RS-1R

JUKI

| Availability: | |

|---|---|

| Quantity: | |

| Advanced SMT Machine Pick and Place Machine

In the world of modern electronics assembly, the JUKI SMT Mounting Machine stands out with quiet elegance and power. It positions surface-mount devices on circuit boards with remarkable speed and precision. From tiny chips to larger components, it handles diverse needs effortlessly. The modular design allows seamless expansion as demands evolve. Intuitive programming and real-time vision monitoring simplify operations. Its slim profile integrates beautifully into production floors. I.C.T ensures full assistance, from initial planning through daily optimization, creating reliable lines that produce high-quality boards consistently for various industries.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

Versatility defines the RS-1R and RS-1XL. With the Takumi head adapting dynamically, they manage mixed productions and irregular shapes gracefully. The RS-1R offers 47,000 CPH and ±35µm accuracy, supporting boards up to 650×370mm. The RS-1XL extends to wider 650×560mm panels, suiting larger applications. Up to 112 feeders enable rapid job switches. Gentle force control safeguards delicate substrates. Vision systems detect issues promptly. These models blend well in flexible lines, maintaining steady flow and high yields across varied tasks.

RX-7R / RX-8 Series Features

Pure speed shines in the RX-7R and RX-8, confined elegantly within 998mm width. The RX-8 reaches 100,000 CPH via the innovative P20 head, leading in density per area. The RX-7R provides 75,000 CPH with parallel operations. Both excel at ultra-small 03015 chips. Enhanced coaxial lighting sharpens vision clarity. Low-impact modes protect fragile elements. Smart data sharing reduces downtime. Ideal for dense, high-volume runs, they deliver exceptional productivity without compromising quality or space.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T crafts complete, SMT high-speed line with careful precision. The PCB magazine loader delivers boards impeccably clean. SMT PCB printing machine applies solder paste uniformly. The JUKI SMT Mounting Machine positions every component with exact care. Multi-zone SMT Soldering Oven secure strong bonds. AOI optical inspection reveal flaws reliably. Tight conveyors and buffers maintain uninterrupted rhythm. Yields rise significantly while costs decline. No compromises in strength. Designed for demanding automotive and similar applications, boards emerge fully prepared for real-world challenges. Full backing ensures lasting performance.

| Customer Success Video

A manufacturer of automotive power supplies shares their story through clear video footage. Complete SMT and DIP lines operate in harmonious flow. Boards arrive pristine via vacuum loader. Solder paste spreads evenly at the printer. The JUKI SMT Mounting Machine mounts components swiftly and precisely. Reflow solidifies connections, followed by cooling and buffering. AOI verifies quality thoroughly. On the DIP side, wave soldering, flipping, and ICT testing complete through-hole assembly seamlessly. The customer notes reliable connections, minimal interruptions, and consistently superior results meeting strict standards. Every stage appears efficient and controlled.

| Service and Training Support

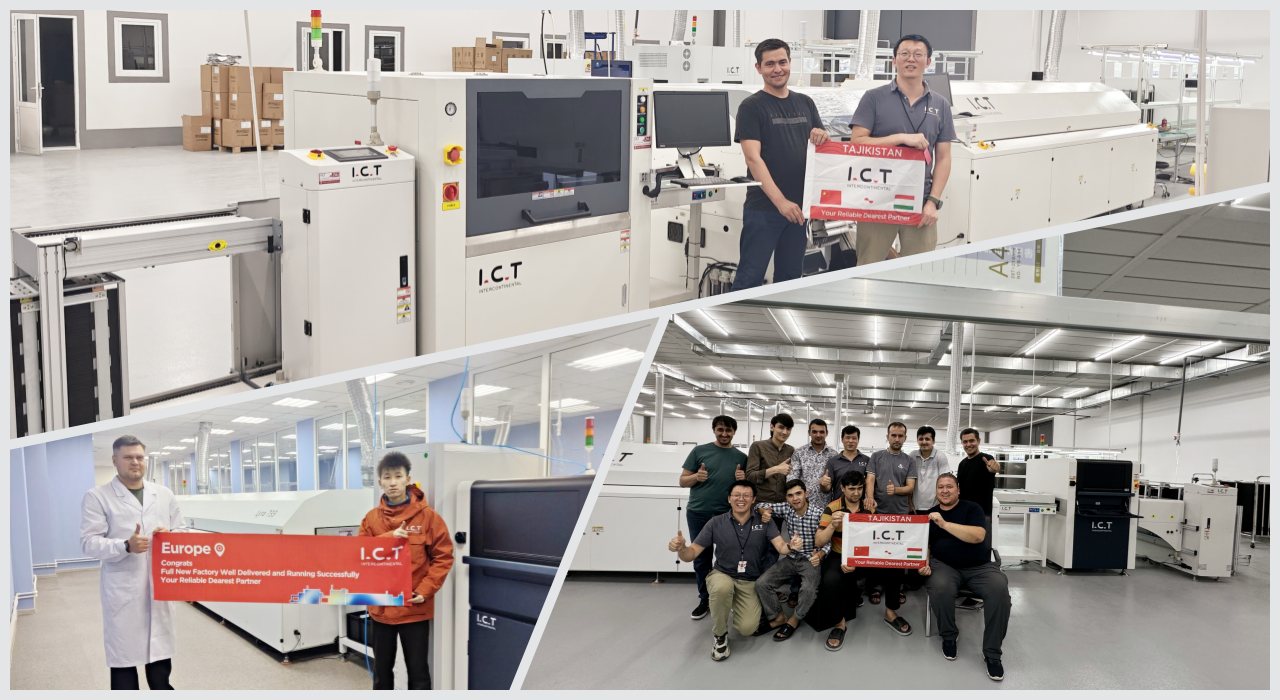

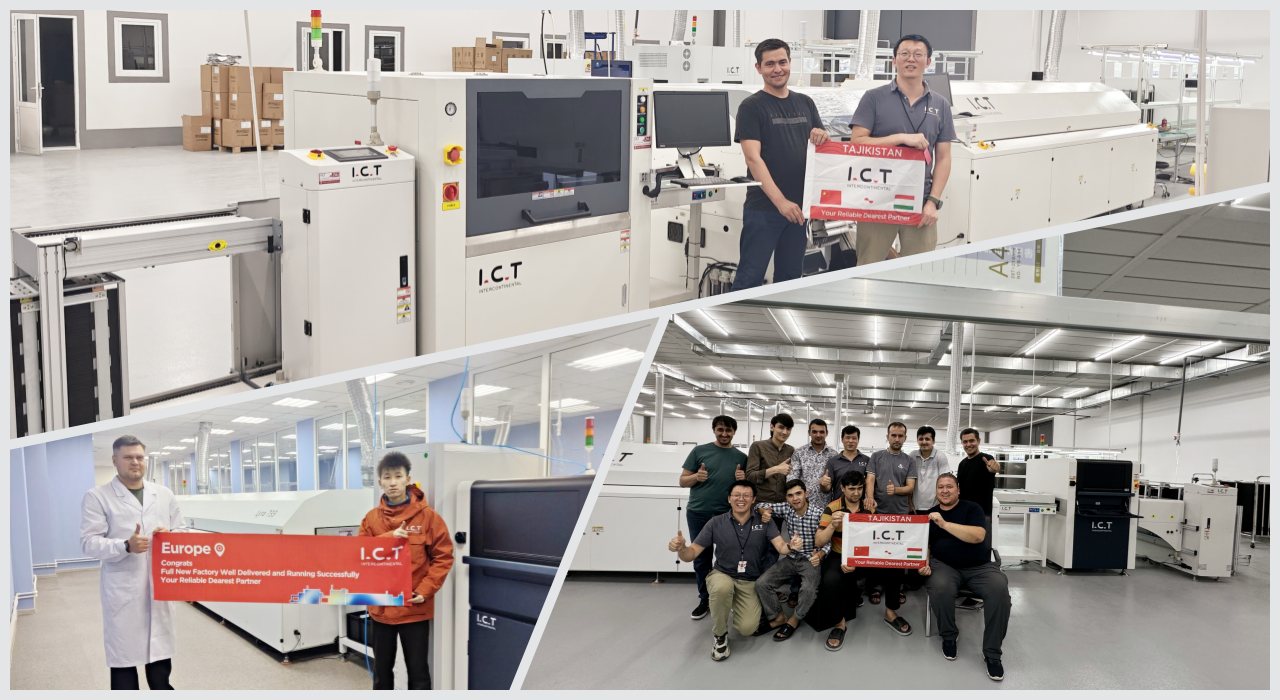

I.C.T provides thorough service and training tailored to each JUKI SMT Mounting Machine. Experienced engineers perform precise installation and initial testing. Hands-on sessions cover operation, programming, and routine maintenance effectively. Remote diagnostics resolve concerns promptly. Scheduled plans sustain peak efficiency over time. Guidance on line improvements and future expansions adds value. Worldwide locations ensure timely assistance regardless of site. Customers experience minimal disruptions and sustained high performance through this committed partnership.

| Customer Feedback

Customers frequently commend the skilled engineers for prompt, effective solutions during setup and beyond. The JUKI SMT Mounting Machine earns admiration for its consistent reliability and impressive speed. Secure packing and safe delivery protect equipment thoroughly. Responses to inquiries arrive quickly, fostering confidence. Overall, the combination of superior machinery and attentive support enhances daily operations noticeably, building lasting trust across projects.

| Certifications and Standards

Each JUKI SMT Mounting Machine complies with essential certifications. CE ensures compliance with European safety requirements. RoHS confirms environmentally responsible materials. ISO9001 maintains rigorous quality processes. Numerous patents safeguard innovative technologies in heads and vision. These credentials demonstrate commitment to worker safety, ecological care, and enduring excellence, meeting international expectations fully.

| About I.C.T Company and Factory

I.C.T maintains dedicated research and development teams advancing SMT innovations continuously. Large-scale factories incorporate stringent testing throughout production. Employee numbers and global branches expand steadily. Serving over 1600 clients across 72 countries reflects strong growth. Comprehensive quality management oversees every stage. The JUKI SMT Mounting Machine emerges robust, designed for demanding daily use worldwide as a trusted industry partner.

| Advanced SMT Machine Pick and Place Machine

In the world of modern electronics assembly, the JUKI SMT Mounting Machine stands out with quiet elegance and power. It positions surface-mount devices on circuit boards with remarkable speed and precision. From tiny chips to larger components, it handles diverse needs effortlessly. The modular design allows seamless expansion as demands evolve. Intuitive programming and real-time vision monitoring simplify operations. Its slim profile integrates beautifully into production floors. I.C.T ensures full assistance, from initial planning through daily optimization, creating reliable lines that produce high-quality boards consistently for various industries.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

Versatility defines the RS-1R and RS-1XL. With the Takumi head adapting dynamically, they manage mixed productions and irregular shapes gracefully. The RS-1R offers 47,000 CPH and ±35µm accuracy, supporting boards up to 650×370mm. The RS-1XL extends to wider 650×560mm panels, suiting larger applications. Up to 112 feeders enable rapid job switches. Gentle force control safeguards delicate substrates. Vision systems detect issues promptly. These models blend well in flexible lines, maintaining steady flow and high yields across varied tasks.

RX-7R / RX-8 Series Features

Pure speed shines in the RX-7R and RX-8, confined elegantly within 998mm width. The RX-8 reaches 100,000 CPH via the innovative P20 head, leading in density per area. The RX-7R provides 75,000 CPH with parallel operations. Both excel at ultra-small 03015 chips. Enhanced coaxial lighting sharpens vision clarity. Low-impact modes protect fragile elements. Smart data sharing reduces downtime. Ideal for dense, high-volume runs, they deliver exceptional productivity without compromising quality or space.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T crafts complete, SMT high-speed line with careful precision. The PCB magazine loader delivers boards impeccably clean. SMT PCB printing machine applies solder paste uniformly. The JUKI SMT Mounting Machine positions every component with exact care. Multi-zone SMT Soldering Oven secure strong bonds. AOI optical inspection reveal flaws reliably. Tight conveyors and buffers maintain uninterrupted rhythm. Yields rise significantly while costs decline. No compromises in strength. Designed for demanding automotive and similar applications, boards emerge fully prepared for real-world challenges. Full backing ensures lasting performance.

| Customer Success Video

A manufacturer of automotive power supplies shares their story through clear video footage. Complete SMT and DIP lines operate in harmonious flow. Boards arrive pristine via vacuum loader. Solder paste spreads evenly at the printer. The JUKI SMT Mounting Machine mounts components swiftly and precisely. Reflow solidifies connections, followed by cooling and buffering. AOI verifies quality thoroughly. On the DIP side, wave soldering, flipping, and ICT testing complete through-hole assembly seamlessly. The customer notes reliable connections, minimal interruptions, and consistently superior results meeting strict standards. Every stage appears efficient and controlled.

| Service and Training Support

I.C.T provides thorough service and training tailored to each JUKI SMT Mounting Machine. Experienced engineers perform precise installation and initial testing. Hands-on sessions cover operation, programming, and routine maintenance effectively. Remote diagnostics resolve concerns promptly. Scheduled plans sustain peak efficiency over time. Guidance on line improvements and future expansions adds value. Worldwide locations ensure timely assistance regardless of site. Customers experience minimal disruptions and sustained high performance through this committed partnership.

| Customer Feedback

Customers frequently commend the skilled engineers for prompt, effective solutions during setup and beyond. The JUKI SMT Mounting Machine earns admiration for its consistent reliability and impressive speed. Secure packing and safe delivery protect equipment thoroughly. Responses to inquiries arrive quickly, fostering confidence. Overall, the combination of superior machinery and attentive support enhances daily operations noticeably, building lasting trust across projects.

| Certifications and Standards

Each JUKI SMT Mounting Machine complies with essential certifications. CE ensures compliance with European safety requirements. RoHS confirms environmentally responsible materials. ISO9001 maintains rigorous quality processes. Numerous patents safeguard innovative technologies in heads and vision. These credentials demonstrate commitment to worker safety, ecological care, and enduring excellence, meeting international expectations fully.

| About I.C.T Company and Factory

I.C.T maintains dedicated research and development teams advancing SMT innovations continuously. Large-scale factories incorporate stringent testing throughout production. Employee numbers and global branches expand steadily. Serving over 1600 clients across 72 countries reflects strong growth. Comprehensive quality management oversees every stage. The JUKI SMT Mounting Machine emerges robust, designed for demanding daily use worldwide as a trusted industry partner.