BLD-600

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Premium SMT Upscale Loader for High-End Production

The I.C.T SMT Upscale Loader is the advanced SMT Loader that handles valuable or large bare boards and feeds them perfectly to your high-end printer or placement machine. It features a robust lifting system to ensure no damage or misalignment. Available in standard or full CE version—both include reinforced hardware, top electrical components, and intelligent software. The SMT Upscale Loader, as a reliable PCB Handling Loader, lowers labor needs, raises production efficiency, operates reliably around the clock, and integrates smoothly into any sophisticated SMT setup.

| Detailed Product Features

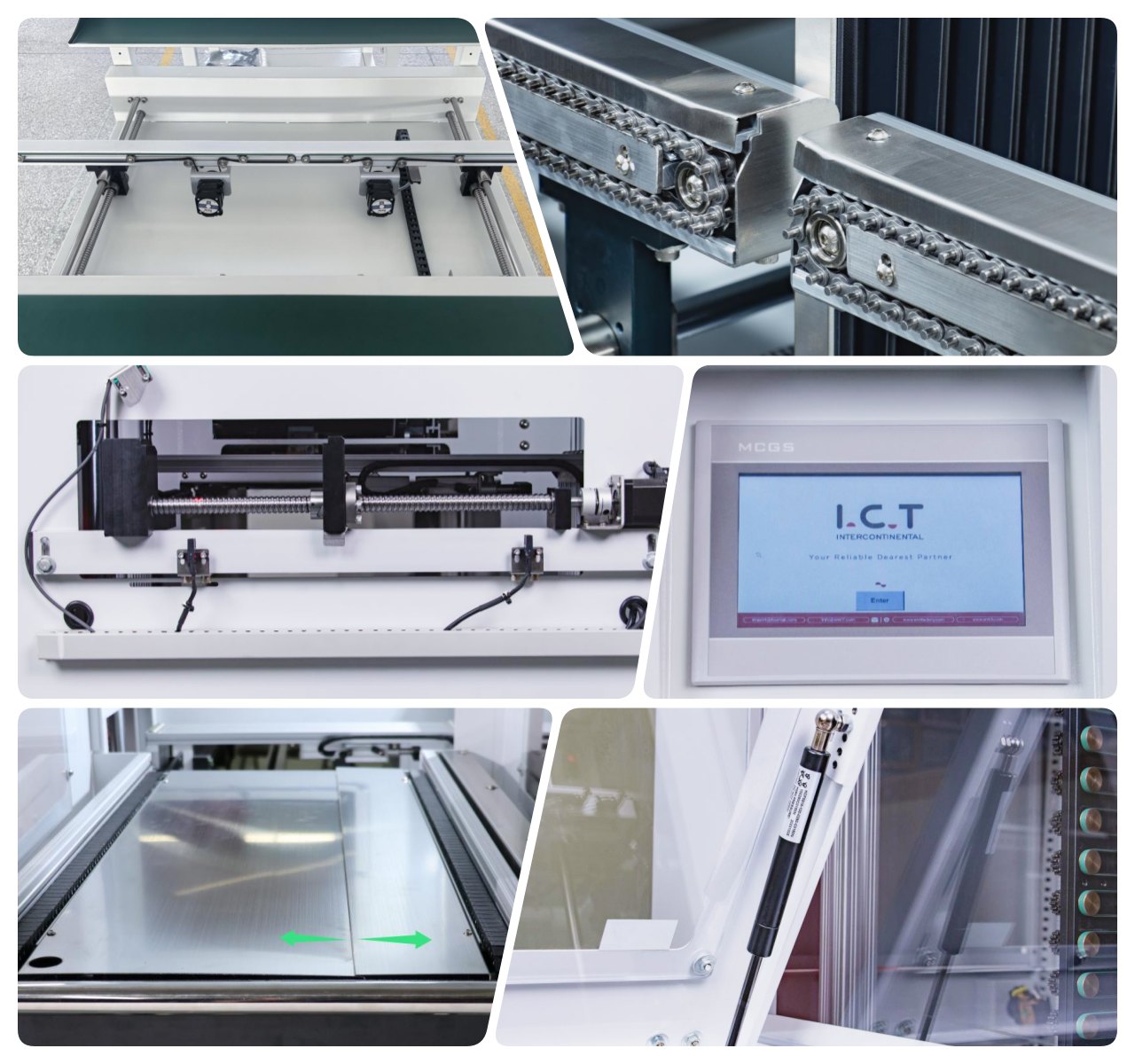

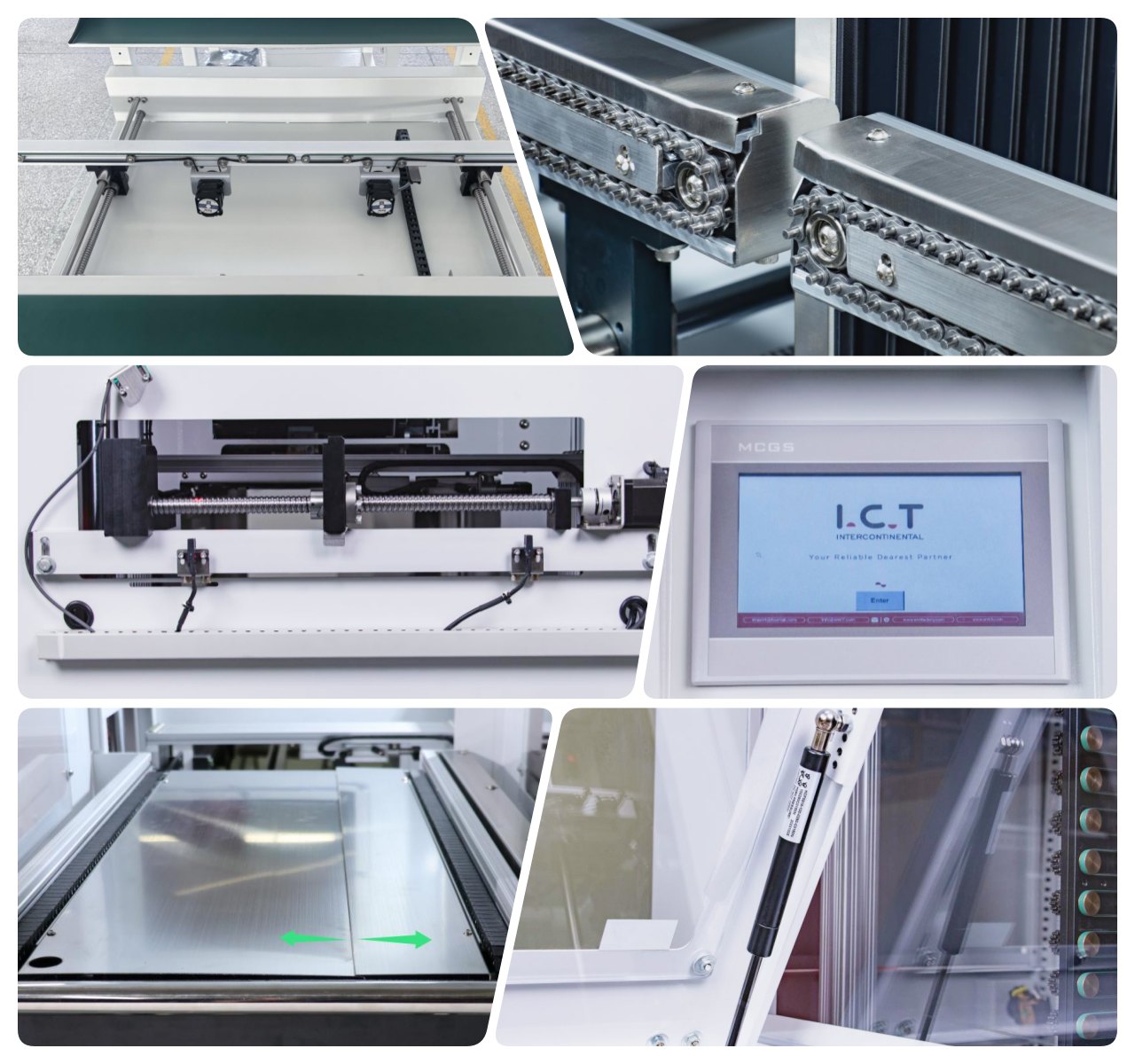

The SMT Upscale Loader uses extra-thick steel rails and solid base construction that complies with ISO and CE requirements. It remains steady during intensive use. Maintenance tasks are straightforward and quick. The machine delivers long-term performance in demanding high-end factories.

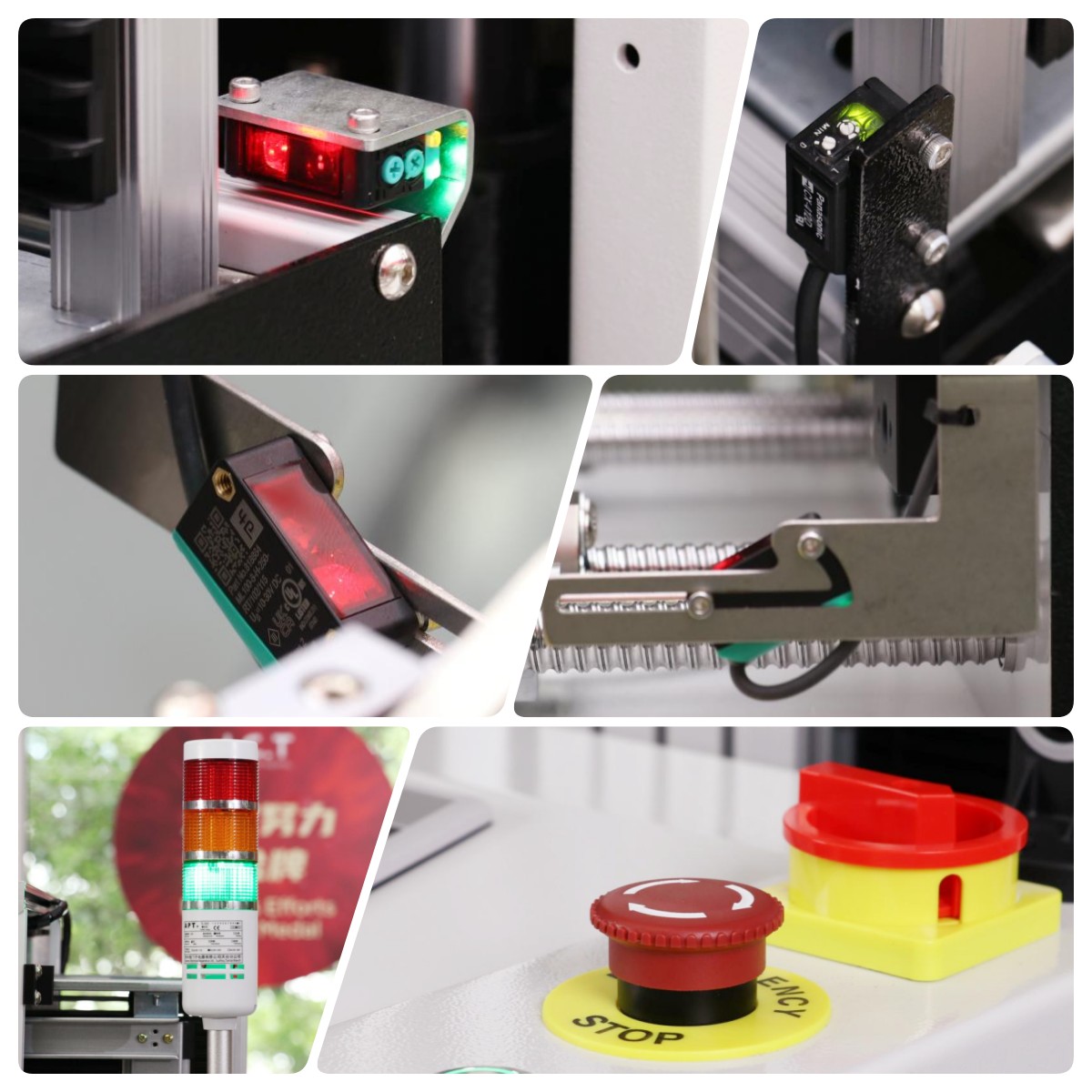

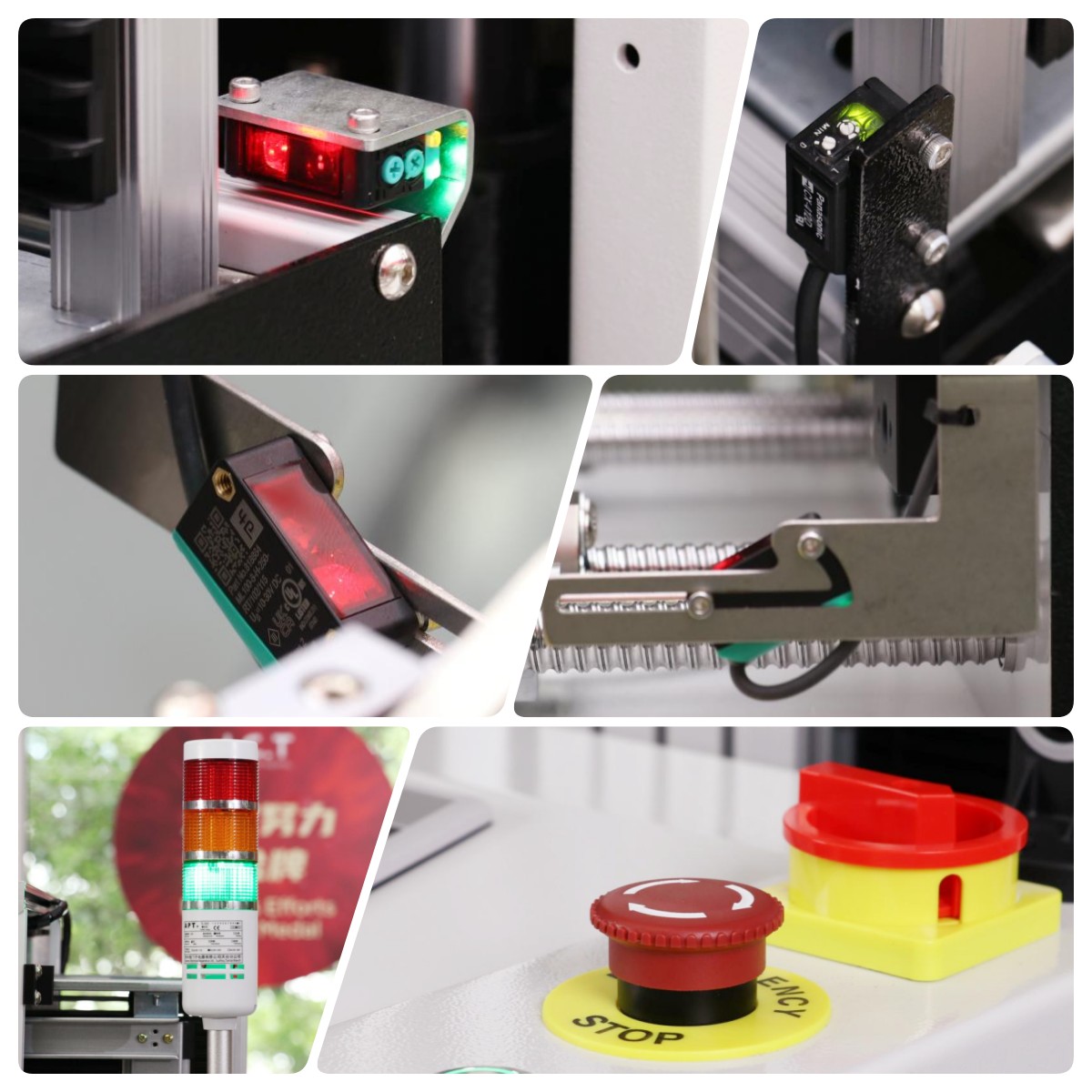

Premium sensors monitor board movement constantly. Clear tower lights display status easily. Responsive buttons work in all conditions. The SMT Upscale Loader identifies potential issues fast and maintains continuous operation without unnecessary interruptions.

The built-in Industry 4.0 control platform is fully upgradable and expandable. Optional IPC-CFX, Hermes, and SEMI SMT-ELS protocols let the Vacuum and Magazine Loader talk seamlessly with upstream and downstream machines, turning your line into a true smart factory with minimum effort.

The built-in system prepares for Industry 4.0 features. Add IPC-CFX, Hermes, or similar protocols anytime. Switch product settings in less than two minutes. The SMT Upscale Loader links to factory networks and adapts automatically to changes.

The lifting unit operates slowly and accurately to prevent harm to expensive boards. The SMT Upscale Loader manages full magazines quietly. Each board exits in exact alignment for the following process.

| Specification

| Model | I.C.T-BLD600 | I.C.T-BUL600 |

| Board size (mm) | 80*50~330*120 | 80*50~330*120 |

| Transmission height (mm) | 900±20 | 900±20 |

| PCB Loading time | 6-16 sec | 6-16 sec |

| Magazine size | 80*50*100-300*150*400 | 80*50*100-300*150*400 |

| PCB thickness | 0.2-2.0mm | 0.2-2.0mm |

| Transmission direction | L to R/R to L | L to R/R to L |

| Compressed air pressure | 0.4~0.6Mpa | 0.4~0.6Mpa |

| Power | AC220V±10V, 50/60HZ 450W | AC220V±10V, 50/60HZ 450W |

| Machine size | 1000х1100х1300 mm | 1000х1100х1300 mm |

| Machine weight | 245KG | 245KG |

| SMT Line Equipment List

Our turnkey High-Quality SMT Production Line delivers fully automatic, high-speed, and ultra-reliable PCBA manufacturing. The proven setup starts with the Vacuum and Magazine Loader, moves to a precision automatic printer for perfect solder paste application, continues with high-speed pick-and-place machines for accurate component placement, passes through a stable reflow oven for strong solder joints, and finishes with advanced AOI inspection to catch any defect. Every machine communicates seamlessly, reducing labor and boosting first-pass yield. This complete solution meets automotive, medical, consumer, and LED industry standards while keeping operating costs low and uptime extremely high.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Story

In 2024 our engineers traveled to Finland and built a complete LED panel production line for a leading European lighting manufacturer. The setup featured the SMT Upscale Loader, 1.5 m automatic printer, SM482PLUS placement machine, L8 reflow oven, cooling buffers, linking conveyors, board splitter, and solder paste mixer. We handled installation, debugging, and full training in five days. The line achieved target speed on the first production day with no defects. The customer highlighted the excellent stability of the SMT Upscale Loader and seamless machine coordination. They cleared the tough European audit easily and placed another order soon.

| Comprehensive Service and Training

We supply remote assistance before delivery, on-site commissioning, and two days of free training for operators and technicians. Our 24/7 hotline connects to experienced engineers. Spare parts come from warehouses worldwide. We arrange regular maintenance visits. Your SMT Upscale Loader operates at peak efficiency with minimal interruptions.

| Satisfied Customer Comments

“Your engineers fixed our issue overnight—outstanding quick response!” “The safe packing ensured perfect arrival after long shipping.” “Our SMT Upscale Loader runs smoothly 24/7 with great reliability.” “The clear training let our team begin production fast.”

| Official Quality Certifications

Every SMT Upscale Loader includes CE, RoHS, and ISO9001 certifications along with multiple patents. Each unit undergoes a 72-hour full-load test and thorough final inspection before shipment. Customers receive verified quality and compliance standards.

| Leading Global SMT Provider

Since 2012 we have developed rapidly with our own R&D department, modern factory, and nearly 90 staff members. We control design, manufacturing, and testing internally with rigorous quality processes. We help over 1,600 customers in 72 countries, from one SMT Upscale Loader to entire factory solutions.

| Premium SMT Upscale Loader for High-End Production

The I.C.T SMT Upscale Loader is the advanced SMT Loader that handles valuable or large bare boards and feeds them perfectly to your high-end printer or placement machine. It features a robust lifting system to ensure no damage or misalignment. Available in standard or full CE version—both include reinforced hardware, top electrical components, and intelligent software. The SMT Upscale Loader, as a reliable PCB Handling Loader, lowers labor needs, raises production efficiency, operates reliably around the clock, and integrates smoothly into any sophisticated SMT setup.

| Detailed Product Features

The SMT Upscale Loader uses extra-thick steel rails and solid base construction that complies with ISO and CE requirements. It remains steady during intensive use. Maintenance tasks are straightforward and quick. The machine delivers long-term performance in demanding high-end factories.

Premium sensors monitor board movement constantly. Clear tower lights display status easily. Responsive buttons work in all conditions. The SMT Upscale Loader identifies potential issues fast and maintains continuous operation without unnecessary interruptions.

The built-in Industry 4.0 control platform is fully upgradable and expandable. Optional IPC-CFX, Hermes, and SEMI SMT-ELS protocols let the Vacuum and Magazine Loader talk seamlessly with upstream and downstream machines, turning your line into a true smart factory with minimum effort.

The built-in system prepares for Industry 4.0 features. Add IPC-CFX, Hermes, or similar protocols anytime. Switch product settings in less than two minutes. The SMT Upscale Loader links to factory networks and adapts automatically to changes.

The lifting unit operates slowly and accurately to prevent harm to expensive boards. The SMT Upscale Loader manages full magazines quietly. Each board exits in exact alignment for the following process.

| Specification

| Model | I.C.T-BLD600 | I.C.T-BUL600 |

| Board size (mm) | 80*50~330*120 | 80*50~330*120 |

| Transmission height (mm) | 900±20 | 900±20 |

| PCB Loading time | 6-16 sec | 6-16 sec |

| Magazine size | 80*50*100-300*150*400 | 80*50*100-300*150*400 |

| PCB thickness | 0.2-2.0mm | 0.2-2.0mm |

| Transmission direction | L to R/R to L | L to R/R to L |

| Compressed air pressure | 0.4~0.6Mpa | 0.4~0.6Mpa |

| Power | AC220V±10V, 50/60HZ 450W | AC220V±10V, 50/60HZ 450W |

| Machine size | 1000х1100х1300 mm | 1000х1100х1300 mm |

| Machine weight | 245KG | 245KG |

| SMT Line Equipment List

Our turnkey High-Quality SMT Production Line delivers fully automatic, high-speed, and ultra-reliable PCBA manufacturing. The proven setup starts with the Vacuum and Magazine Loader, moves to a precision automatic printer for perfect solder paste application, continues with high-speed pick-and-place machines for accurate component placement, passes through a stable reflow oven for strong solder joints, and finishes with advanced AOI inspection to catch any defect. Every machine communicates seamlessly, reducing labor and boosting first-pass yield. This complete solution meets automotive, medical, consumer, and LED industry standards while keeping operating costs low and uptime extremely high.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Story

In 2024 our engineers traveled to Finland and built a complete LED panel production line for a leading European lighting manufacturer. The setup featured the SMT Upscale Loader, 1.5 m automatic printer, SM482PLUS placement machine, L8 reflow oven, cooling buffers, linking conveyors, board splitter, and solder paste mixer. We handled installation, debugging, and full training in five days. The line achieved target speed on the first production day with no defects. The customer highlighted the excellent stability of the SMT Upscale Loader and seamless machine coordination. They cleared the tough European audit easily and placed another order soon.

| Comprehensive Service and Training

We supply remote assistance before delivery, on-site commissioning, and two days of free training for operators and technicians. Our 24/7 hotline connects to experienced engineers. Spare parts come from warehouses worldwide. We arrange regular maintenance visits. Your SMT Upscale Loader operates at peak efficiency with minimal interruptions.

| Satisfied Customer Comments

“Your engineers fixed our issue overnight—outstanding quick response!” “The safe packing ensured perfect arrival after long shipping.” “Our SMT Upscale Loader runs smoothly 24/7 with great reliability.” “The clear training let our team begin production fast.”

| Official Quality Certifications

Every SMT Upscale Loader includes CE, RoHS, and ISO9001 certifications along with multiple patents. Each unit undergoes a 72-hour full-load test and thorough final inspection before shipment. Customers receive verified quality and compliance standards.

| Leading Global SMT Provider

Since 2012 we have developed rapidly with our own R&D department, modern factory, and nearly 90 staff members. We control design, manufacturing, and testing internally with rigorous quality processes. We help over 1,600 customers in 72 countries, from one SMT Upscale Loader to entire factory solutions.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT