Views: 0 Author: I.C.T Publish Time: 2025-07-14 Origin: Site

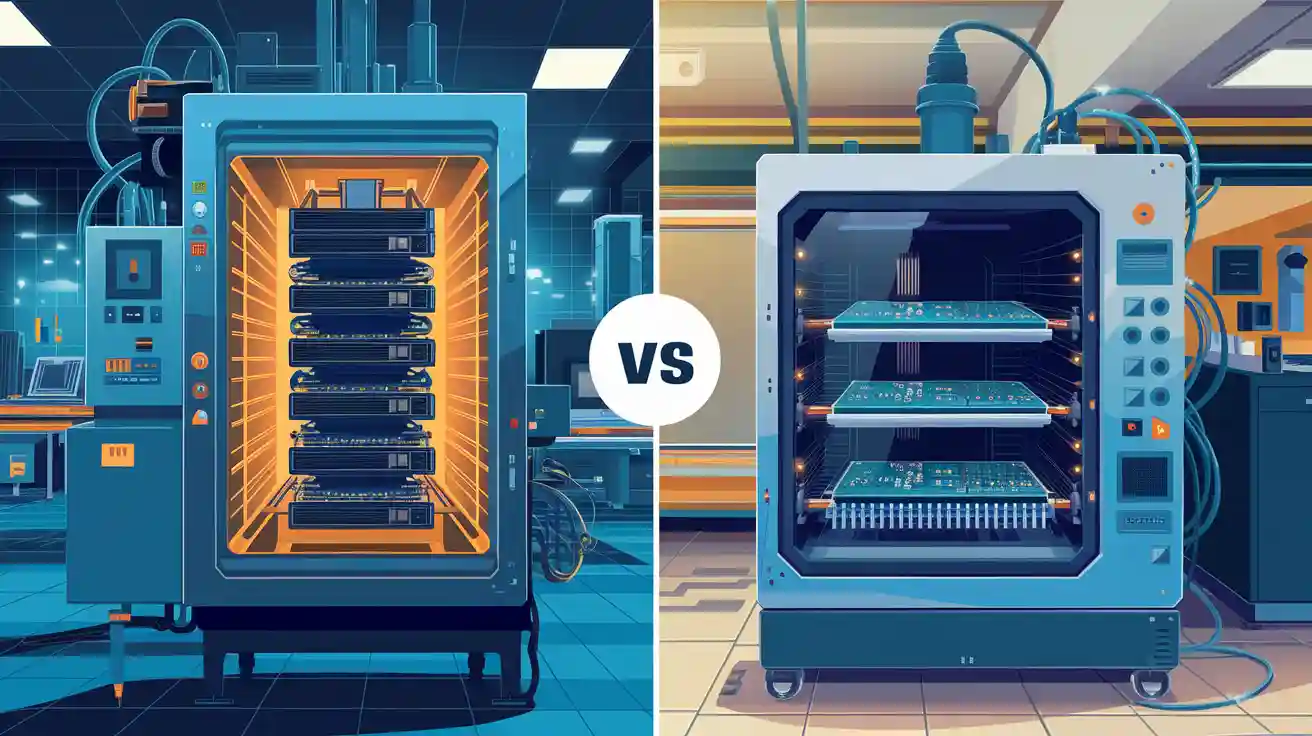

When you pick between smt vertical ovens and a horizontal reflow oven, your needs matter. You may want a small oven for your smt line. Or you may need to make many surface mounted technology products fast. Smt vertical ovens help save space. A reflow oven can work with many board sizes. If you want better smt reflow technology in your factory, check how each reflow oven fits your work steps. Many factories in the China Reflow Soldering Oven market use both types. This helps them meet different reflow needs.

· SMT vertical ovens use less floor space because they stack heating zones. This makes them good for small or crowded factories.

· Horizontal reflow ovens can work on more boards at once. They heat boards evenly. This helps make better soldering and fewer mistakes.

· Horizontal ovens are cheaper to buy and fix. Vertical ovens cost more but have more heating zones. They also control temperature better.

· Both ovens can use lead-free soldering and nitrogen. This helps make strong and reliable solder joints.

· Pick your oven by looking at your factory space, how much you make, board size, and money. This helps you get the best results and work faster.

When you compare SMT vertical ovens and horizontal reflow ovens, you notice some big differences. You need to pick the reflow oven that matches your needs. Each convection reflow oven moves air in its own way. In a horizontal reflow oven, air goes from the front to the back of the PCB. This makes a swirling wind inside. The convection reflow oven keeps the heat even on the board. This means there are fewer hot spots and the solder joints are better.

A vertical reflow oven moves air up and down. This convection reflow oven has many heating zones stacked on top of each other. You can set the temperature for each zone. Some vertical ovens, like the I.C.T Lyra733N, have up to 10 heating zones. They also use PID closed-loop temperature control. This helps keep the reflow process steady. Vertical ovens often need more advanced flux management systems. You might use more nitrogen in a vertical reflow oven because the chamber is bigger.

A horizontal convection reflow oven is easier to take care of. It uses less nitrogen and costs less to run. A vertical reflow oven takes up less space, but it is harder to use and costs more to operate. Both types of reflow ovens can do lead-free soldering and work with nitrogen to make solder joints better.

Tip: If you want a convection reflow oven that is easy to clean and costs less, a horizontal reflow oven is a good choice. If you need to save space or want more heating zones, try a vertical reflow oven.

Feature/Aspect | Horizontal Reflow Oven | Vertical Reflow Oven |

Air Circulation Method | Horizontal cyclone convection | Vertical convection |

Temperature Uniformity | High, even across PCB | Good, but may have less uniformity |

Heating Zones | 3 top & 3 bottom (common) | Up to 10 vertical zones |

Flux Management | Simple, less residue | Complex, needs more cleaning |

Nitrogen Usage | Low, efficient chamber design | Higher, larger chamber |

Equipment Complexity | Simple, easy to maintain | More complex, higher upkeep |

Space Needed | Larger footprint | Smaller footprint |

Lead-Free Compatibility | Yes | Yes |

Operational Cost | Lower | Higher |

You can look at this table to see how each convection reflow oven is different. This makes it easier to pick the best reflow oven for your factory.

Throughput means how many boards you can finish in a certain time. It is very important for any reflow oven. If you make lots of products, you need high throughput. Horizontal reflow ovens help with this. They use belts or pins to move boards through heat zones. You can have more than one lane or chamber in these ovens. This lets you work on many boards at once. You get more done and your line works better.

Most factories pick horizontal reflow ovens for big jobs. These ovens are old technology and work well. Many large SMT factories use them because they can handle more boards. The air in a horizontal convection reflow oven moves sideways. This helps keep the heat the same on every board. Even heat means you get the same results and fewer mistakes. You can trust these ovens to give you good quality every time.

SMT vertical ovens work in another way. They stack boards in tall zones. Air moves up and down, and each board has its own hot area. This saves space but does not match the speed of horizontal ovens. Vertical ovens have trouble when you want to make more products. They take up less room, but they do not finish as many boards. It can also be harder to make the process better for big batches. If you want to make more boards fast, pick a horizontal reflow oven.

Note: If you want to make lots of boards and fill big orders, use a horizontal reflow oven. You will get better results and your line will run smoother.

Temperature control is also very important in the reflow process. You want every board to get the right heat at the right time. In a convection reflow oven, the way air moves and the number of heat zones matter a lot. Horizontal reflow ovens use air that moves sideways. This helps spread heat across the whole board. You get even heat, which is good for strong soldering and fewer mistakes.

You can set up a horizontal reflow oven with many top and bottom heat zones. Each zone can have its own temperature. This lets you change the heat for different products. You can do lead-free soldering and use different flux types. The even air also helps keep flux from building up. You spend less time cleaning and more time making boards.

SMT vertical ovens use air that moves up and down. Each board goes through stacked heat zones. You can set the temperature for each zone, so you get good control. Some vertical ovens have up to ten zones. This helps you make a special heat plan for your boards. Sometimes, you get more balanced heat in these ovens. But vertical ovens are harder to use. You need to watch for flux buildup and make sure air moves right. If you do not check these things, you might get uneven heat or soldering problems.

Both ovens can do lead-free soldering and use nitrogen to make solder joints better. You should look at what your products need and pick the oven that fits your work. If you want easy cleaning and simple care, a horizontal convection reflow oven is a good pick. If you want more heat zones and tight control, an SMT vertical oven might be better.

Tip: Always check your reflow oven’s heat plan and flux system. Good control gives you better soldering and fewer mistakes.

When you plan your SMT line, space matters. You want to fit all your machines without crowding your factory. Horizontal reflow ovens take up a lot of floor space. These ovens stretch out in a long line. You need to leave room for loading and unloading boards. If your factory has limited space, this can be a problem.

SMT vertical ovens help you save floor space. These ovens stack their heating zones on top of each other. You get a tall machine that uses less room on the ground. You can place other machines or work tables nearby. This makes your factory look neat and organized. If you work in a small area, a vertical oven can be a smart choice.

Tip: Measure your available floor space before you buy an oven. A vertical oven fits better in tight spots.

You need to think about how your oven fits into your production line. Horizontal ovens work well in long, straight lines. You can connect them to other machines easily. If you have a big factory with lots of room, a horizontal oven can fit right in.

Vertical ovens give you more options. You can place them in corners or between other machines. You do not need a long, open space. This helps you design a flexible layout. You can change your line if your needs grow. Some factories use both oven types to get the best fit.

· Horizontal ovens: Best for large, open layouts.

· Vertical ovens: Best for small or crowded spaces.

You should match your oven to your factory’s shape and size. This helps you work faster and keeps your line running smoothly.

You want every board to have strong, shiny solder joints. The reflow oven you pick can change your soldering results. In a horizontal reflow oven, air moves sideways over the board. This keeps the temperature the same everywhere. You get fewer cold spots, so soldering is more reliable. These ovens also help lower flux residue. Less flux means fewer problems and less cleaning.

A vertical reflow oven stacks boards in tall layers. Air moves up and down, so each board gets its own heat. This can help keep the temperature balanced, but you must watch for too much flux. If you do not control the flux, you might get more soldering problems. Both ovens let you use nitrogen. Nitrogen lowers oxygen, which helps the soldering process. You get better solder wetting and fewer issues like tombstoning or solder balls. This is very important for sensitive parts.

Tip: Pick a reflow oven that works with nitrogen if you want strong solder joints. You will see fewer problems and better results.

You may need to solder different board sizes or types. Both ovens can handle many PCB sizes, but horizontal ovens are better for big or odd-shaped boards. The reflow process in these ovens is easy to change. You can set different heat zones for each board. This helps you control the flux and soldering for every product.

Vertical reflow ovens save space and work well for small or medium boards. You can set each heating zone for special needs. Both ovens support lead-free soldering and work with many kinds of flux. Here is a table that shows lead-free compatibility:

Oven Model | Lead-Free Compatibility | Soldering Types Supported | Nitrogen Purging Capability |

APS Novastar GF-125 HC/HT | Yes (all lead and lead-free applications) | Leaded, Lead-Free | Yes |

ATCO PRO 1600 SMT Reflow Oven | Yes (Pb-Free standards compliant) | Leaded, Lead-Free | Yes |

You can trust both ovens for today’s soldering needs. Just pick the oven that fits your board size and how you make products. Always check your flux system and temperature plan for the best results.

When you choose an oven for your SMT line, you must think about the money you spend at the start. Horizontal reflow ovens usually cost less to buy. You can find many models that fit small or large budgets. These ovens have a simple design. You do not need to pay extra for special features. SMT vertical ovens cost more at first. You pay for advanced controls and more heating zones. If you want to save floor space, you may need to spend more.

A table can help you compare the costs:

Oven Type | Initial Cost | Special Features |

Horizontal Reflow | Lower | Basic controls |

SMT Vertical Ovens | Higher | More zones, compact |

Tip: Always check your budget before you buy. Think about what you need now and what you may need later.

You must also think about how much it costs to keep your oven running. Horizontal ovens need less cleaning. The design helps with flux extraction and removal. You see less flux buildup inside the oven. This means you spend less time and money on upkeep. You can run your line with better efficiency.

SMT vertical ovens need more care. The tall design can trap more flux. You must use strong flux extraction and removal systems. If you do not, flux can build up fast. This can hurt your soldering results. You may need to stop your line more often for cleaning. Good flux extraction and removal helps lower this risk. You should check your oven often for flux problems.

Note: If you want less downtime and easy cleaning, pick an oven with good flux extraction and removal. This keeps your line running and your boards clean.

If your factory makes lots of boards each day, you need a fast reflow oven. High-volume work means you want to finish many boards quickly. You also want the results to be strong and steady. Pick a reflow oven with many heating zones. Ovens with 10 or more zones heat each board evenly. This is important for high-density PCBA. Even heat means fewer mistakes and better soldering.

Most factories use horizontal reflow ovens for big jobs. These ovens move boards on a conveyor through heat zones. You can change the speed and set the temperature in each zone. This gives you more control and helps you finish more boards faster. Some ovens, like the Lyra series, have special features. They have two cooling systems and can use nitrogen. These features help you get better quality and cool boards quickly.

Vacuum reflow ovens are good for fancy electronics. They help make solder joints stronger and reduce empty spots. Automation and adjustable conveyor speeds make your work easier. You can trust these ovens to help you finish lots of boards.

· Multi-zone reflow ovens heat high-density boards evenly.

· Vacuum reflow ovens make solder joints stronger.

· Automation and strong cooling help with big jobs.

· Nitrogen support gives better soldering results.

Tip: For high-volume work, pick a reflow oven with many heating zones, strong cooling, and automation. You will get better results and finish more boards every day.

If you make many kinds of boards, you need a reflow oven that can change fast. High-mix work means you switch between products a lot. You want an oven that can handle different PCB sizes and heat needs. SMT vertical ovens are good for this. They save space and let you set each heating zone for special needs. You can change the temperature for each product. This helps you get good results every time.

Horizontal reflow ovens also work for high-mix lines. They are good if you have big or odd-shaped boards. You can set different heat zones and change the conveyor speed. This helps you match the heat to each board. Both ovens can do lead-free soldering and use nitrogen. This helps you meet today’s standards.

When you pick between SMT vertical ovens and horizontal reflow ovens, think about your board size and heat needs. If you have small or medium boards and want to save space, pick a vertical oven. If you need to work with big boards or want easy cleaning, pick a horizontal reflow oven.

Application Type | Best Oven Choice | Key Features Needed |

High-Volume | Horizontal Reflow Oven | Multi-zone, automation, cooling |

High-Mix | SMT Vertical Oven | Flexible zones, compact design |

Large PCBs | Horizontal Reflow Oven | Wide conveyor, adjustable zones |

Sensitive Parts | Vacuum Reflow Oven | Nitrogen, void reduction |

Note: Always match your oven to your product needs. Check your PCB size and heat plan before you choose. The right reflow oven helps you get better soldering and finish more boards.

You now know SMT vertical ovens save space and have flexible heating zones. Horizontal reflow ovens let you make more boards fast and are easy to clean. The best oven for you depends on what you make, how much space you have, and your budget. Experts think more people will buy reflow ovens as small electronics and lead-free soldering get popular. Use this guide to help you choose. For the best advice, ask suppliers who know what you need.

You save floor space with smt vertical ovens. These ovens stack heating zones, so you fit them in tight spots. You keep your smt line organized and improve efficiency, especially if your factory has limited room.

A convection reflow oven moves hot air around your boards. This even airflow gives you steady temperatures. You get strong solder joints and fewer defects. You also see less flux buildup, which means less cleaning and better results.

Throughput shows how many boards you finish in a set time. If you want higher throughput, you pick a reflow oven that matches your production speed. This helps you meet big orders and keeps your surface mounted technology line running smoothly.

You use special systems for flux extraction and removal. These systems pull out extra flux during reflow. You keep your oven clean and protect your boards. Good flux control helps you keep high efficiency and strong soldering results.

content is empty!