I.C.T-PP3025

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Inline PCBA Placement Machine – Heart of the SMT Line

The I.C.T Inline PCBA Placement Machine stands in the middle of the line and does the hardest work. Its Multi-Head PCBA Placement Machine heads move together, picking chips from feeders and setting them down exactly where the solder paste waits. Customers choose standard or full CE model. Both have stronger steel, better cameras, and software that learns new products overnight. The Inline PCBA Placement Machine cuts changeover time, raises daily output, and keeps running shift after shift. It speaks the same language as every printer and reflow oven on the floor.

| Detailed Product Features

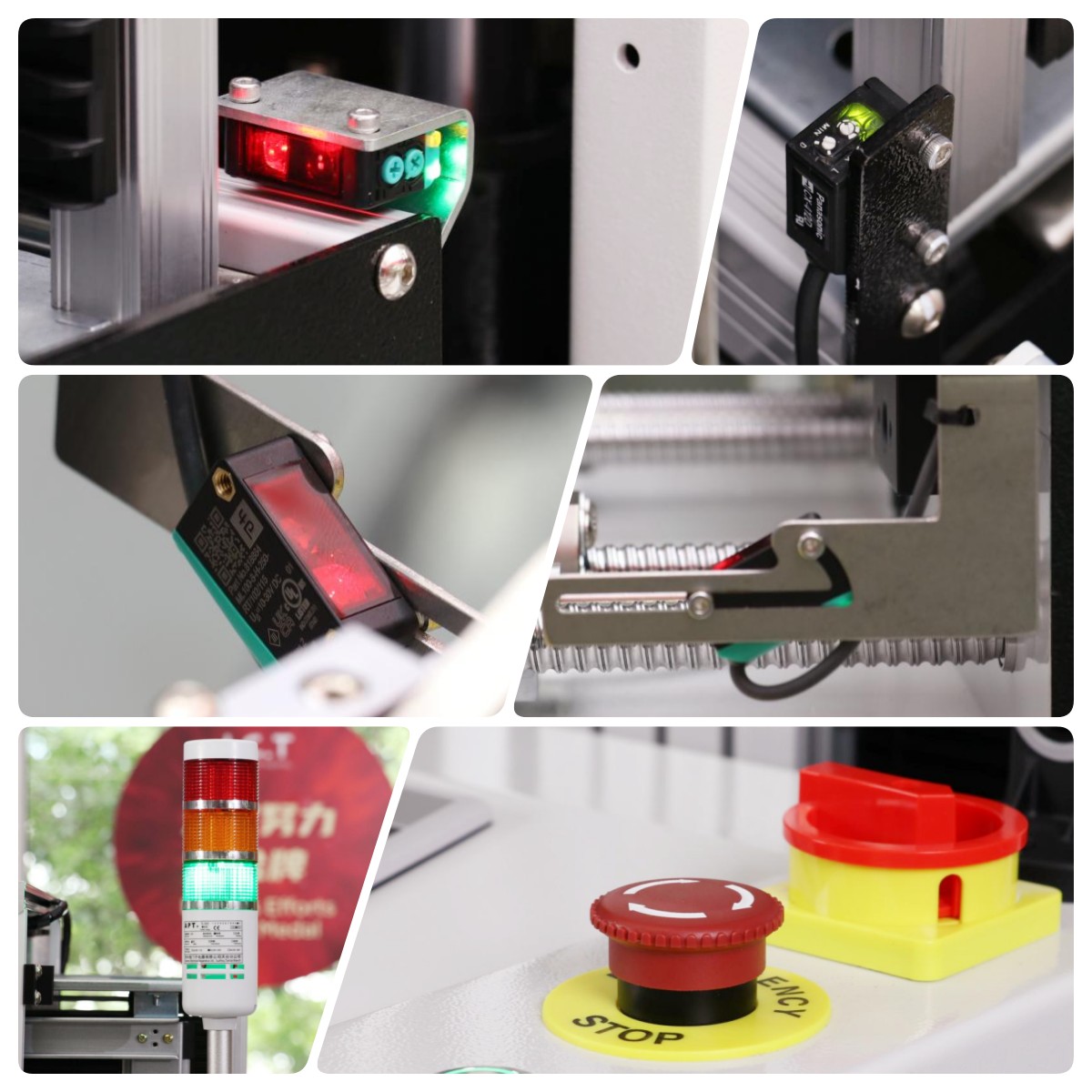

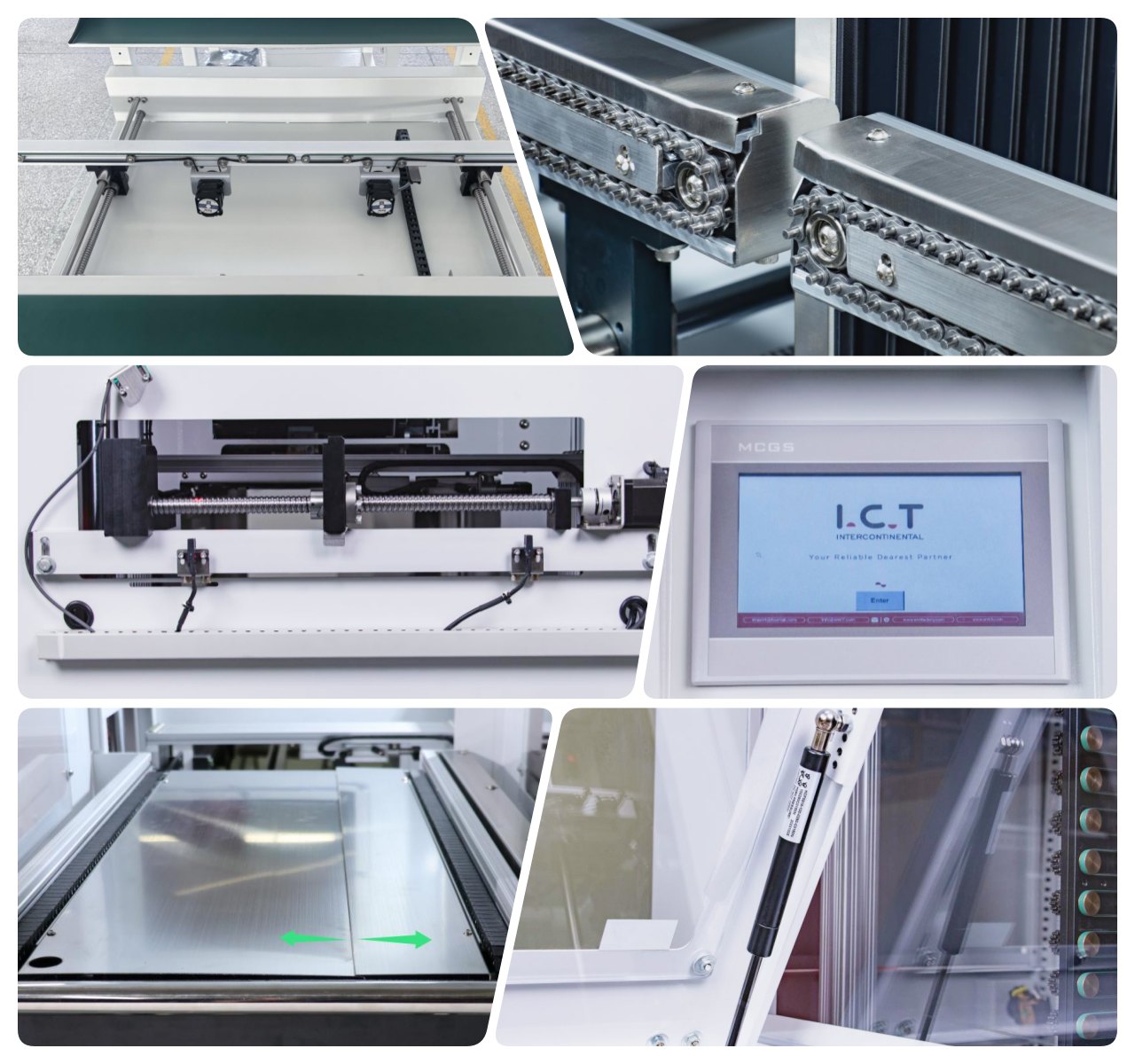

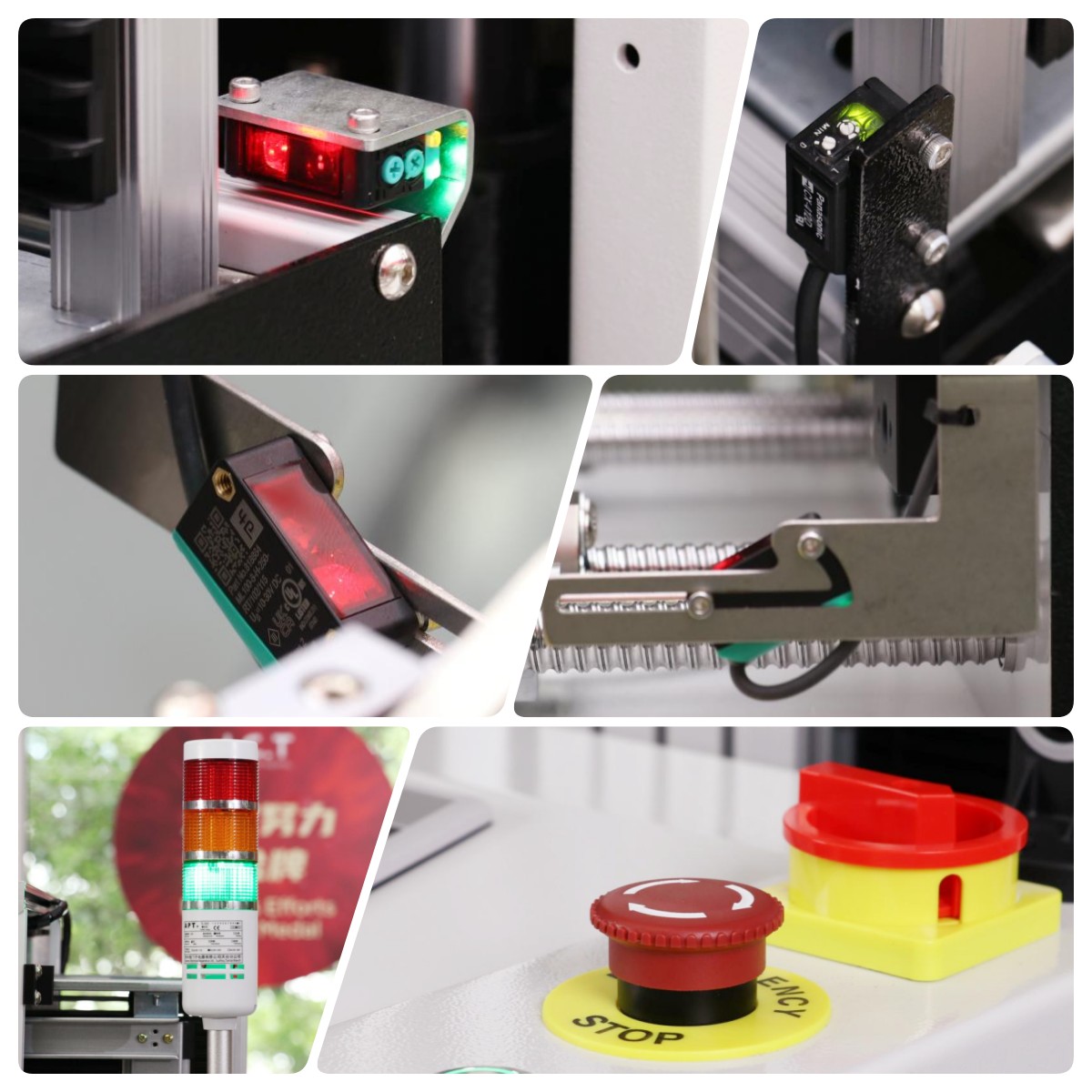

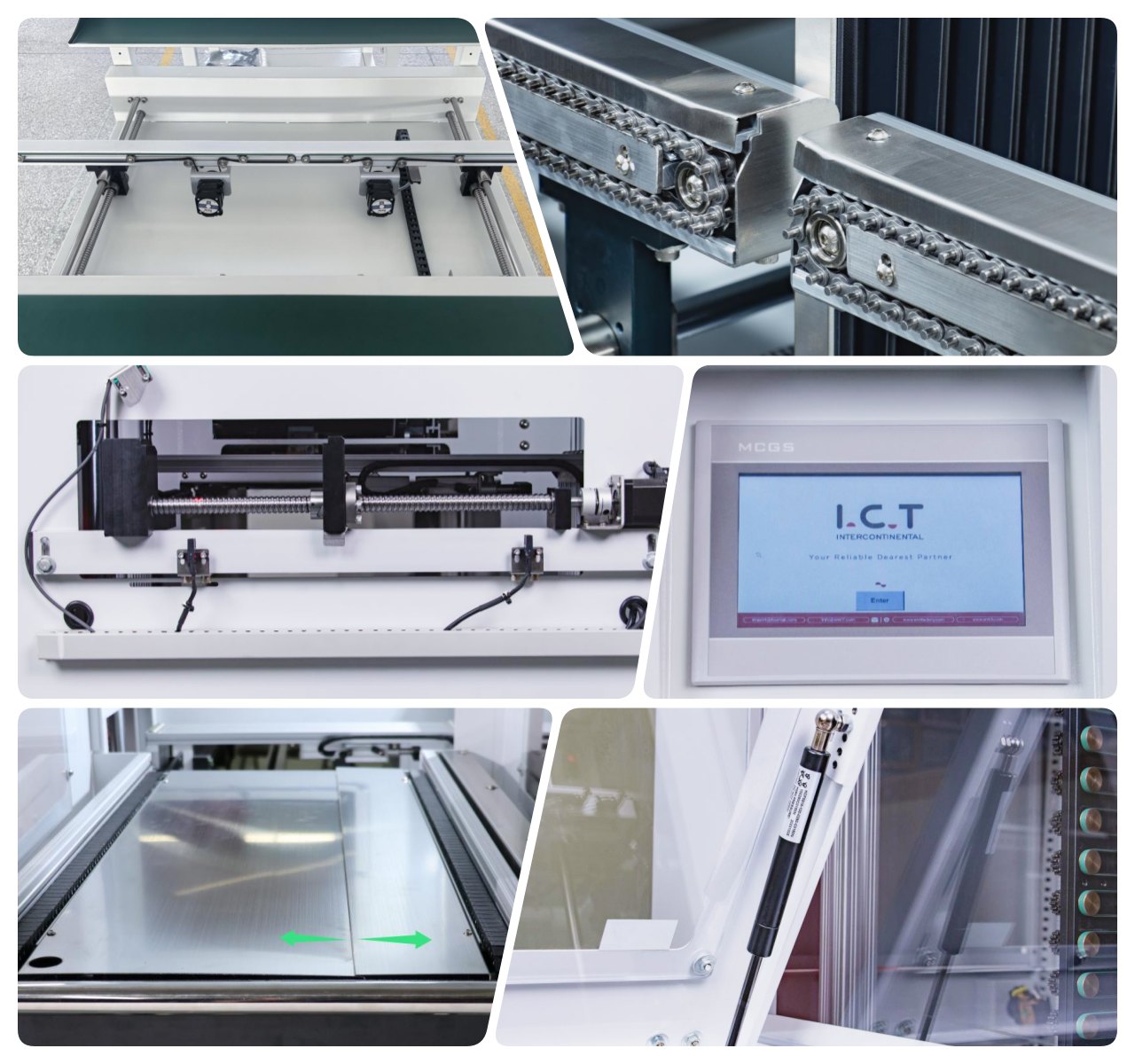

The Inline PCBA Placement Machine rests on thicker steel beams and linear rails. Every part follows ISO and CE rules. The base stays steady even at maximum speed. Maintenance crews reach everything easily. The machine keeps placing parts year after year.

Cameras look down and up. Nozzles move fast and true. The Multi-Head PCBA Placement Machine sees fiducials, checks component shape, and places each part within microns. Placement accuracy stays high from the first board to the last.

Software runs Industry 4.0 standards. IPC-CFX, Hermes, and SEMI SMT-ELS come as options. New programs load in minutes. The Inline PCBA Placement Machine talks to the factory MES and adjusts feeder setup before the operator finishes coffee.

Multiple placement heads work at the same time. Large boards finish as fast as small ones. The Inline PCBA Placement Machine handles 01005 resistors and BGA packages without changing heads. Throughput stays high all day.

SMEMA signals are standard. Smart protocols are ready when needed. The Inline PCBA Placement Machine receives boards from the printer, sends them to reflow, and never stops the flow. Changeovers happen while the line keeps moving.

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

I.C.T engineers flew to Finland and built a complete LED panel line for one of Europe’s largest lighting companies. The line carried the Inline PCBA Placement Machine, 1.5 m printer, L8 reflow oven, buffers, conveyors, and inspection stations. They finished installation and training in five days. Production reached full speed on the first official day. Defects stayed at zero. The customer spoke well of the Inline PCBA Placement Machine and how cleanly it talked to every other station. They passed the European audit without a single remark and ordered another full line the following week.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCB to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

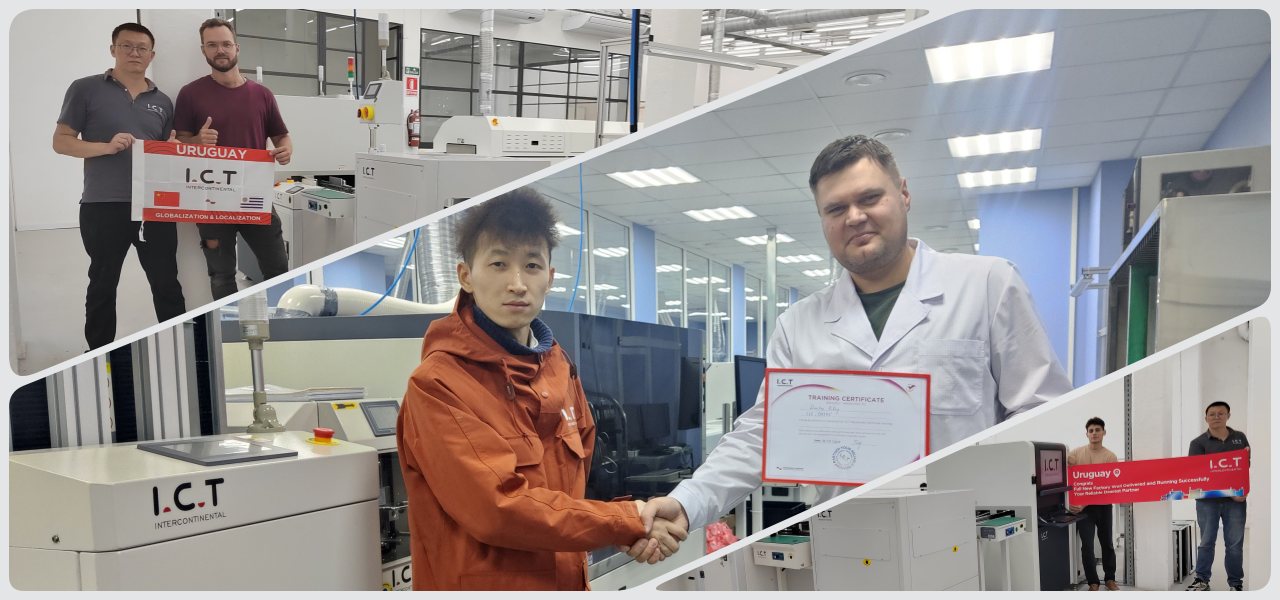

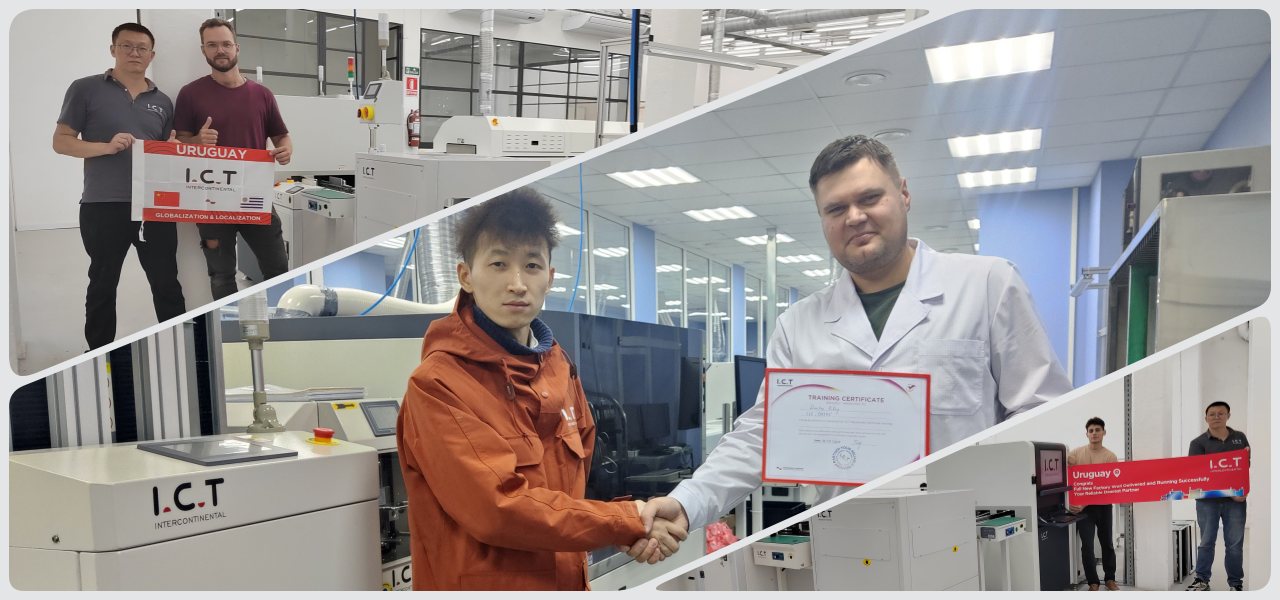

| Customer Success Story

I.C.T engineers flew to Finland and built a complete LED panel line for one of Europe’s largest lighting companies. The line carried the Inline PCBA Placement Machine, 1.5 m printer, L8 reflow oven, buffers, conveyors, and inspection stations. They finished installation and training in five days. Production reached full speed on the first official day. Defects stayed at zero. The customer spoke well of the Inline PCBA Placement Machine and how cleanly it talked to every other station. They passed the European audit without a single remark and ordered another full line the following week.

| Professional Training & Support

I.C.T sends remote checks before the crate leaves the dock. Engineers arrive for start-up. Operators and technicians train for free. The 24/7 hotline answers every call. Spare parts move from warehouses around the world. Regular visits keep everything tuned. The Inline PCBA Placement Machine almost never sits idle when it should be running.

| Customer Praise

“Your engineer fixed it at 3 a.m. their time—best support on the planet!” “Forty-five days at sea and the crate arrived perfect—no damage.” “My PCB SMT Unloader machine has run three shifts for 20 straight months—no failures.” “After one day of training our newest operators ran the whole line alone.”

| Our Certification

Every Inline PCBA Placement Machine carries CE, RoHS, and ISO9001 certifications plus several exclusive patents. Each unit passes a 72-hour full-load test and final inspection before it ships. Customers receive proven quality and complete compliance from the first power-on.

| About Us and Factory

Since 2012 I.C.T has run a 12,000 m² factory with nearly 90 people and its own R&D center. Everything is designed, built, and tested under one roof with strict quality rules. More than 1,600 customers in 72 countries run I.C.T equipment—from one Inline PCBA Placement Machine to complete turnkey lines.

| Inline PCBA Placement Machine – Heart of the SMT Line

The I.C.T Inline PCBA Placement Machine stands in the middle of the line and does the hardest work. Its Multi-Head PCBA Placement Machine heads move together, picking chips from feeders and setting them down exactly where the solder paste waits. Customers choose standard or full CE model. Both have stronger steel, better cameras, and software that learns new products overnight. The Inline PCBA Placement Machine cuts changeover time, raises daily output, and keeps running shift after shift. It speaks the same language as every printer and reflow oven on the floor.

| Detailed Product Features

The Inline PCBA Placement Machine rests on thicker steel beams and linear rails. Every part follows ISO and CE rules. The base stays steady even at maximum speed. Maintenance crews reach everything easily. The machine keeps placing parts year after year.

Cameras look down and up. Nozzles move fast and true. The Multi-Head PCBA Placement Machine sees fiducials, checks component shape, and places each part within microns. Placement accuracy stays high from the first board to the last.

Software runs Industry 4.0 standards. IPC-CFX, Hermes, and SEMI SMT-ELS come as options. New programs load in minutes. The Inline PCBA Placement Machine talks to the factory MES and adjusts feeder setup before the operator finishes coffee.

Multiple placement heads work at the same time. Large boards finish as fast as small ones. The Inline PCBA Placement Machine handles 01005 resistors and BGA packages without changing heads. Throughput stays high all day.

SMEMA signals are standard. Smart protocols are ready when needed. The Inline PCBA Placement Machine receives boards from the printer, sends them to reflow, and never stops the flow. Changeovers happen while the line keeps moving.

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

I.C.T engineers flew to Finland and built a complete LED panel line for one of Europe’s largest lighting companies. The line carried the Inline PCBA Placement Machine, 1.5 m printer, L8 reflow oven, buffers, conveyors, and inspection stations. They finished installation and training in five days. Production reached full speed on the first official day. Defects stayed at zero. The customer spoke well of the Inline PCBA Placement Machine and how cleanly it talked to every other station. They passed the European audit without a single remark and ordered another full line the following week.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCB to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Story

I.C.T engineers flew to Finland and built a complete LED panel line for one of Europe’s largest lighting companies. The line carried the Inline PCBA Placement Machine, 1.5 m printer, L8 reflow oven, buffers, conveyors, and inspection stations. They finished installation and training in five days. Production reached full speed on the first official day. Defects stayed at zero. The customer spoke well of the Inline PCBA Placement Machine and how cleanly it talked to every other station. They passed the European audit without a single remark and ordered another full line the following week.

| Professional Training & Support

I.C.T sends remote checks before the crate leaves the dock. Engineers arrive for start-up. Operators and technicians train for free. The 24/7 hotline answers every call. Spare parts move from warehouses around the world. Regular visits keep everything tuned. The Inline PCBA Placement Machine almost never sits idle when it should be running.

| Customer Praise

“Your engineer fixed it at 3 a.m. their time—best support on the planet!” “Forty-five days at sea and the crate arrived perfect—no damage.” “My PCB SMT Unloader machine has run three shifts for 20 straight months—no failures.” “After one day of training our newest operators ran the whole line alone.”

| Our Certification

Every Inline PCBA Placement Machine carries CE, RoHS, and ISO9001 certifications plus several exclusive patents. Each unit passes a 72-hour full-load test and final inspection before it ships. Customers receive proven quality and complete compliance from the first power-on.

| About Us and Factory

Since 2012 I.C.T has run a 12,000 m² factory with nearly 90 people and its own R&D center. Everything is designed, built, and tested under one roof with strict quality rules. More than 1,600 customers in 72 countries run I.C.T equipment—from one Inline PCBA Placement Machine to complete turnkey lines.