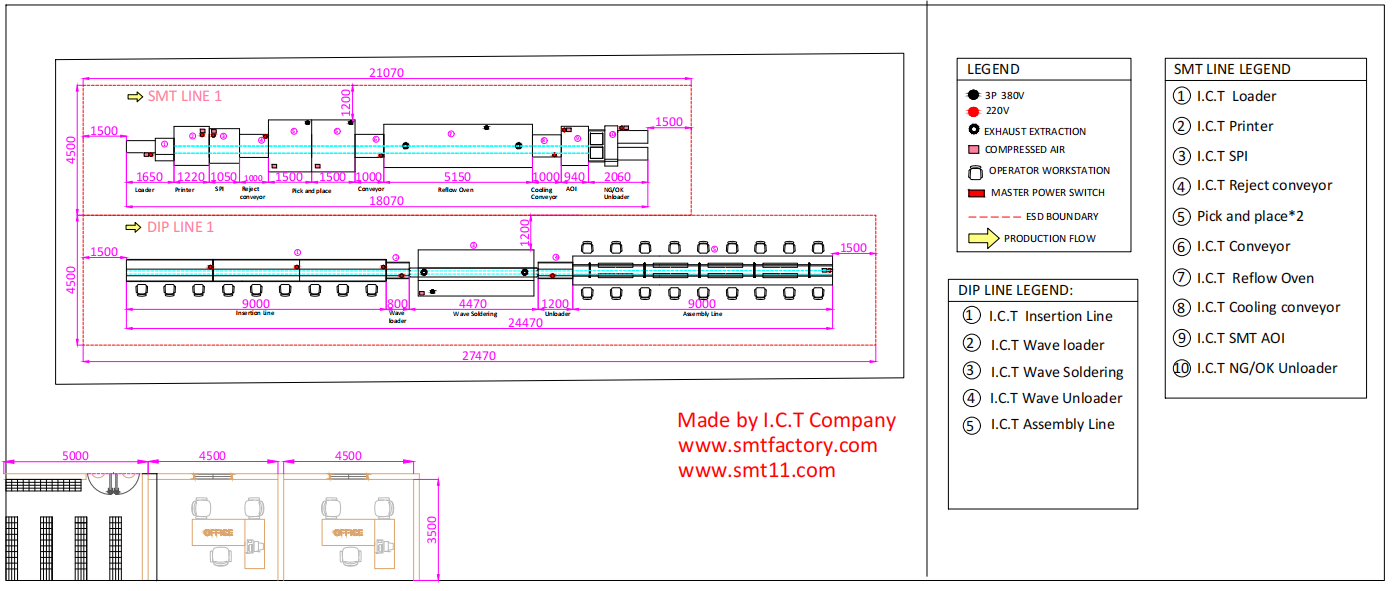

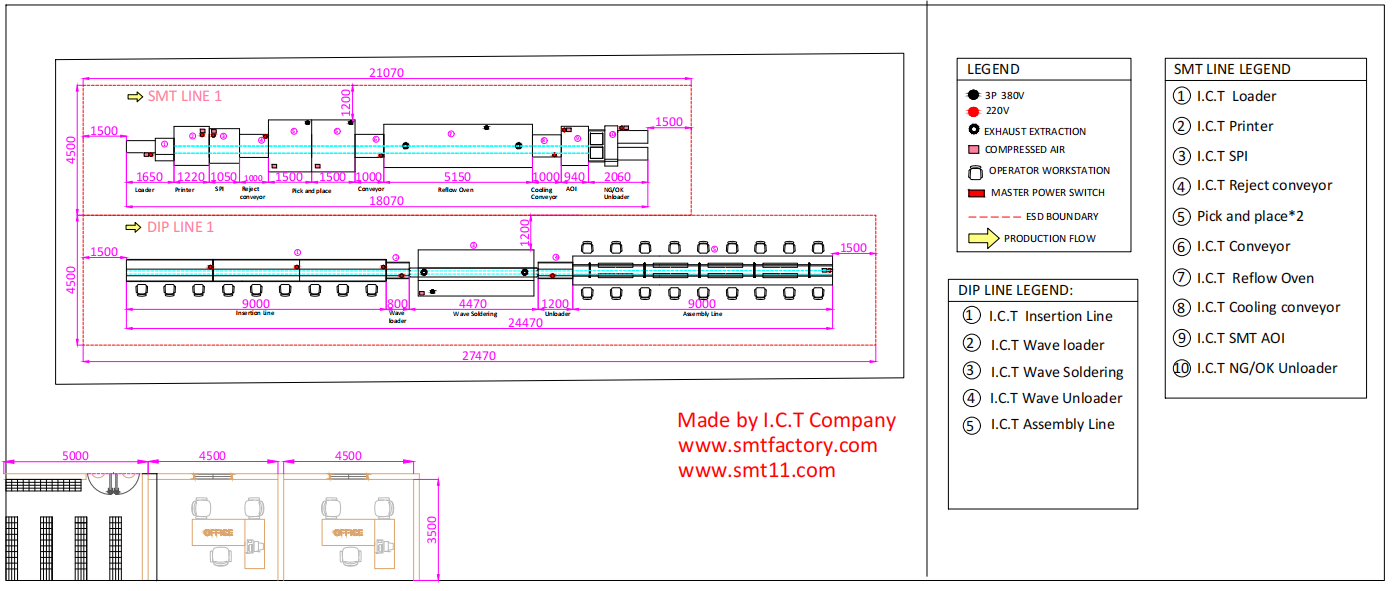

I.C.T pioneers Smart Factory Solution for IFPD through three wholly-owned factories and over 22 years of SMT/DIP mastery, offering expert factory planning, detailed layouts, labor assessments, and ROI strategies for interactive flat-panel displays. We deliver semi-auto and full-auto systems with auto loaders, precision printers, versatile placers, zoned reflow ovens, AOI inspectors, and smart unloaders.

One operator handles full shifts effortlessly. Energy-efficient at 18Kw/H for eco-conscious production. Serving education, conferencing, signage sectors globally. 3-day setup includes air, power, exhaust, lighting, and 23±1.5°C environment checks. 7-15 days cover software, maintenance, safety, troubleshooting.

15+ years overseas service ensures reliability. Smart Factory Solution for Interactive Flat-Panel Display Production incorporates MES, IoT, analytics for intelligent, high-uptime operations. This comprehensive package streamlines setup, boosts scalability for IFPD innovators worldwide.

| Feature

Intelligent Ecosystem Integration

Smart Factory Solution for IFPD harmonizes equipment via advanced MES for live monitoring, yield optimization, and process insights. Loaders auto-configure for 55-100+ inch boards across IFPD ranges. Printers deploy 3D vision for accurate paste on LED arrays and fine pitches. Placers manage 01005 components with speed and precision. Reflow maintains ±1.5°C stability for defect-free soldering. AOI applies AI for instant flaw detection. Unloaders route to testing or packing. Yields improve 25%+ in Smart Factory Solution for Interactive Flat-Panel Display Production. Supports 4K/8K upgrades. Buffers manage flows, remote access enables oversight, recipe auto-loads speed changes, traceability logs materials for flexible IFPD variants with reduced downtime and full compliance tracking.

Precision Deposition Module

Printers in Smart Factory Solution for IFPD achieve micron-level stencil alignment with large-frame support for expansive panels. Quick-change features minimize interruptions. Auto-dispense and cleaning ensure cycle consistency. 3D SPI validates paste metrics to avoid pre-reflow issues. Essential for dense IFPD backlights. Compatible with various pastes, including low-temp for sensitive elements. Dynamic squeegee adjustments deliver uniform layers on varied surfaces, enhancing print reliability and output quality.

Thermal Control Excellence

Reflow units feature 12+ zones with independent convection for tailored heating. Nitrogen options yield superior joints for display longevity. Profiles adapt automatically to board specs. Rapid cooling prevents structural issues in big formats. Heat recovery aids 18Kw/H efficiency. Interfaces store extensive recipes. Vital for Smart Factory Solution for Interactive Flat-Panel Display Production in rigorous applications. Conveyors integrate seamlessly with MES for synchronized pacing.

Advanced Inspection Layer

AOI systems capture 8K images at line speed, identifying warpage, misalignments, or anomalies. AI refines accuracy from production data. Feedback enables placer auto-adjustments. Cuts defects in Smart Factory Solution for IFPD. Provides analytics for continuous improvement. Auto-reroute rejects without stopping flow.

Scalable Expansion Framework

Semi-auto start with full-auto upgrades via modular additions. Layouts reserve for SPI, buffers, IoT. Models show 70% labor efficiency gains. Options include cleanroom, ESD, ERP connectivity.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

Algerian functional phone manufacturer arrived for hands-on verification. Supplying over ten PCBs and components, they watched live assembly. Full-auto printer started with exact paste. SPI confirmed deposits. RX-8 placed small items swiftly. RS-1R handled larger parts accurately. Tray feeder supplied shields uninterrupted. Reflow solidified connections. AOI verified quality. 5700 separator divided panels precisely.

Flawless execution demonstrated speed, integration. Adapts Smart Factory Solution for IFPD concepts to mobile, proving flexibility. Clients validated specs, praised seamless flow, envision home replication with Smart Factory Solution for Interactive Flat-Panel Display Production.

| Service and Training Support

Dedicated leads guide Smart Factory Solution for IFPD from planning to optimization. 3-day onsite: validation, trials, tuning. 7-15 day curriculum: MES, panel ops, diagnostics, PM, safety. IoT for forecasts, remote aid. Parts from 8 warehouses. 15-year global expertise, multilingual. Annual audits, updates maintain excellence.

| Client Testimonials

Quick remote resolutions for Smart Factory Solution for IFPD. Ovens stable round-the-clock. Secure transport. SLA-exceeding responses. Smart Factory Solution for Interactive Flat-Panel Display Production scales to millions. Intuitive for fast staff ramp-up.

| Certifications and Standards

CE for safety. RoHS eco-materials. ISO9001 quality systems. Patents on conveyors, AI. Ensures Smart Factory Solution for IFPD global fit. Pre-shipment tests rigorous.

| About I.C.T Company and Factory

Three factories 12000m². 89 staff, 20 engineers. 25 years, 1600 clients, 72 countries. R&D for custom Smart Factory Solution for Interactive Flat-Panel Display Production. QC multi-stage. Global centers, warehouses, branches. Vision: cross-value electronics platform.

| SMT Line Solutions for IFPD Details

I.C.T pioneers Smart Factory Solution for IFPD through three wholly-owned factories and over 22 years of SMT/DIP mastery, offering expert factory planning, detailed layouts, labor assessments, and ROI strategies for interactive flat-panel displays. We deliver semi-auto and full-auto systems with auto loaders, precision printers, versatile placers, zoned reflow ovens, AOI inspectors, and smart unloaders.

One operator handles full shifts effortlessly. Energy-efficient at 18Kw/H for eco-conscious production. Serving education, conferencing, signage sectors globally. 3-day setup includes air, power, exhaust, lighting, and 23±1.5°C environment checks. 7-15 days cover software, maintenance, safety, troubleshooting.

15+ years overseas service ensures reliability. Smart Factory Solution for Interactive Flat-Panel Display Production incorporates MES, IoT, analytics for intelligent, high-uptime operations. This comprehensive package streamlines setup, boosts scalability for IFPD innovators worldwide.

| Feature

Intelligent Ecosystem Integration

Smart Factory Solution for IFPD harmonizes equipment via advanced MES for live monitoring, yield optimization, and process insights. Loaders auto-configure for 55-100+ inch boards across IFPD ranges. Printers deploy 3D vision for accurate paste on LED arrays and fine pitches. Placers manage 01005 components with speed and precision. Reflow maintains ±1.5°C stability for defect-free soldering. AOI applies AI for instant flaw detection. Unloaders route to testing or packing. Yields improve 25%+ in Smart Factory Solution for Interactive Flat-Panel Display Production. Supports 4K/8K upgrades. Buffers manage flows, remote access enables oversight, recipe auto-loads speed changes, traceability logs materials for flexible IFPD variants with reduced downtime and full compliance tracking.

Precision Deposition Module

Printers in Smart Factory Solution for IFPD achieve micron-level stencil alignment with large-frame support for expansive panels. Quick-change features minimize interruptions. Auto-dispense and cleaning ensure cycle consistency. 3D SPI validates paste metrics to avoid pre-reflow issues. Essential for dense IFPD backlights. Compatible with various pastes, including low-temp for sensitive elements. Dynamic squeegee adjustments deliver uniform layers on varied surfaces, enhancing print reliability and output quality.

Thermal Control Excellence

Reflow units feature 12+ zones with independent convection for tailored heating. Nitrogen options yield superior joints for display longevity. Profiles adapt automatically to board specs. Rapid cooling prevents structural issues in big formats. Heat recovery aids 18Kw/H efficiency. Interfaces store extensive recipes. Vital for Smart Factory Solution for Interactive Flat-Panel Display Production in rigorous applications. Conveyors integrate seamlessly with MES for synchronized pacing.

Advanced Inspection Layer

AOI systems capture 8K images at line speed, identifying warpage, misalignments, or anomalies. AI refines accuracy from production data. Feedback enables placer auto-adjustments. Cuts defects in Smart Factory Solution for IFPD. Provides analytics for continuous improvement. Auto-reroute rejects without stopping flow.

Scalable Expansion Framework

Semi-auto start with full-auto upgrades via modular additions. Layouts reserve for SPI, buffers, IoT. Models show 70% labor efficiency gains. Options include cleanroom, ESD, ERP connectivity.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

Algerian functional phone manufacturer arrived for hands-on verification. Supplying over ten PCBs and components, they watched live assembly. Full-auto printer started with exact paste. SPI confirmed deposits. RX-8 placed small items swiftly. RS-1R handled larger parts accurately. Tray feeder supplied shields uninterrupted. Reflow solidified connections. AOI verified quality. 5700 separator divided panels precisely.

Flawless execution demonstrated speed, integration. Adapts Smart Factory Solution for IFPD concepts to mobile, proving flexibility. Clients validated specs, praised seamless flow, envision home replication with Smart Factory Solution for Interactive Flat-Panel Display Production.

| Service and Training Support

Dedicated leads guide Smart Factory Solution for IFPD from planning to optimization. 3-day onsite: validation, trials, tuning. 7-15 day curriculum: MES, panel ops, diagnostics, PM, safety. IoT for forecasts, remote aid. Parts from 8 warehouses. 15-year global expertise, multilingual. Annual audits, updates maintain excellence.

| Client Testimonials

Quick remote resolutions for Smart Factory Solution for IFPD. Ovens stable round-the-clock. Secure transport. SLA-exceeding responses. Smart Factory Solution for Interactive Flat-Panel Display Production scales to millions. Intuitive for fast staff ramp-up.

| Certifications and Standards

CE for safety. RoHS eco-materials. ISO9001 quality systems. Patents on conveyors, AI. Ensures Smart Factory Solution for IFPD global fit. Pre-shipment tests rigorous.

| About I.C.T Company and Factory

Three factories 12000m². 89 staff, 20 engineers. 25 years, 1600 clients, 72 countries. R&D for custom Smart Factory Solution for Interactive Flat-Panel Display Production. QC multi-stage. Global centers, warehouses, branches. Vision: cross-value electronics platform.