Views: 0 Author: Site Editor Publish Time: 2025-07-08 Origin: Site

Reflow oven conveyor systems affect PCB quality in every line. Rail conveyor ovens give strong support for boards that need accuracy. They work well for high-precision or double-sided assemblies. Mesh conveyor ovens are good for big, delicate, or bendy boards. They help spread heat evenly across the board. Many systems use both rail and mesh conveyors for different needs. Conveyor ovens with rail systems are easy to keep up in busy factories. Mesh conveyor ovens can help lower downtime in some cases. Good temperature control is important for every conveyor type. Lyra Reflow Oven with Nitrogen is a top choice for new conveyor ovens in electronics.

· Rail conveyor ovens grip PCBs by the sides. This makes them good for jobs that need high accuracy. They also work well for double-sided soldering.

· Mesh conveyor ovens hold up the whole board. This stops the board from bending. They give even heat to the board. They are best for large, soft, or fragile PCBs.

· Hybrid conveyor ovens use both rail and mesh features. This gives factories more choices. They are helpful when board types change or are mixed.

· Cleaning and taking care of conveyor parts often is important. It helps ovens work well and cuts down on breaks.

· Picking the right conveyor system makes PCB quality better. It saves money and helps factories work better.

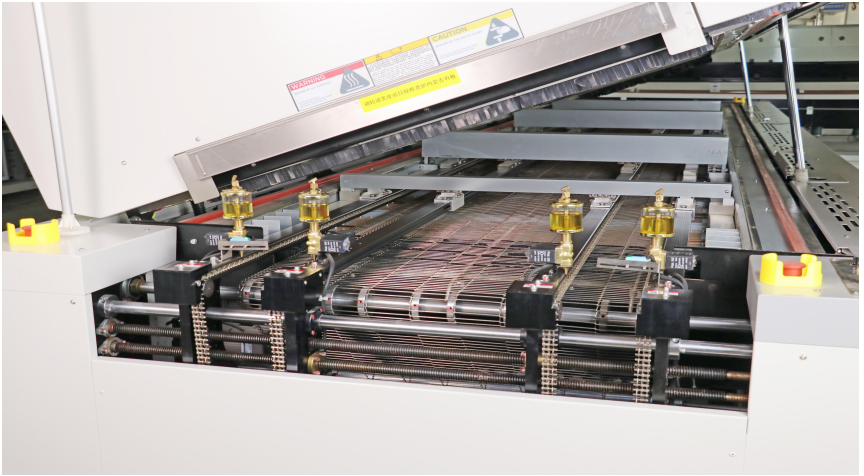

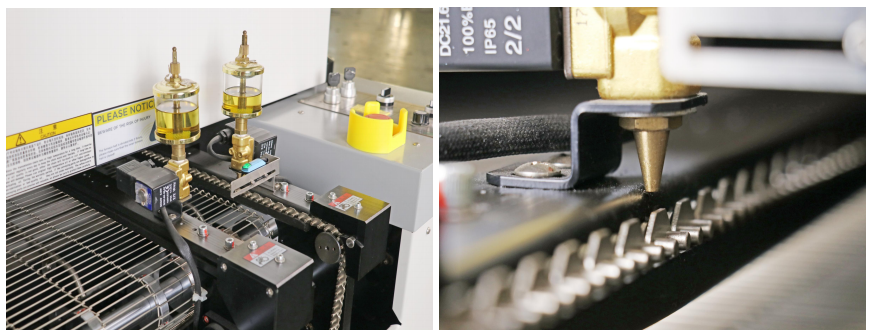

Rail conveyor ovens are also called pin edge or chain type. They use strong rails made of stainless steel. These rails hold PCBs by their edges. The bottom of the board does not touch anything. This is good for double-sided processing. Rail conveyor systems can change width to fit different boards. Many ovens have automatic oiling and width change tools. These help the oven run smoothly. Rail conveyor ovens are great for jobs that need high accuracy. They are best when boards must line up just right. Some vertical conveyor ovens with rails save space in busy factories.

Mesh conveyor ovens use a mesh belt to move PCBs. The mesh belt holds the whole board. This helps stop the board from bending or getting dents from heat. Mesh conveyor systems are good for big, soft, or bendy boards. They give even support while the board moves through the oven. These ovens heat boards evenly and run smoothly. Many factories use mesh conveyor ovens for single-sided boards. The mesh design makes cleaning and fixing easy. This helps lower the time the oven is not working.

Some ovens use both rail and mesh conveyor parts. These are called hybrid conveyor ovens. They can use rails and mesh belts together. This helps them work with many board sizes and needs. Hybrid ovens often have special width and speed controls. This lets them handle many types of boards well. Hybrid conveyor ovens are good for lines with both single and double-sided boards. Many vertical ovens use hybrid systems to work faster and change easily. Using both pin edge and mesh conveyor parts makes these ovens useful for new electronics factories.

Tip: The table below shows the main features of each conveyor system type.

Conveyor System Type | Applications | Key Components and Features | |

Chain Type (Rail) | Stainless steel chain with adjustable width | Single/double panel welding | Chain, automatic lubrication, adjustable width |

Mesh Belt Type | Mesh belt prevents heat-induced denting | Single-panel welding | Mesh belt (central support), smooth operation |

Chain/Mesh Belt Dual | Combines advantages of chain and mesh belt | Various PCB board sizes | Rails, mesh belts, chains, motors, width adjustment, speed control |

Conveyor ovens help hold PCBs during soldering. Rail conveyor ovens use rails to grip the board edges. This keeps the bottom of the board safe. Pin edge systems are good for double-sided soldering. They protect the solder paste and parts on both sides. Mesh conveyor ovens use a mesh belt to hold the whole board. This is helpful for big or fragile boards that might bend. Mesh systems give even support and help stop warping. Hybrid conveyor ovens use both rails and mesh belts. These ovens can work with many board types and sizes.

Note: Support rail systems help boards line up well, but mesh systems are better for weak boards.

Flexibility is important in today’s factories. Rail conveyor ovens can change to fit different board widths. Workers move the rails for each new batch. Pin edge ovens are good for lines with many board sizes. Mesh conveyor ovens work with boards of many shapes and thicknesses. The mesh belt fits odd or thin PCBs. Hybrid ovens can switch between rail and mesh. This makes them great for mixed jobs. Hybrid conveyor ovens help factories fill new orders fast.

· Rail conveyor ovens: Best for jobs that need to be exact and repeatable.

· Mesh conveyor ovens: Good for boards that are big, soft, or different.

· Hybrid conveyor ovens: Great for lines that change a lot.

Thermal performance is important for good soldering. Rail conveyor ovens use heat zones to control temperature. The rails keep boards steady for even heating. Pin edge ovens are best for double-sided soldering. Both sides get the same heat. Mesh conveyor ovens let hot air touch the whole board. The mesh belt helps heat spread evenly and stops cold spots. Hybrid ovens use both ways for balanced heat. Hybrid ovens often give the best heat for tricky boards.

Tip: Mesh conveyor ovens often heat big or thick boards more evenly.

Maintenance keeps ovens running well. Rail conveyor ovens need the rails and chains cleaned often. Automatic oiling helps stop parts from wearing out. Pin edge ovens may need more checks to keep rails lined up. Mesh conveyor ovens need the mesh belt cleaned to stop solder from building up. The open mesh is easy to clean. Hybrid ovens need both kinds of care. Hybrid ovens may need more work but are more flexible. Clean ovens work better and stop less often.

· Rail conveyor ovens: Need chain and rail cleaning.

· Mesh conveyor ovens: Need mesh belt cleaning.

· Hybrid conveyor ovens: Need both types of care.

Cost is important when picking an oven. Rail conveyor ovens cost more because they use special parts. Mesh conveyor ovens usually cost less at first. They are good for simple or one-sided jobs. Hybrid ovens cost the most but can do the most jobs. Hybrid ovens work with many board types and changes. Energy use also changes long-term costs. Ovens with good heat design use less energy and save money. Factories should think about both the first price and long-term savings.

Alert: Buying energy-saving and reliable ovens can help save money later.

Rail conveyor ovens are best for jobs that need high accuracy. These ovens hold each board by its edges. This keeps the bottom open for double-sided soldering. Rail conveyors can place boards very exactly, as close as +/- 0.04 mm at the drive end. They use strong guide rails and tough metal frames to stay steady. Many rail conveyors move boards fast and do not shake much. This helps make sure the solder is always good. Factories that want steady results and little shaking pick rail systems for their ovens. These ovens can work with PLCs and robots. This makes them good for busy lines that run all the time. Rail conveyors can also fit many board sizes. This helps big factories make lots of different boards.

Tip: Rail conveyors are best when you need accuracy, repeatable results, and double-sided soldering.

Mesh conveyor ovens are good for big, soft, or bendy boards. The mesh belt holds the whole board so it does not bend during soldering. Mesh conveyors let hot air touch every part of the board. This gives even heat and good solder joints. These ovens are great for single-sided jobs and boards that cannot be held by the edges. Mesh conveyors are easy to clean and fix. This means less time when the oven is not working. Factories that make many shapes or sizes of boards often pick mesh conveyors. Mesh systems help keep solder quality steady in places that make lots of different boards but not too many of each.

· Mesh conveyors: Best for boards that are fragile, big, or thin.

· Mesh belts: Stop dents and help heat spread evenly.

Hybrid conveyor ovens use both rail and mesh parts to handle hard jobs. These ovens can do both single and double-sided soldering. In busy places with many work areas and machines, hybrid ovens help plan work better. They help balance how fast things move, setup costs, and getting orders done. A smart system can help set the best process steps. This makes work faster and cuts down waiting time. Hybrid ovens can change quickly for different board types. This helps with flexible plans and making lots of boards. The table below shows how hybrid ovens help with tough jobs:

Scenario | Hybrid System Advantage |

Mixed board types | Switches between rail and mesh easily |

High production complexity | |

Frequent changeovers | Adapts quickly to new processing needs |

Note: Hybrid conveyor ovens give the most choices for factories that need to change solder jobs and work with many kinds of boards.

Picking the right conveyor system means looking at key features. The table below shows rail, mesh, and hybrid conveyor systems. It points out things like how much weight each can hold, how flexible they are, and what jobs they do best. This makes it easy to see which system is good for each job.

Conveyor System Type | Load Capacity | Flexibility | Typical Applications |

Rail (Pin Edge/Chain) | High | Moderate | Double-sided PCBs, High-precision |

Mesh Belt | Moderate | High | Large, Delicate, Single-sided PCBs |

Hybrid (Rail + Mesh) | High | Very High | Mixed Production, Rapid Changeover |

Note: Rail systems are strong and hold heavy or exact boards well. Mesh belts are better for boards that are odd shapes or easy to break. Hybrid systems mix both strengths for tough jobs with many board types.

Each conveyor system works best for certain jobs. The list below tells you when to pick each one:

· Rail Conveyor:

o Great for double-sided soldering

o Good for jobs that need high accuracy

o Best for heavy or stiff boards

· Mesh Conveyor:

o Good for big, thin, or soft boards

o Works for single-sided soldering

o Handles boards that cannot be held by the edges

· Hybrid Conveyor:

o Changes to fit many board types

o Helps cut down time when switching jobs

o Good for factories that change products a lot

Tip: Factories with lots of board types or new orders often do best with hybrid conveyor ovens. These systems help keep work fast and quality high when things change often.

Picking the right conveyor system is important for making good PCBs and having a smooth factory.

· Rail systems help keep boards steady and work well for double-sided boards.

· Mesh conveyors are good for big or fragile boards and are simple to clean.

· Hybrid systems can handle many board types and help when jobs change.

If your factory has tricky or changing needs, experts can help you choose the best system. Using the right conveyor system helps you make good boards and save money.

Rail conveyor systems are best for double-sided PCB soldering. They grip the board by the edges. This keeps both sides safe from damage. The bottom stays open for soldering work.

Mesh conveyor ovens work well with light or bendy boards. Heavy or thick PCBs can bend the mesh belt. Rail conveyors are better for strong support and less bending.

Factories should clean conveyor systems after every shift. Cleaning stops solder from building up. This helps the oven work well. Both mesh belts and rails need cleaning to avoid problems.

Hybrid conveyor ovens need care for rails and mesh belts. They take more time to keep up than single systems. Many factories still pick hybrids for their flexibility.

Yes, conveyor systems change how much energy ovens use. Good designs with strong heat control save energy. All types work better with regular care and the right settings.

content is empty!