Views: 0 Author: Site Editor Publish Time: 2025-07-04 Origin: Site

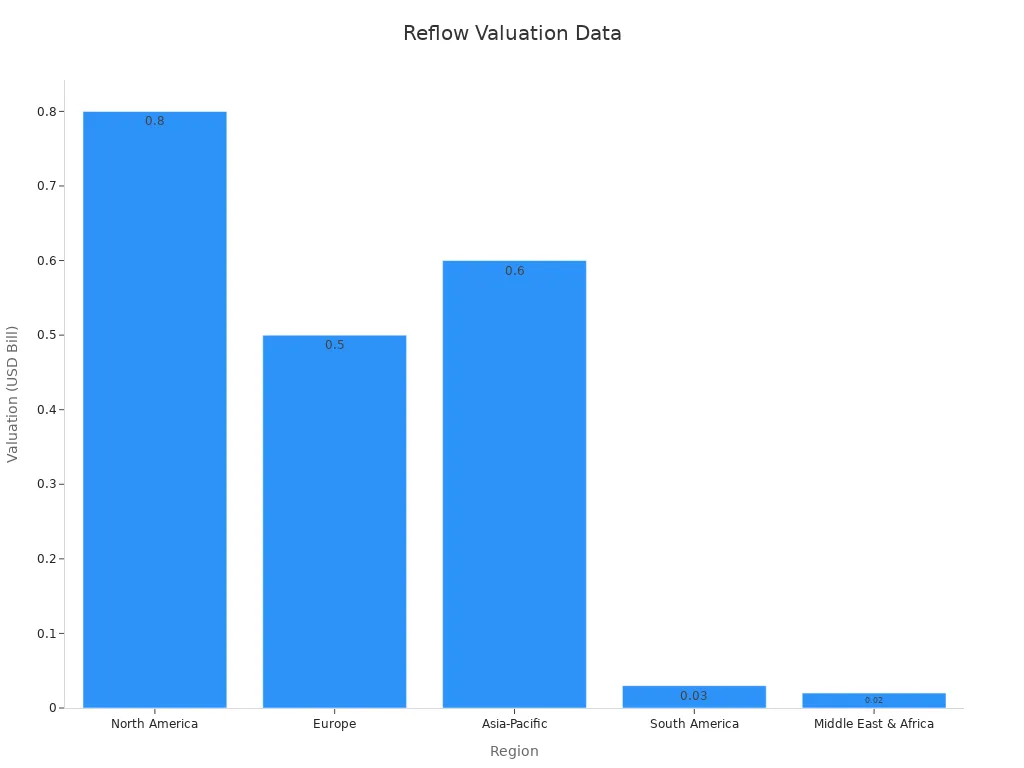

If you want to buy your first reflow oven, you might ask, “How much does a reflow oven cost?” Small models for hobby use start at $58.99. Big industrial machines can cost over $50,000. The price of a reflow oven depends on the type, region, and features. The Asia-Pacific region sells the most because they make lots of electronics. Many people pick convection ovens. They give a good mix of price and performance.

Reflow oven prices are very different. Some hobby models cost less than $100. Big industrial machines can cost over $200,000. The total cost is more than just the oven. You also pay for accessories, shipping, installation, and setup. Make sure to plan your budget well. Pick an oven size and type that fits how many boards you make each day. This helps you not spend too much. There are also costs that keep coming. You will pay for maintenance, repairs, energy, and supplies over time. Good setup, regular care, and proper training help the oven work better. These things also help you save money later.

When you want to buy an smt reflow oven, you should know what makes up the cost. The total reflow oven cost is not just the machine. You also need to think about accessories, shipping, installation, and setup. Each part can change how much you pay in the end.

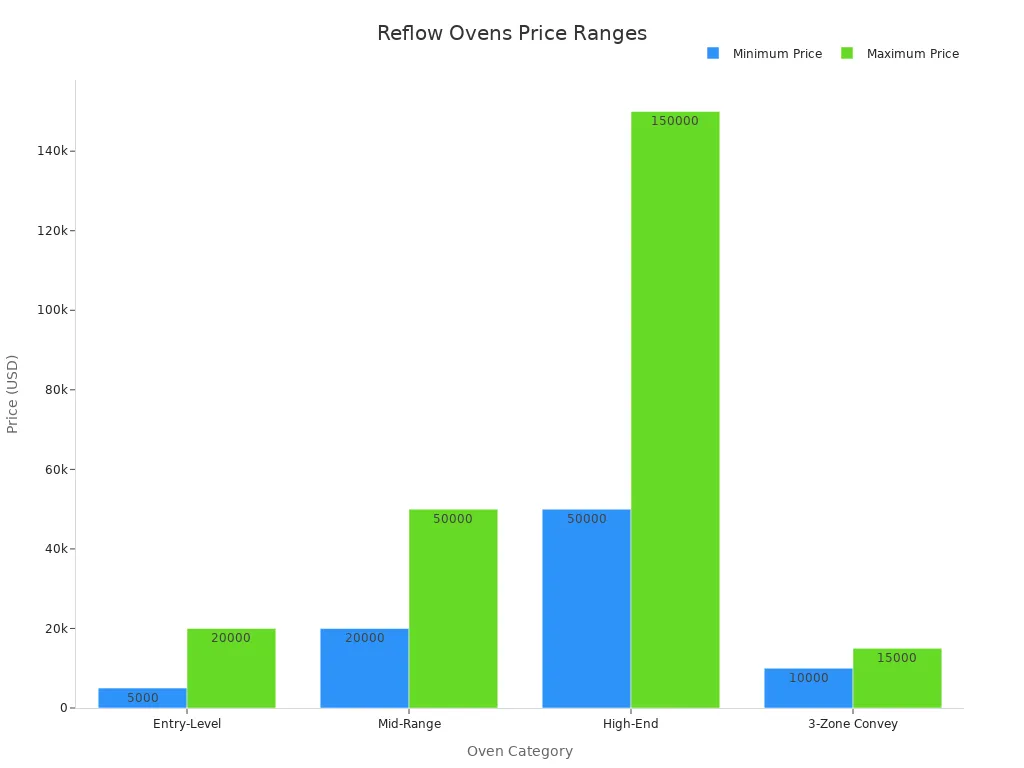

Most of your reflow oven cost comes from the equipment. The kind of smt reflow oven you pick will change the price. Entry-level ovens are good for small jobs or hobbies. Mid-range ovens work for small companies or growing lines. High-end ovens are for big smt soldering jobs and have more features.

Here is a table to help you see the usual prices for different smt reflow ovens:

| Category | Typical Price Range (USD) | Description |

Entry-Level Ovens | $5,000 - $20,000 | Basic functionality, suitable for small-scale or prototyping |

Mid-Range Ovens | $20,000 - $50,000 | Balanced cost and performance, better temperature control and features |

High-End Ovens | $50,000 - $150,000 or more | Advanced automation, multiple zones, large-scale production |

You might also need extra things for your smt reflow oven. These can be solder paste printers, conveyors, loaders, unloaders and inspection tools. The cost of these extras can get high, so remember to add them to your budget.

If you want to see how board throughput and oven type change the price, look at this table:

Board Throughput | Oven Type / Zones | Typical Cost Range (USD) |

1-5 boards/day | Single or dual hot plate; no zones | $1,000 - $2,000 |

12-15 boards/day | Batch oven, single zone | $2,500 - $6,000 |

100 boards/day | Conveyorized 3-zone oven | $10,000 - $15,000 |

Over 100 boards/day | Multiple zones, speed dependent | Up to $200,000 |

Tip: More zones and higher throughput mean a higher reflow oven price. Pick the right size for your needs so you do not spend too much.

Shipping and installation can change your total reflow oven cost. Big smt reflow ovens are heavy and need special care. Shipping costs depend on size, weight, and how far it travels. Some suppliers include shipping in the reflow oven price, but some do not.

When your smt reflow oven gets to you, you might need help to move it. Some companies offer installation services. These services make sure your oven is set up right and safe. The cost for installation can be a few hundred or even thousands of dollars. It depends on the oven size and your building.

I.C.T Reflow Oven Packaging

Note: Shipping and installation costs can change by region and supplier. Always ask for a full quote before you buy.

After your smt reflow oven is installed, you need to set it up for your work. Commissioning means testing the oven, setting the right temperatures, and making sure it works with your boards. Some suppliers include setup and training in the reflow oven price. Others charge more for these services.

You might need to pay for a technician to come to your place. This person will help you start your first jobs and teach your team how to use the oven. The cost for setup and commissioning can be $500 to $5,000. It depends on how complex your smt reflow oven is.

Tip: Good setup and training help you get the best results from your smt reflow oven and avoid costly mistakes.

When you add up equipment, accessories, shipping, installation, and setup, you get the real reflow oven cost. Always check what is included in the reflow oven price from each supplier. This helps you compare offers and pick the best value for your needs.

I.C.T Global Service

I.C.T Global Service

I.C.T Global Service

Need Global Support Service? Contact I.C.T >>>

When you shop for a reflow oven, you will see many prices. The reflow oven price changes with size, features, and how much you want to make. There are ovens for hobbies, small businesses, and big factories. Let’s look at each group so you can pick the right smt reflow oven for your work.

If you are new to soldering or want to make small things at home, entry-level reflow ovens are a good choice. These ovens are simple and easy to use. Some cost as little as $58.99, but most are between $1,000 and $2,000. They can handle a few boards each day and have basic controls.

You can use these ovens for learning, testing ideas, or making small batches.

Many hobbyists like them because they are cheap and do not need much space.

Some ovens have simple screens and basic temperature settings.

Tip: If you want to spend less, you can look for used smt reflow oven models online. Many people sell their old ovens when they get new ones.

Mid-range reflow ovens are good for small businesses or growing lines. These ovens have better temperature control and more features than entry-level ones. Most mid-range ovens cost from $5,000 to $20,000. You can use them for small manufacturing or regular testing.

These ovens often have conveyor belts, more heating zones, and better airflow.

You can make more boards each day, which helps if your business is growing.

Some ovens have advanced controls for better soldering and repeat jobs.

You can also find imported smt reflow oven choices in this price range. Many companies in China, South Korea and the USA sell these ovens. Sometimes, you can get a good deal on a used oven from a trusted seller.

Note: Always check the warranty and support when you buy a used or imported oven. This helps you avoid problems later.

If you run a big factory or need to make thousands of boards every day, you need a high-end smt reflow oven. These ovens have advanced features like nitrogen, more heating zones, and full automation. The reflow oven price for these starts at $50,000 and can go over $200,000 for new models.

Here is a table with real prices for new and used industrial ovens:

| Shipment Date | Product Description | Origin Country | Destination Country | Quantity | Price (USD) |

18-Jun-2022 | Reflow Oven (New) | China | Vietnam | 1 PCE | 222,000 |

29-Apr-2022 | Lead Free Nitrogen Reflow Oven (High-end) | China | Philippines | 3 Pieces | 52,400 |

08-Apr-2022 | Used Welding Furnace-Reflow Oven (2015) | South Korea | Vietnam | 1 PCE | 6,720.99 |

You can see that new high-end ovens from China can cost over $200,000. Used ovens from South Korea can be much cheaper, sometimes under $7,000. The price depends on the year, features, and condition.

High-end ovens help you get the best soldering and fast production.

Many factories pick imported ovens for their features and reliability.

You can find both new and used ovens, so you can match your budget and needs.

Tip: When you buy a high-end smt reflow oven, think about the total cost, including shipping, installation, and setup. These costs can add up fast.

You can find smt reflow oven options for any budget. The reflow oven price changes based on what you need and how much you want to make. Used and imported ovens give you more choices and can help you save money while still getting good results.

When you buy a reflow oven, you pay more than just the price. Some costs come up after you start using it. These extra costs can change your budget over time.

You need to take care of your reflow oven to keep it working well. Doing regular checks helps stop sudden problems. You might have to clean the oven, look at the fans, and set the right temperature. Some companies use sensors to find fan issues early. This can help you save money on repairs. If something breaks, you may need to fix it fast. Buying new fans or sensors costs extra money. You also need to check the oven’s settings often to make sure it works right.

Checking and fixing your oven helps it last longer.

You might need new parts at any time.

Sensors can help you find problems before they get worse.

Fixing and caring for your oven keeps it working and your soldering good.

Reflow ovens use a lot of power, especially if you run them a lot. You will see this on your electric bill each month. Some ovens use nitrogen gas to help with soldering. If you use nitrogen, you have to buy it often. You also need solder paste for every job. All these things cost money over time.

| Consumable | Typical Use | Ongoing Cost Impact |

Electricity | Every operation | High |

Nitrogen gas | If required | Medium to High |

Solder paste | Every batch | Medium |

Using less energy and keeping the oven cool can save you money and protect your boards.

You pay once when you buy your oven, but you keep paying for other things. Things like repairs, power, and supplies add up over the years. If you use your oven for a long time, these costs can be more than what you paid at first. You should think about both the first price and the costs over time before you buy.

One-time costs: buying, shipping, and setting up your oven.

Long-term costs: fixing, power, and supplies.

Planning ahead helps you avoid problems and keeps your soldering working well for a long time.

When you look at an smt reflow oven, you want to know if you get good value for your money. Start by thinking about your production needs. Ask yourself how many boards you need to make each day and how complex your products are. A bigger oven with more heating zones can handle more boards and different types of components. If you run a small shop, you may not need the largest model. For large factories, high-speed ovens with advanced controls can boost your output.

You should also consider extra costs like space, utilities, and training. These add to the total price. Some ovens offer better supply chain support and use less energy, which can save you money over time. Always match the oven’s features to your real needs in surface mount technology.

You can use a simple model to see if your smt reflow oven will pay off. ROI, or return on investment, shows how fast you earn back your money. Here is a basic way to figure it out:

| Parameter | Example Value |

Total Investment (USD) | $50,000 |

Boards per Month | 7,500,000 |

Profit per Board (USD) | $0.001 |

Monthly Profit (USD) | $7,500 |

If your oven helps you make more boards each month, your profit goes up. Even one extra hour of production each week can add thousands of dollars to your yearly profit. This model helps you see how better uptime and faster soldering can make your investment worthwhile.

You can get more value from your smt reflow oven by using a few smart tips:

Adjust the oven’s ramping and cooling settings to improve solder joint quality.

Keep your oven clean and check it often to avoid breakdowns.

Train your team so they use the oven the right way every time.

Studies show that changing your reflow profile can boost self-alignment by 10%. This means fewer defects and better products. When you set up your oven well, you save money and make your surface mount technology line more reliable.

Tip: Always review your production data and adjust your process for the best results.

You now understand what changes the cost of a reflow oven. You have looked at prices for different types. You also learned about extra costs like fixing and power. Always think about both the first price and what you will pay later. Use this checklist before you buy:

Look at the cost of the oven and extras

Find out how much shipping, setup, and installation cost

Think about future costs for repairs and power

Are you ready to pick your reflow oven? Take your time, think about what you need, and make a good choice!

You should match the oven size to your daily board output. Small ovens work for a few boards. Large ovens fit busy lines. Always check your future needs before you buy.

You may pay for repairs, spare parts, and energy. Some ovens need nitrogen gas. You also need solder paste for every job. These costs add up over time.

Yes, you can use a used oven. Check its condition and ask for a test run. Make sure you get support and spare parts from the seller.

You should clean and check your oven every week. Replace worn parts as needed. Regular care helps your oven last longer and keeps your boards safe.

content is empty!