Views: 0 Author: I.C.T Publish Time: 2025-07-10 Origin: Site

Image Source: unsplash

Smart factory integration is very important for industry 4.0 in today’s factories. The I.C.T Lyra Reflow Oven has smart features that change the process from manual to digital. Smart sensors and real-time data help teams act fast and keep products good. > Manufacturers get quick benefits because smart factory integration helps them use data to make choices and meet industry 4.0 needs at every step.

· Smart reflow ovens have sensors and use real-time data. This helps make products better and cuts down on waste. - Sharing data and talking openly lets factories watch ovens from far away. They can also fix problems fast. - Adding smart sensors to old ovens saves money. It also gives many Industry 4.0 benefits. - Automation and predictive maintenance help stop machines from breaking. This means less downtime and better factory work. - Smart factory integration gets factories ready for the future. This includes things like AI, lights-out manufacturing, and faster production.

Smart factory integration starts with strong IoT and good connections. Modern reflow ovens have smart sensors that gather data at every step. These ovens link to factory networks and send live data to main systems. Teams can check oven status, temperature, and quality from anywhere.

· New IoT reflow ovens can save up to 30% energy.

· The global reflow oven market may grow over 4% each year until 2028, reaching about USD 850 million.

· IoT features give useful data that helps improve how equipment works and is maintained.

Smart ovens help the internet of manufacturing by letting teams fix problems and update software from far away. This connection turns ovens into tools that can change fast for production needs. Data from these ovens helps teams set the best process and keep quality steady.

Communication protocols are important for smart factory integration. Open standards like MQTT let different machines share data easily. These protocols help reflow ovens send and get process data with other factory systems.

Smart ovens use these protocols for live monitoring and to predict when repairs are needed. Teams can see process data right away, so they can make quick choices. Automation and energy-saving ovens lower costs and help teams work better.

Open communication protocols let data move smoothly in the smart factory. This helps meet industry 4.0 needs and helps factories keep high quality.

System interoperability makes sure all factory equipment works together. Smart factory integration needs ovens that can share data with MES, ERP, and other big systems. This lets data from the reflow oven help with planning, inventory, and quality checks.

· IoT lets teams watch ovens in real time, predict repairs, and make processes better.

· Digital platforms let teams update software and fix ovens from far away, making ovens connected tools.

· Smart ovens with IoT help industry 4.0 by letting teams change processes from afar and check quality with data.

A smart factory needs easy data sharing. When systems share data, teams can see all of production. This helps them spot problems early and make each step better. Smart factory integration builds a connected place where data helps teams make better choices and reach industry 4.0 goals.

Image Source: pexels

Modern reflow ovens in industry 4.0 use automation and smart controls. These ovens collect data with IoT and check heat levels. Siemens and KIC Embedded Designs made a system that sends recipes and checks oven status by itself. This system uses open standards, so every batch has the right oven setup. Automation helps lower labor costs and stops delays. It also makes quality and output better. Some ovens can set up their own profiles and use tools to guess the best settings. These tools look at many recipes to find the best way to run the oven. This makes factories stronger and more efficient. Smart sensors and automatic controls help ovens work better and let factories change quickly.

Predictive maintenance is important for reflow oven processes. Smart ovens check machine and process data for each PCB. They sound alarms if the heat is wrong or close to the limit. The system can stop the line to avoid bad products. Sharing data in real time and using smart guesses helps plan work and keep things running well. Failure prediction systems are very accurate and precise. Smart sensors like photoelectric and laser types watch conveyor and fan speeds. Solid state relays find heater problems and send alerts. These features let teams control ovens from different places and fix problems before they get worse. This cuts down on delays and keeps quality high.

Process transparency means teams can see and track every step. Smart reflow ovens show live process data and collect it as they work. Teams can watch heat, process steps, and oven status at all times. Digital platforms let teams check ovens and update software from far away. This clear view helps teams follow rules and keep getting better. Automated data checks help teams spot problems early and fix them fast. Better process checks and tracking help people trust the factory’s quality and reach industry 4.0 goals.

Many factories still use old reflow ovens. These ovens do not have smart features. Teams can make these ovens better with new parts. Adding smart sensors and modules lets ovens collect data in real time. Engineers put in temperature sensors, airflow monitors, and digital controllers. These changes help old ovens send data to main systems.

A step-by-step plan works best: 1. Check what the oven can do now. 2. Pick smart sensors and modules that fit. 3. Add hardware for data and control. 4. Link the oven to the factory network. 5. Test the system to make sure it works right.

Retrofitting lets factories keep using their old ovens but get smart oven benefits. Teams can now watch process changes, check oven health, and fix problems fast.

Tip: Retrofitting old ovens saves money and cuts waste. It is cheaper than buying new ovens.

Software tools are important for smart factory integration. These tools collect, study, and show data from reflow ovens. New platforms let teams watch and control ovens in real time. Teams use dashboards to see oven status, temperature, and trends.

Some software tools can guess when repairs are needed. They use data to stop downtime before it happens. Connecting with MES and ERP systems helps data move across the factory.

A normal software upgrade has these steps: - Put process monitoring software on factory computers. - Set up dashboards for live data. - Link the software to MES and ERP. - Teach staff how to use new features.

Smart software tools help teams make better choices. They help improve quality and lower mistakes. Teams can also let the software change settings using real-time data.

Data exchange is key for Industry 4.0 readiness. Smart ovens must share data with other systems. Open protocols like MQTT and OPC UA help data move easily. These protocols let ovens send data to IIoT and enterprise systems.

A strong data exchange process helps with: - Watching processes in real time. - Fast action when things change. - Good planning and scheduling.

Experts made models to check how well factories share data. They use decision support systems and AHP to rank process parts.Thirty experts from schools and factories gave scores from 1 to 9. Their scores help factories pick which upgrades to do first. Better data exchange means faster work, more products, and lower costs. Digitalization and IoT make these changes possible.

Note: Good data exchange tracks every step and makes it better. Teams can find and fix problems before they get big.

A smart oven with strong data exchange helps factories reach Industry 4.0 goals. Teams can see all process data and change things fast. This way, factories keep getting better and succeed for a long time.

Smart factory integration helps factories make better products. Teams see fewer mistakes and less waste. This saves money and helps the company earn more. Smart ovens use sensor data to make each batch better. This means more good products and less trash. Changeover used to slow things down, but now smart systems fix recipes and schedules fast. Workers do not need to do as many simple jobs. They can focus on more important work. Teams use real-time data to find problems quickly. This stops bad products and helps the process get better all the time. These changes make the line work faster and improve how the factory runs.

· Less waste and lower rework costs

· More good products and less trash

· Faster changeovers

· Save labor and use workers better

· Find and fix problems faster

Recent surveys say 80% of CEOs spend money on digital tools. Also, 86% of manufacturers think smart factories will help them win by 2025. But only 5% have finished switching, so there is still a lot to improve.

Smart reflow ovens help factories stop downtime and keep working. Automation and live checks let teams see problems before they stop the line. Predictive maintenance uses data to plan repairs at the best time. This stops surprise breakdowns. Remote checks and data study make ovens more reliable and cheaper to fix. These things help factories make more products and keep quality high. Better flux control and self-cleaning mean less fixing is needed. So, factories have fewer stops and work more smoothly.

Smart tech in reflow ovens helps teams keep up good work and steady lines.

The future of smart factories is lights-out production. Smart reflow ovens now use AI to make processes better. They also use live heat pictures and remote checks. These new tools cut downtime by up to 30% and make 15% more good products. Ovens with IoT can change for different jobs, which helps fast-growing areas like car electronics and phones. Industry 4.0 tech like AI, machine learning, and digital twins help with repairs and live data checks. 5G and edge computing let teams make fast choices right on the line. The PCB reflow oven market may more than double by 2033. This is because people want better, automatic ovens. As these changes keep going, factories will get closer to fully automatic, lights-out work with great quality, tracking, and speed.

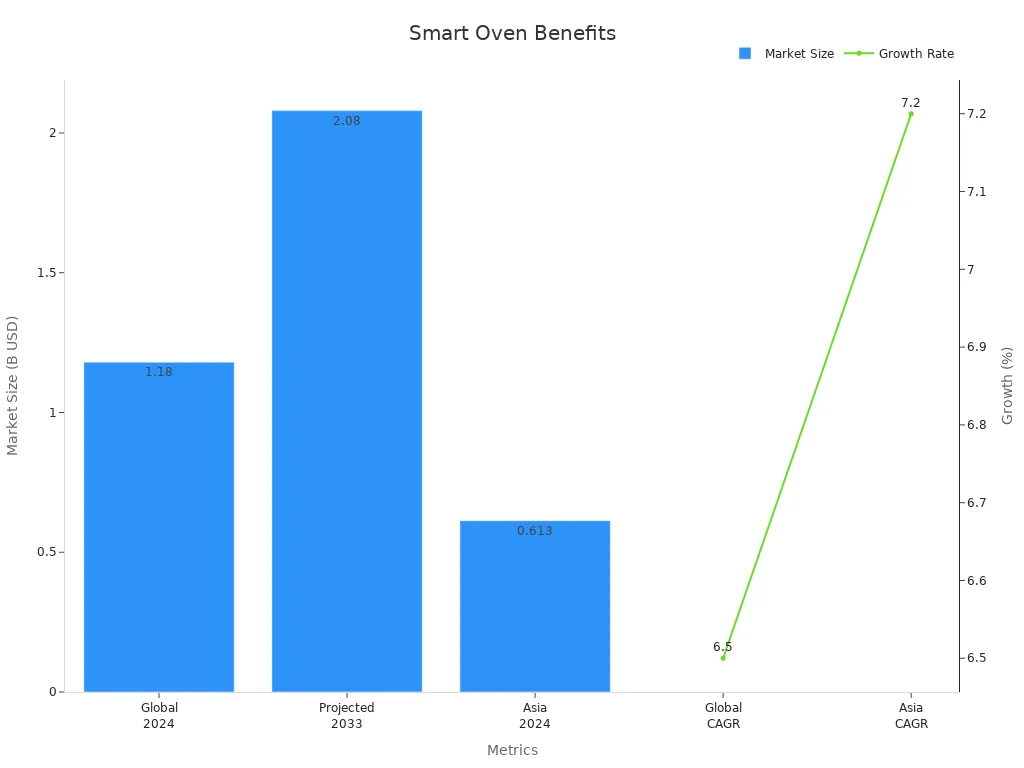

Smart reflow oven integration helps factories work together better. Companies get more good products and better quality. They also follow industry rules well. The table below lists main benefits and market trends:

Aspect | Data / Insight |

Global Market Size (2024) | |

Projected Market Size (2033) | USD 2.08 billion |

CAGR (2025-2033) | 6.5% |

Key Benefits | Improved yields, defect minimization, energy efficiency |

Industry 4.0 Features | Real-time monitoring, predictive maintenance, data analytics |

Factories that buy smart ovens are ahead in new ways of making things. Teams should start now to meet Industry 4.0 goals.

Smart factory integration lets teams watch ovens live. They can spot and fix problems quickly. This helps make better products. There is less waste and work gets done faster.

Yes, engineers can add smart sensors to old ovens. These upgrades help old ovens collect data. They also let ovens connect to new factory systems.

Smart ovens use sensors to watch for problems. Data analytics help guess when something might break. Teams get alerts before the line stops. This helps keep everything running well.

Manufacturers use special codes and safe networks. These steps keep oven data safe from hackers and other threats.

Upgrade Type | Typical Cost Impact |

Retrofitting | Lower upfront cost |

New Smart Ovens | Higher initial cost |

Both | Long-term savings |

Teams usually spend less on repairs and energy as time goes on.

content is empty!